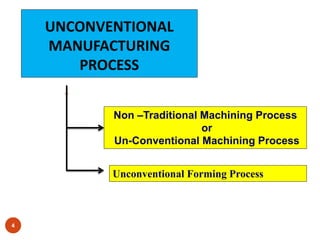

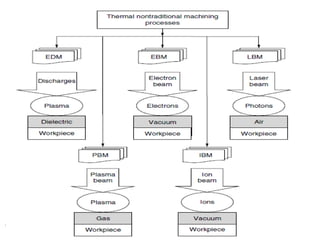

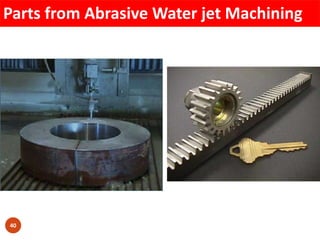

The document outlines the history and evolution of unconventional machining processes, which emerged as a solution to the limitations of traditional methods. It highlights the need for such processes in machining advanced materials and complex shapes, including the advantages and classifications of various techniques like electrical, mechanical, and thermal processes. Despite higher costs and lower material removal rates, unconventional machining offers improved accuracy and surface finish, making it essential in industries such as aerospace and automotive.