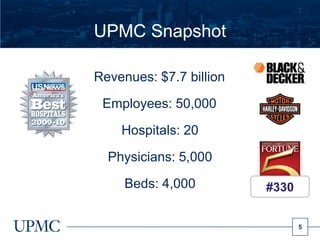

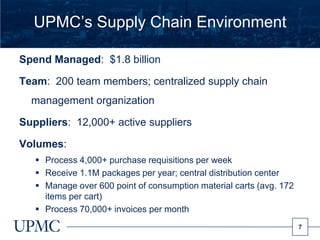

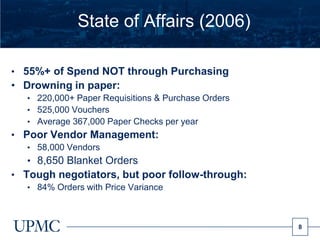

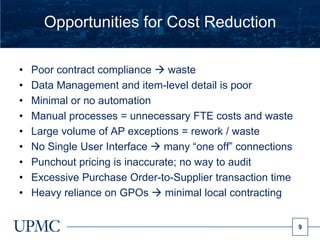

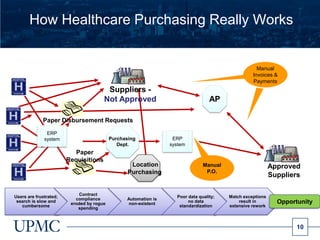

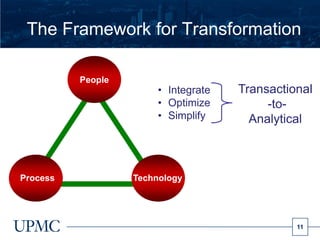

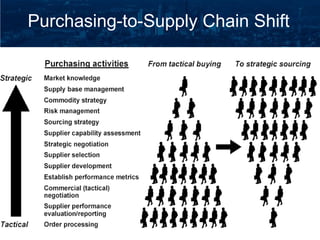

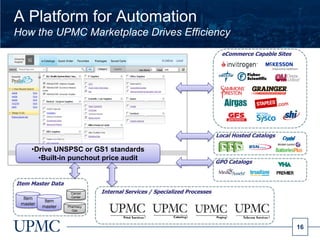

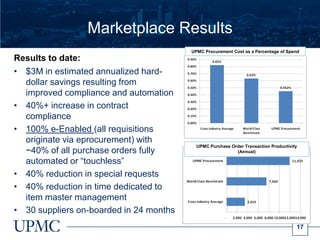

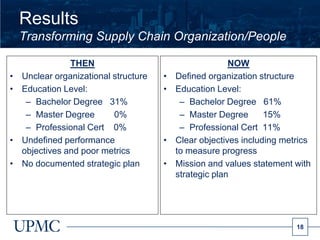

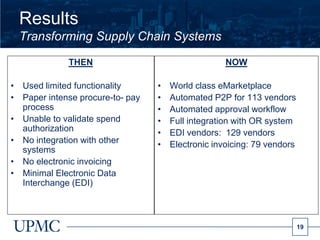

UPMC is a large integrated health system based in Pittsburgh. The document discusses UPMC's transformation of its supply chain management over the past decade. Previously, UPMC had an inefficient, paper-based supply chain with poor contract compliance and automation. UPMC implemented a new framework focused on people, processes, and technology. This included restructuring the organization, investing in staff training, and implementing an e-procurement marketplace. As a result, UPMC achieved an estimated $3 million in annual savings, improved compliance by 40%, and increased automation and efficiency across its supply chain.