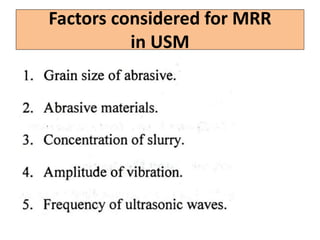

The document discusses the ultrasound machining (USM) process, detailing the components such as ultrasonic generators, transducers, and tool materials, and the way they convert electrical energy into mechanical vibrations. It compares magnetostrictive and piezoelectric transducers, highlighting their advantages and disadvantages, while also exploring factors that affect material removal rate (MRR) and wear ratio in machining different materials. The document concludes with a summary of the advantages, disadvantages, and applications of the USM process.