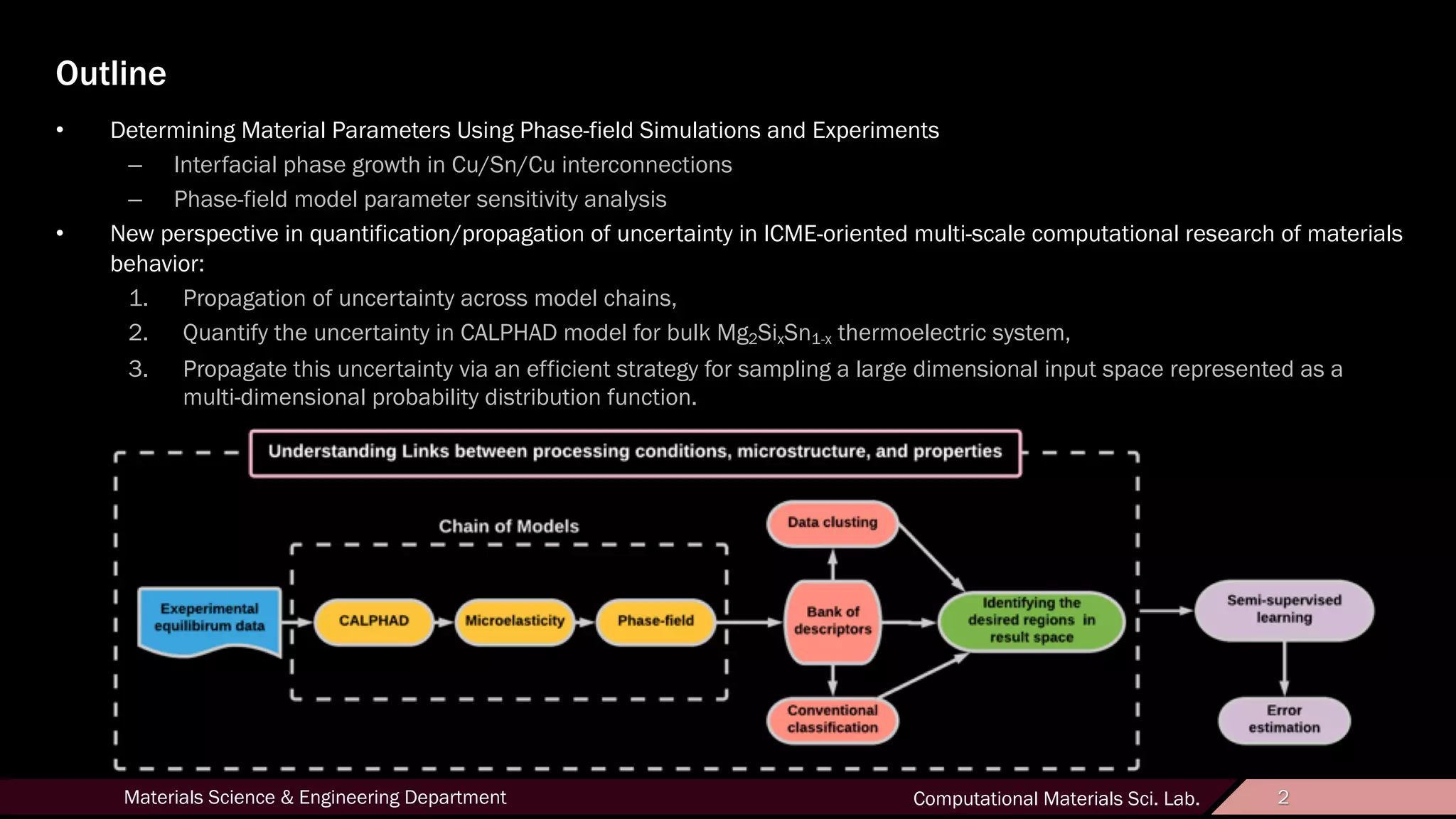

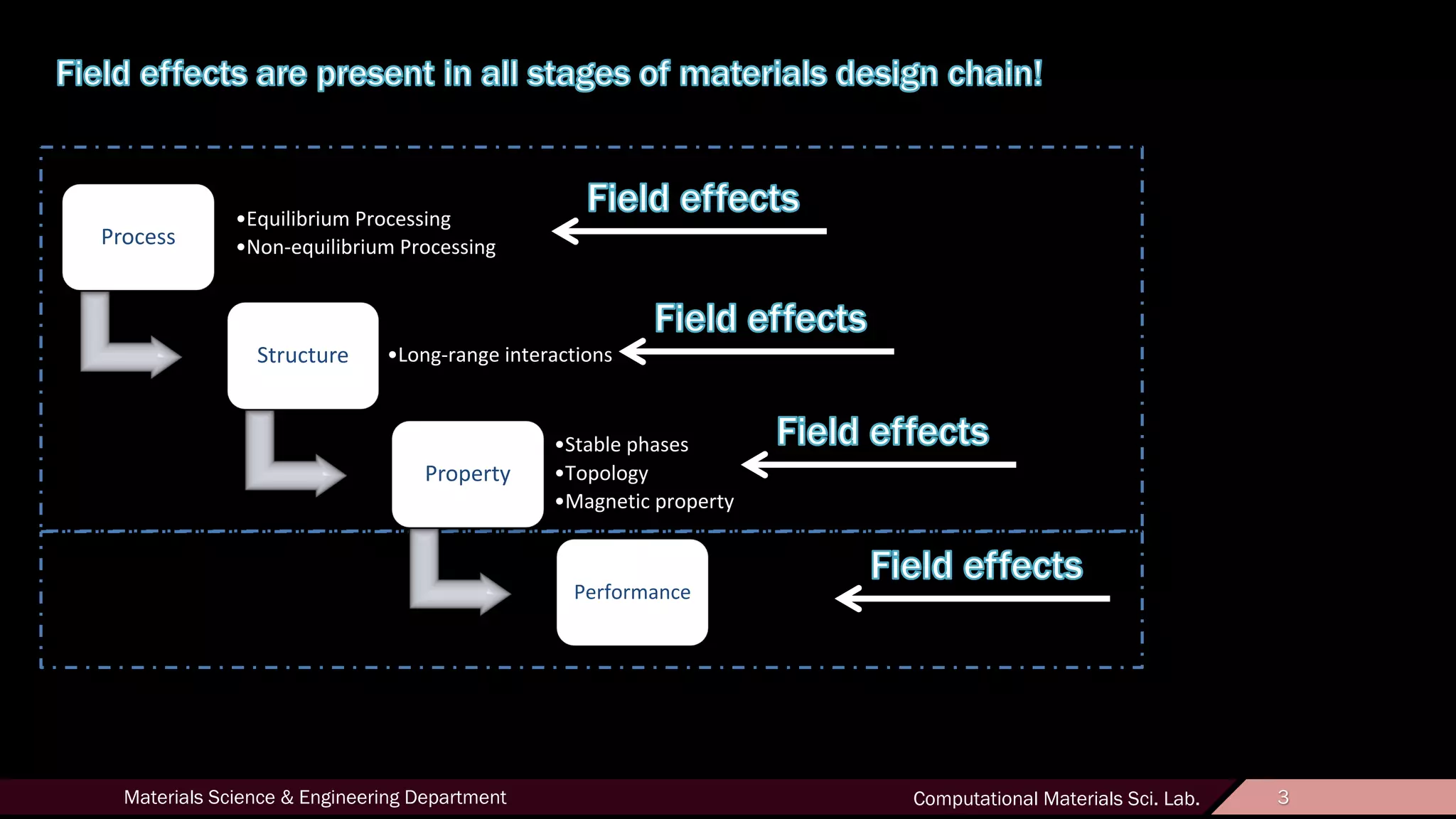

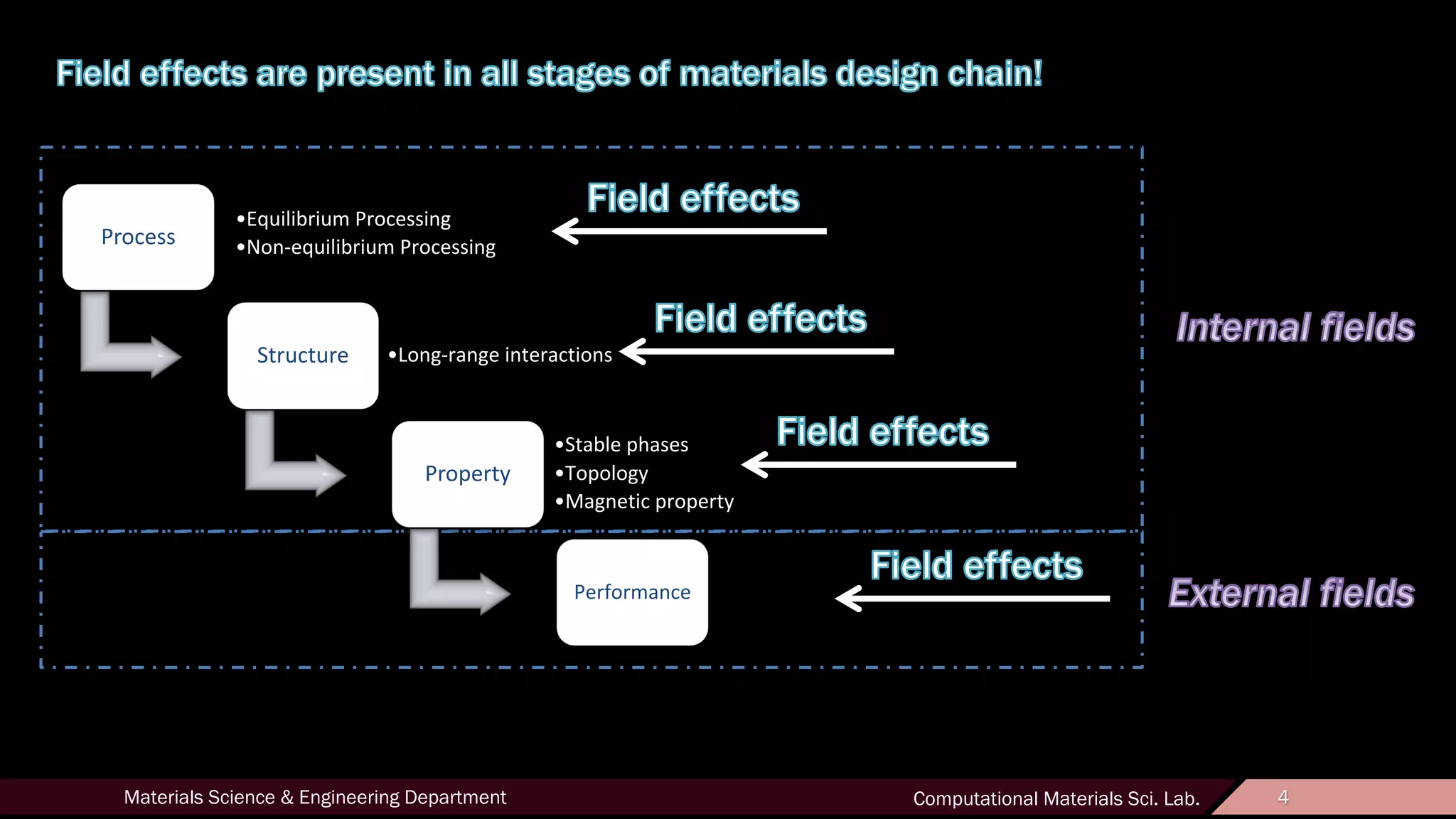

