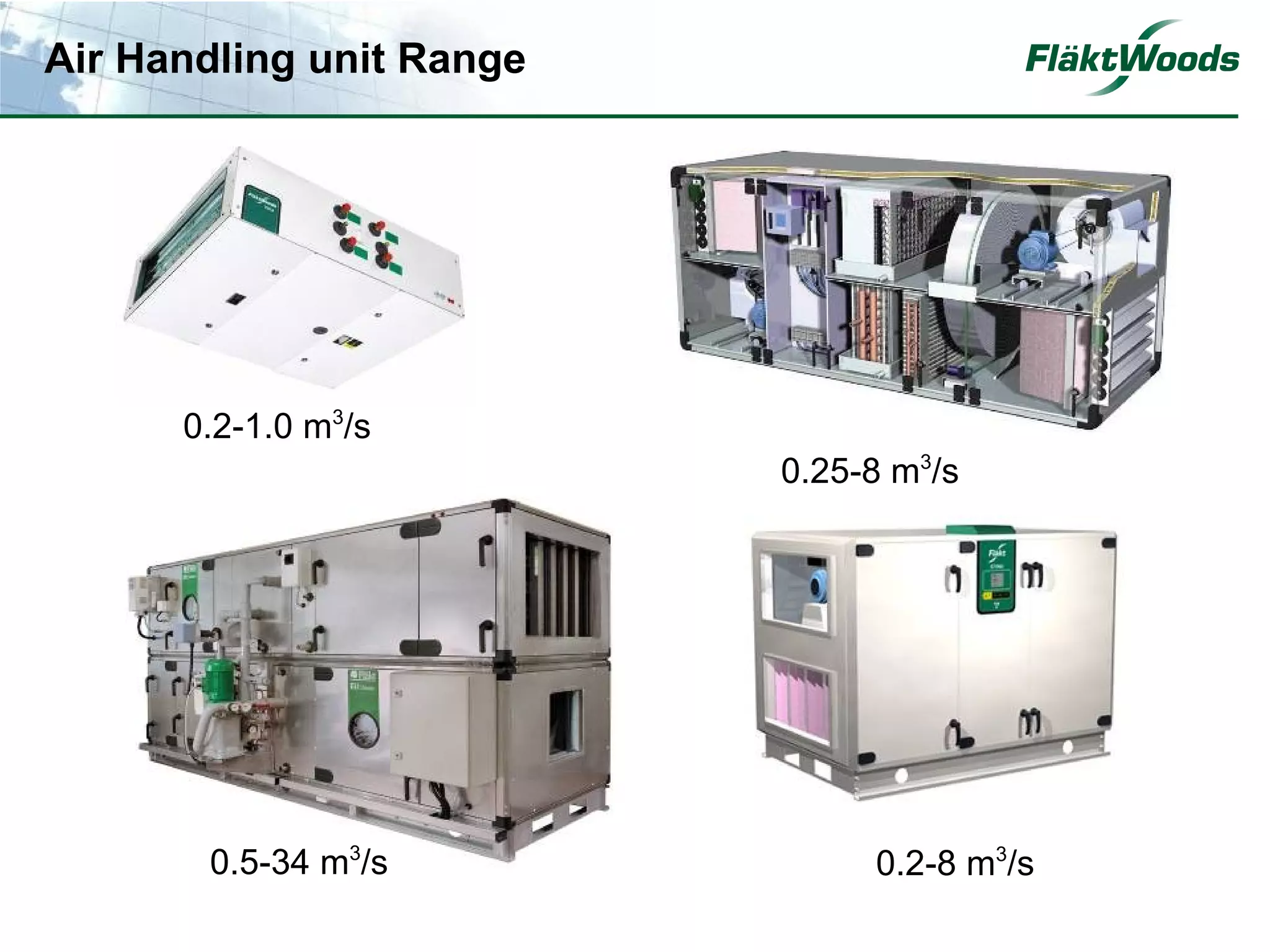

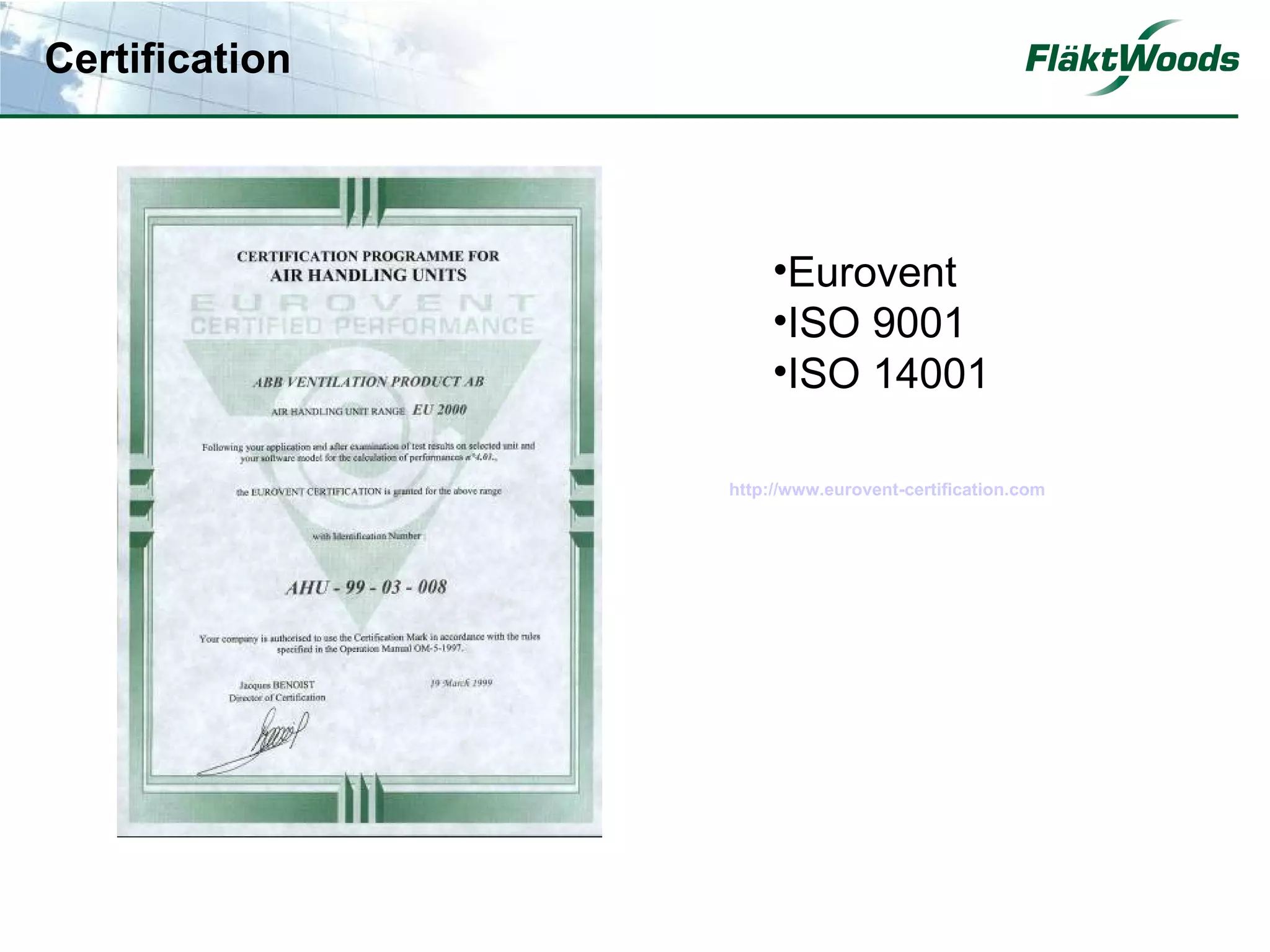

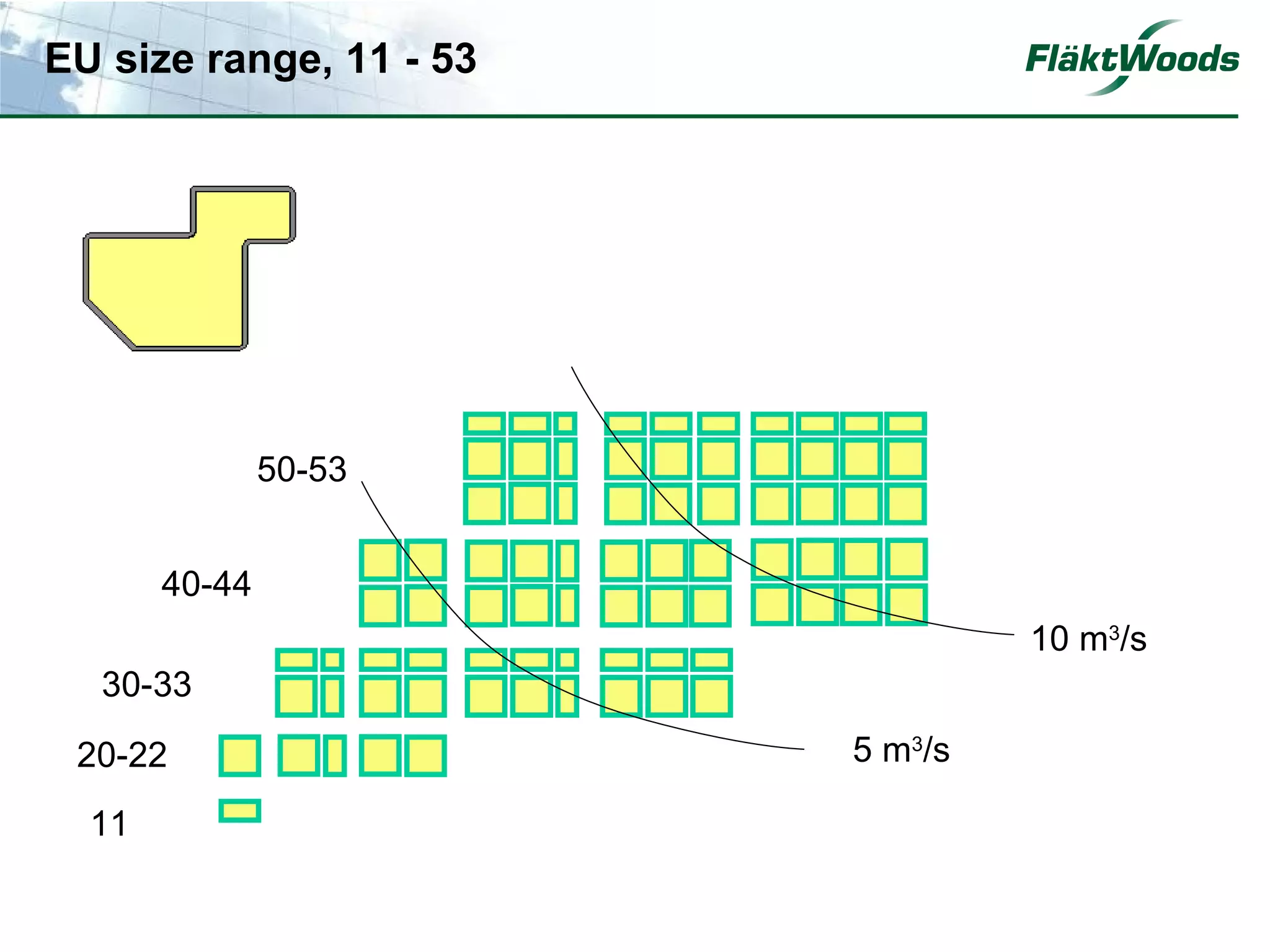

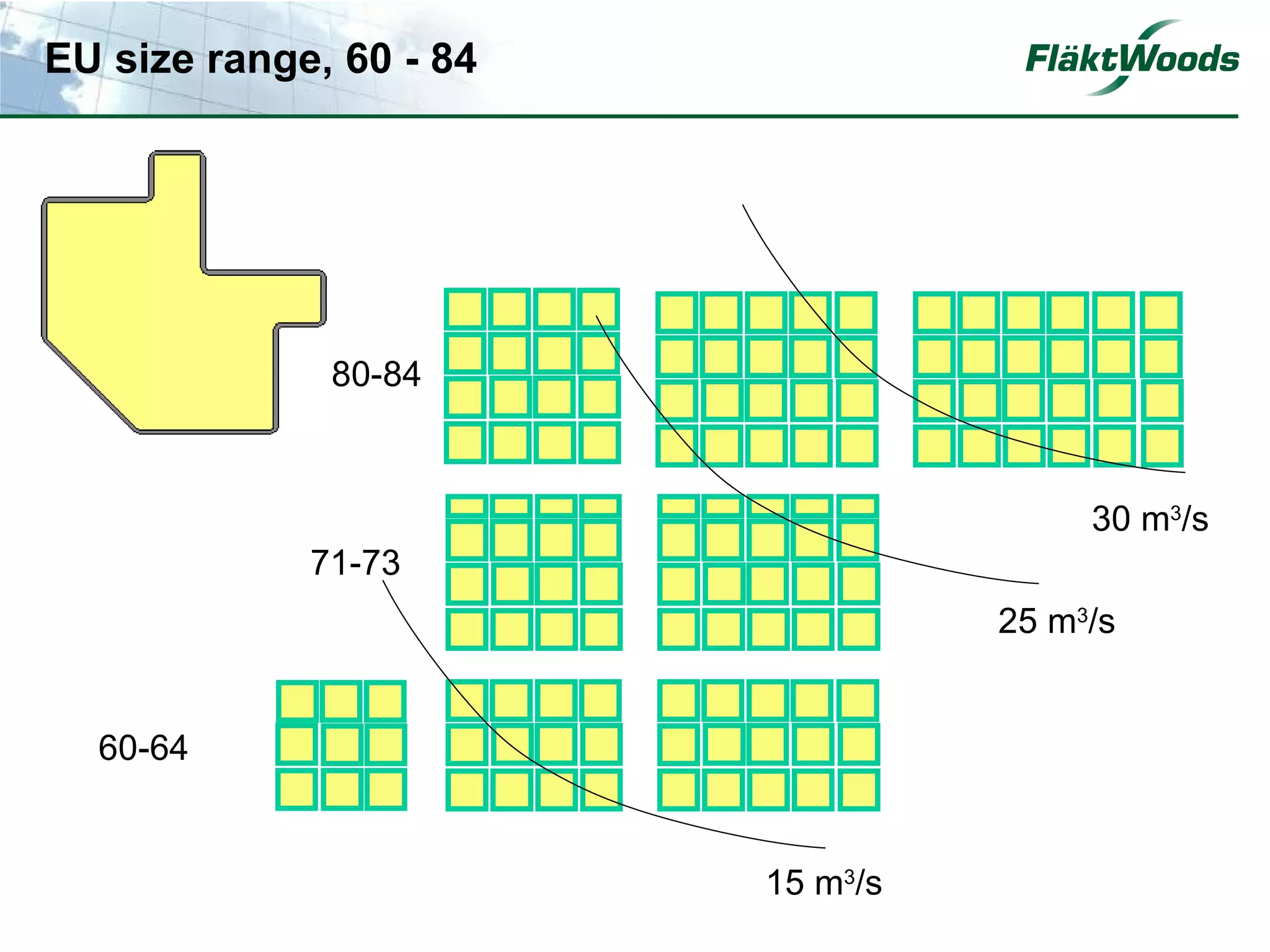

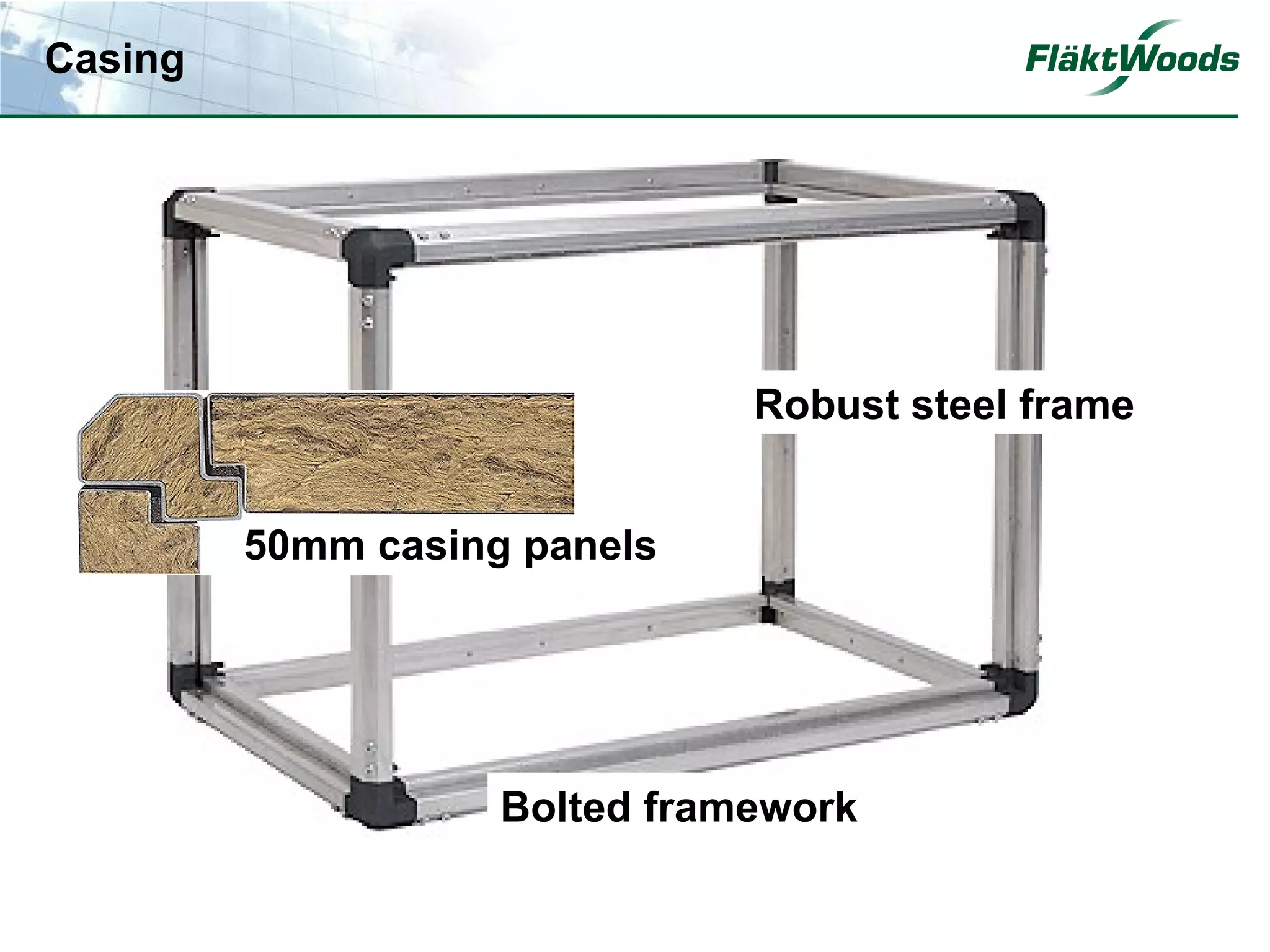

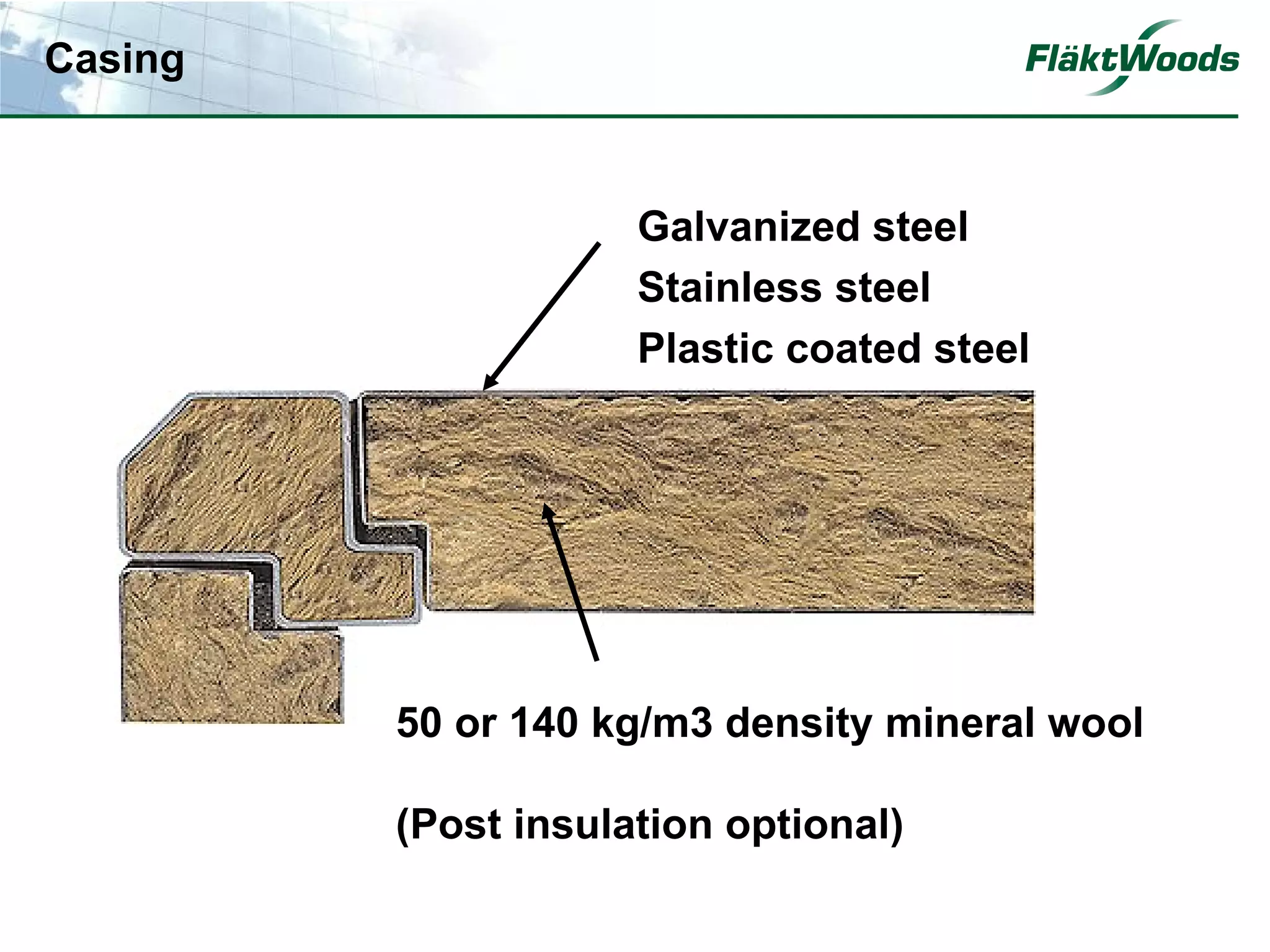

