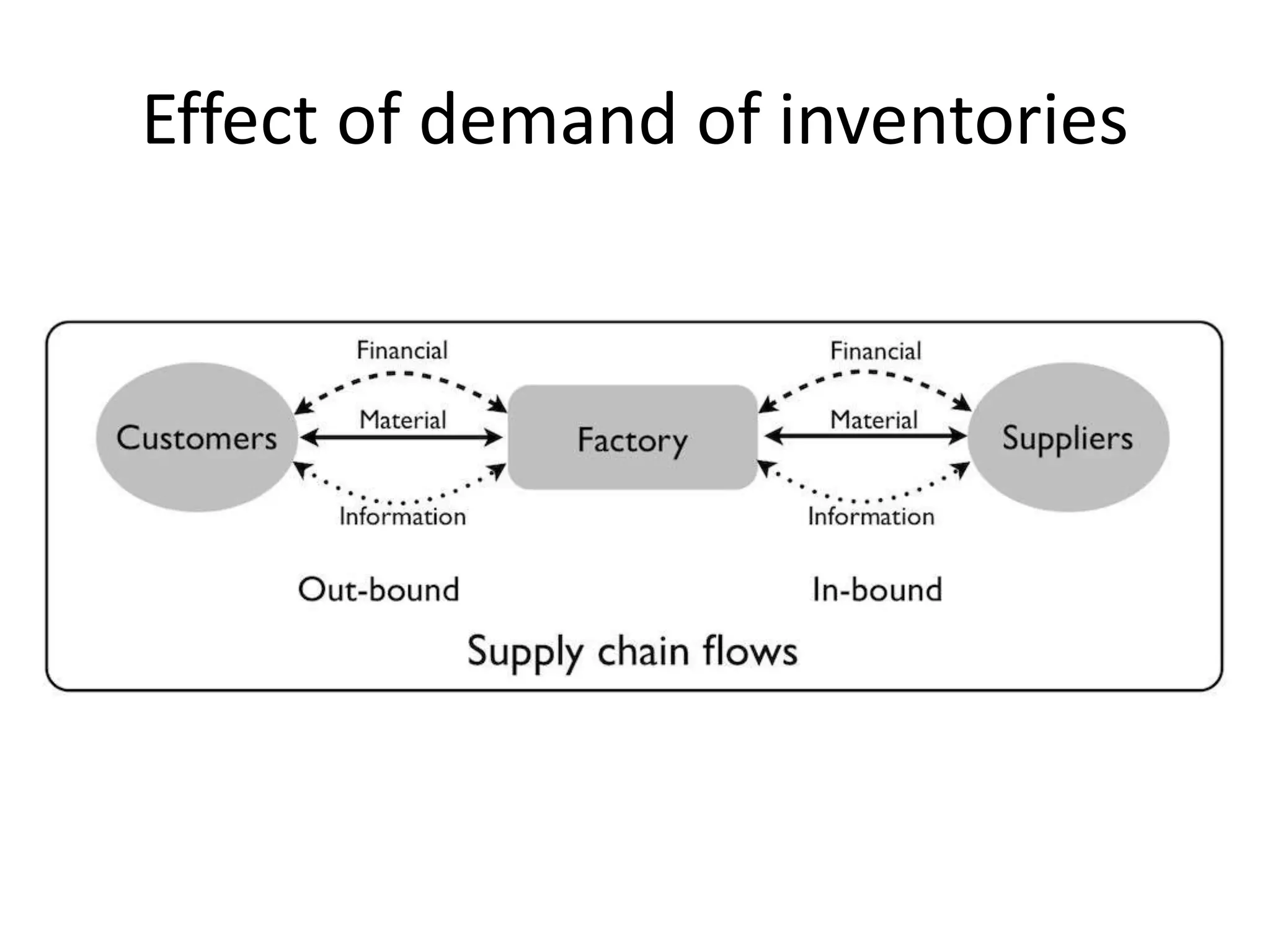

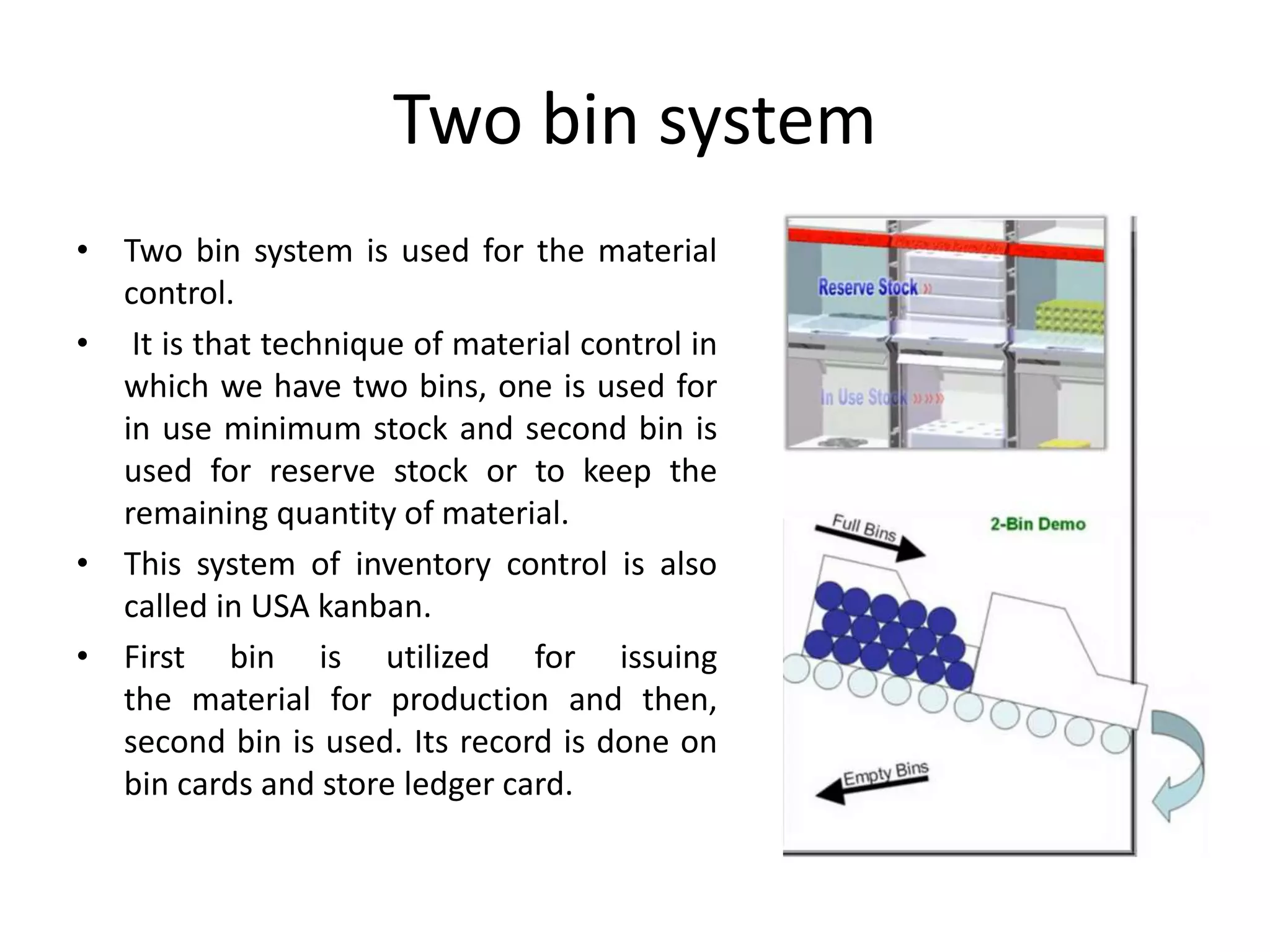

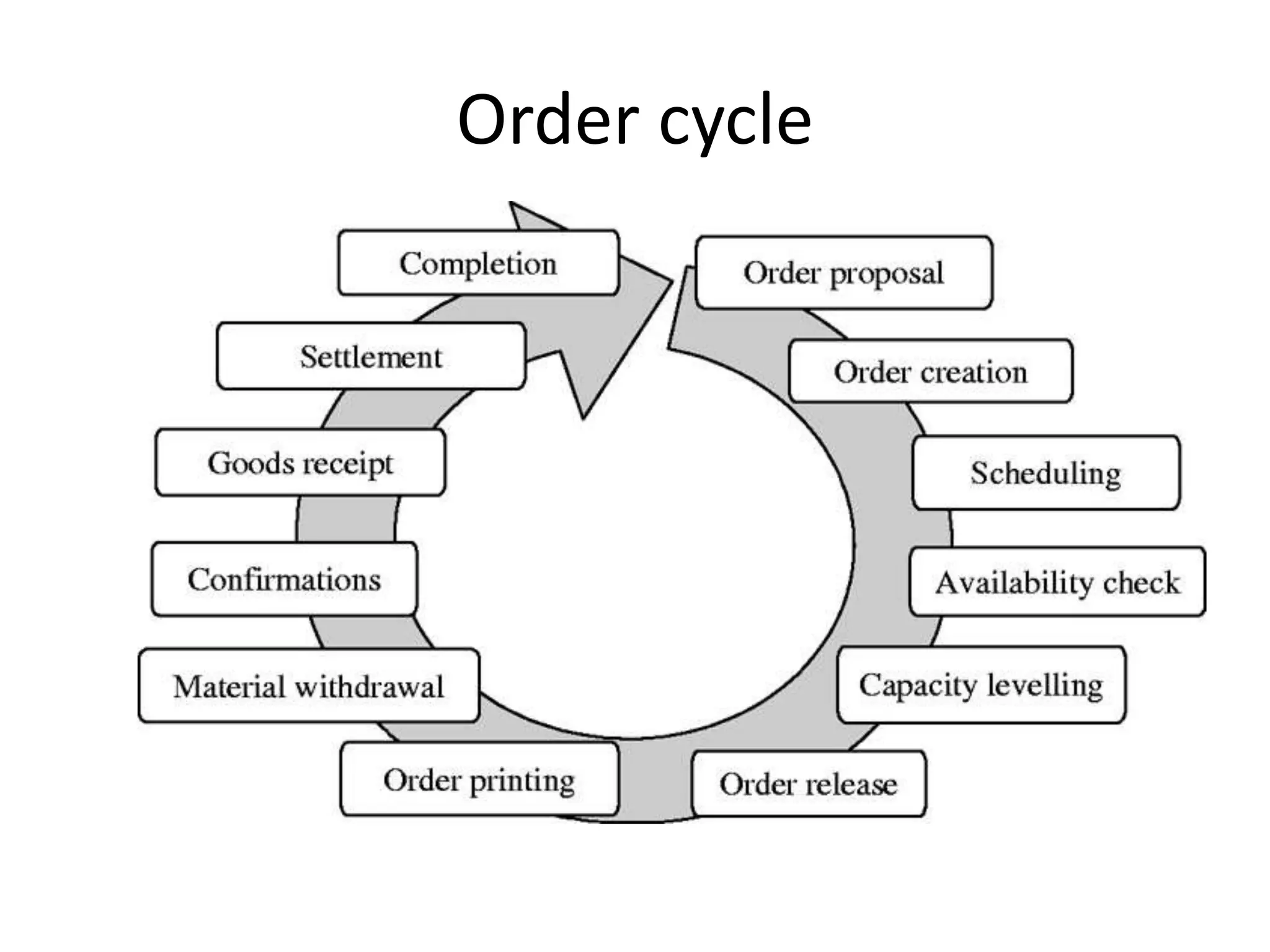