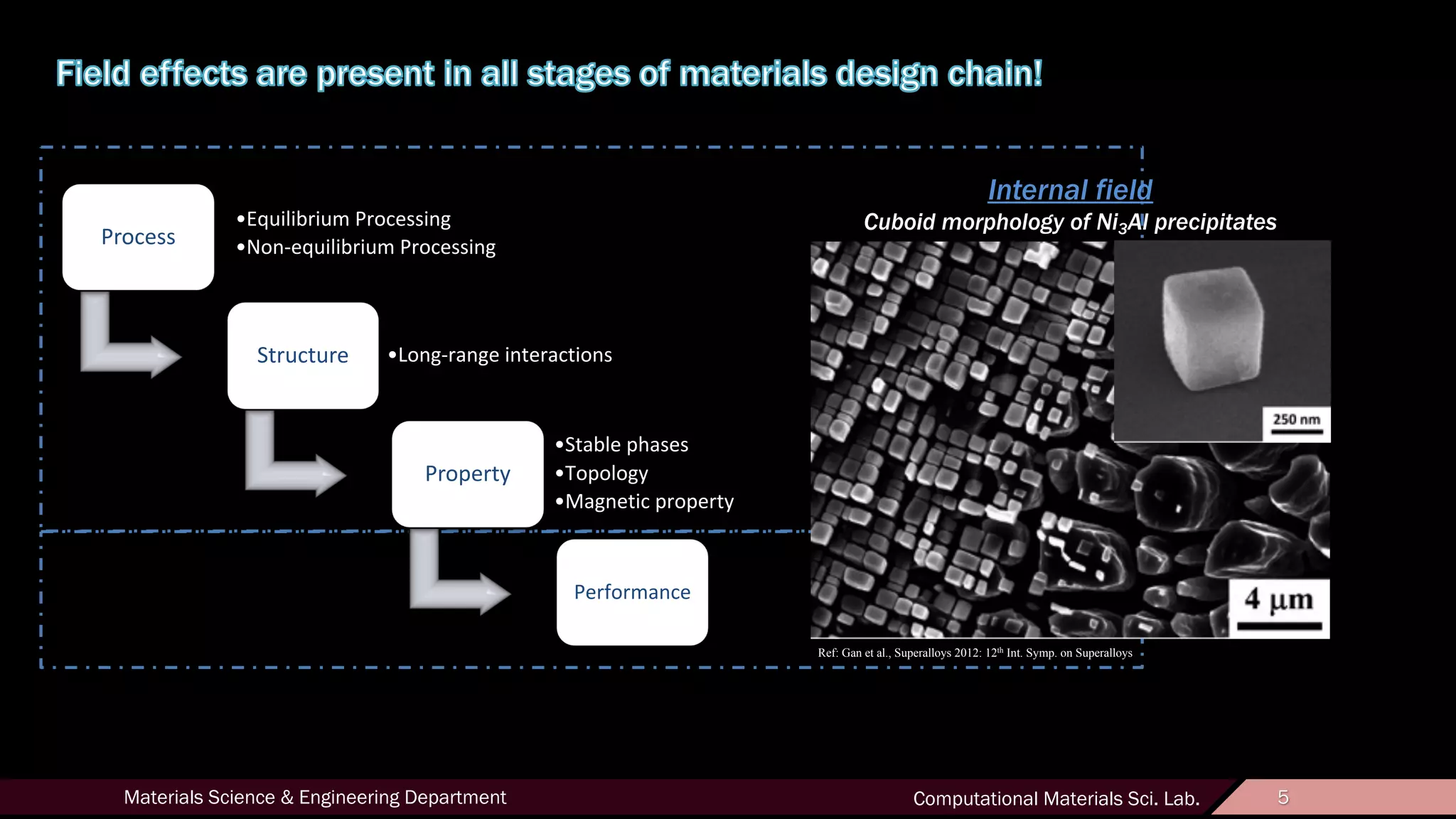

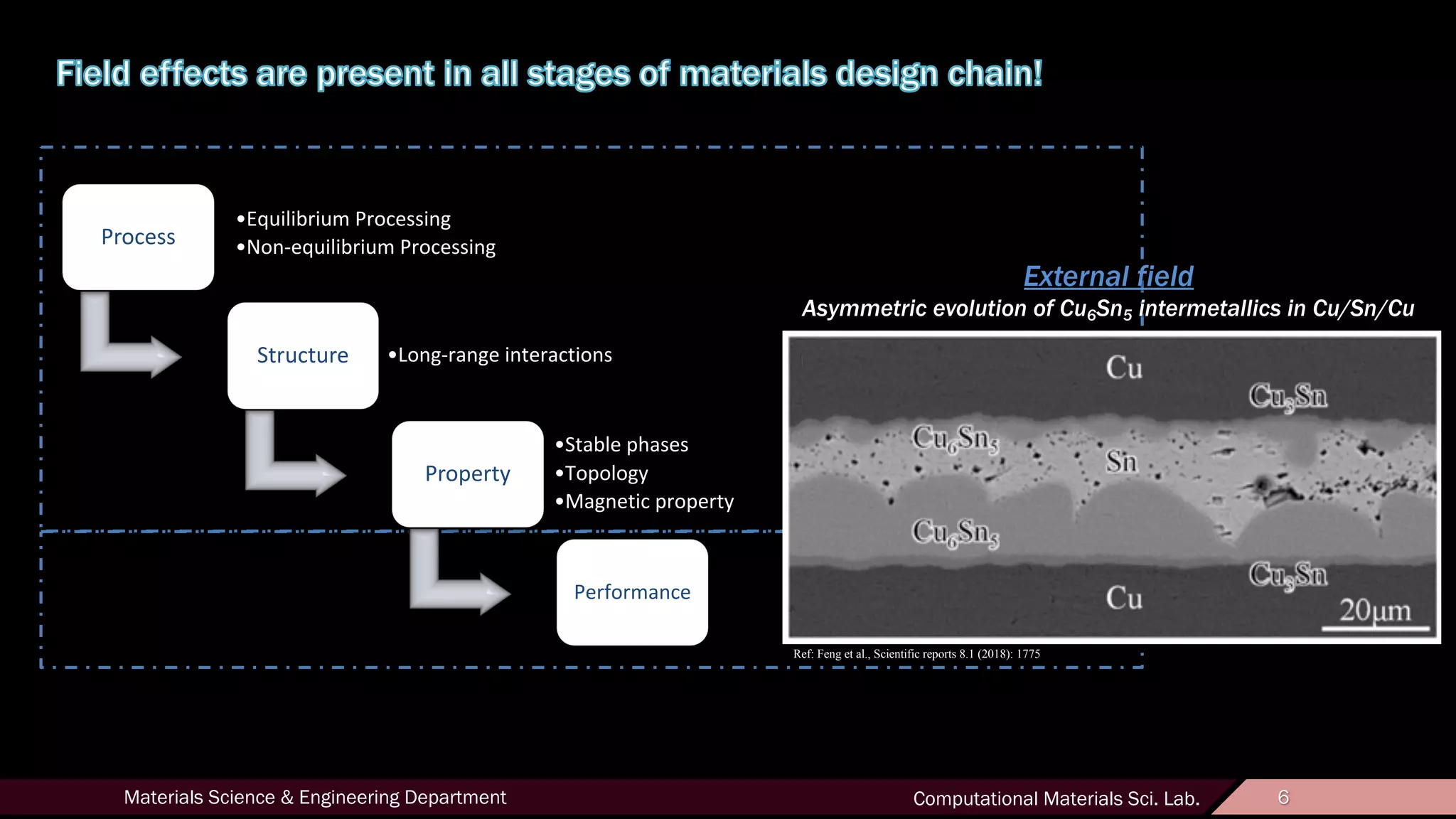

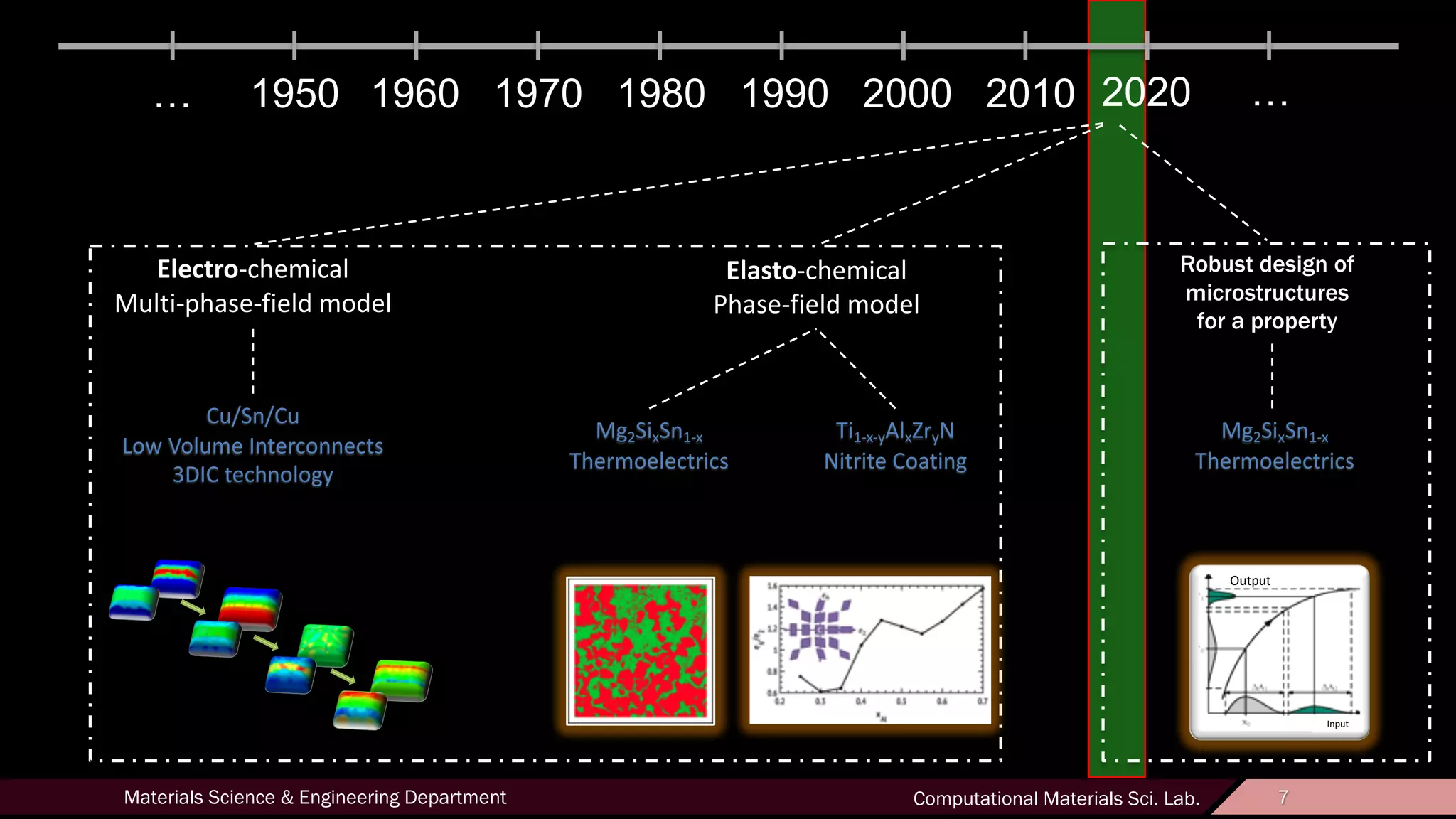

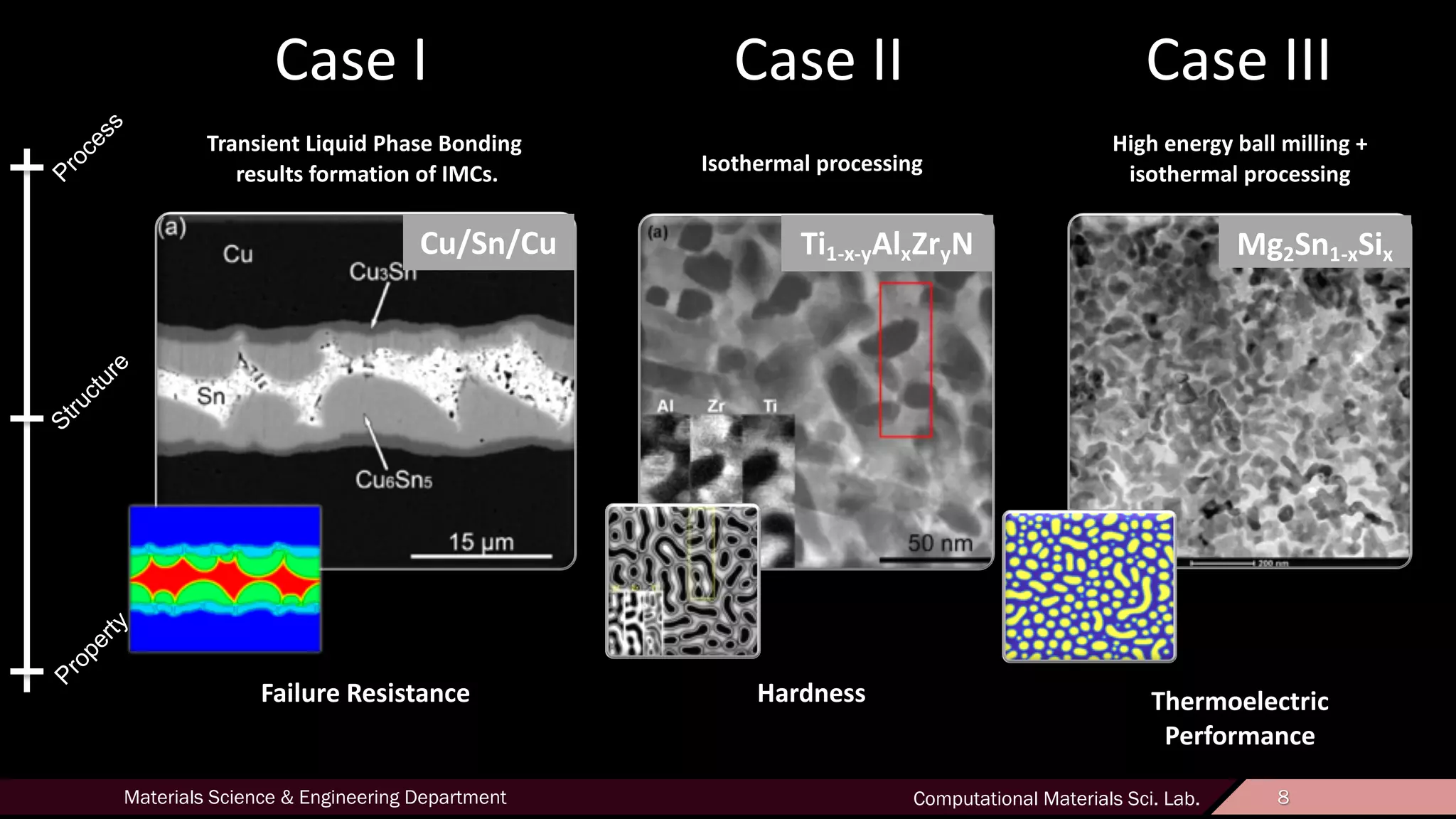