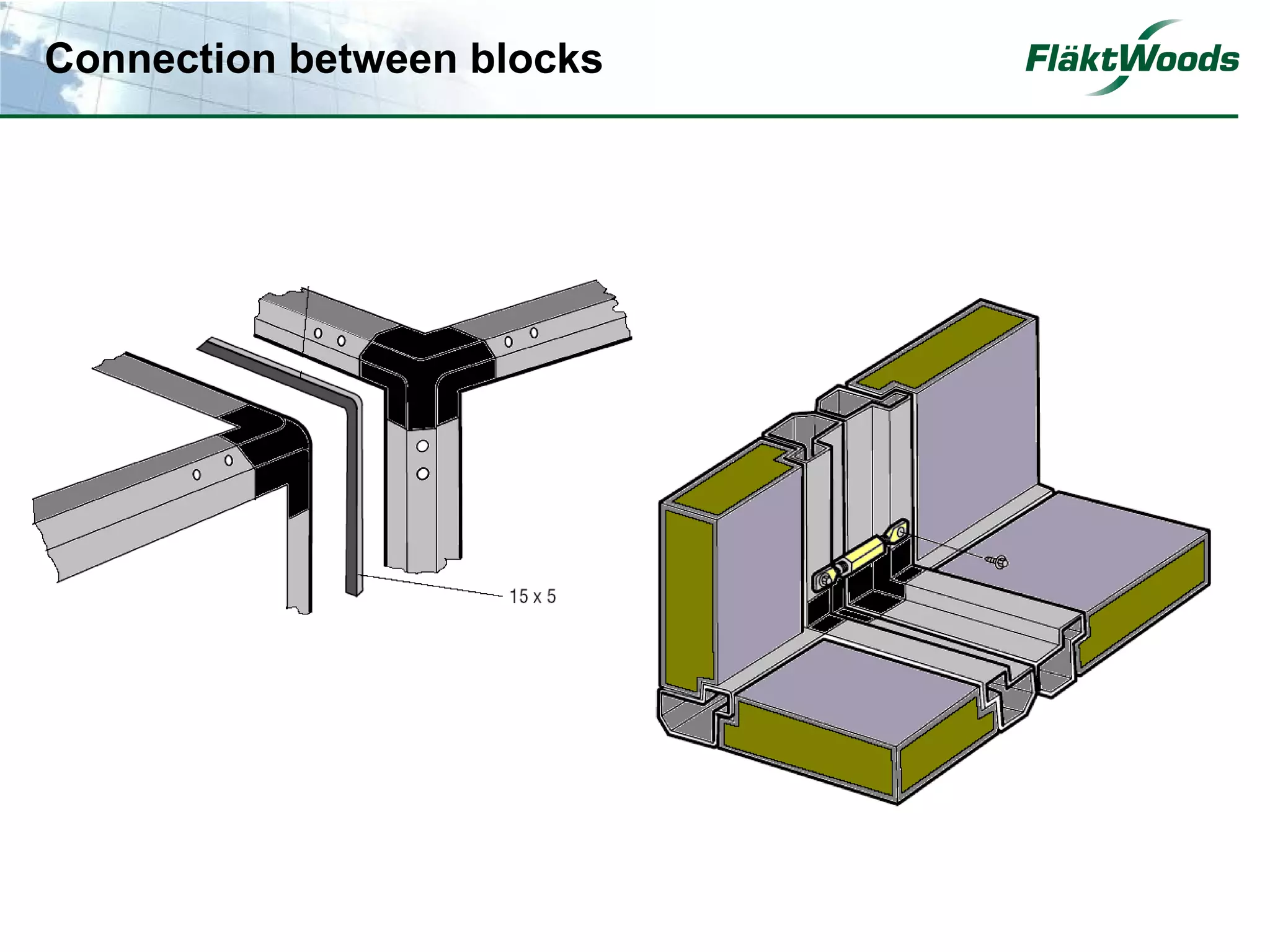

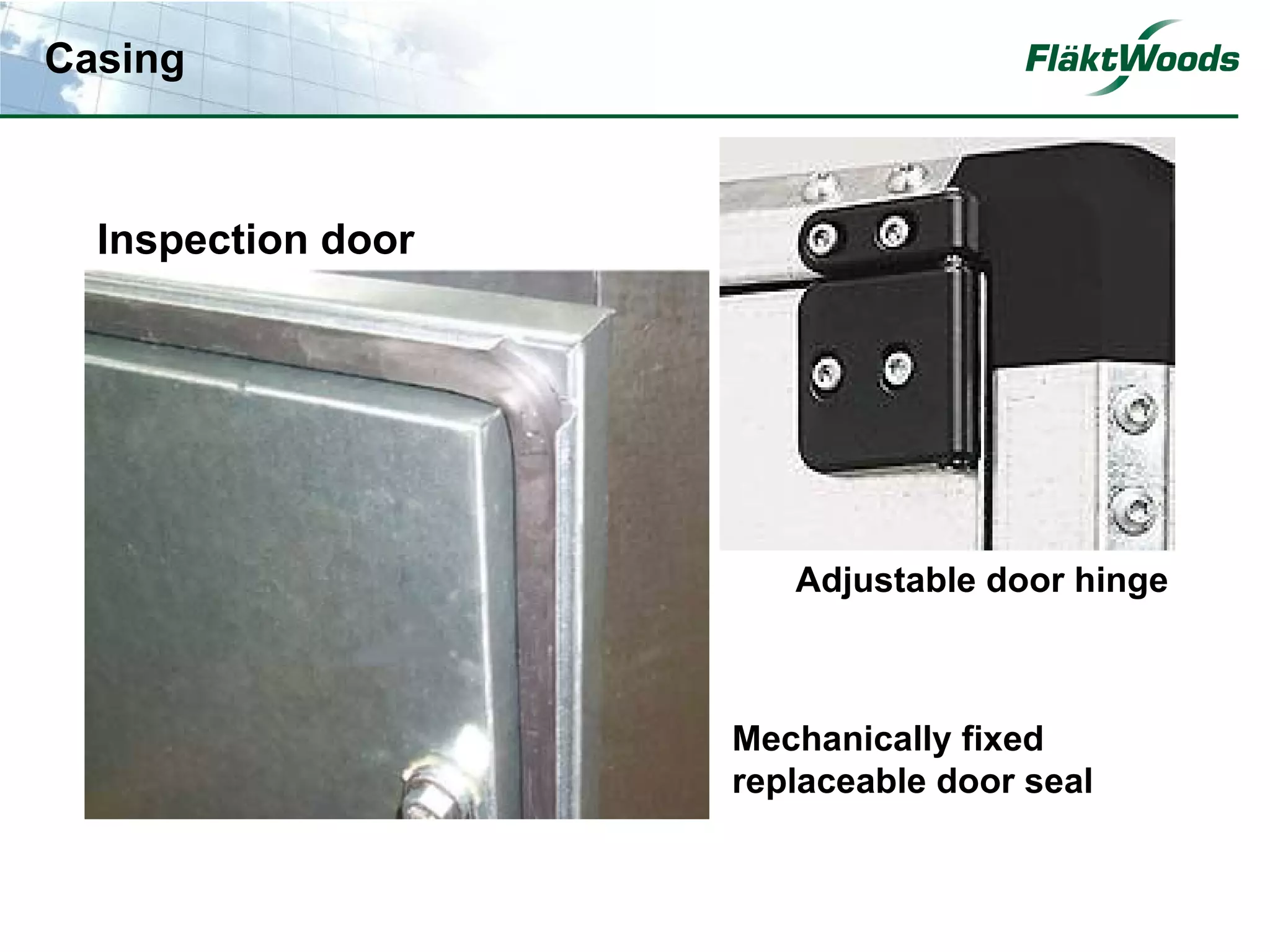

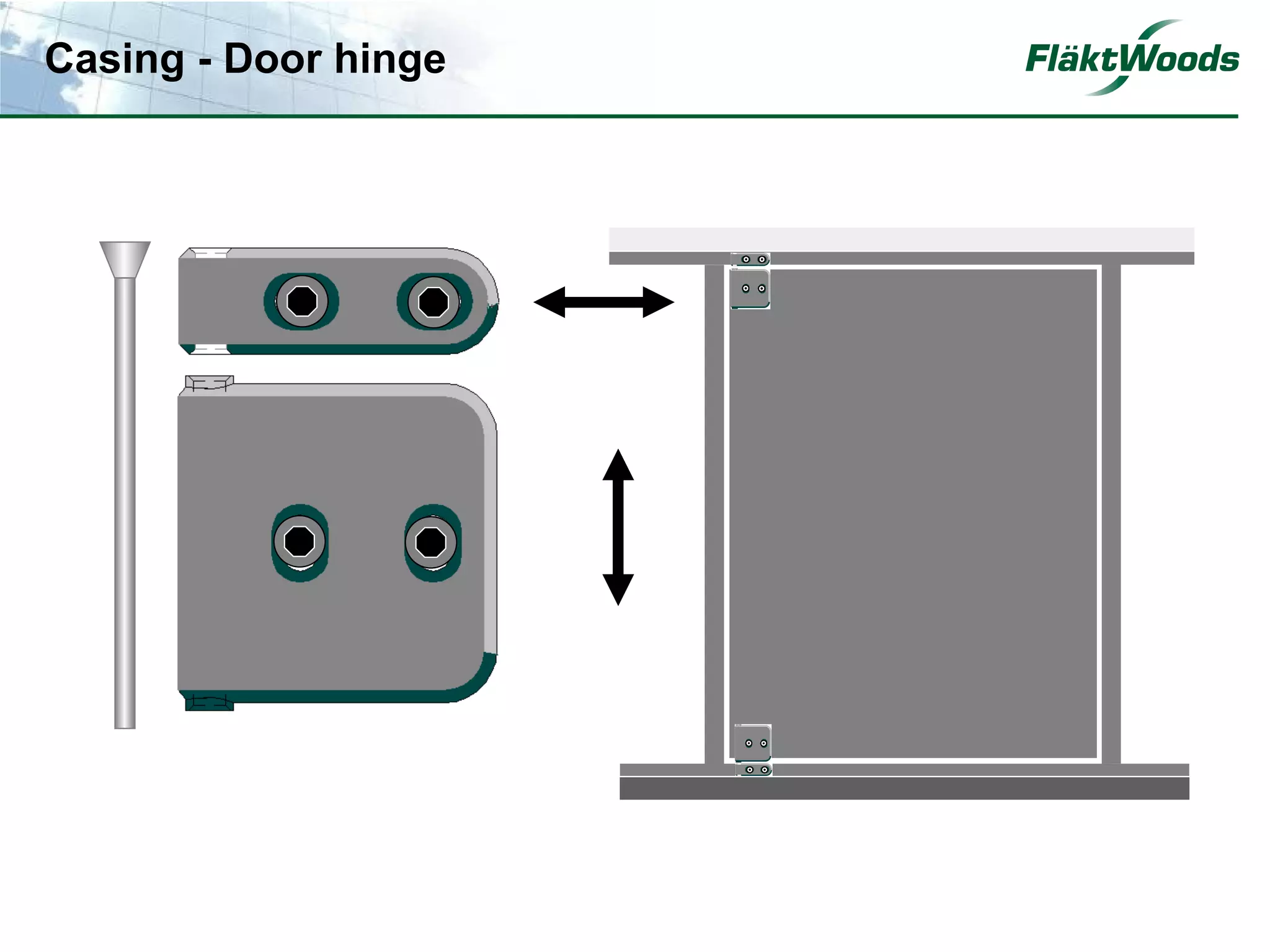

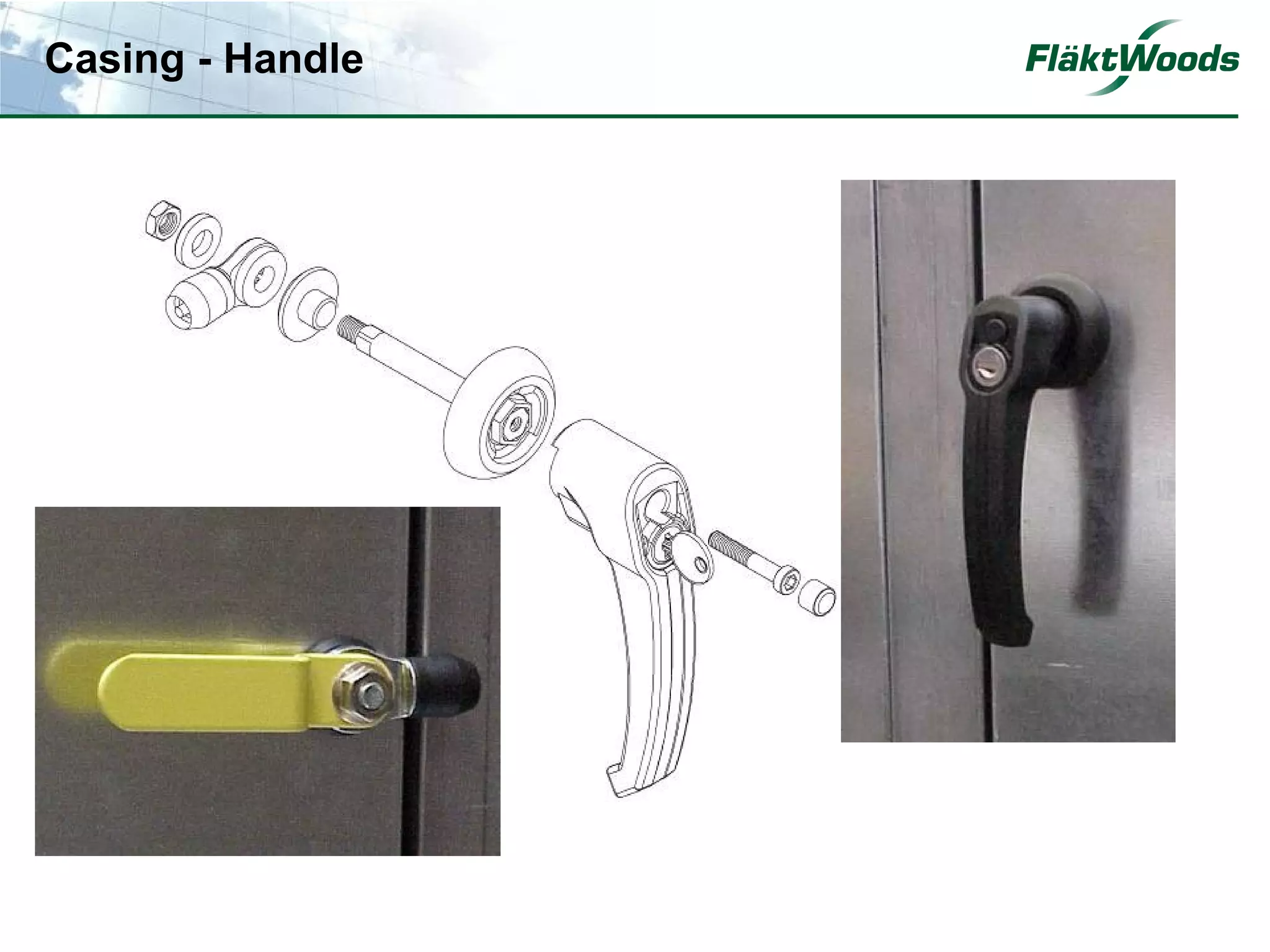

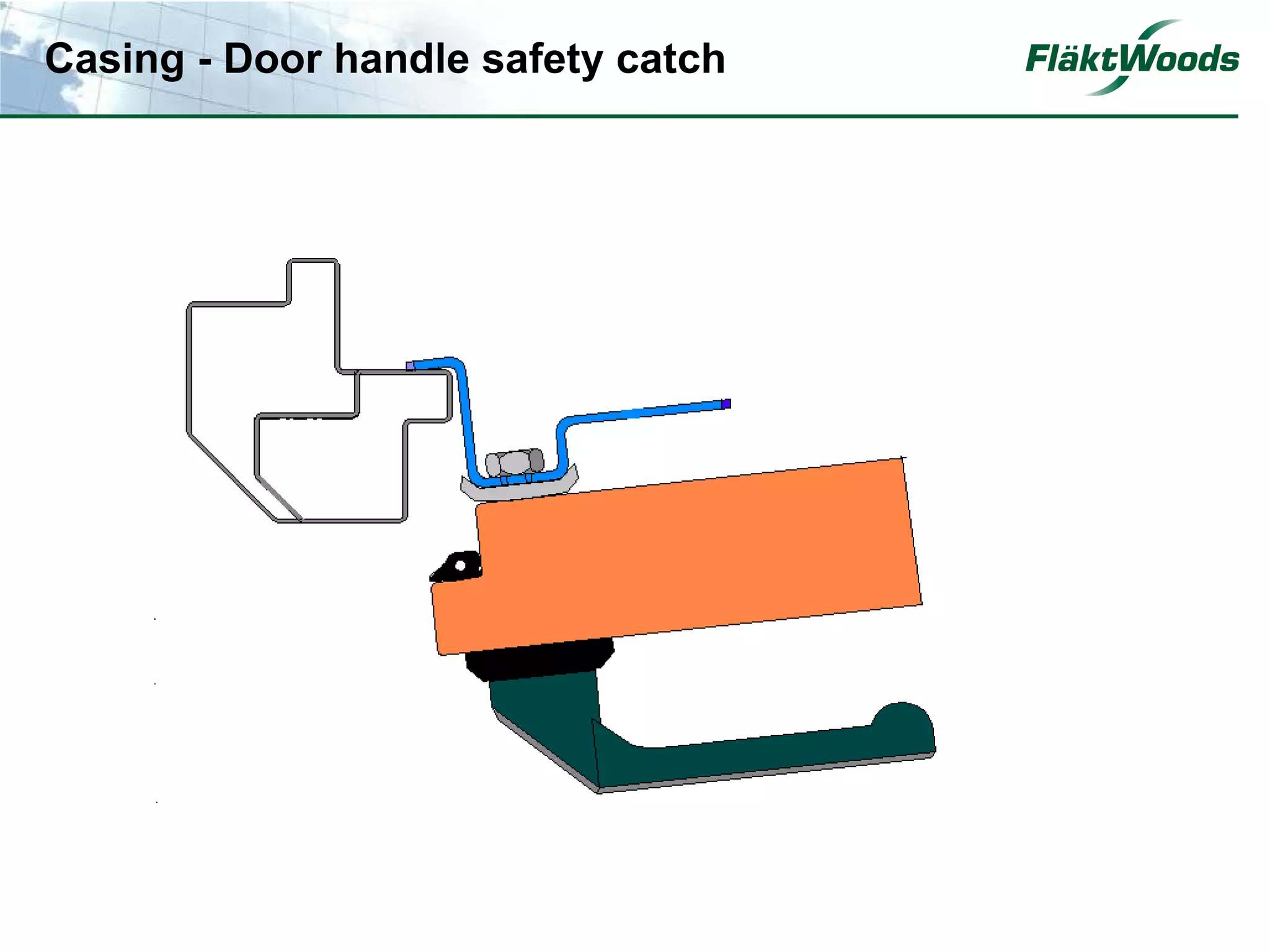