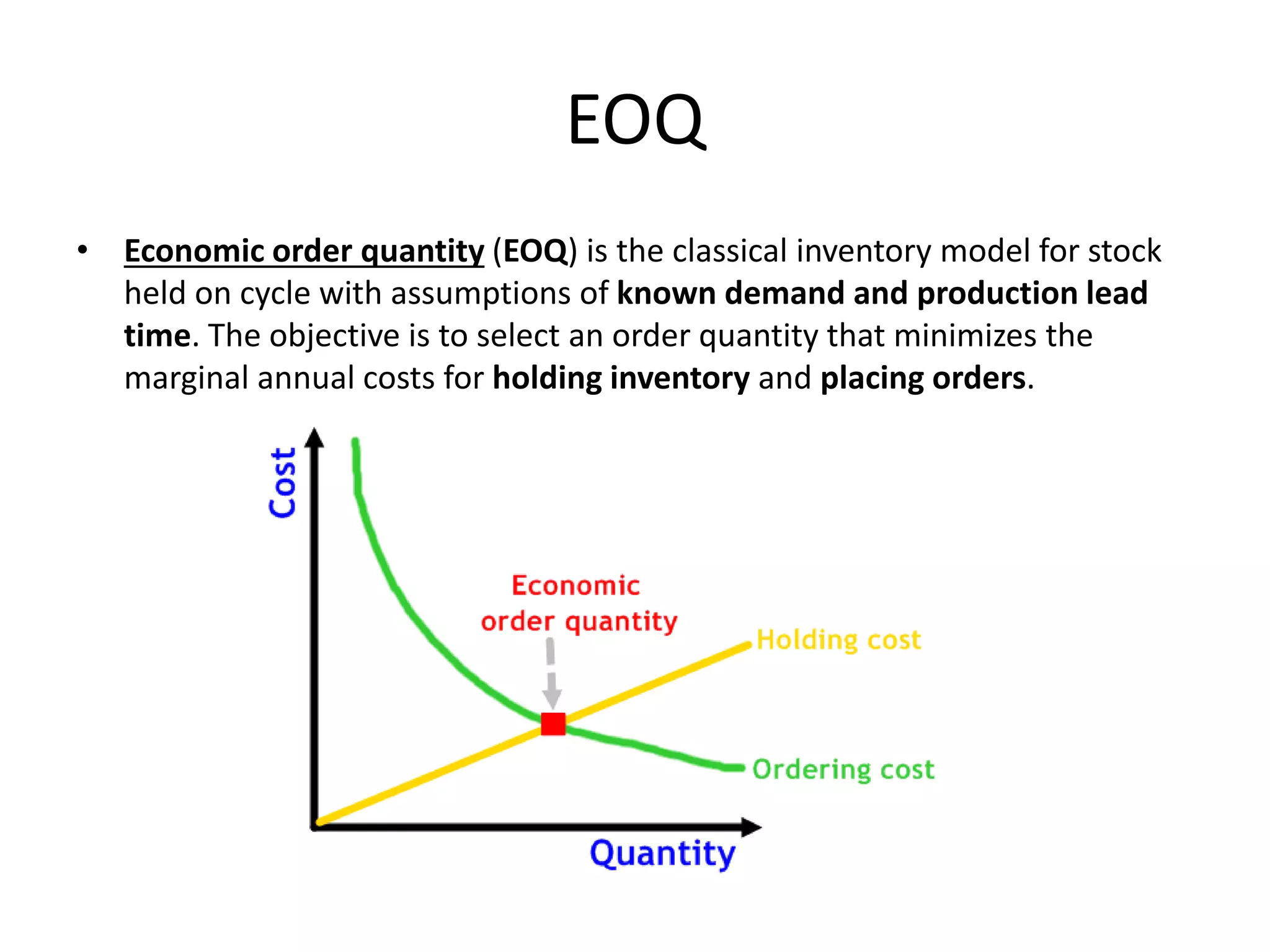

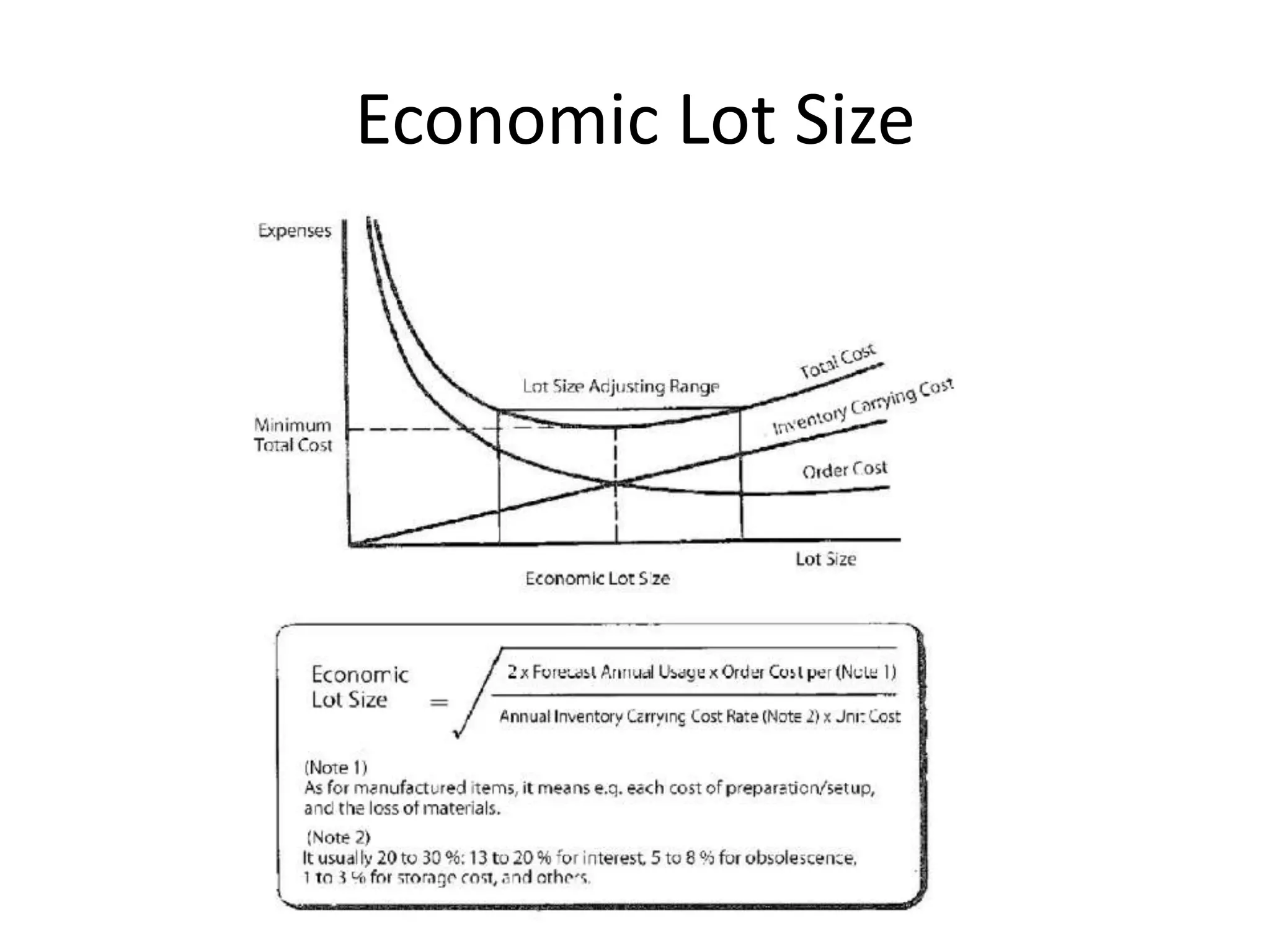

