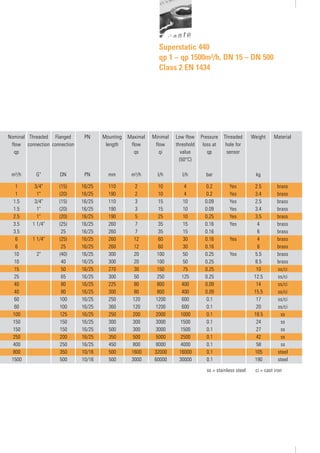

The Superstatic 440 is a heat and cooling meter that uses a static fluidic oscillation measuring principle without moving parts to precisely and reliably measure flow over a long period of time. It has a wide measurement range from DN15 to DN500 and can be integrated with communication modules to work in various building management systems. Recalibration only requires changing the measuring head to reduce costs and downtime.