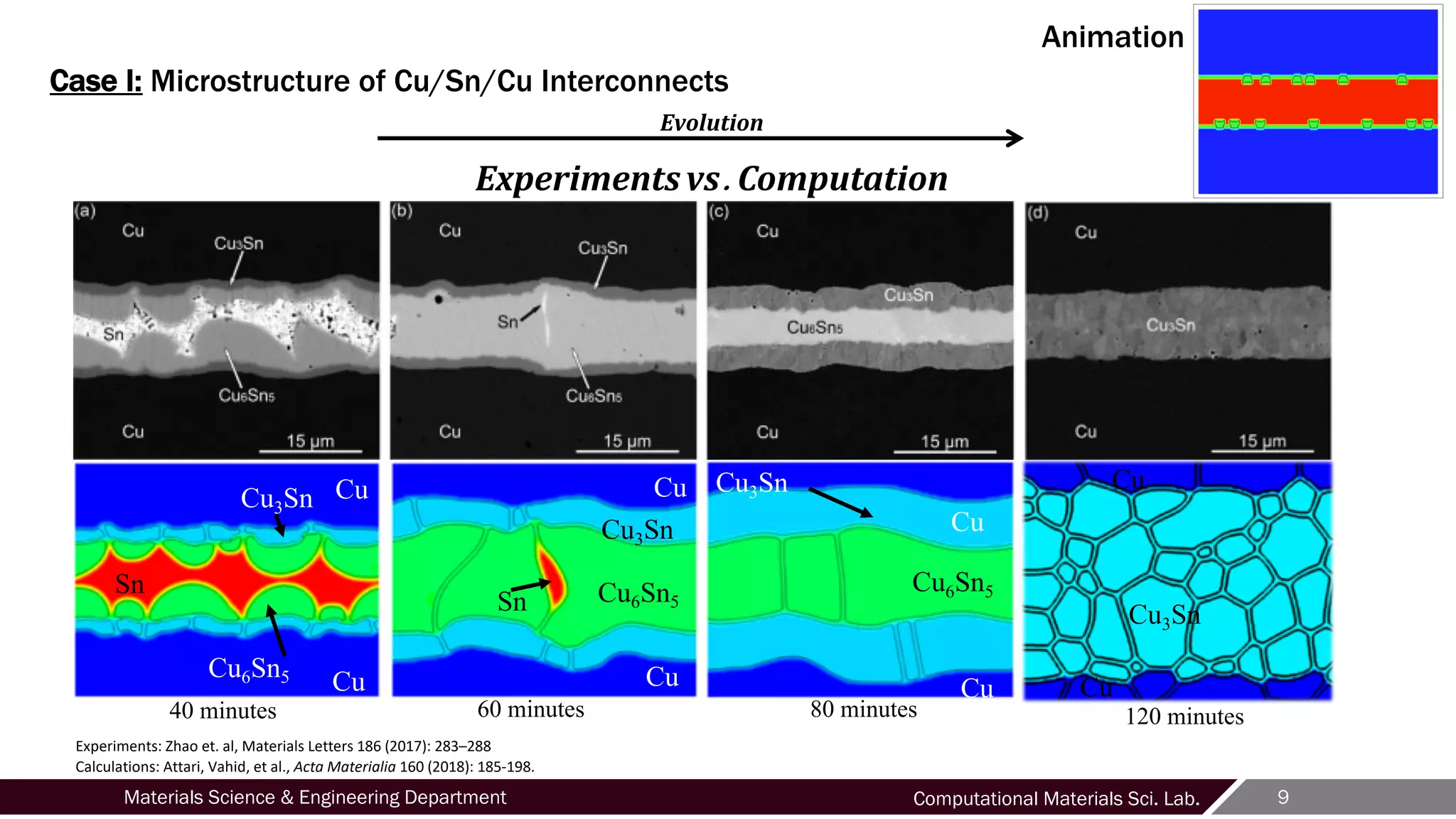

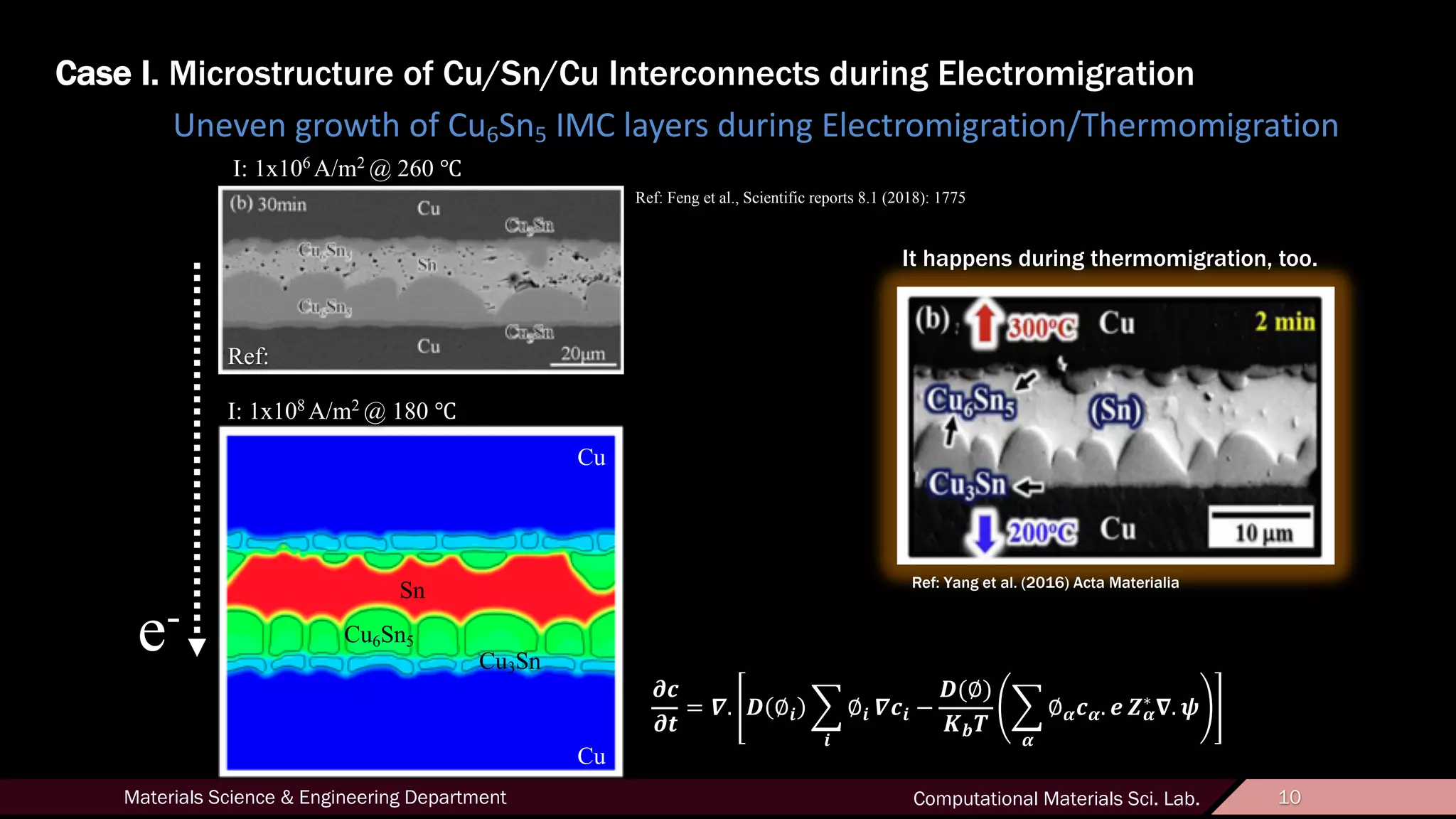

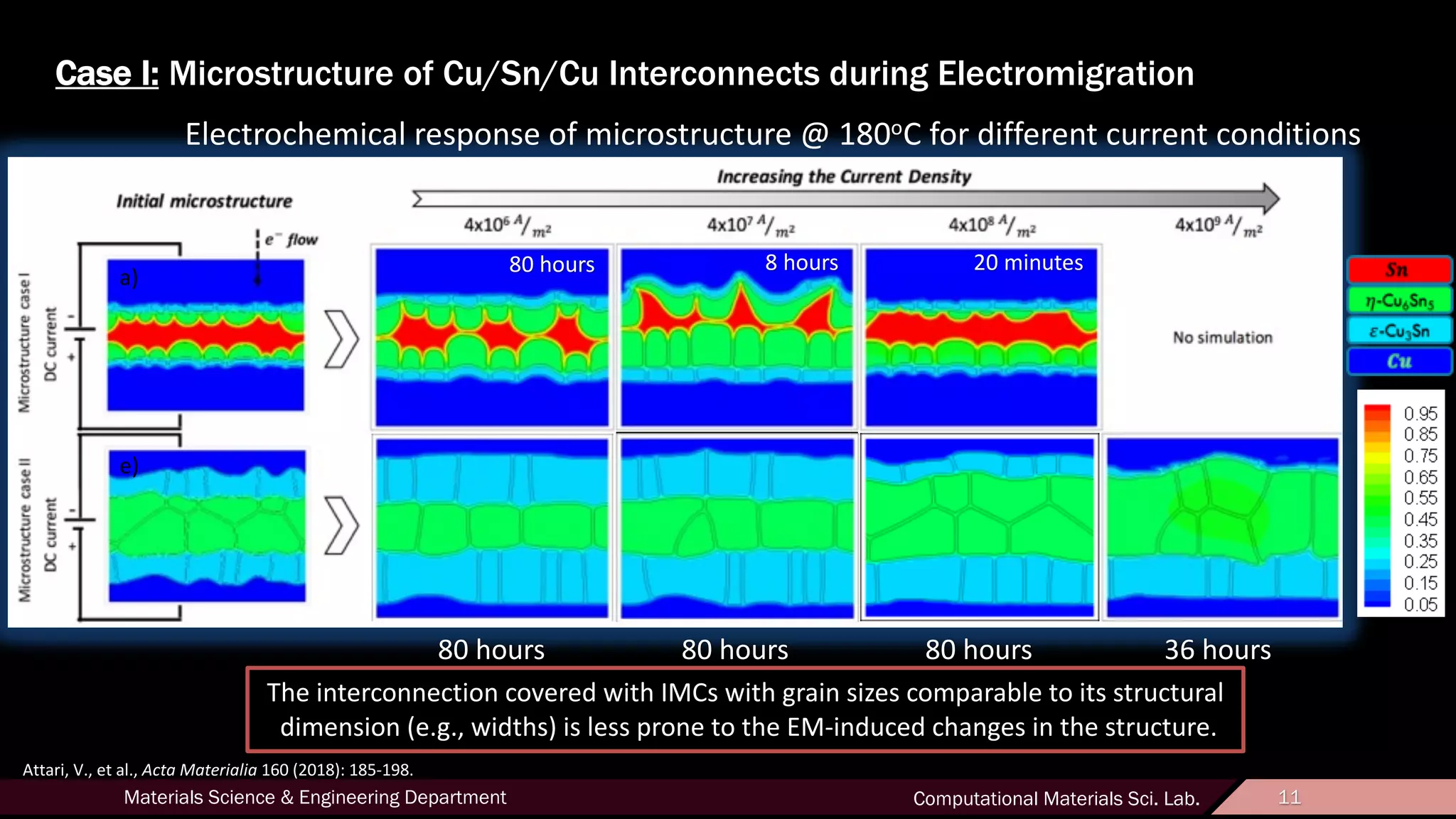