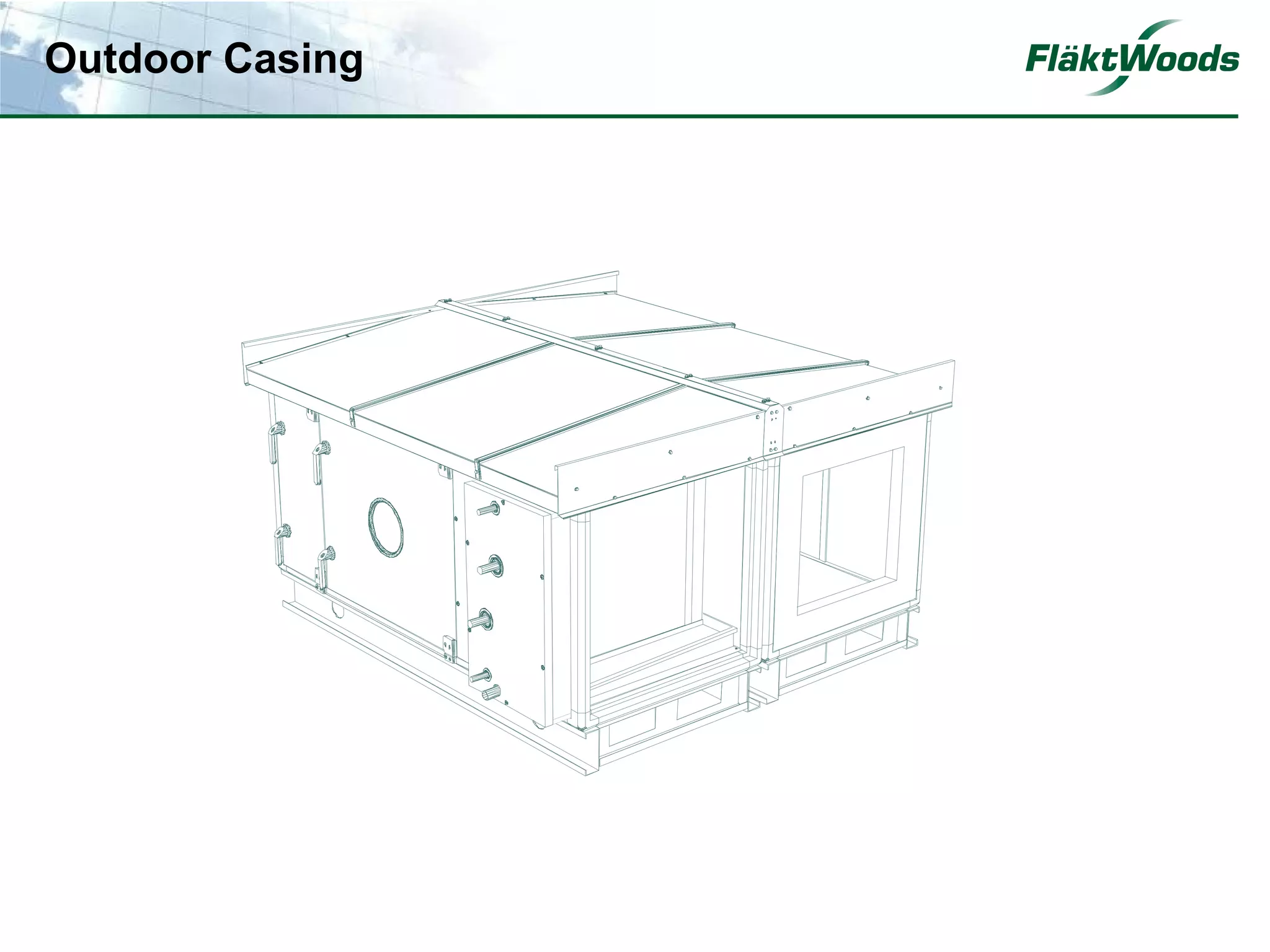

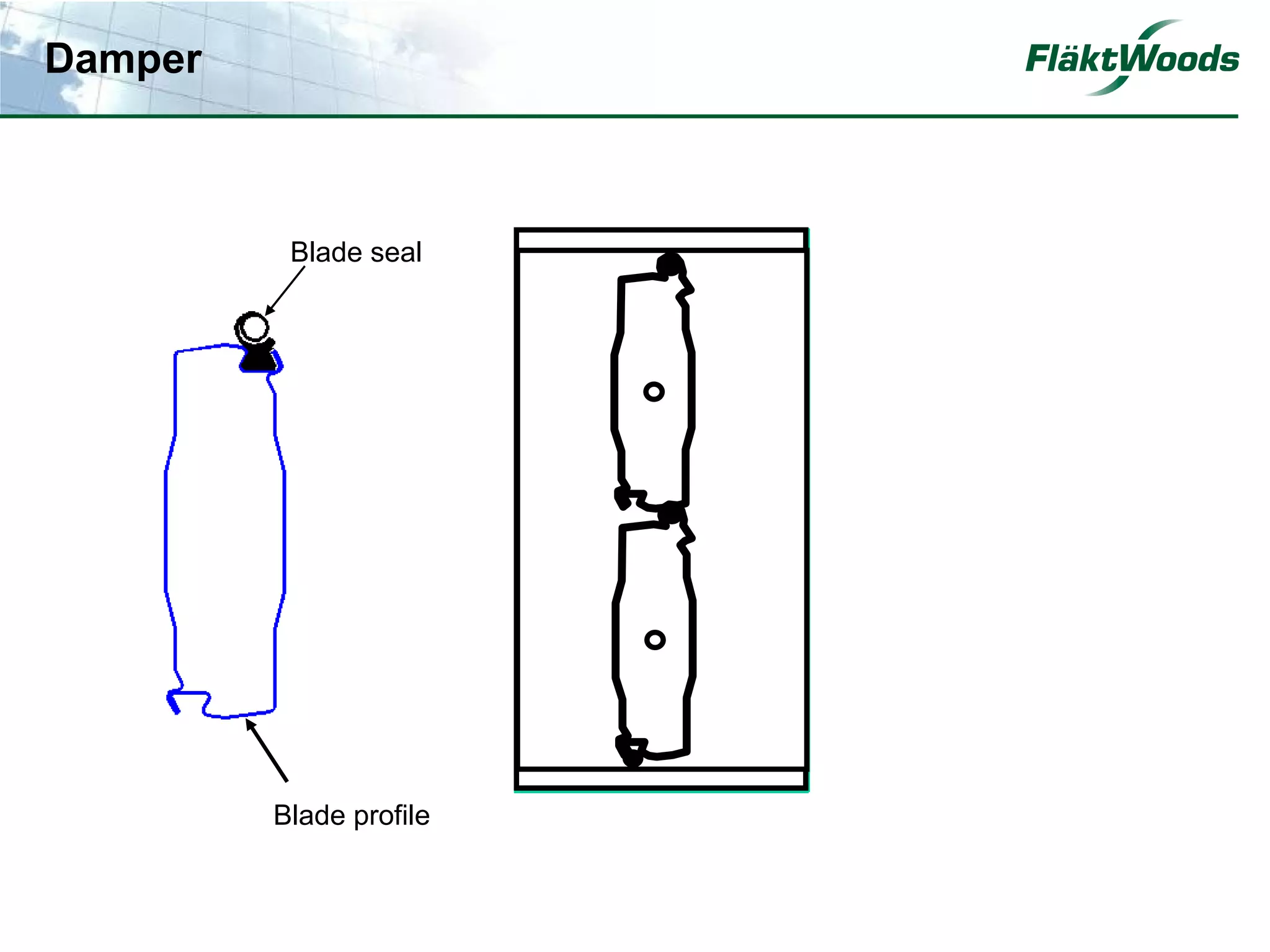

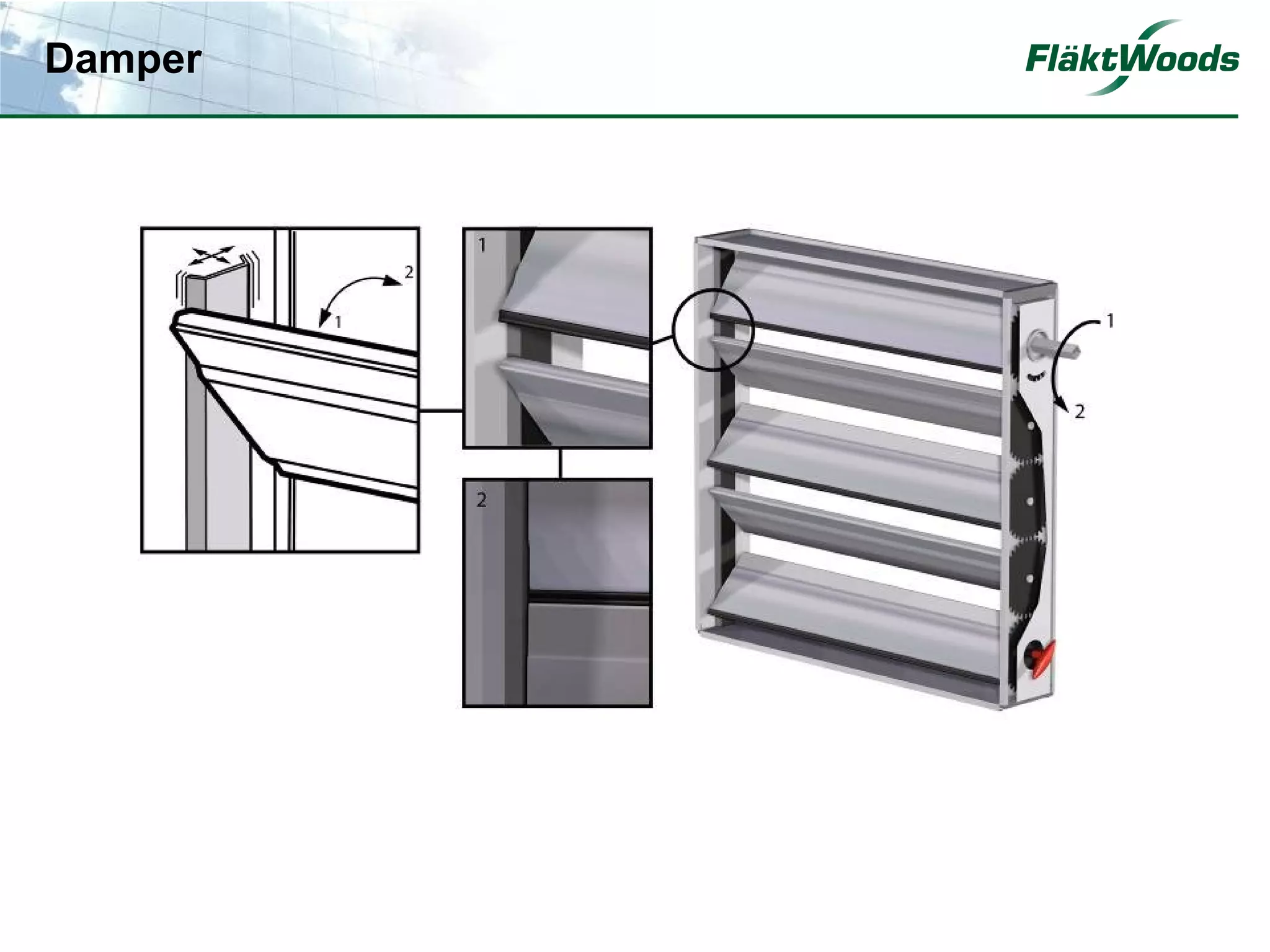

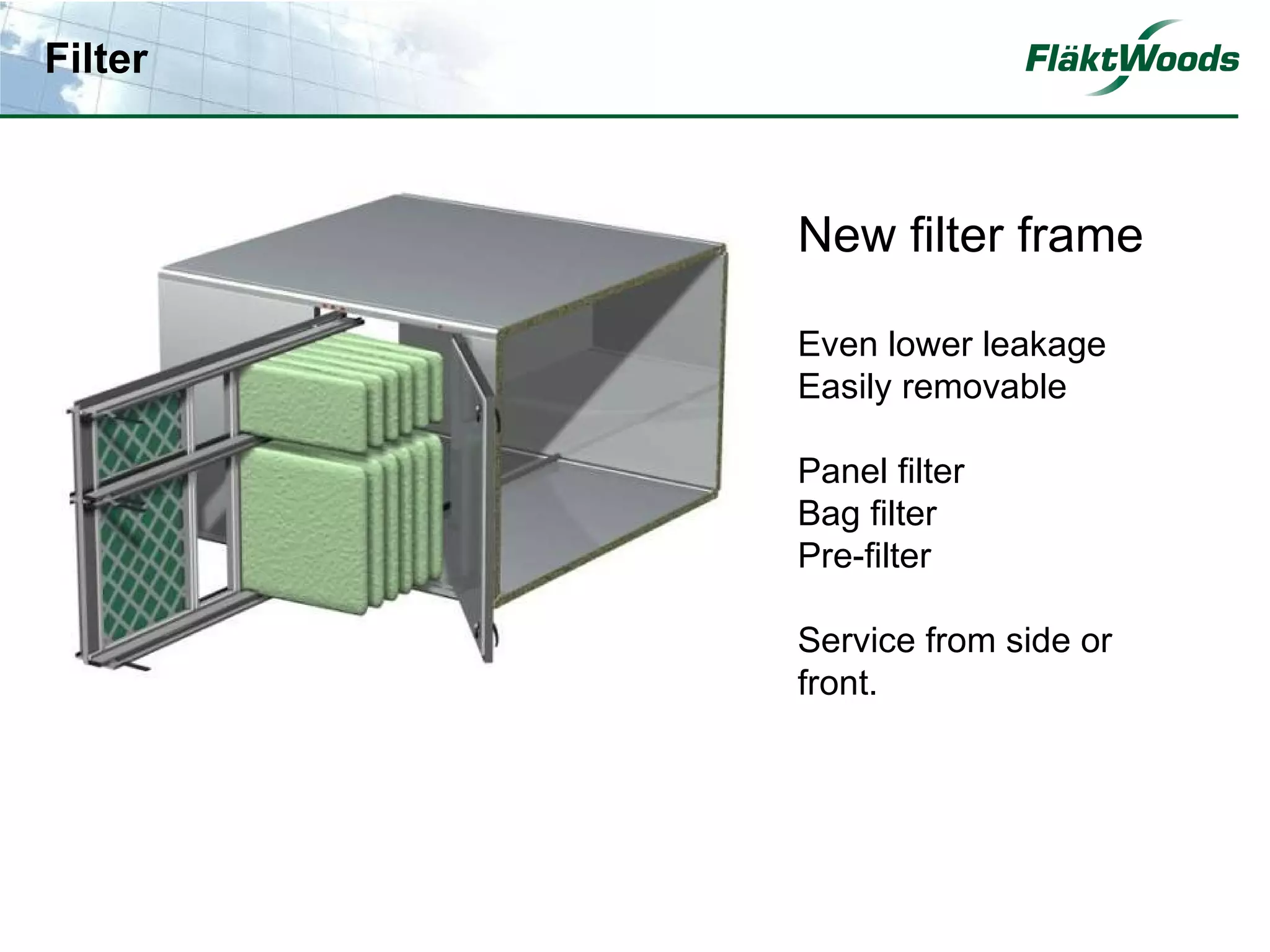

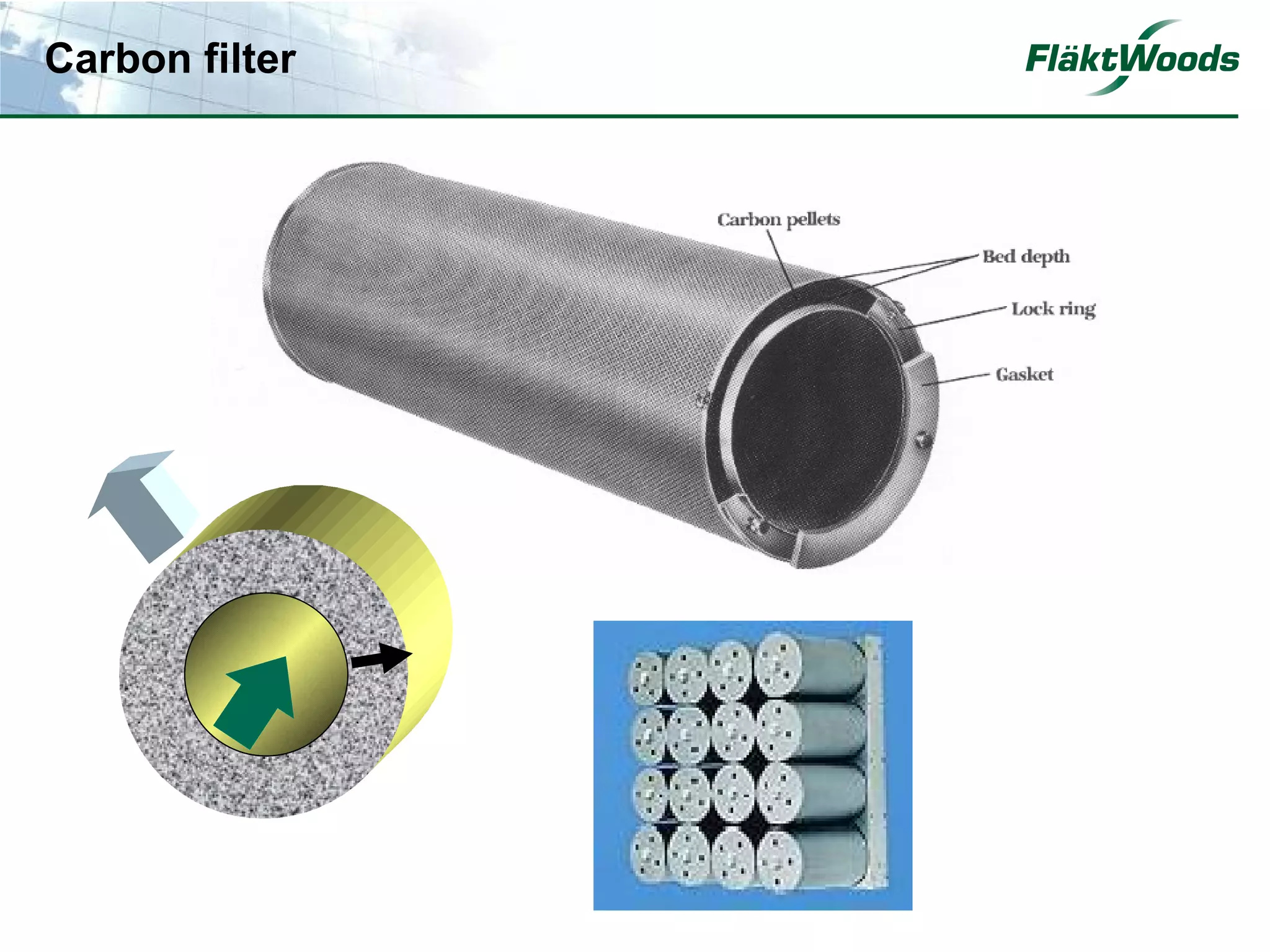

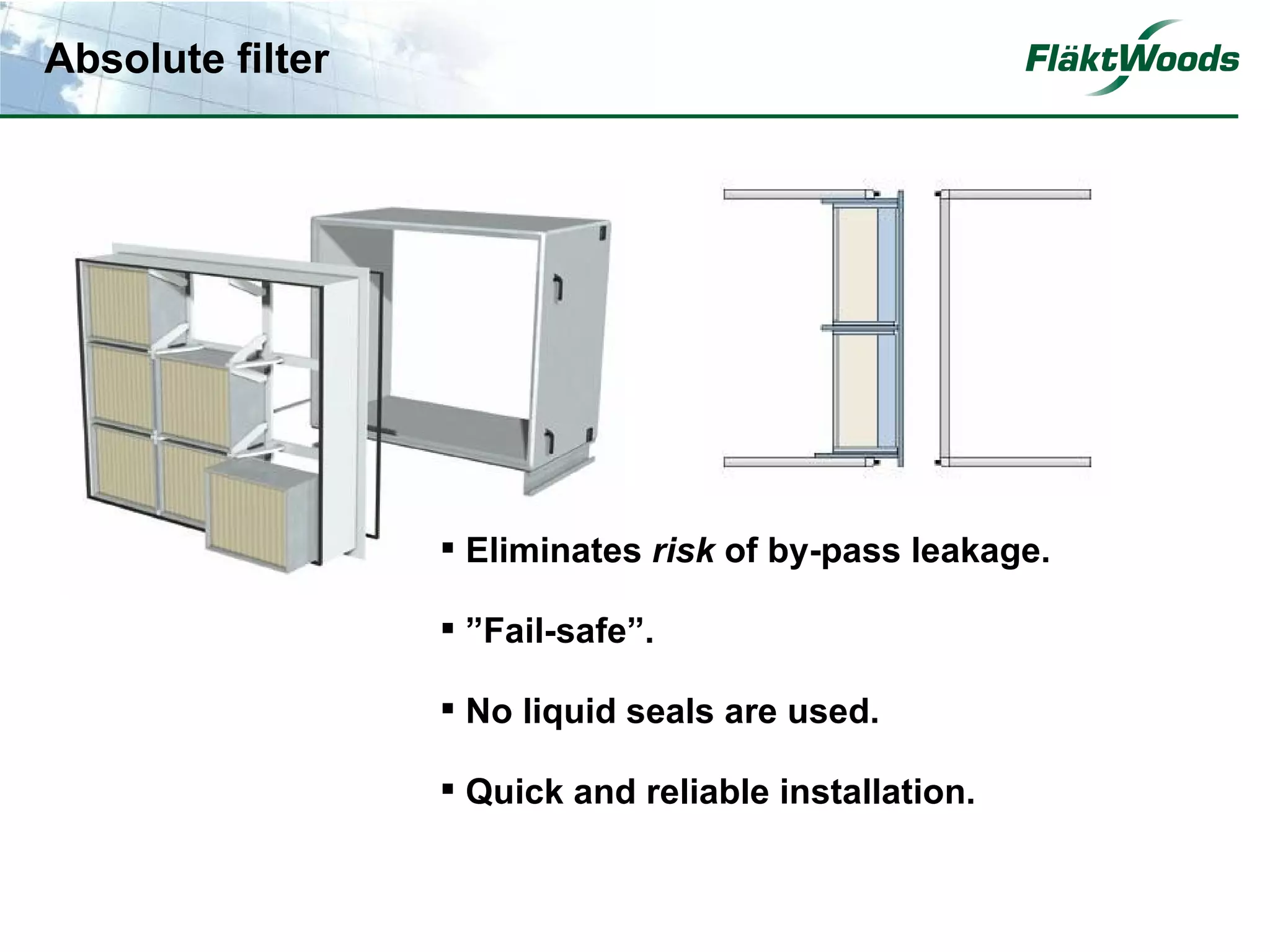

