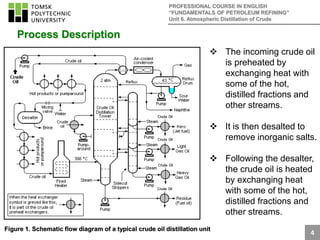

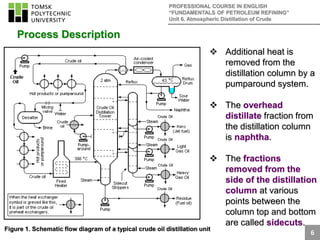

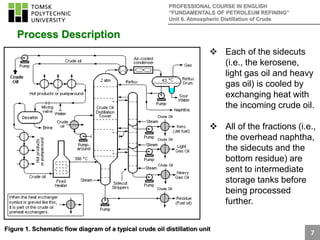

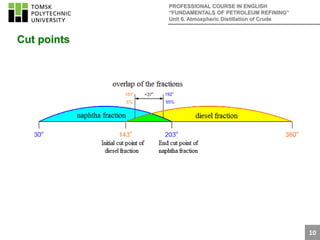

The document describes the process of atmospheric distillation of crude oil. It discusses how crude oil is preheated, desalted, and heated to 398°C before being routed into the distillation unit. In the unit, fractions such as naphtha, kerosene, gas oil and atmospheric residue are separated based on their boiling points. The operation is characterized by factors like cut points, degree of fractionation, overflash, column pressure and overhead temperature which determine the quality and yield of products from the unit.