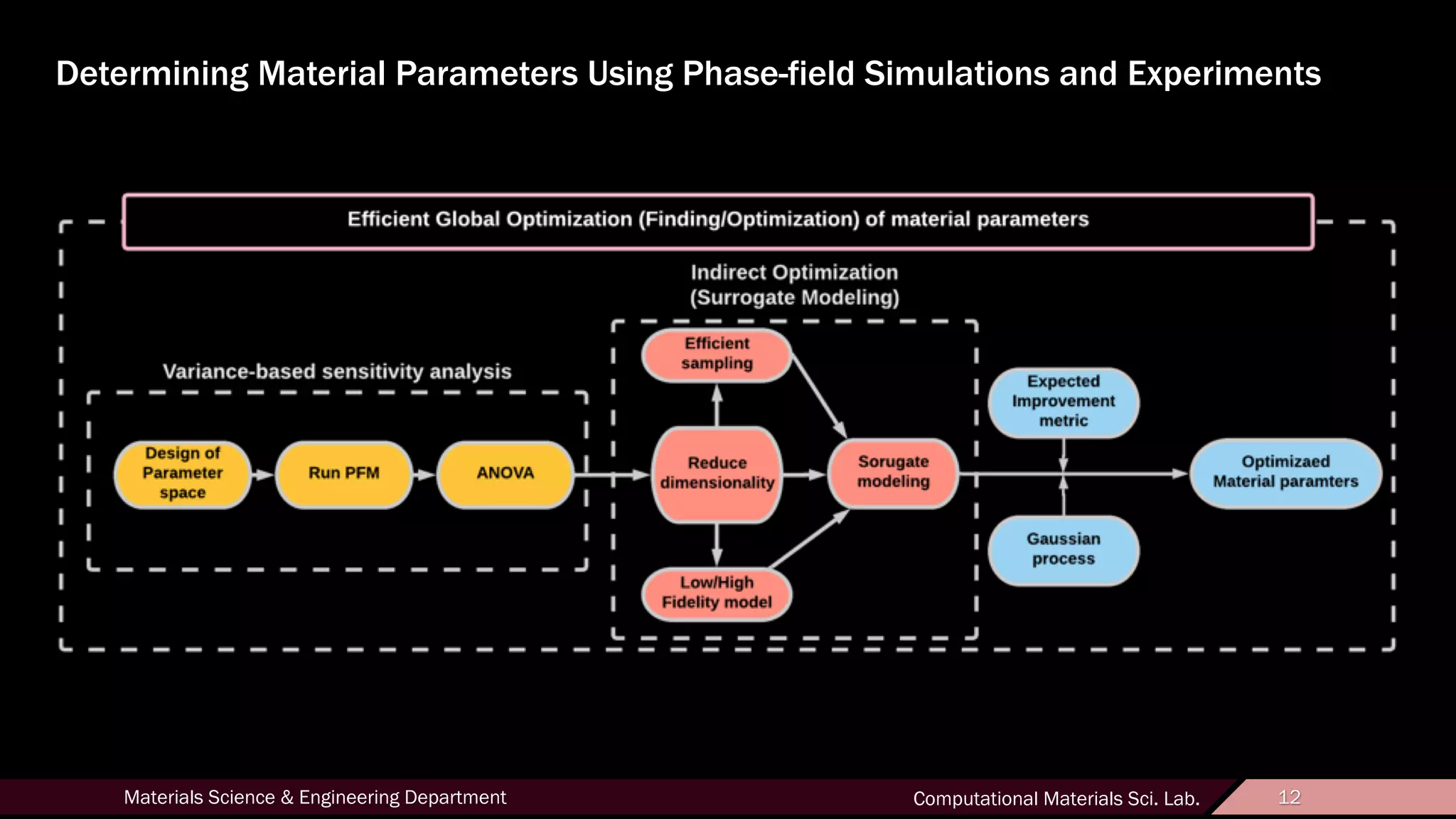

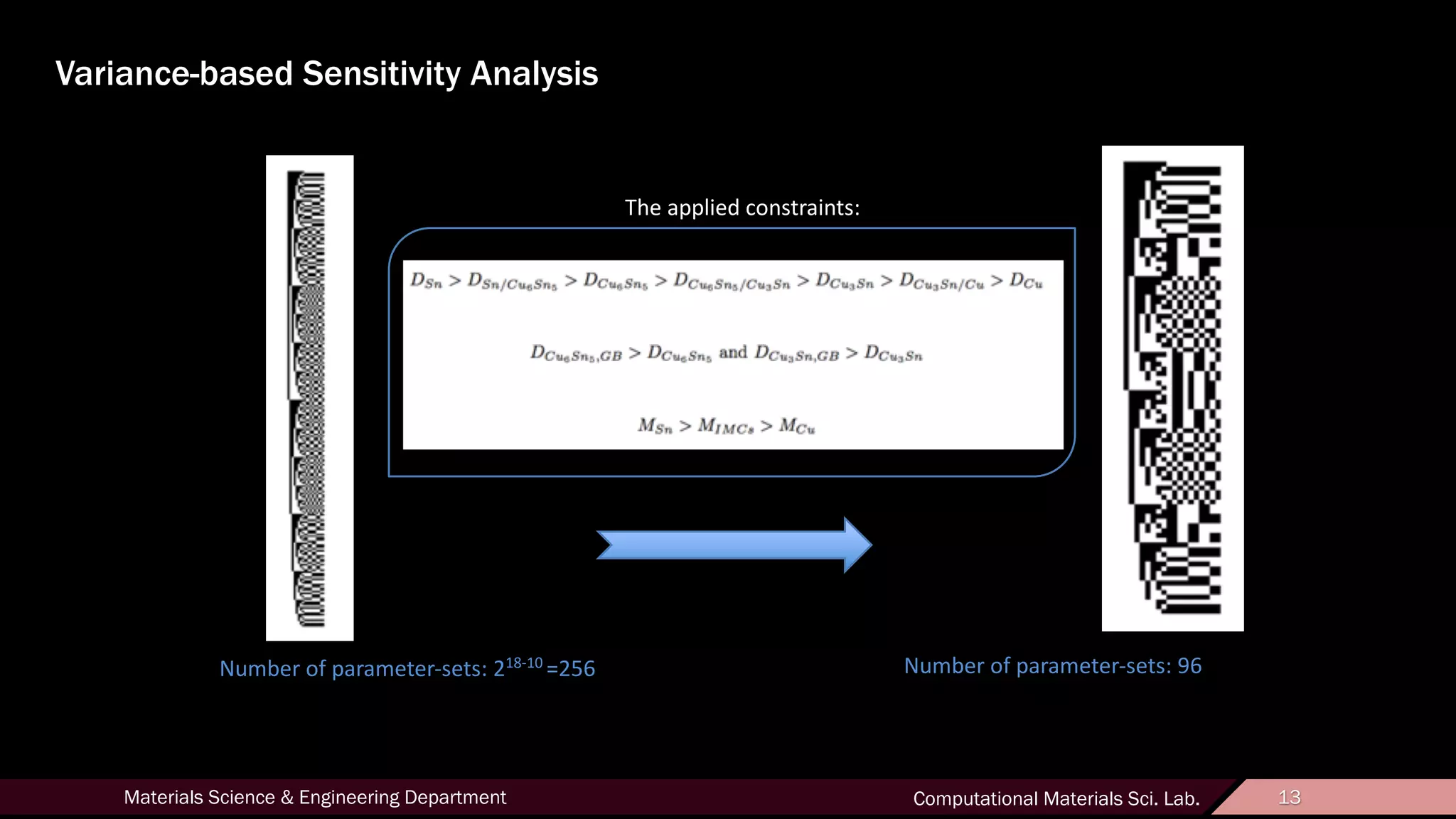

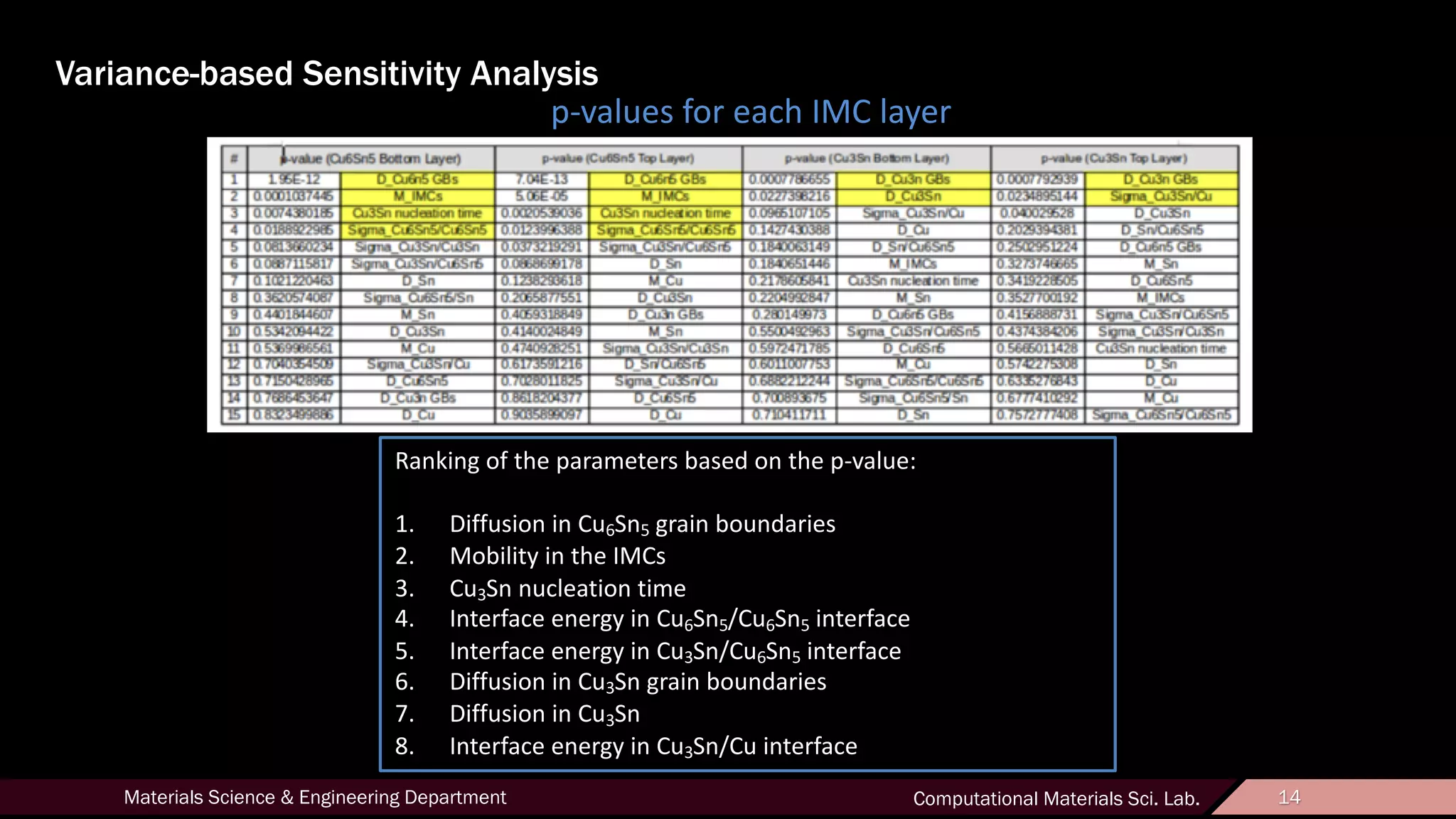

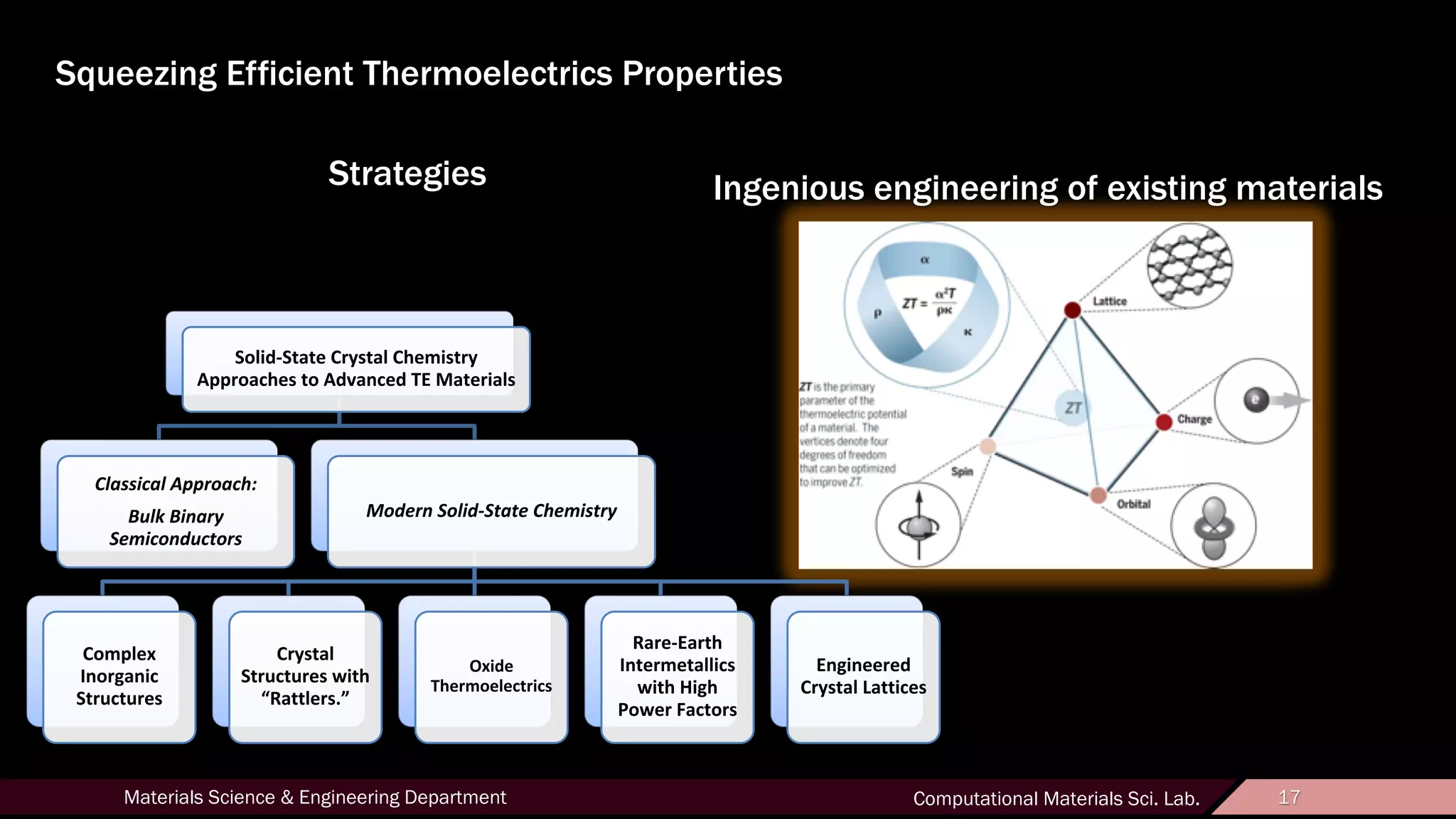

