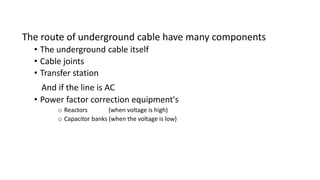

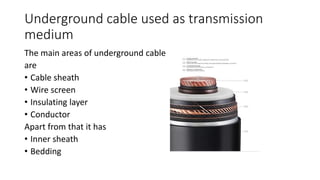

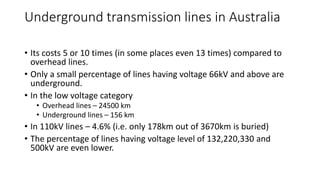

Underground transmission cables have several advantages over overhead lines including improved reliability, reduced electromagnetic fields, and allowing construction over cable routes. However, they also have some disadvantages such as higher initial installation costs and difficulties locating faults. Maintenance and repair of underground cables can also be more complex than overhead lines. Overall, underground cables are well-suited for transmission at voltages up to around 115kV for distances of a few kilometers, but overhead lines are generally used for longer high voltage transmission.