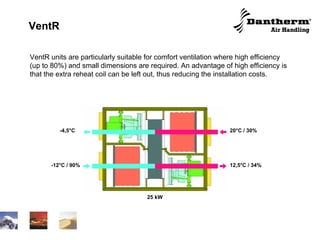

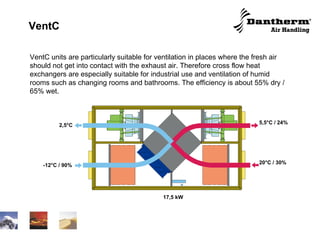

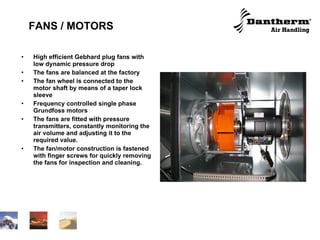

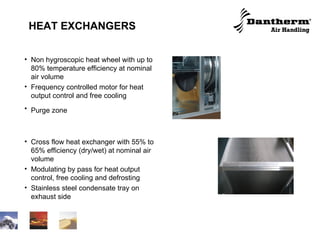

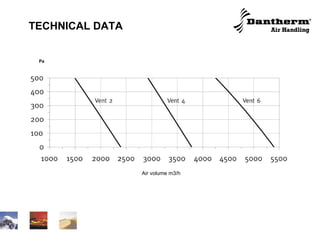

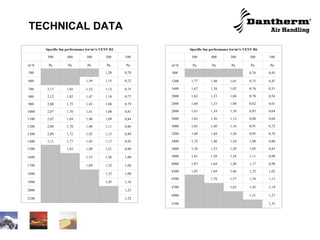

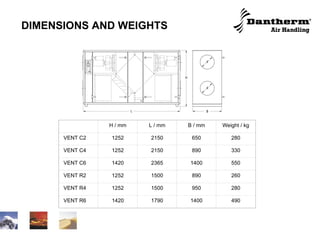

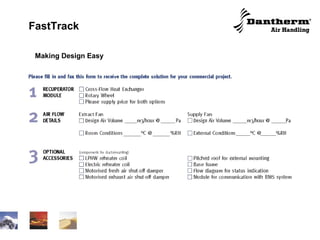

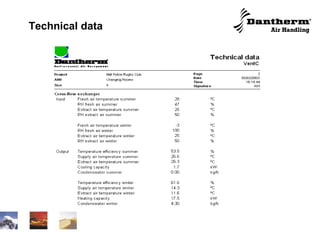

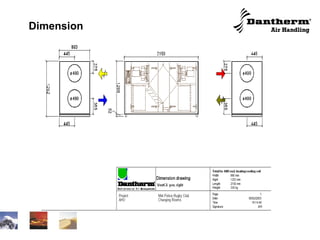

The document summarizes ventilation units from Dantherm A/S including VentR and VentC units. VentR units are suitable for comfort ventilation with up to 80% heat recovery efficiency and small dimensions. VentC units are suitable for industrial ventilation where fresh and exhaust air should not mix, with 55-65% efficiency. The document describes the unit construction, fans/motors, heat exchangers, filters, controls, advantages over other units, and Dantherm's calculation program for unit selection.