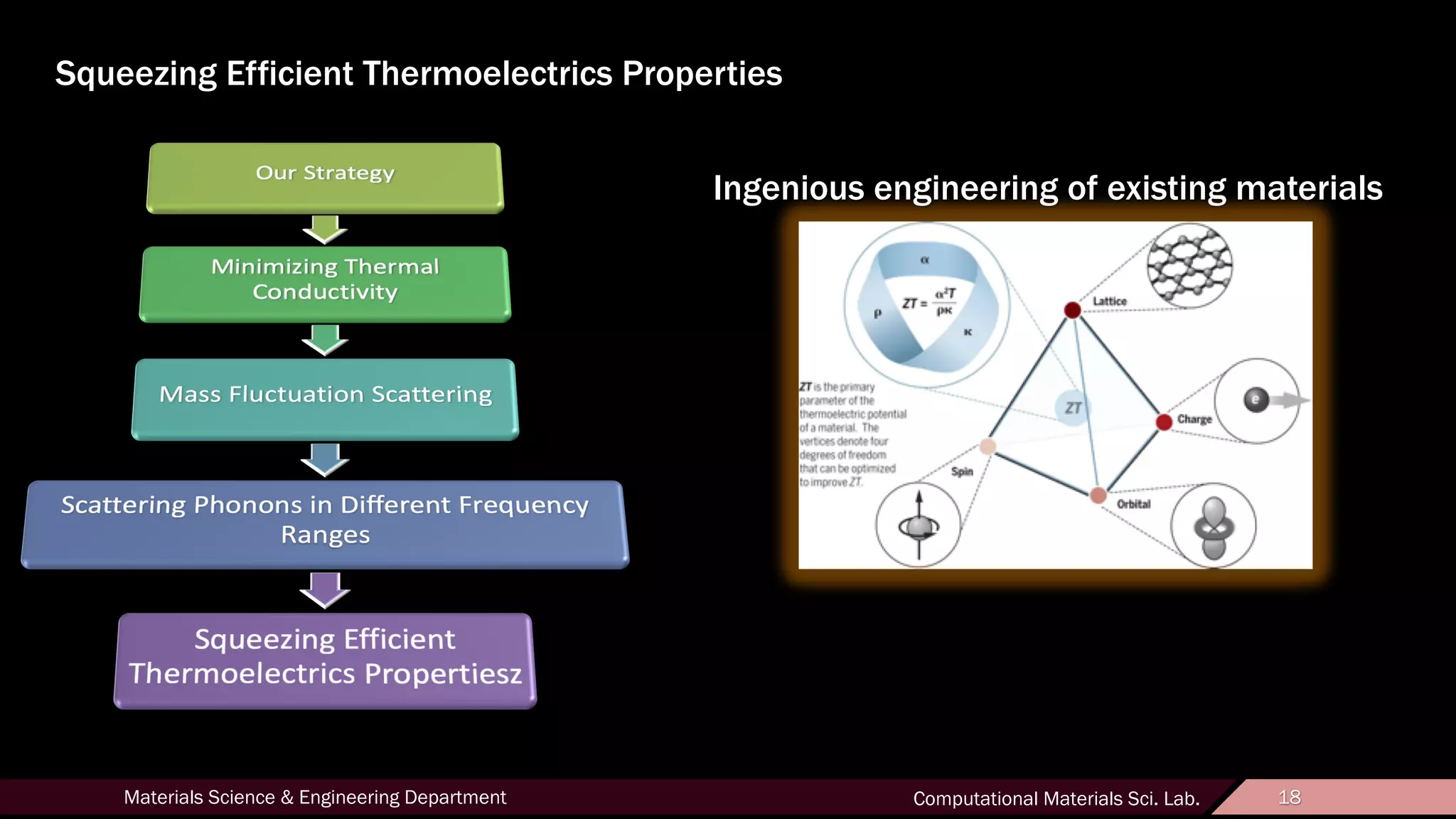

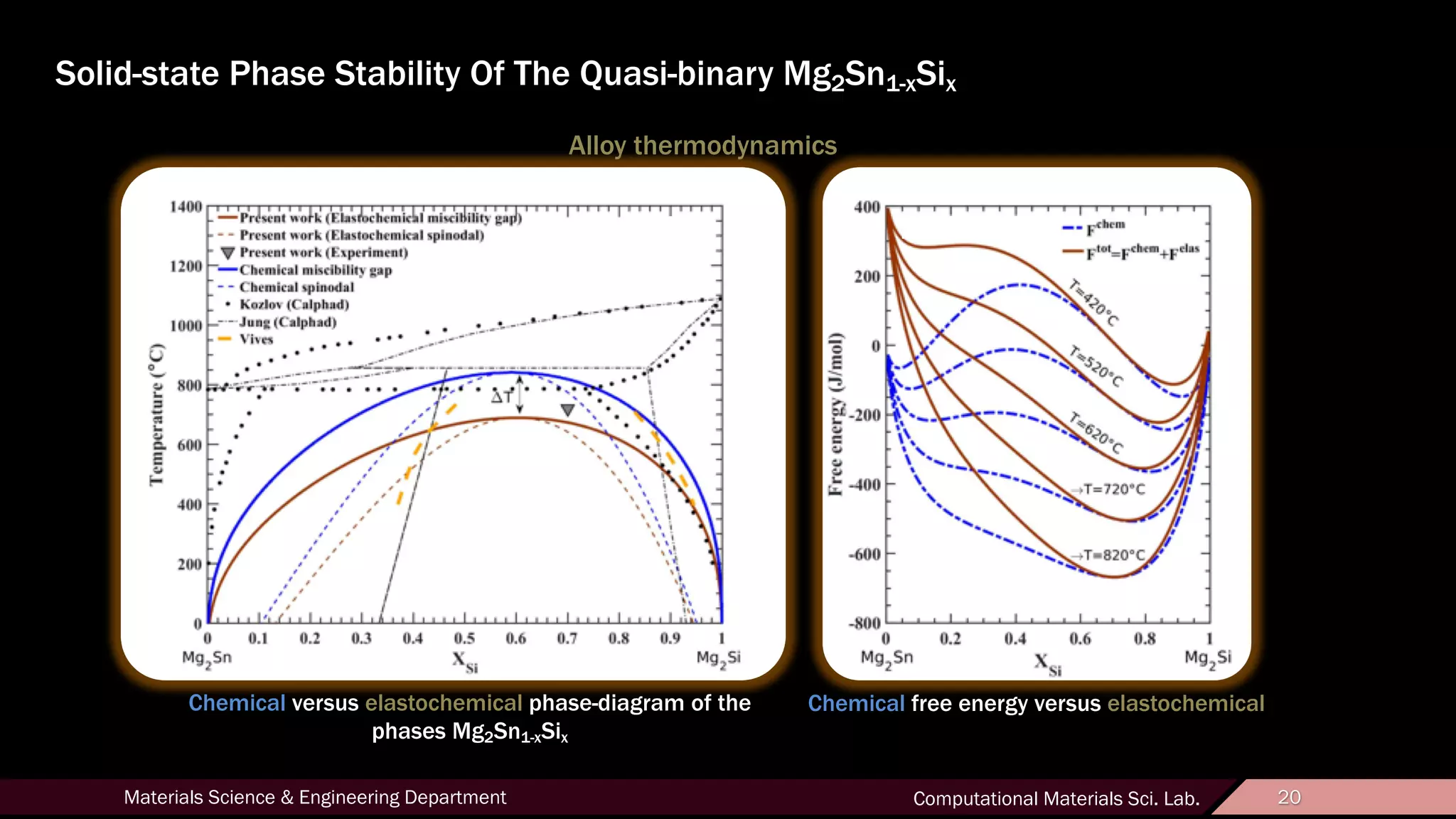

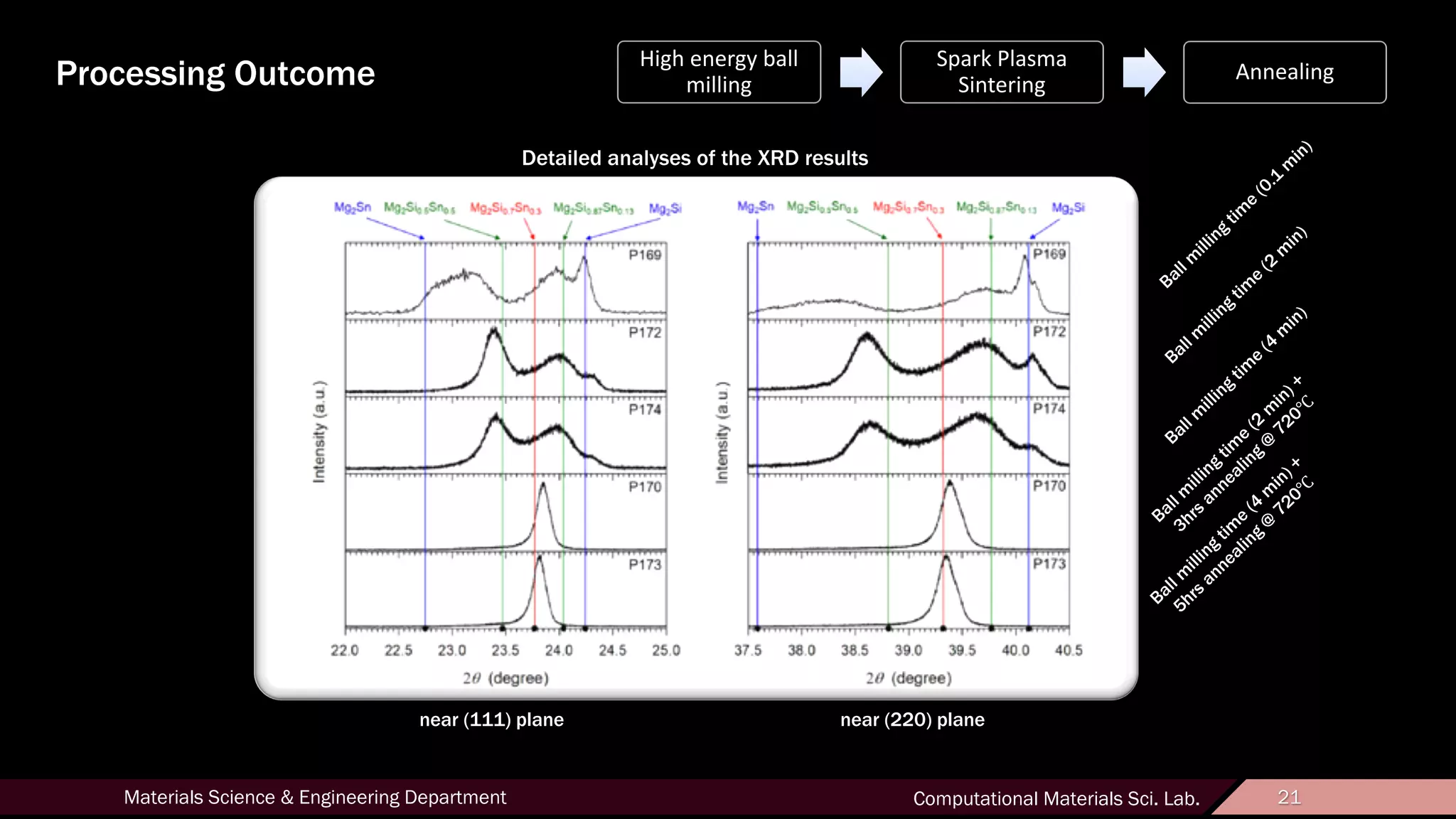