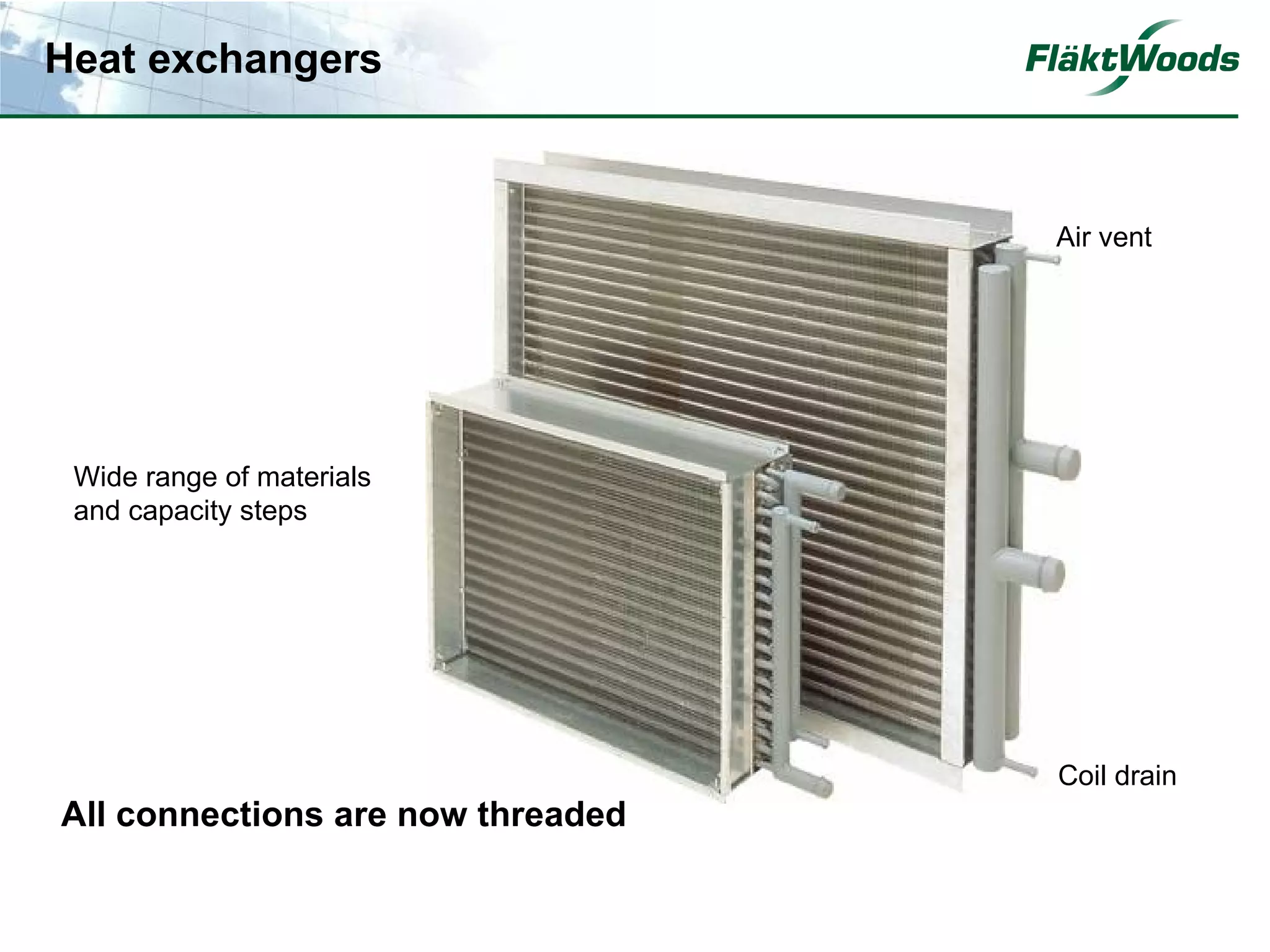

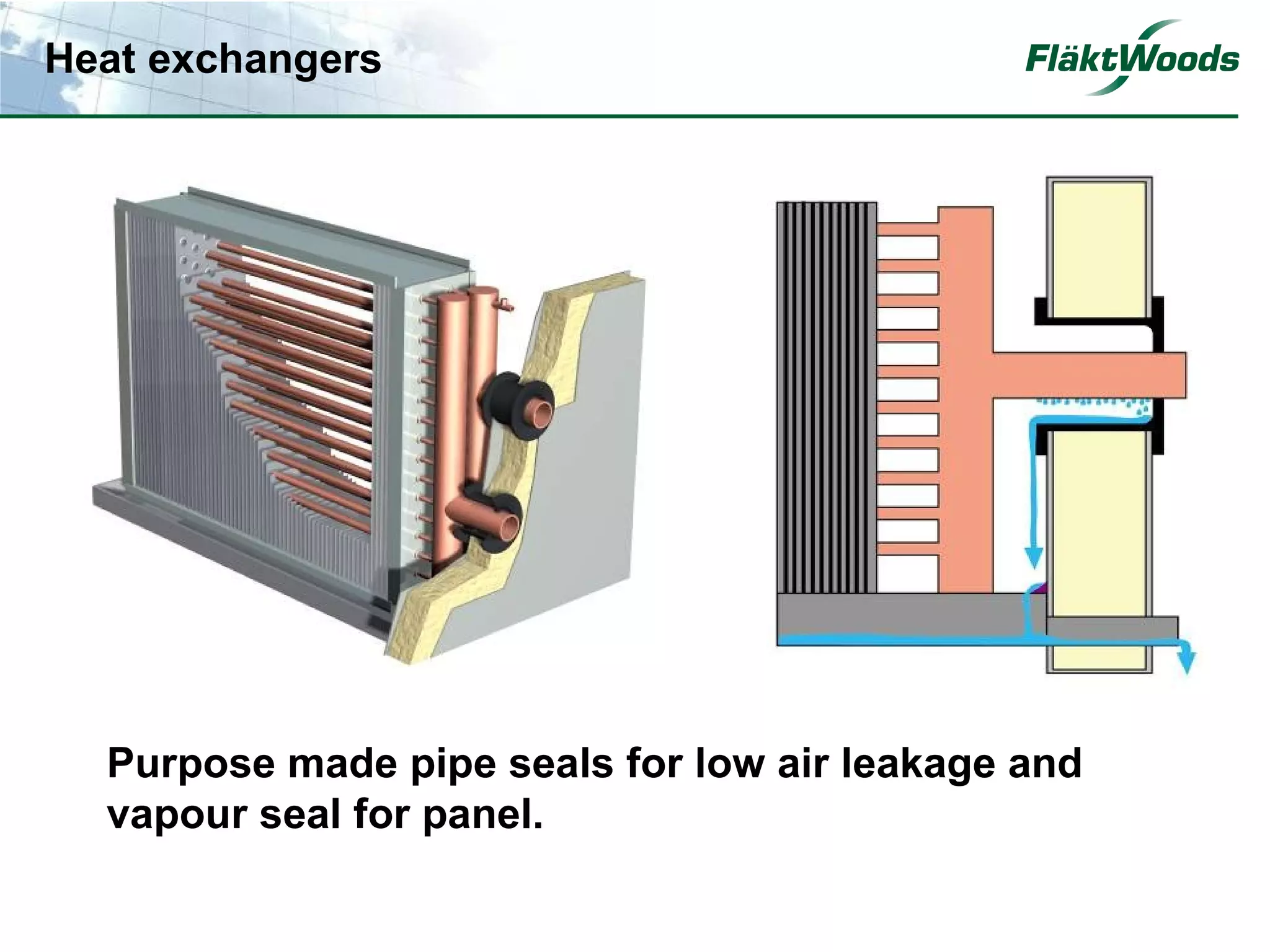

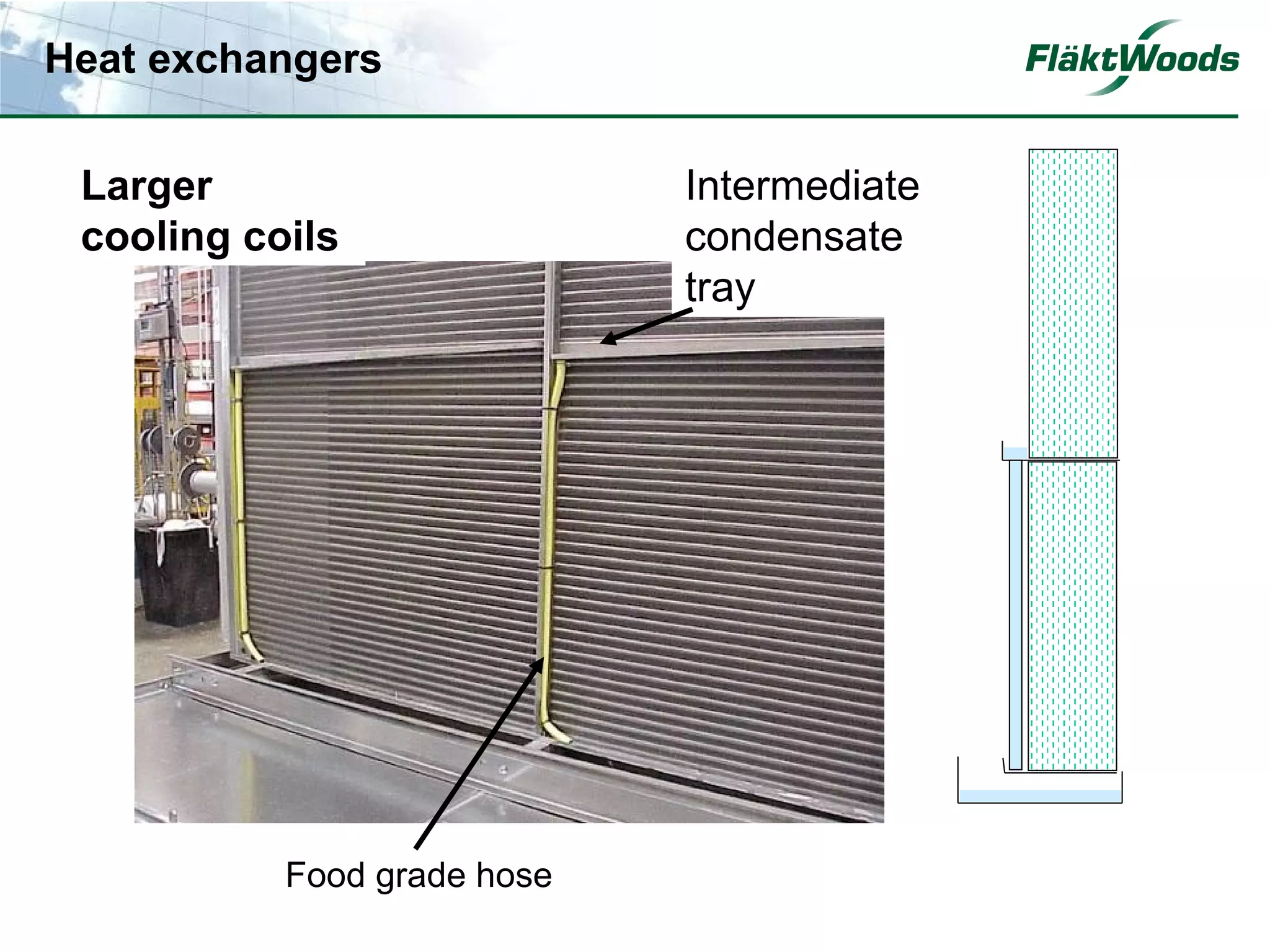

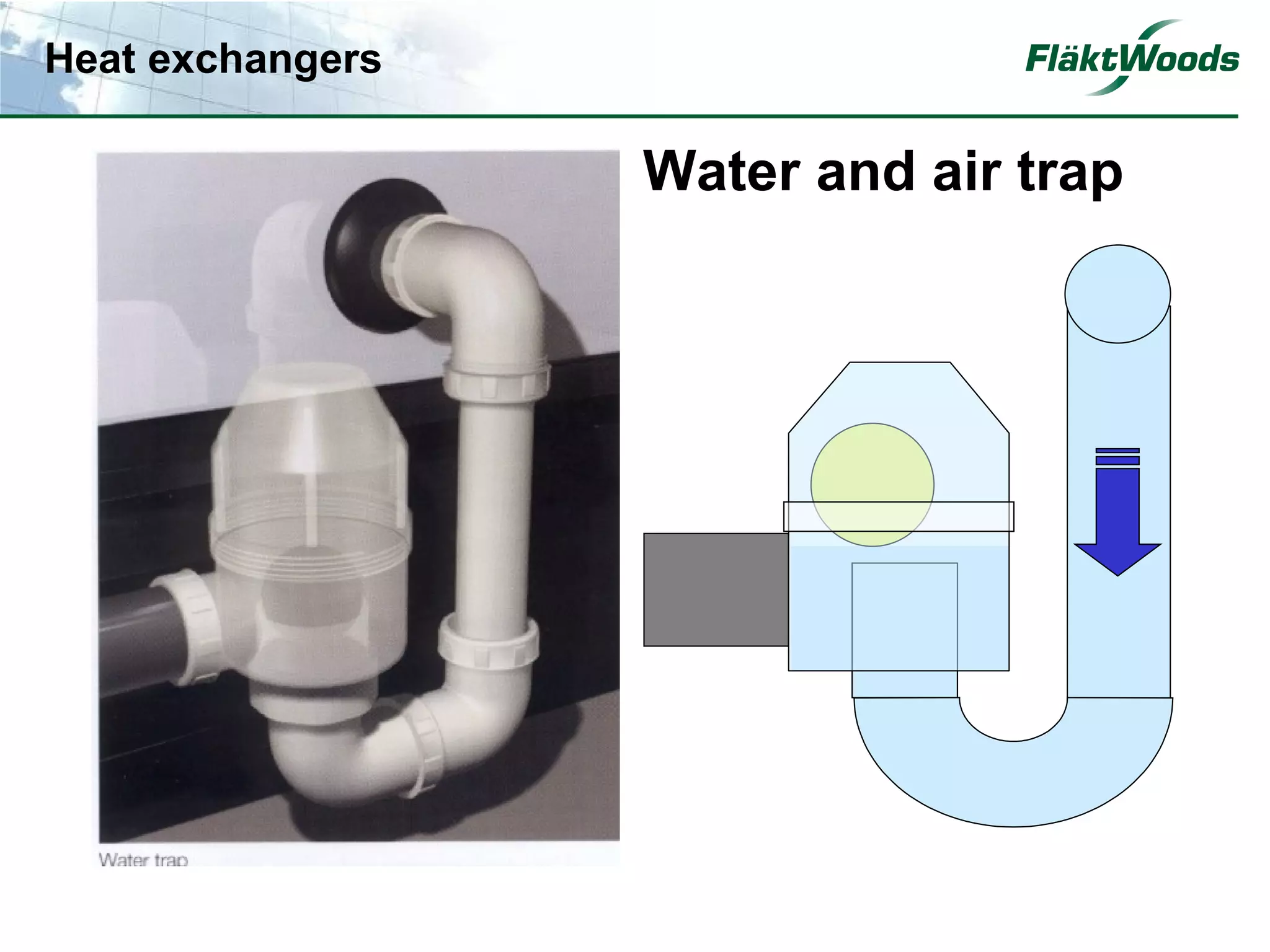

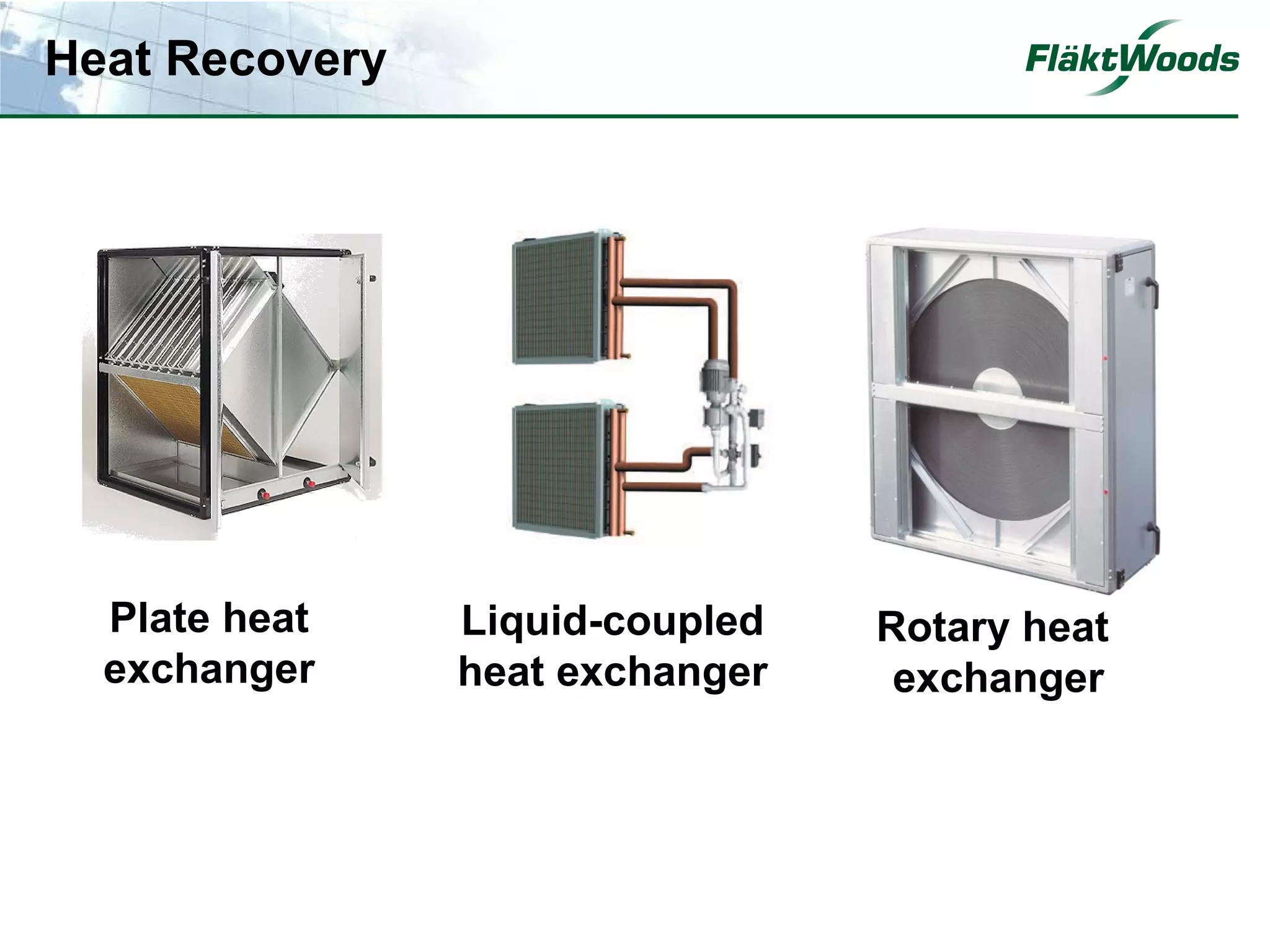