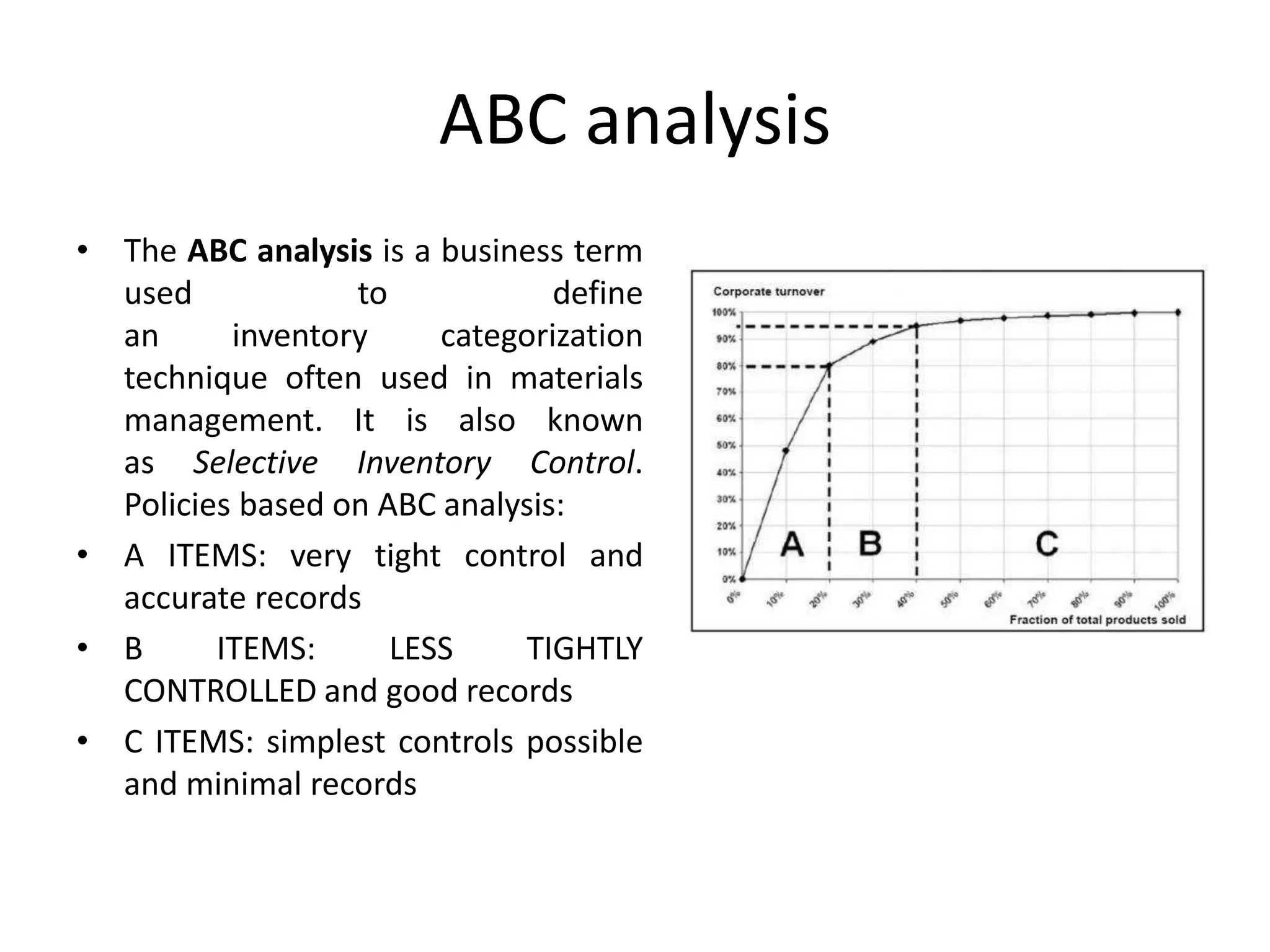

Inventory control aims to ensure adequate supply without excessive overstock. It answers questions about when to order, where to store inventory, and how much to order. Two common inventory management techniques are the two-bin system and economic order quantity (EOQ) modeling, which aim to minimize total inventory costs. ABC analysis categorizes inventory into A, B, and C items to apply appropriate control policies to each.