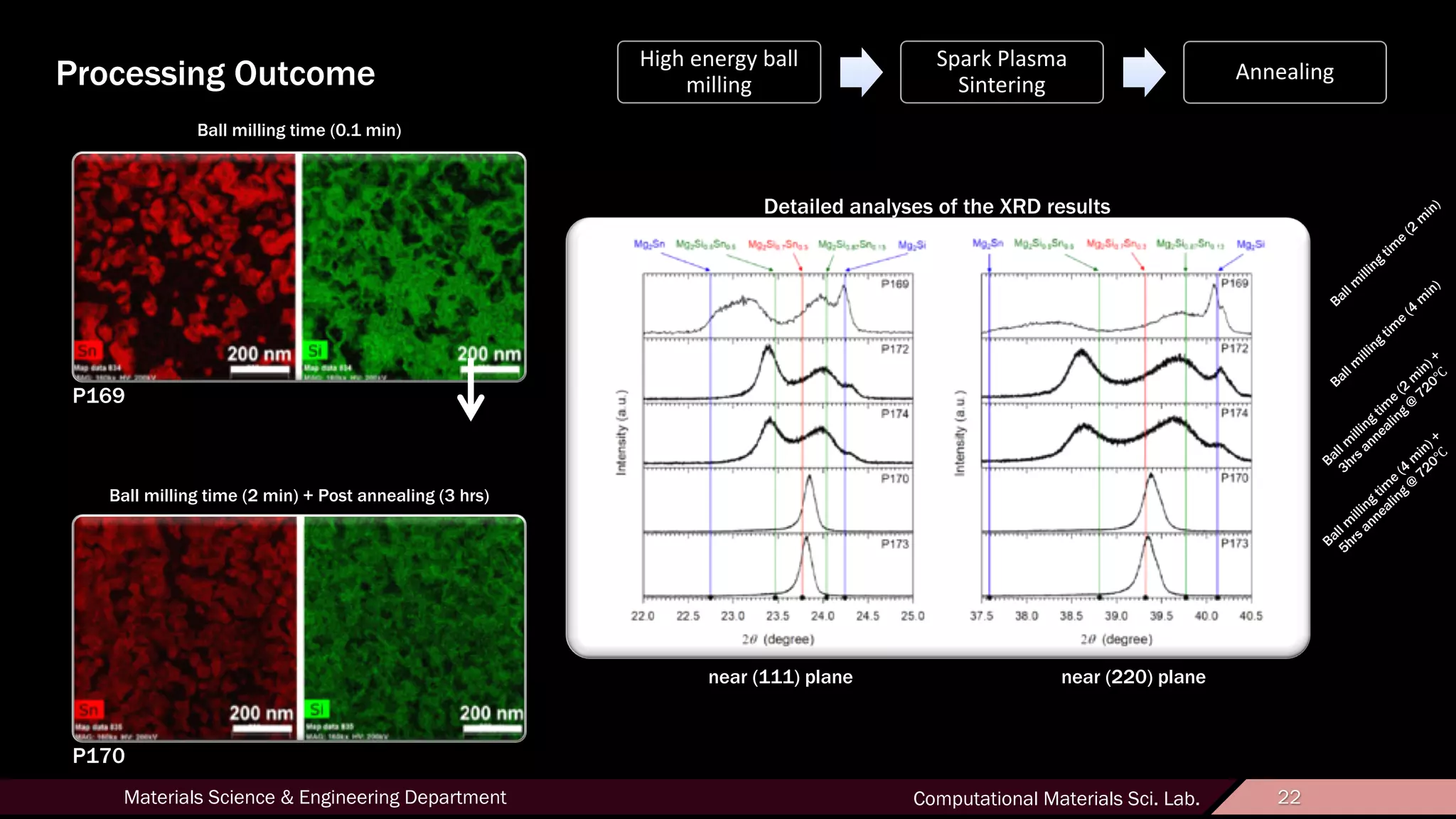

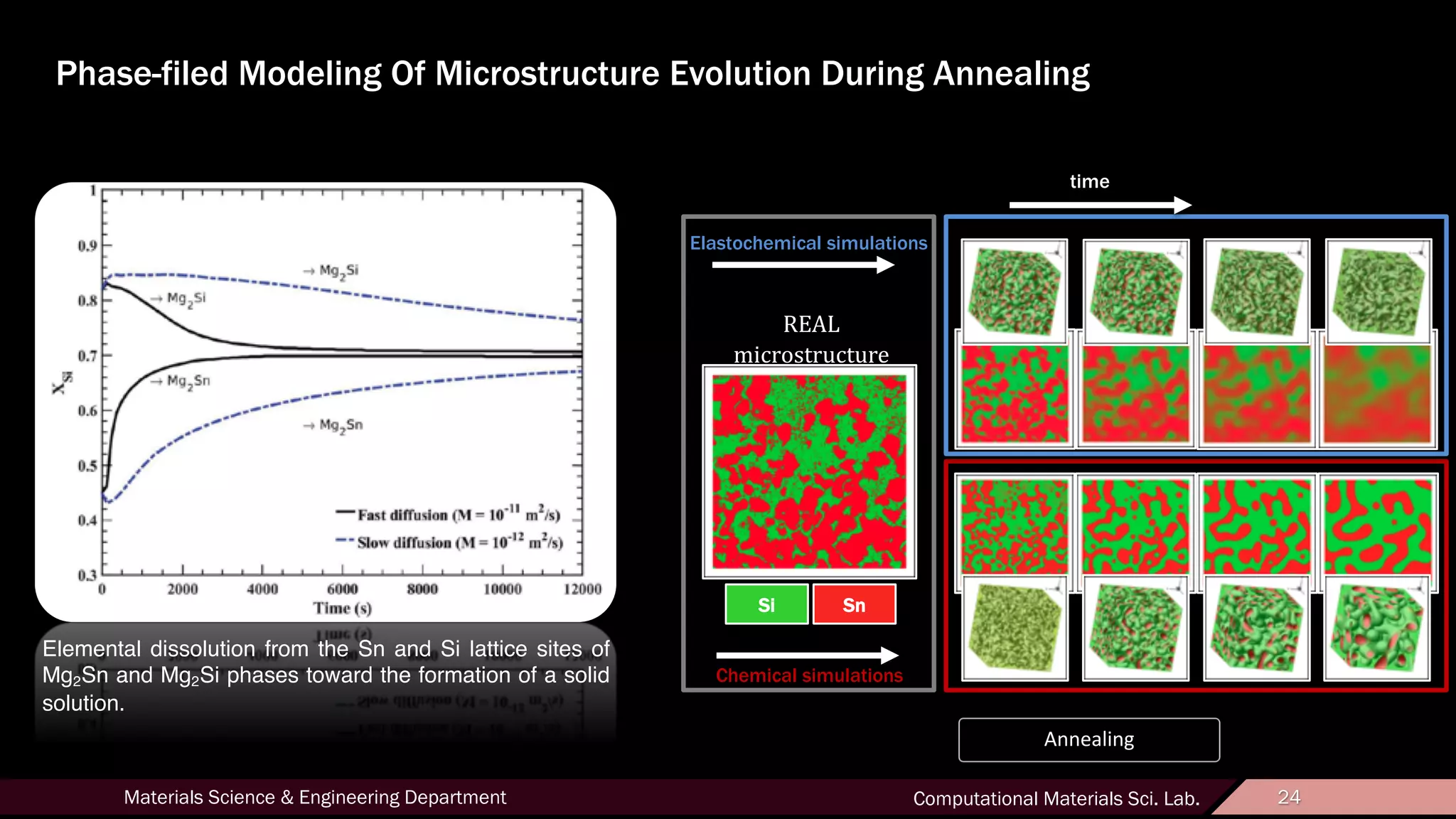

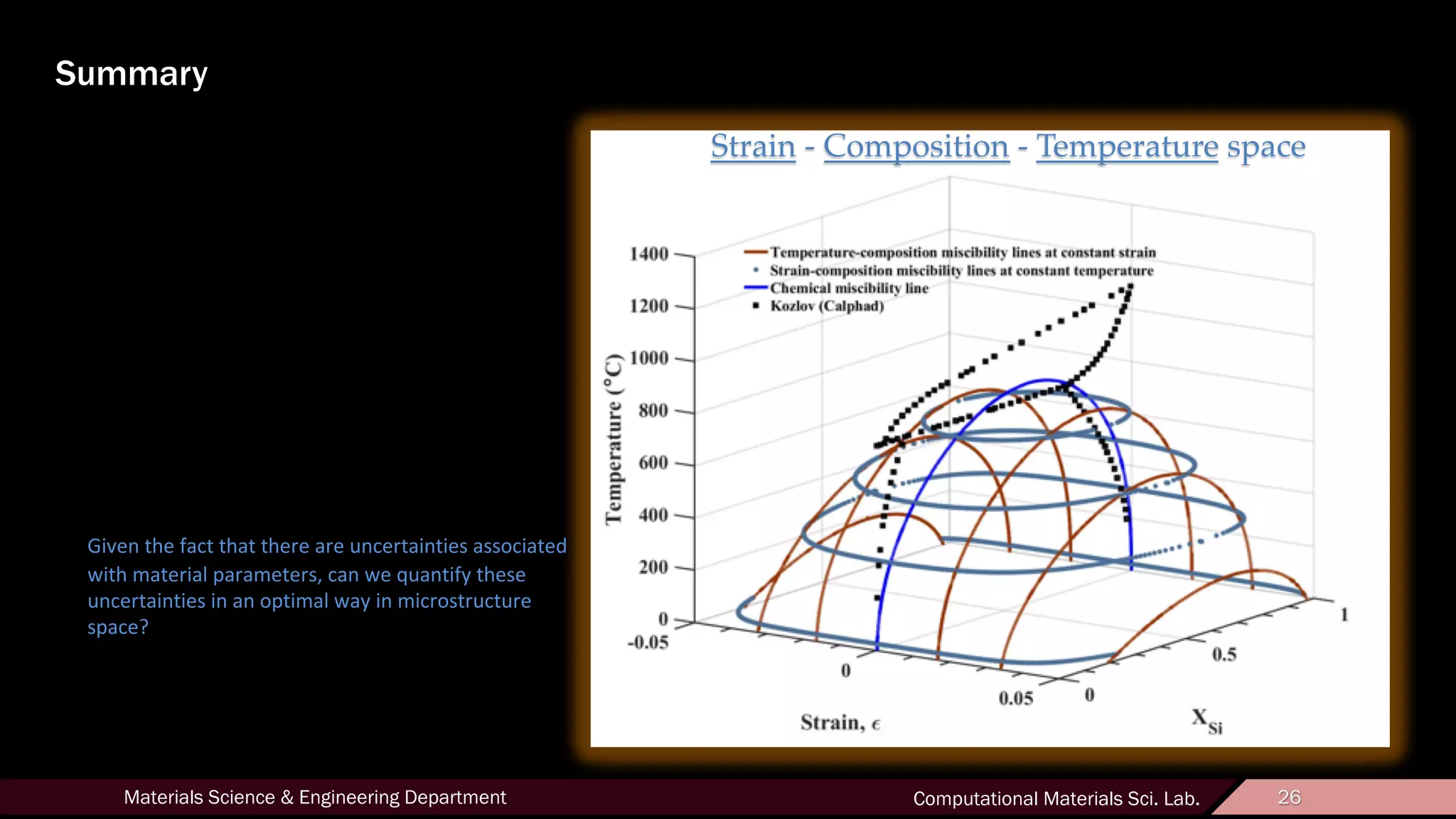

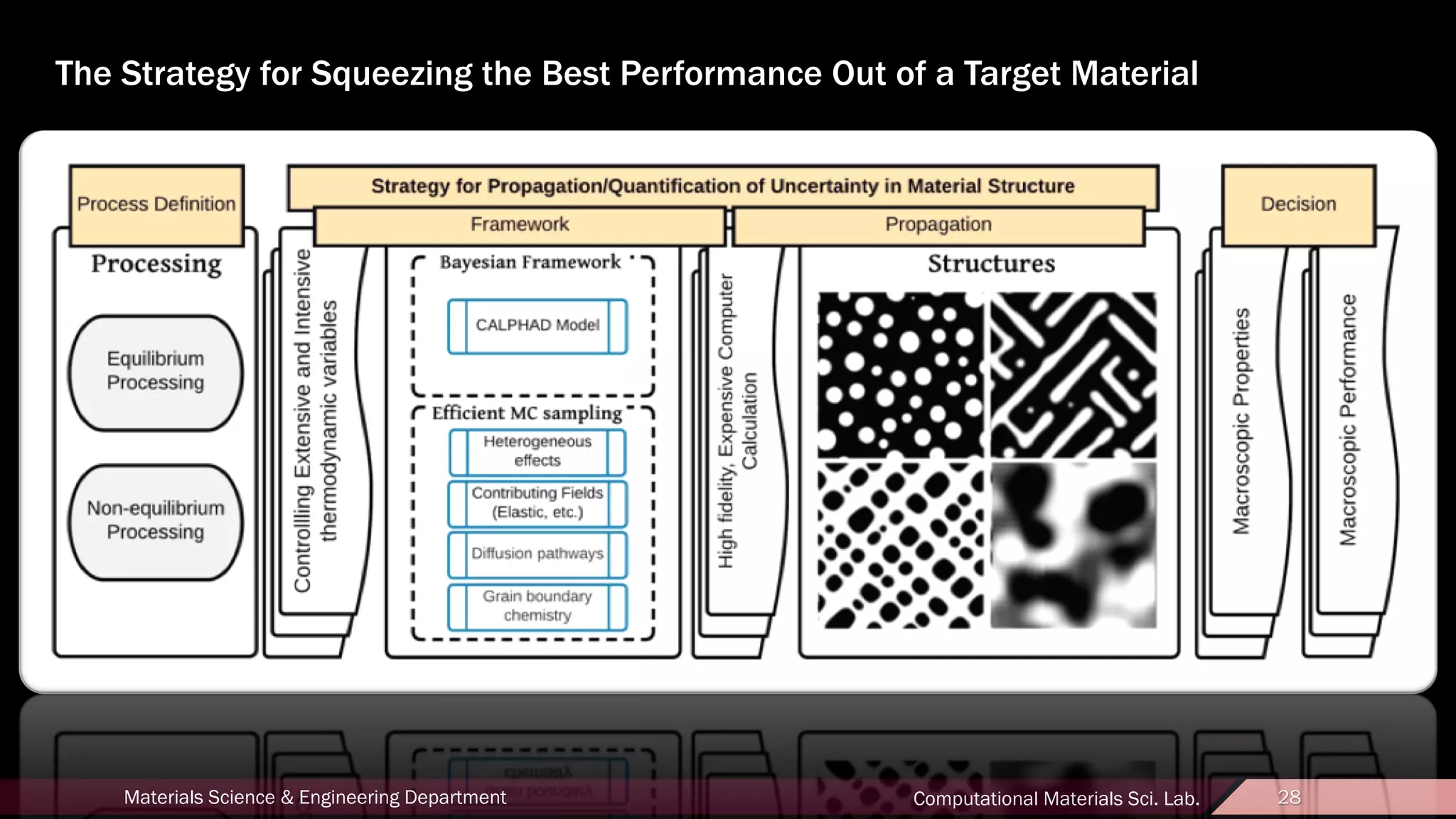