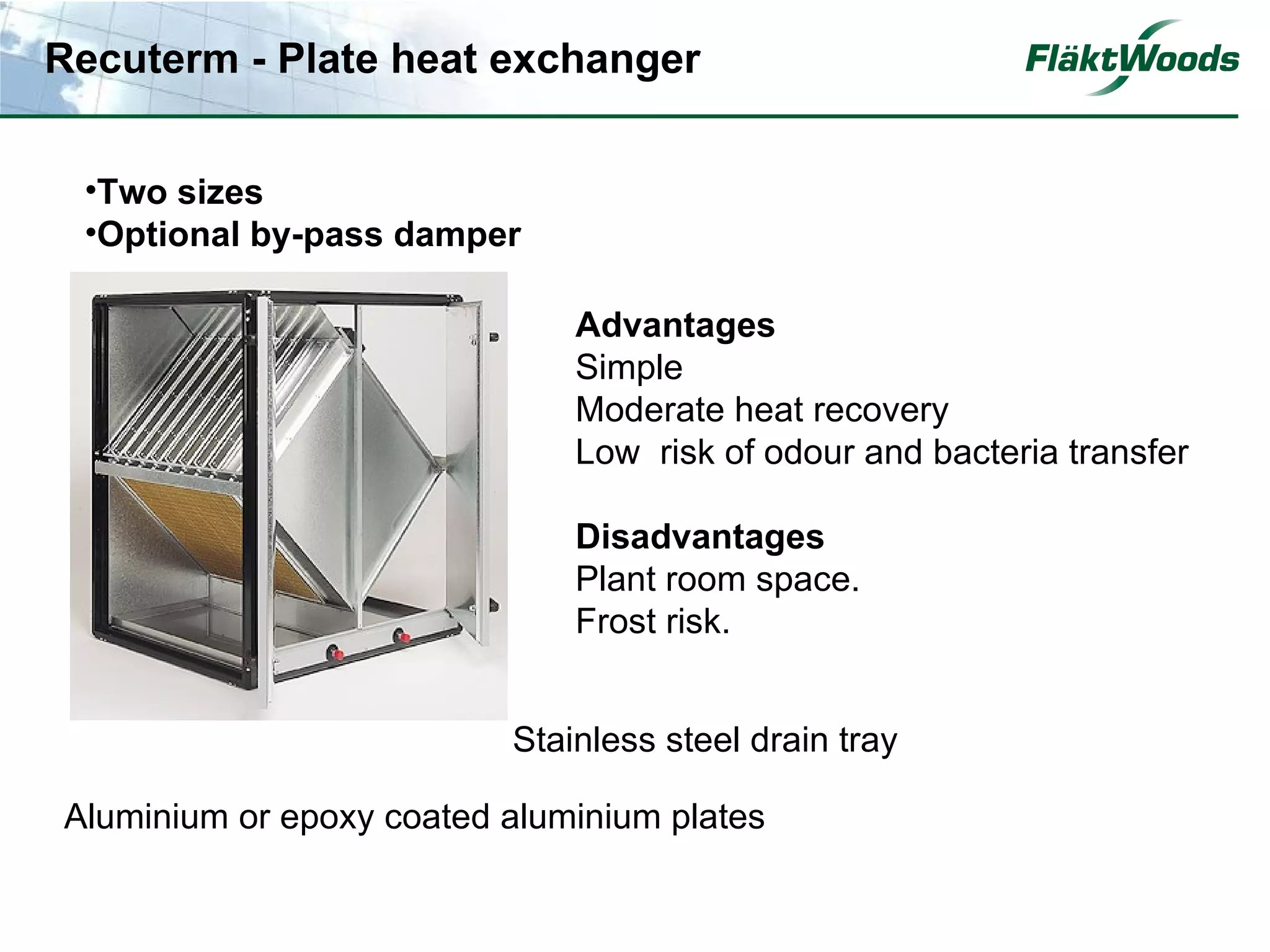

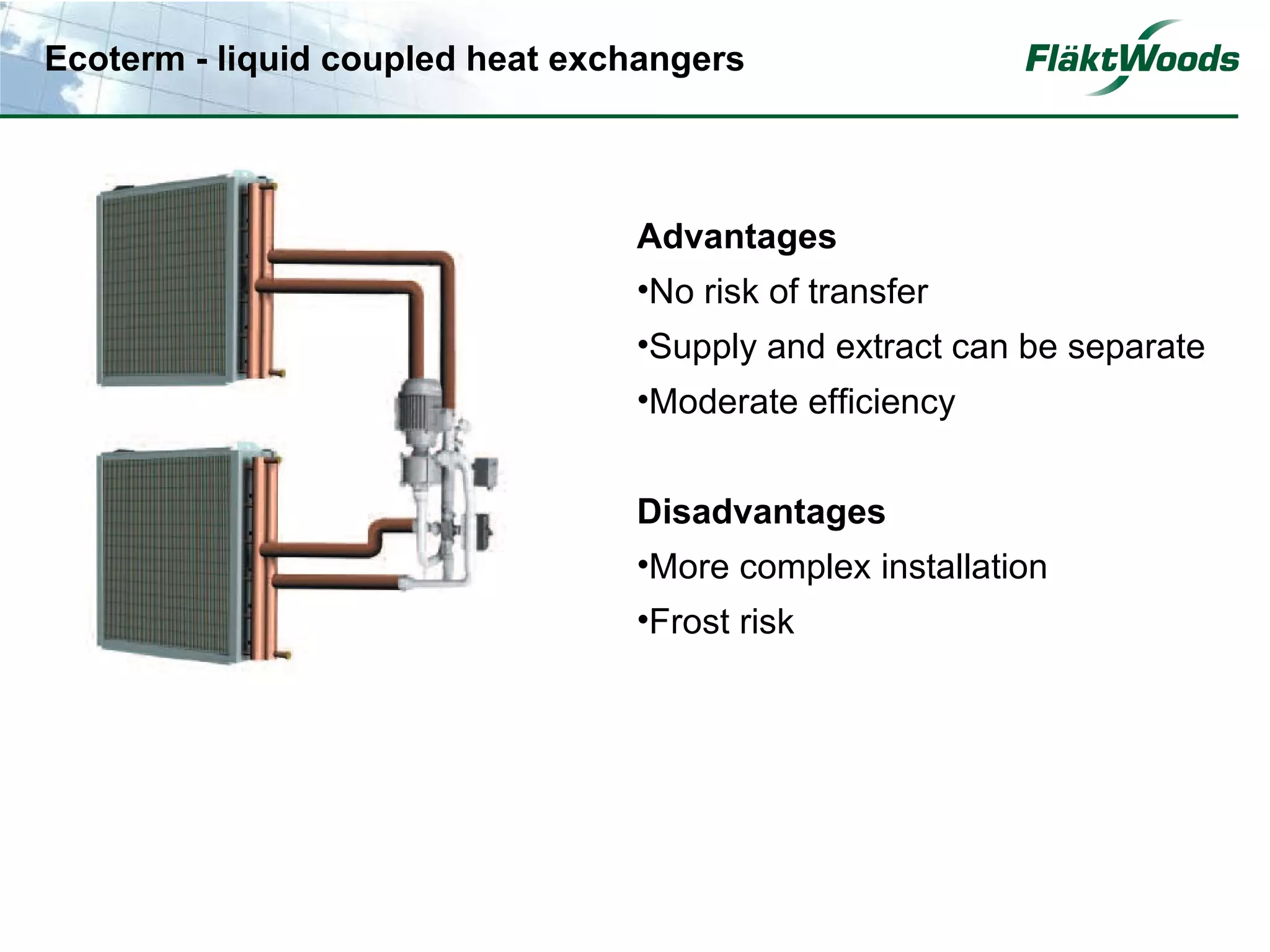

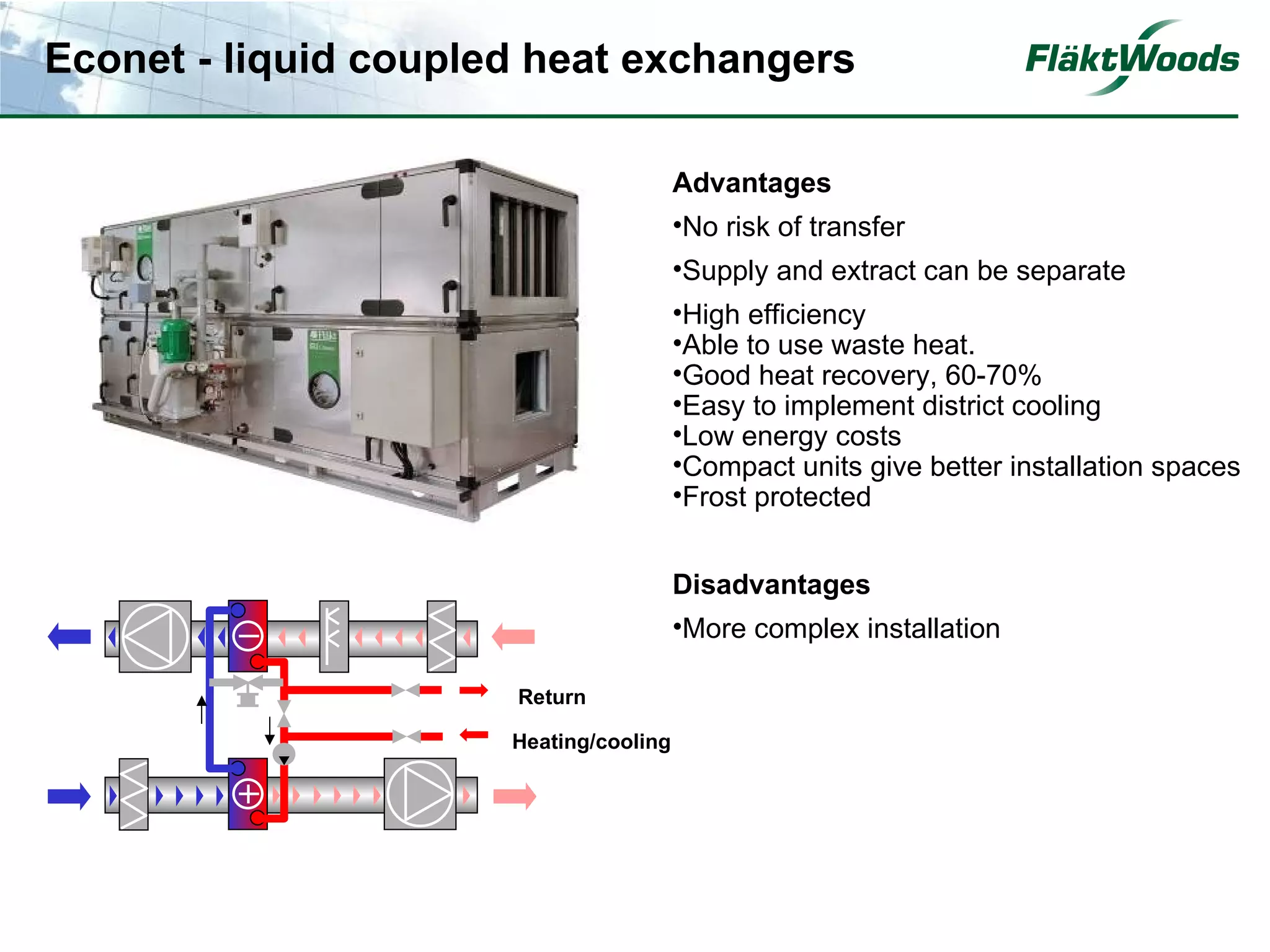

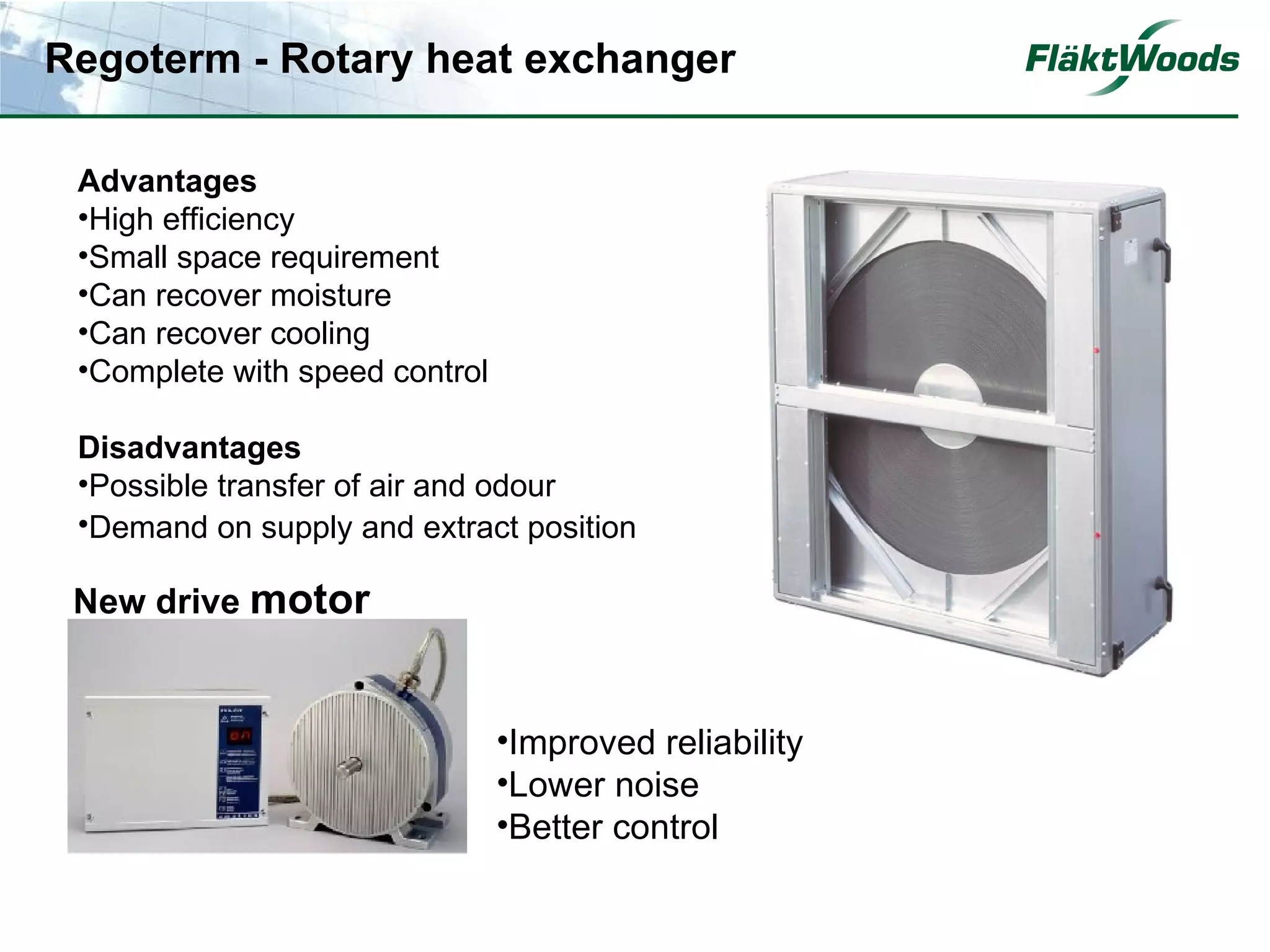

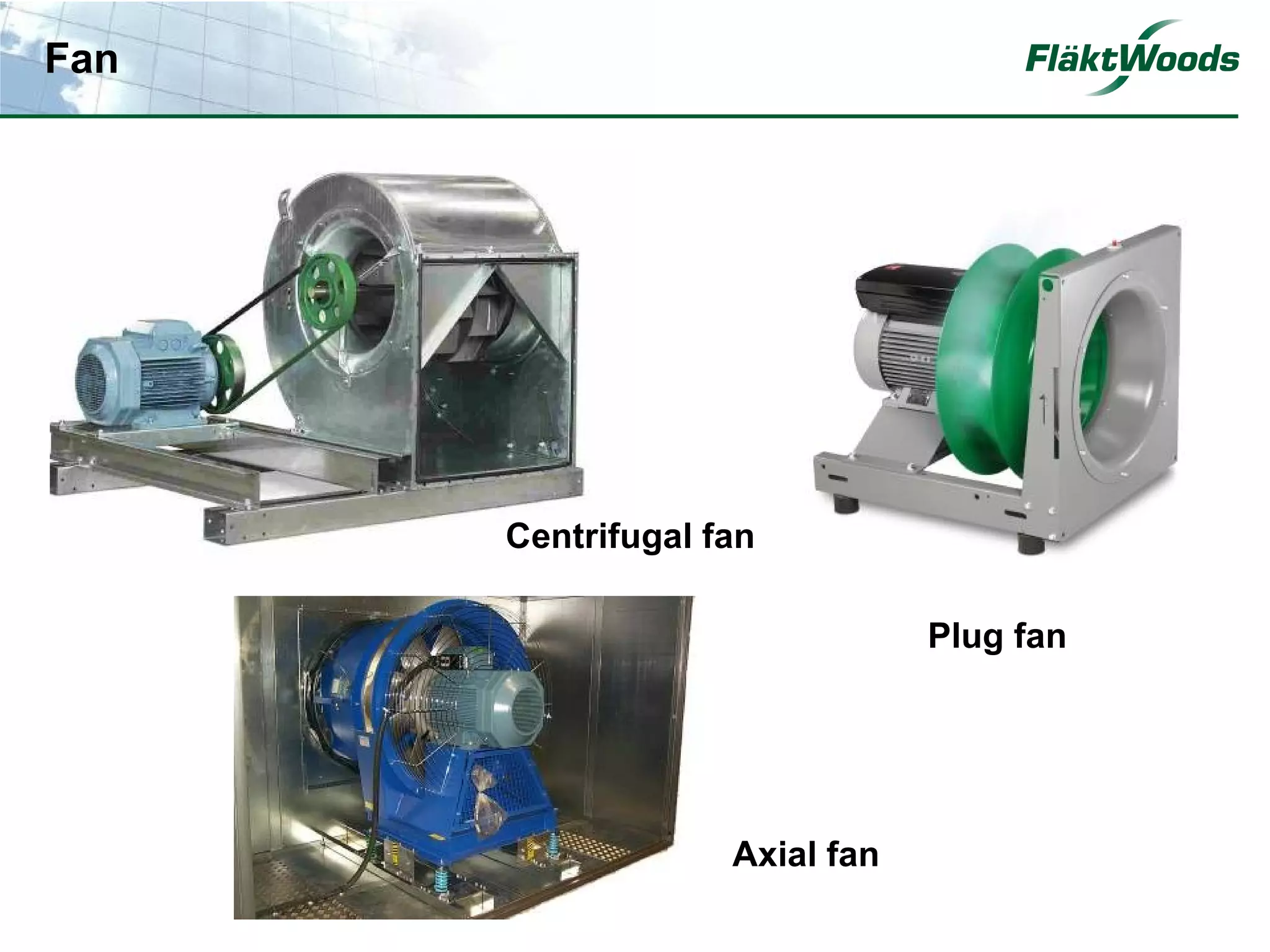

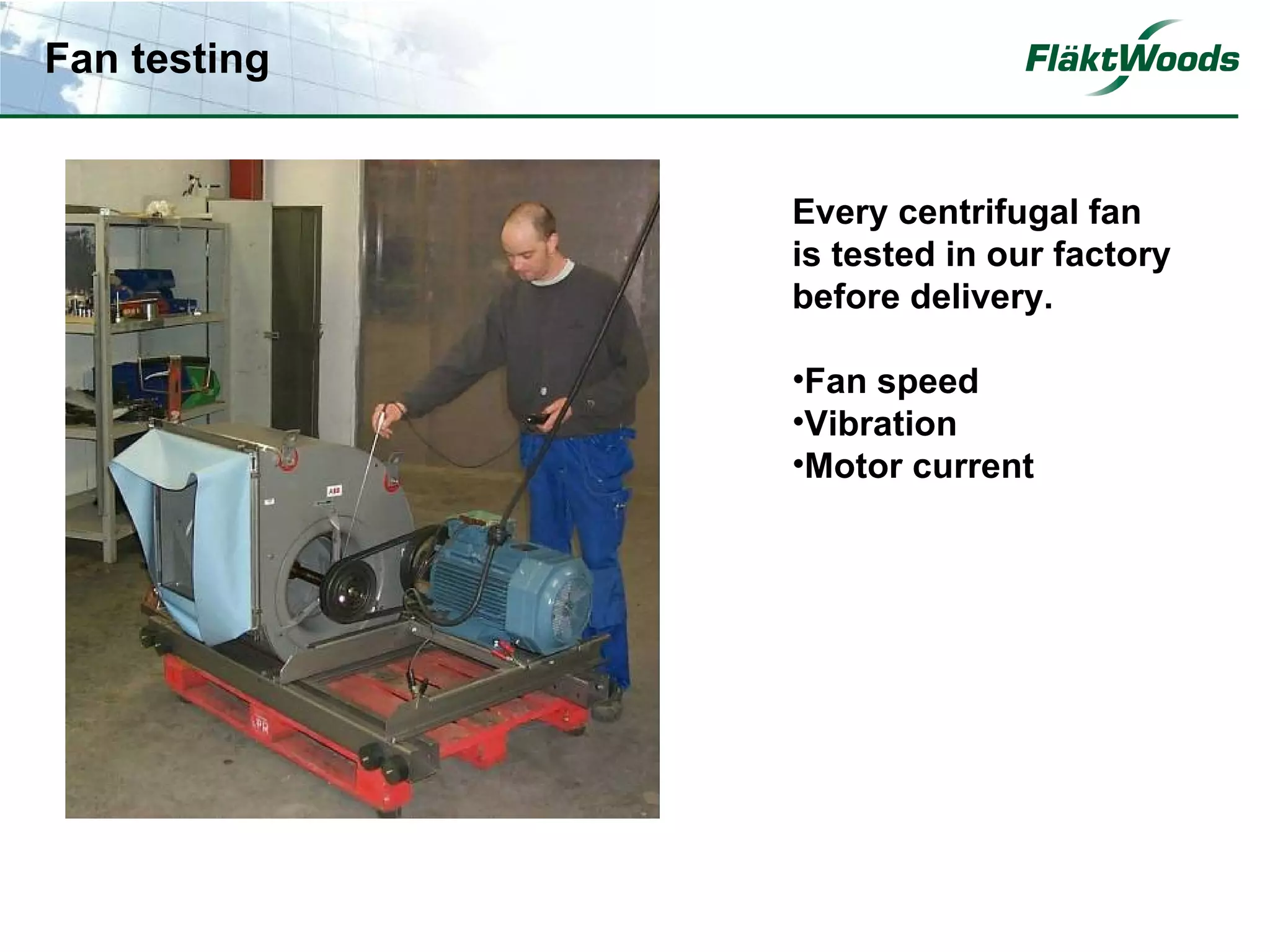

