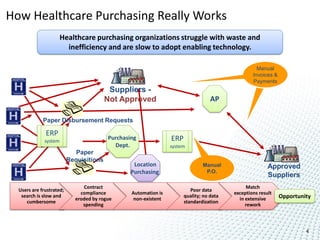

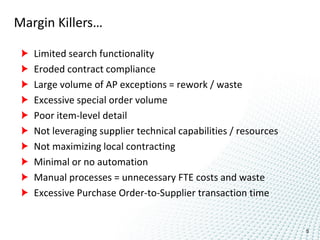

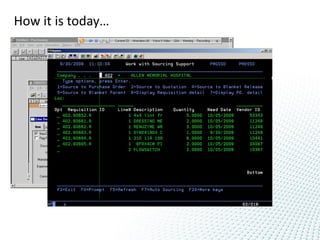

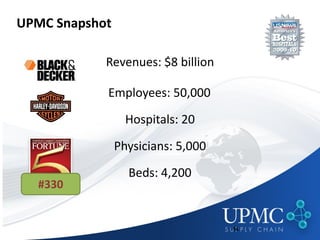

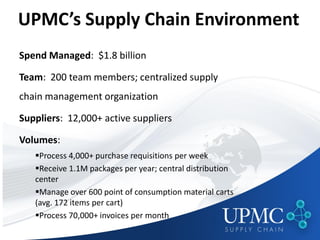

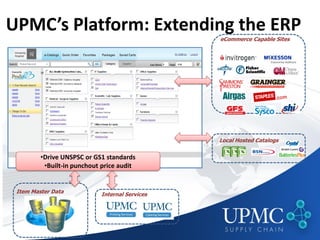

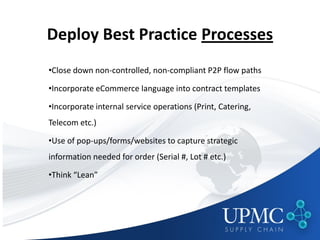

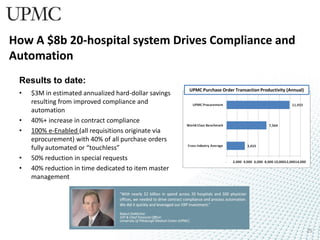

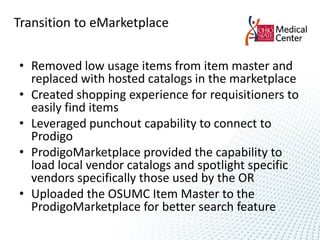

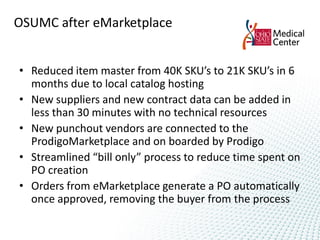

The document outlines five critical strategies for improving healthcare e-procurement processes, emphasizing automation, compliance, and effective content management. It highlights challenges faced by healthcare purchasing organizations, such as inefficiencies and bloated item masters, and provides examples of successful implementations at UPMC and OSUMC. Key benefits include significant cost savings, increased contract compliance, and improved data management through strategic inventory practices.