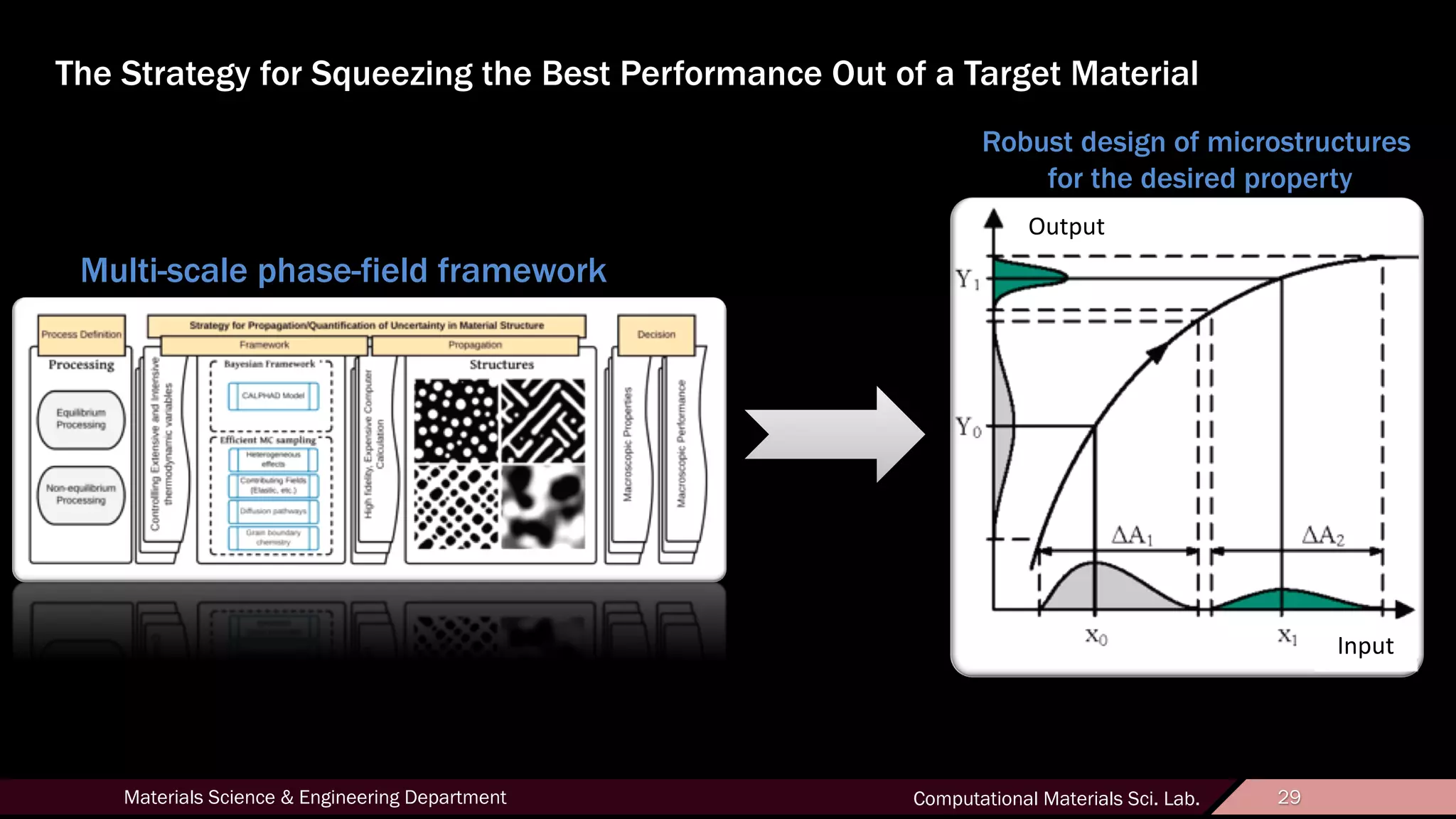

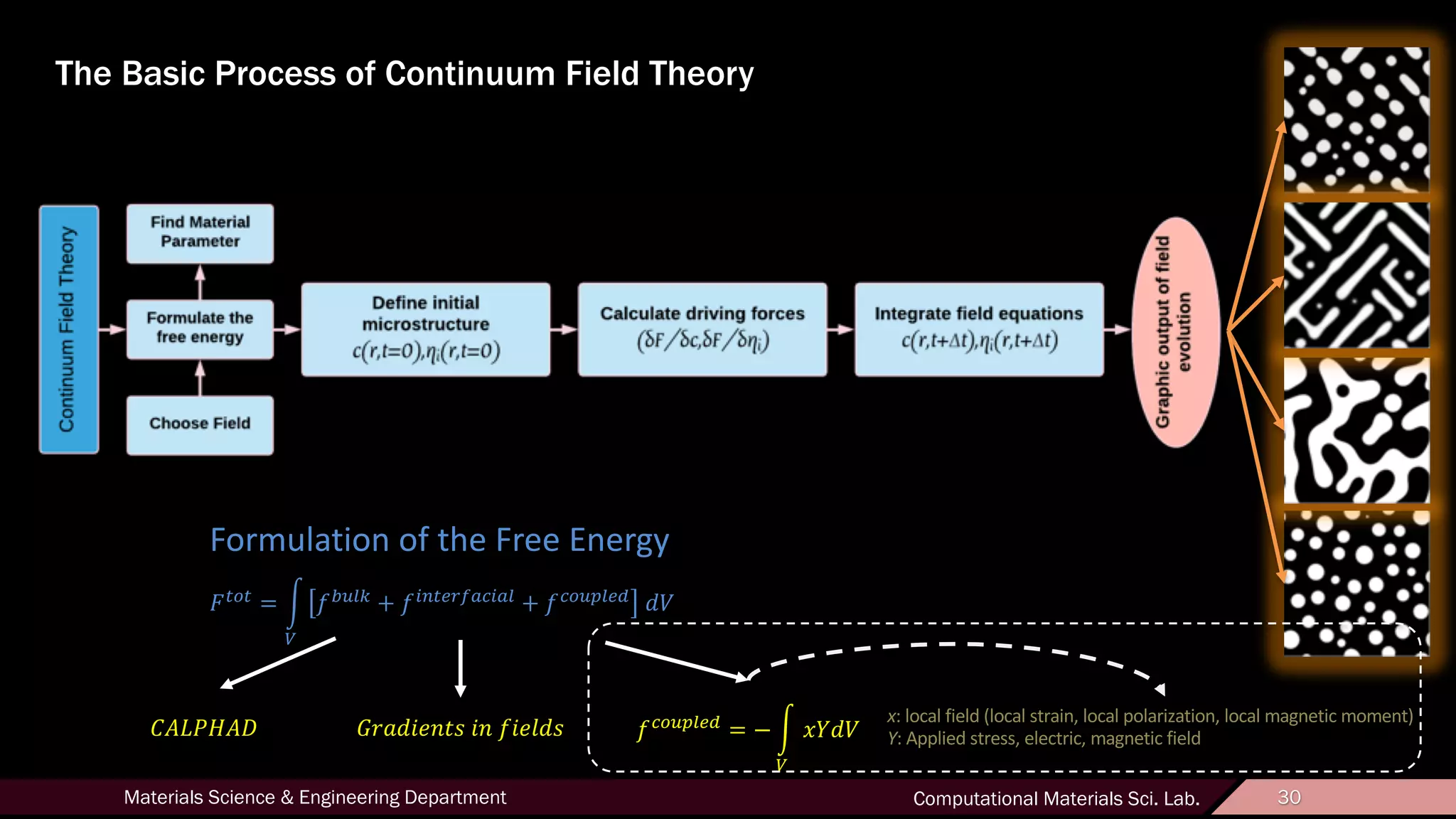

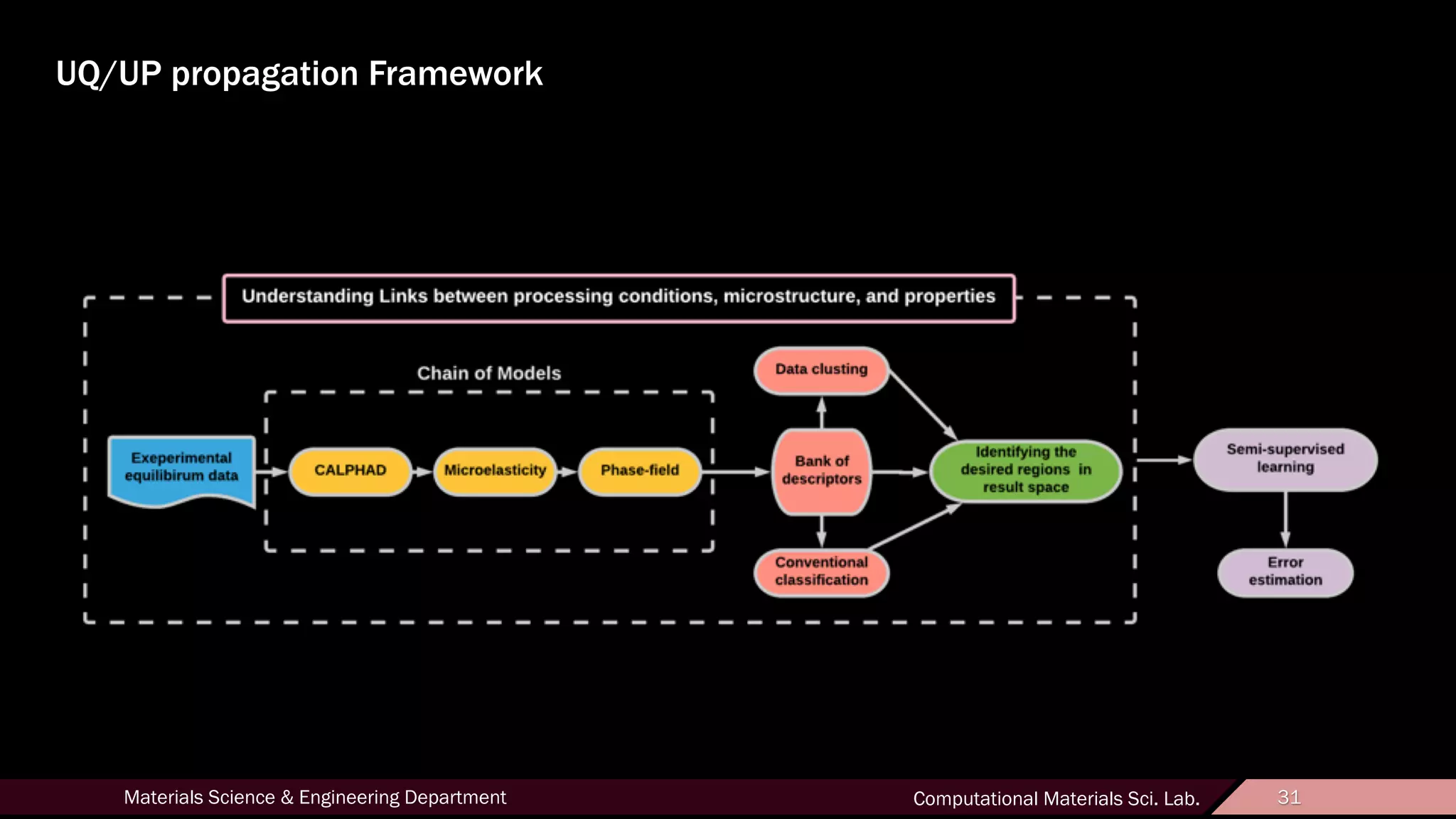