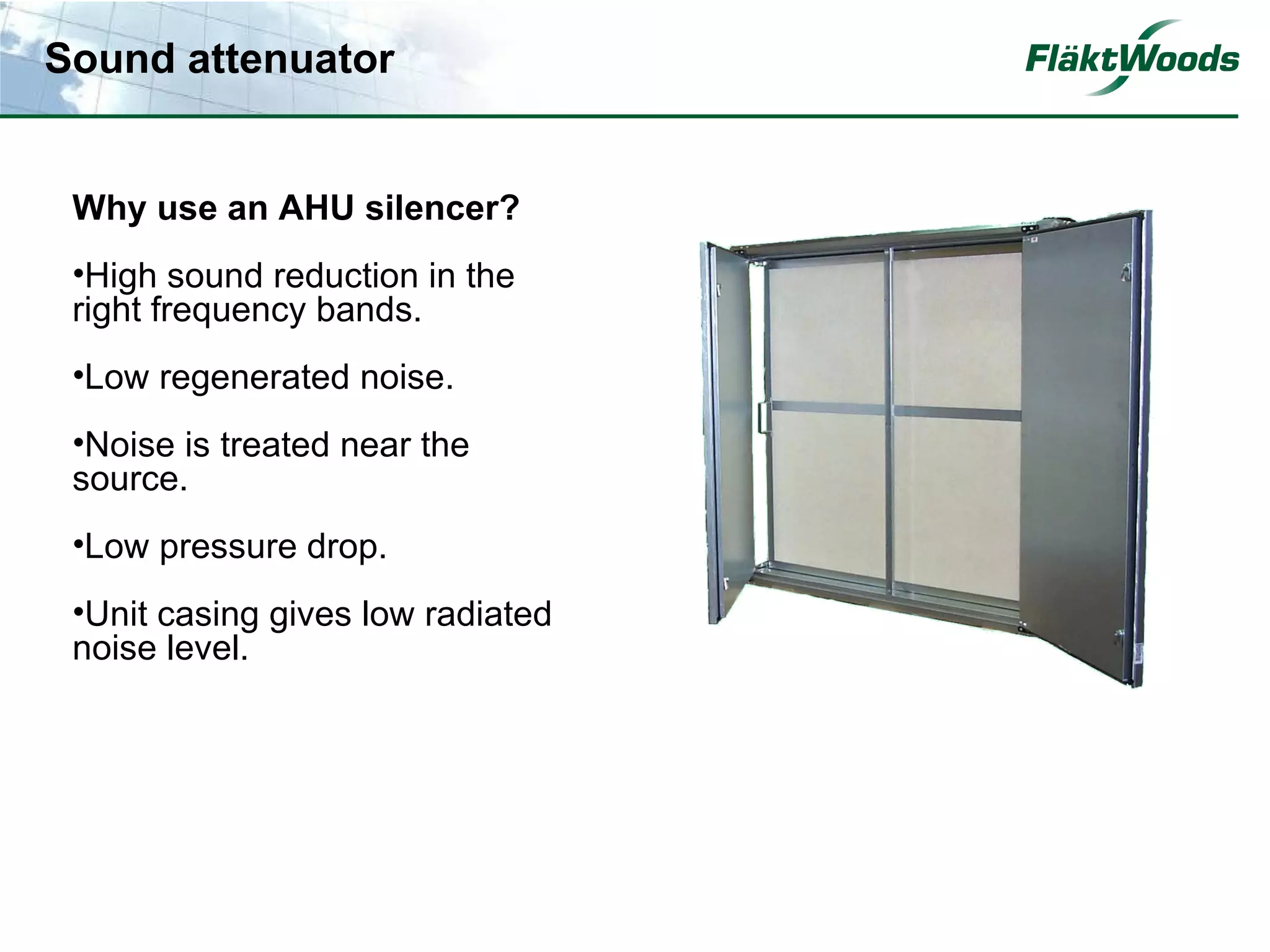

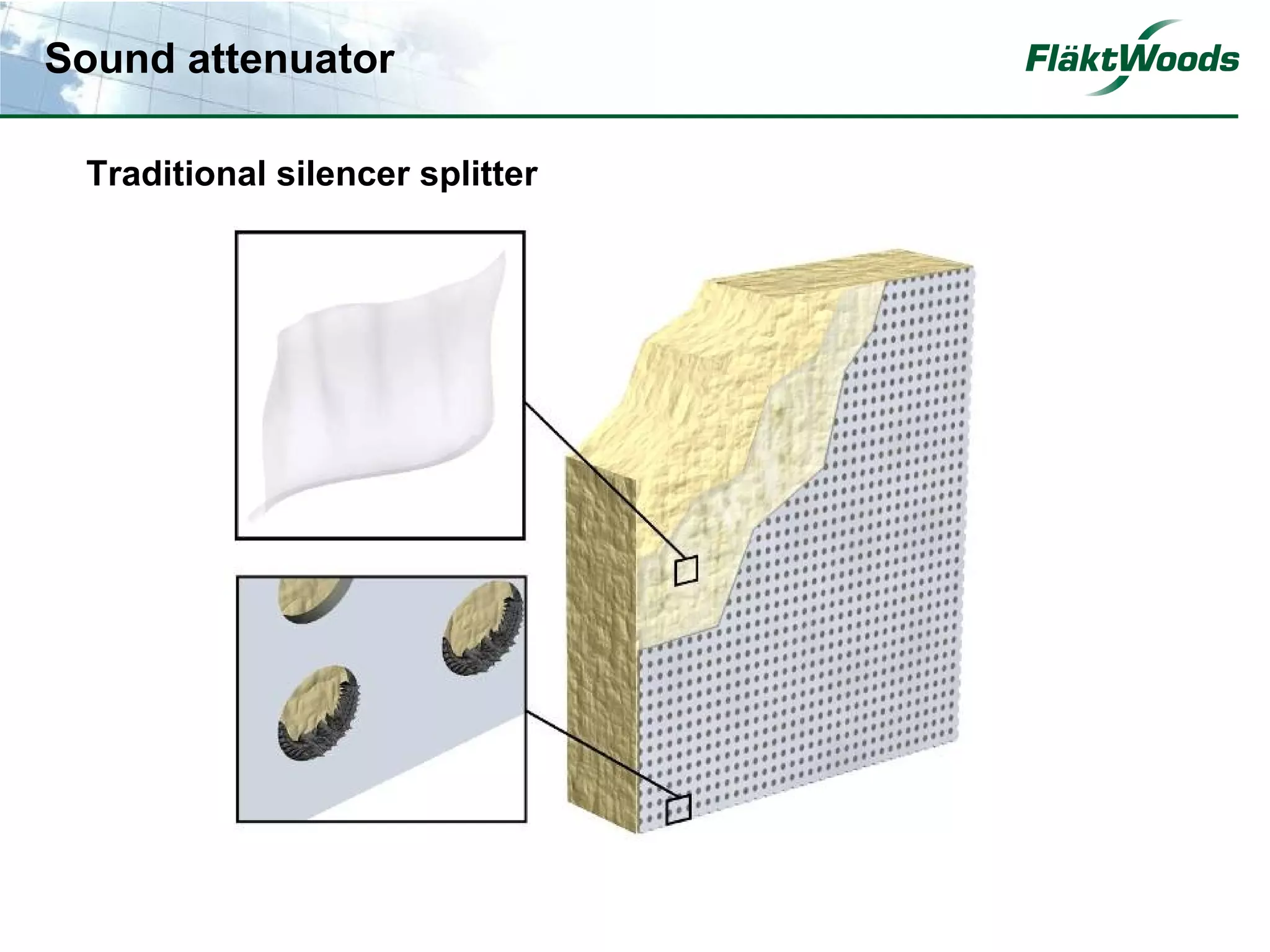

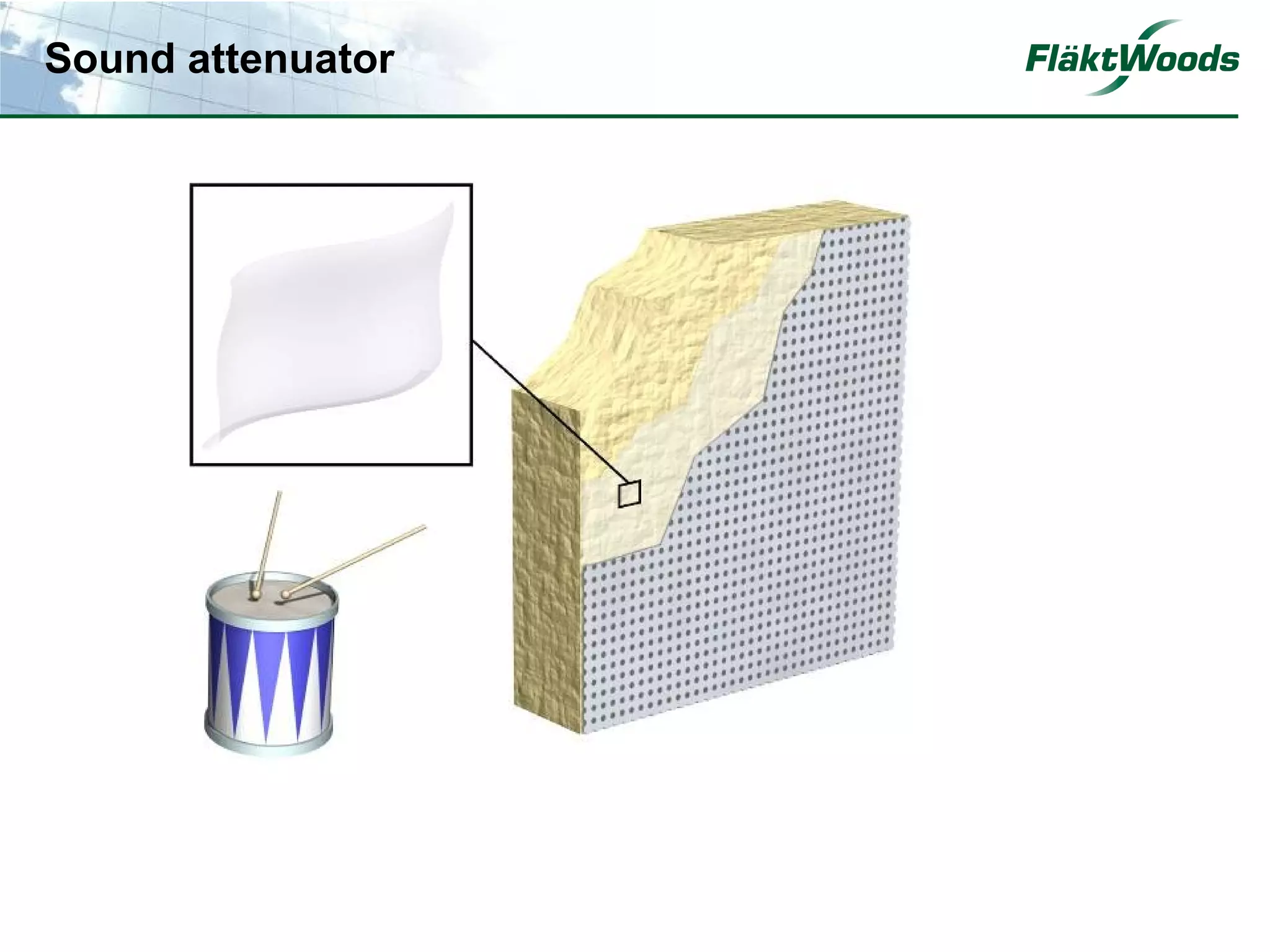

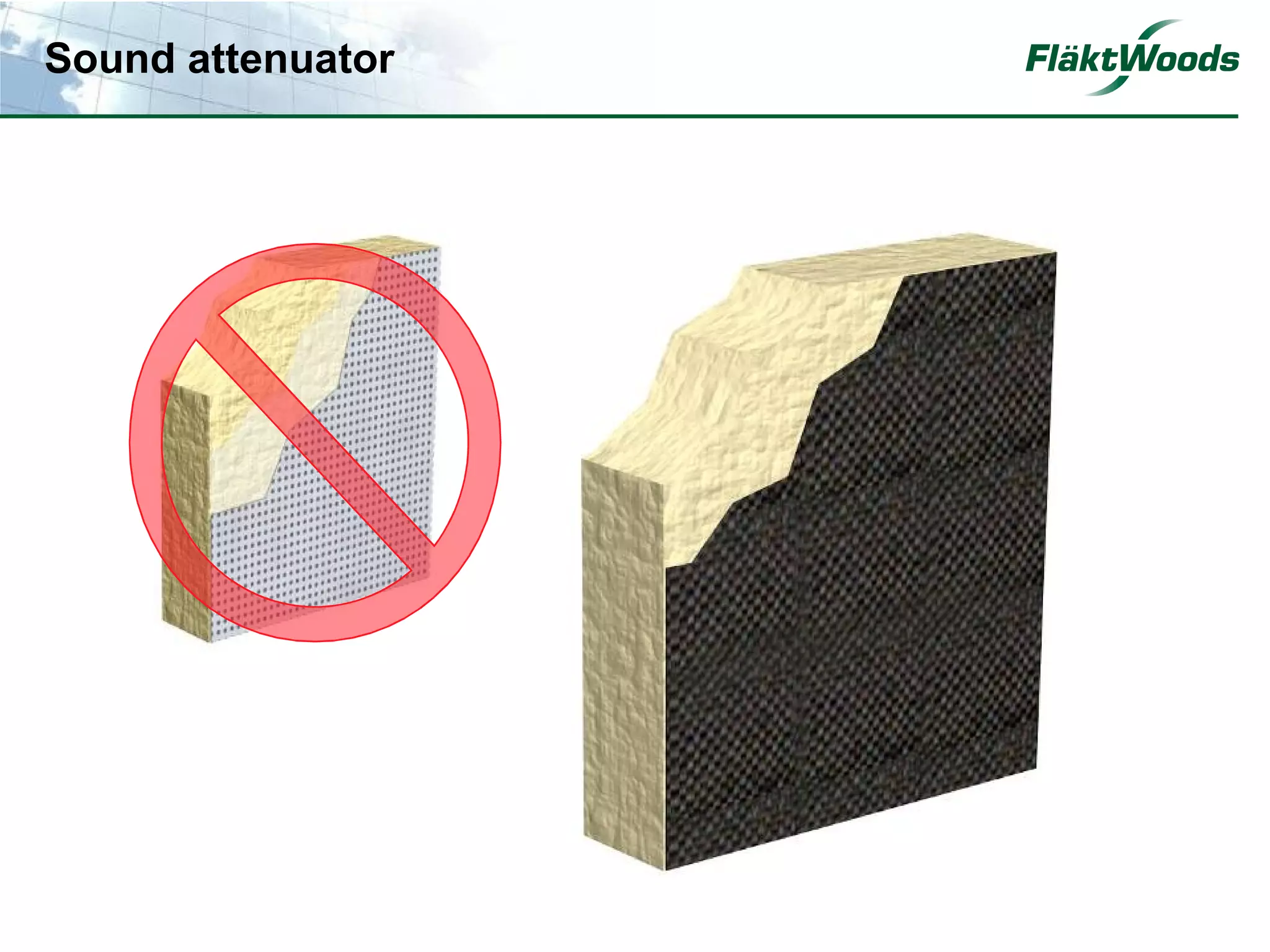

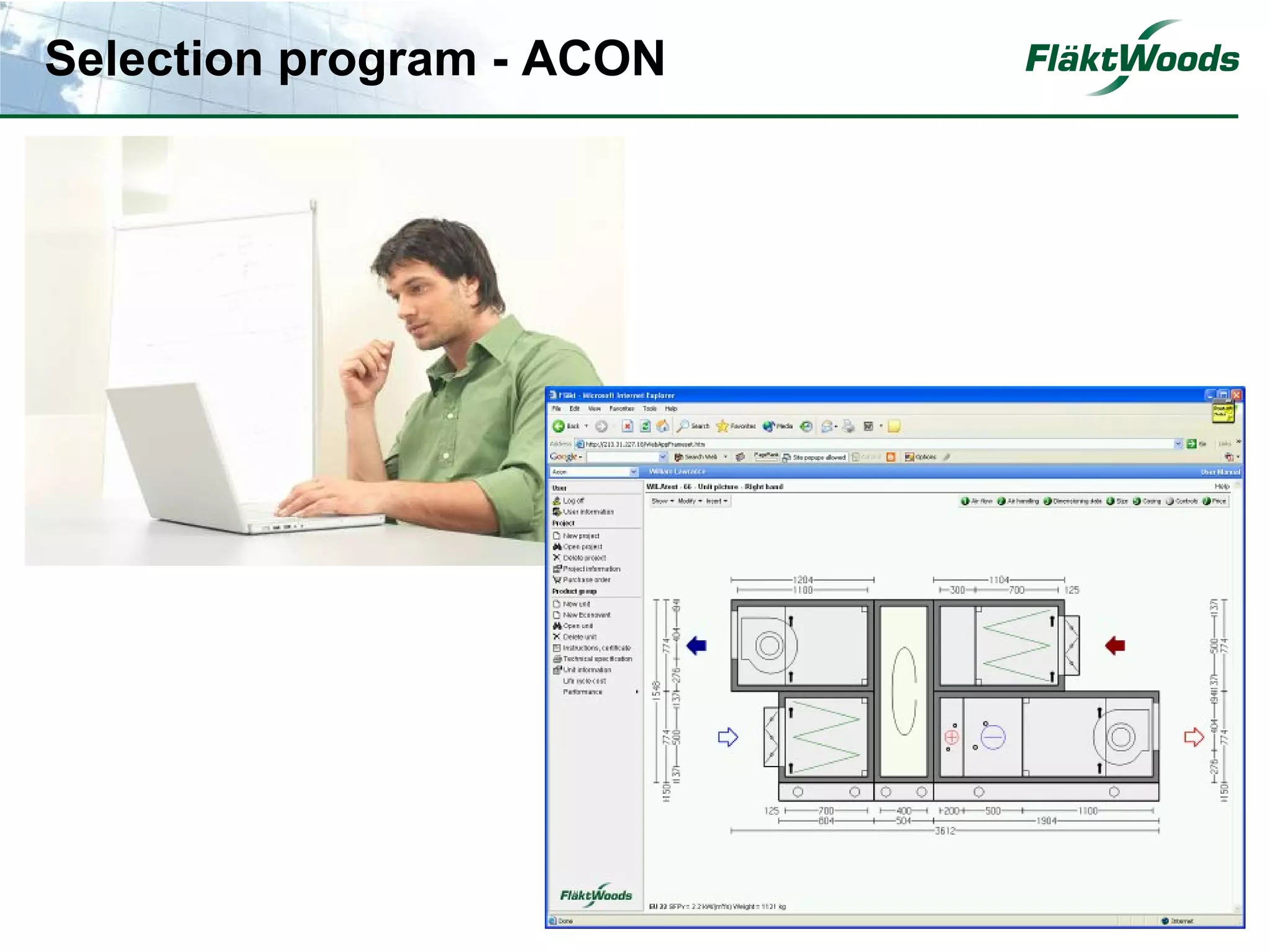

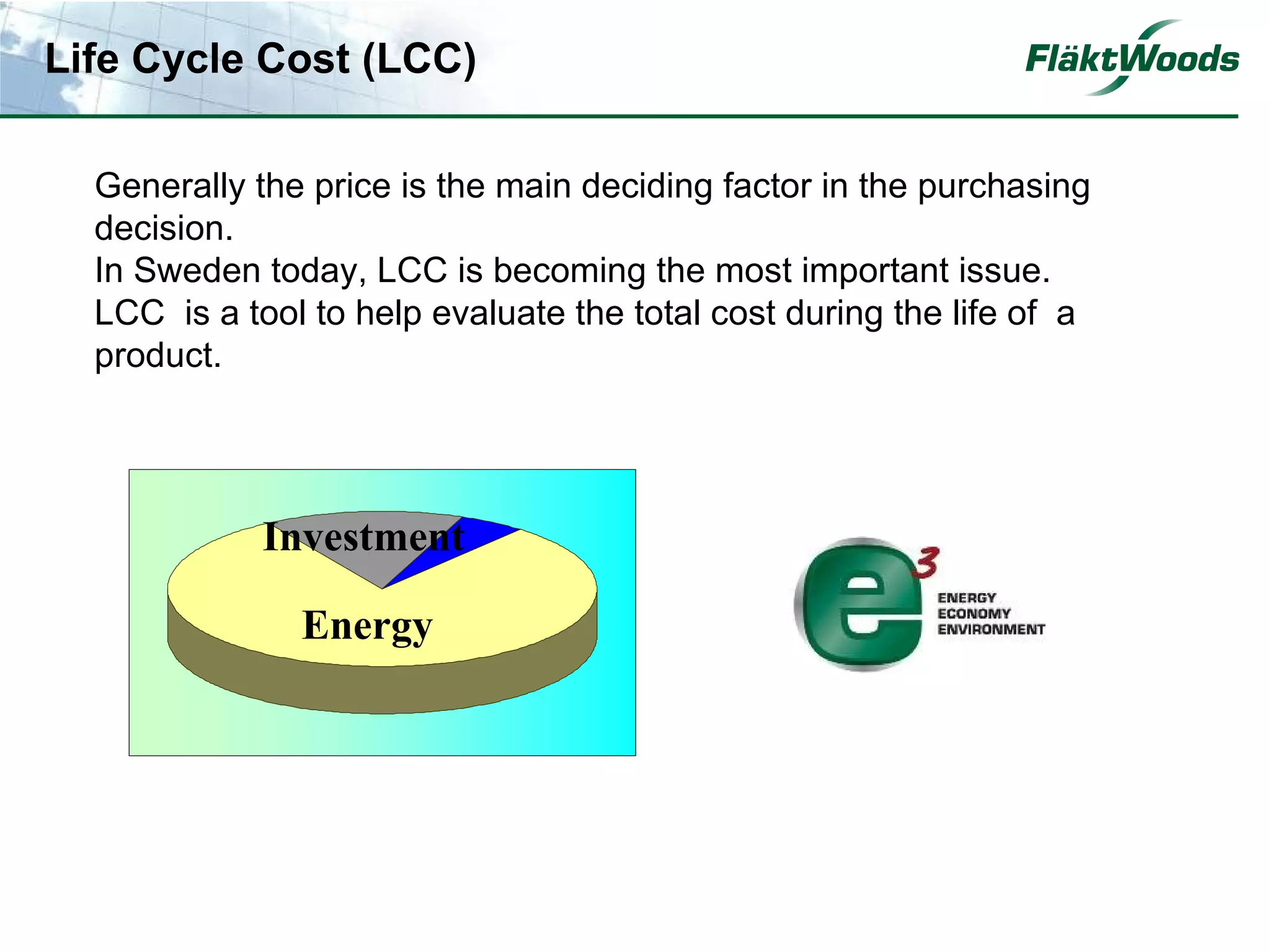

This document describes modular air handling units (AHUs) and their components. It discusses the EU size ranges from 0.2-34 m3/s and their casing, dampers, filters, coils, heat recovery, fans, and silencers. It provides details on materials, performance standards, installation, and maintenance for these various components. The purpose is to outline the technical specifications and options for modular AHUs to assist in selection and documentation.