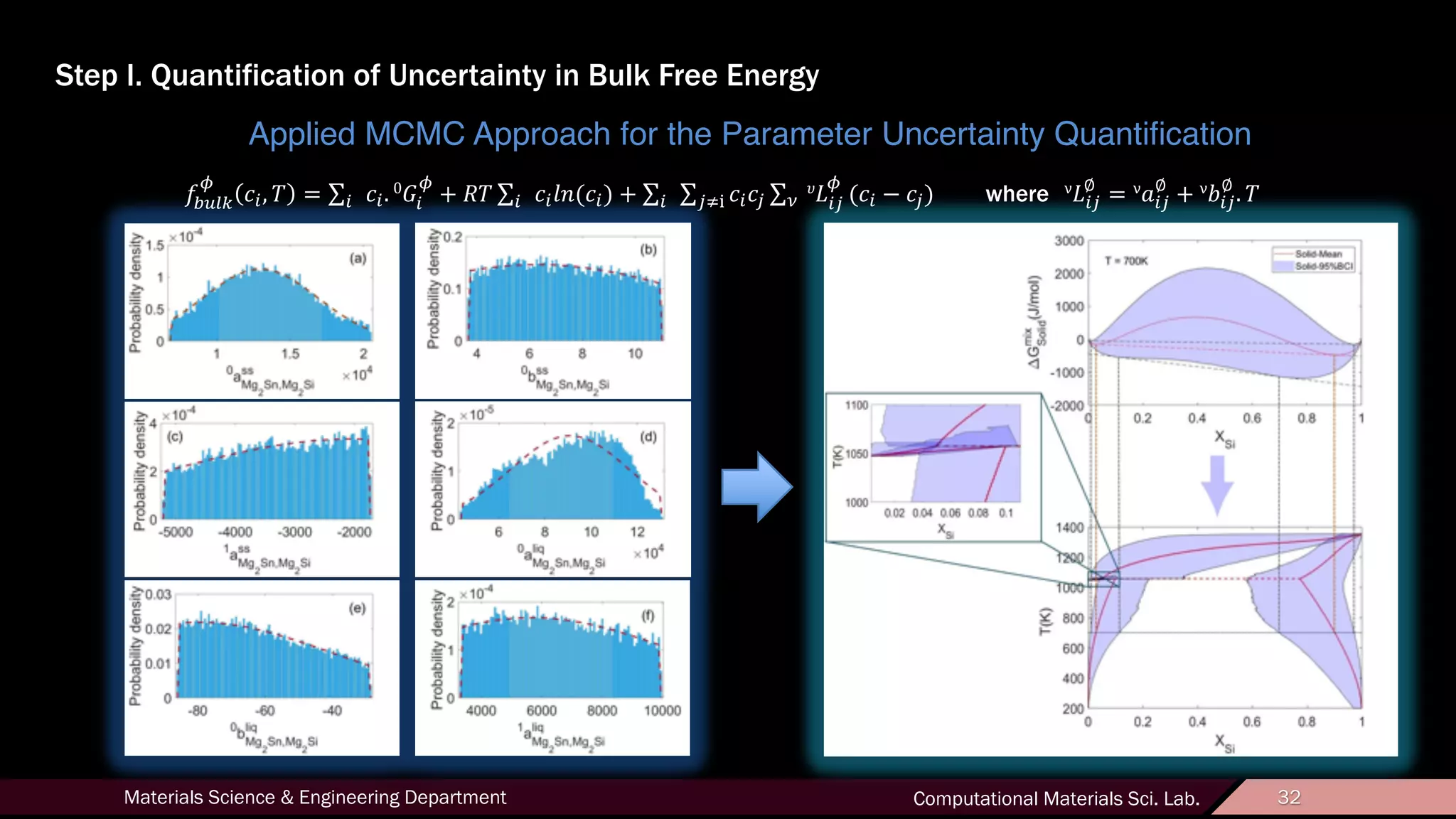

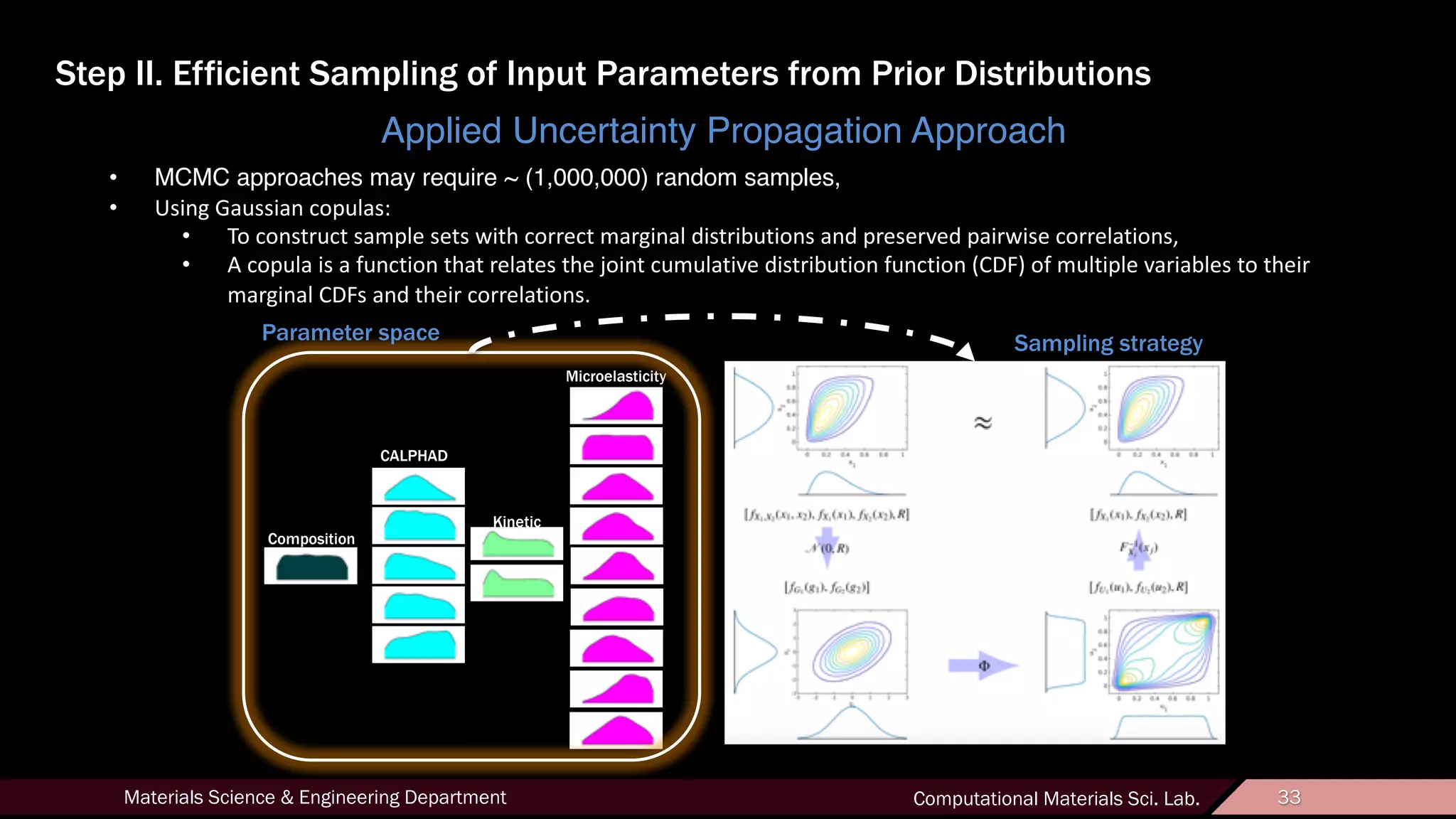

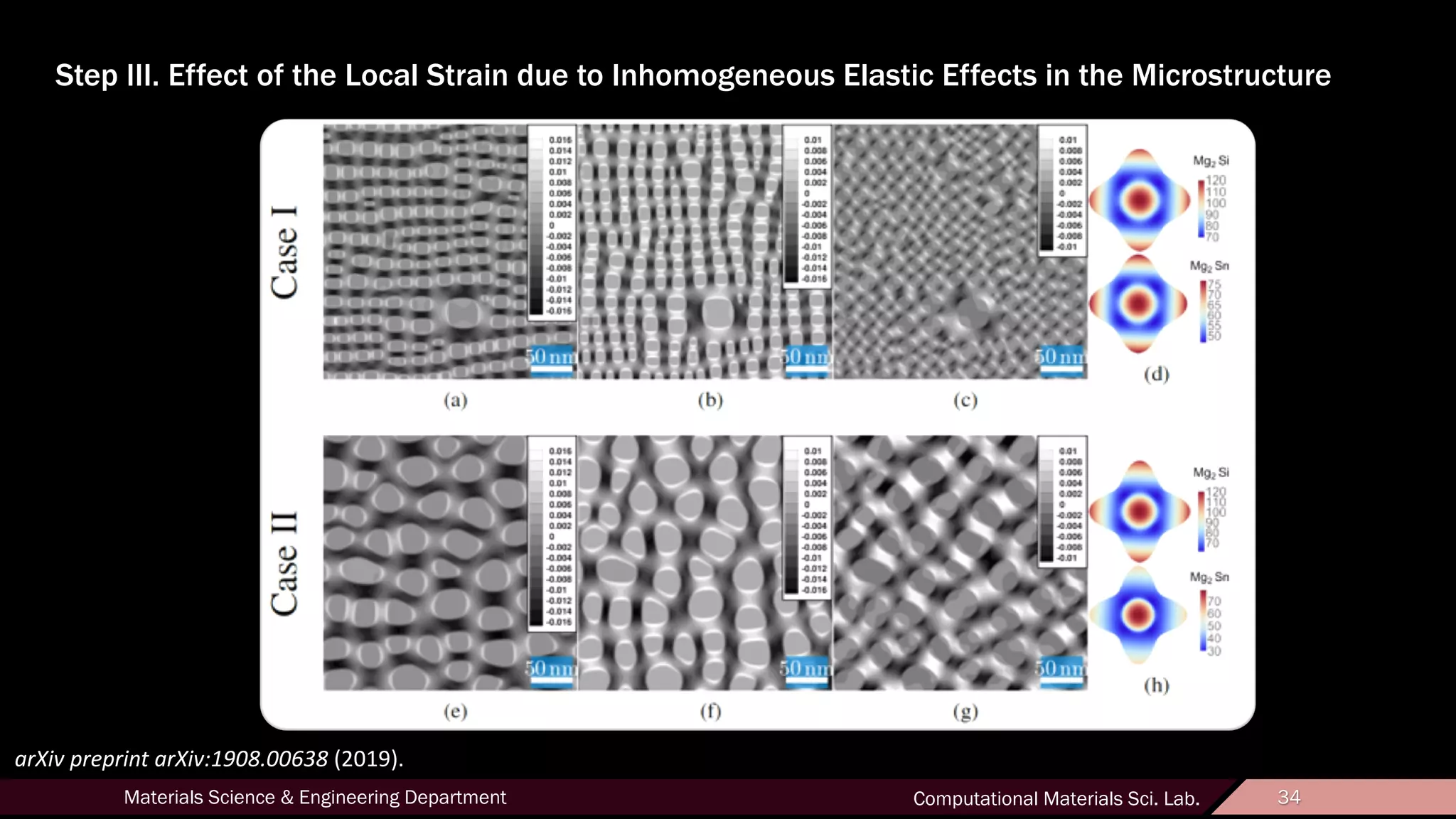

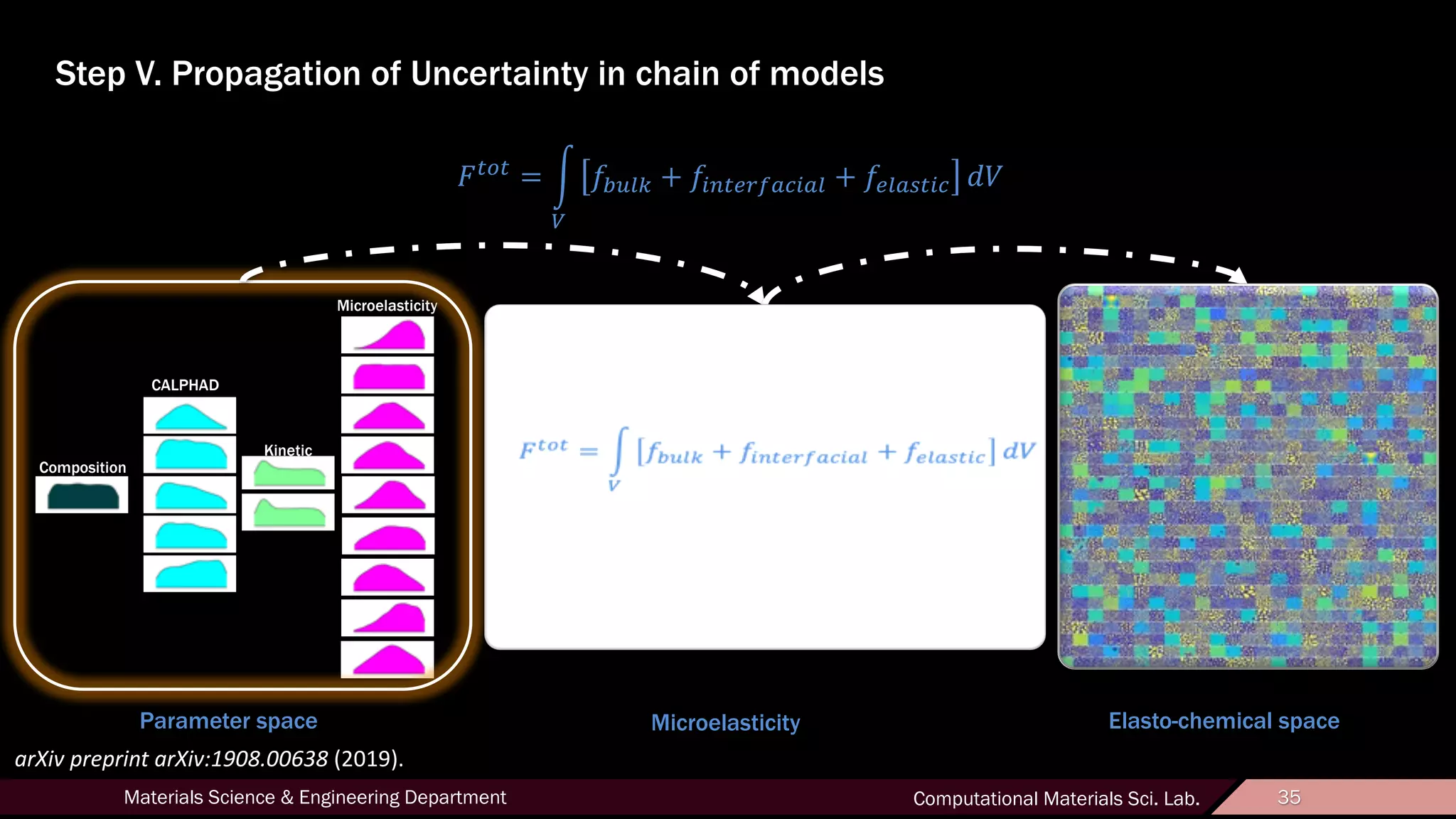

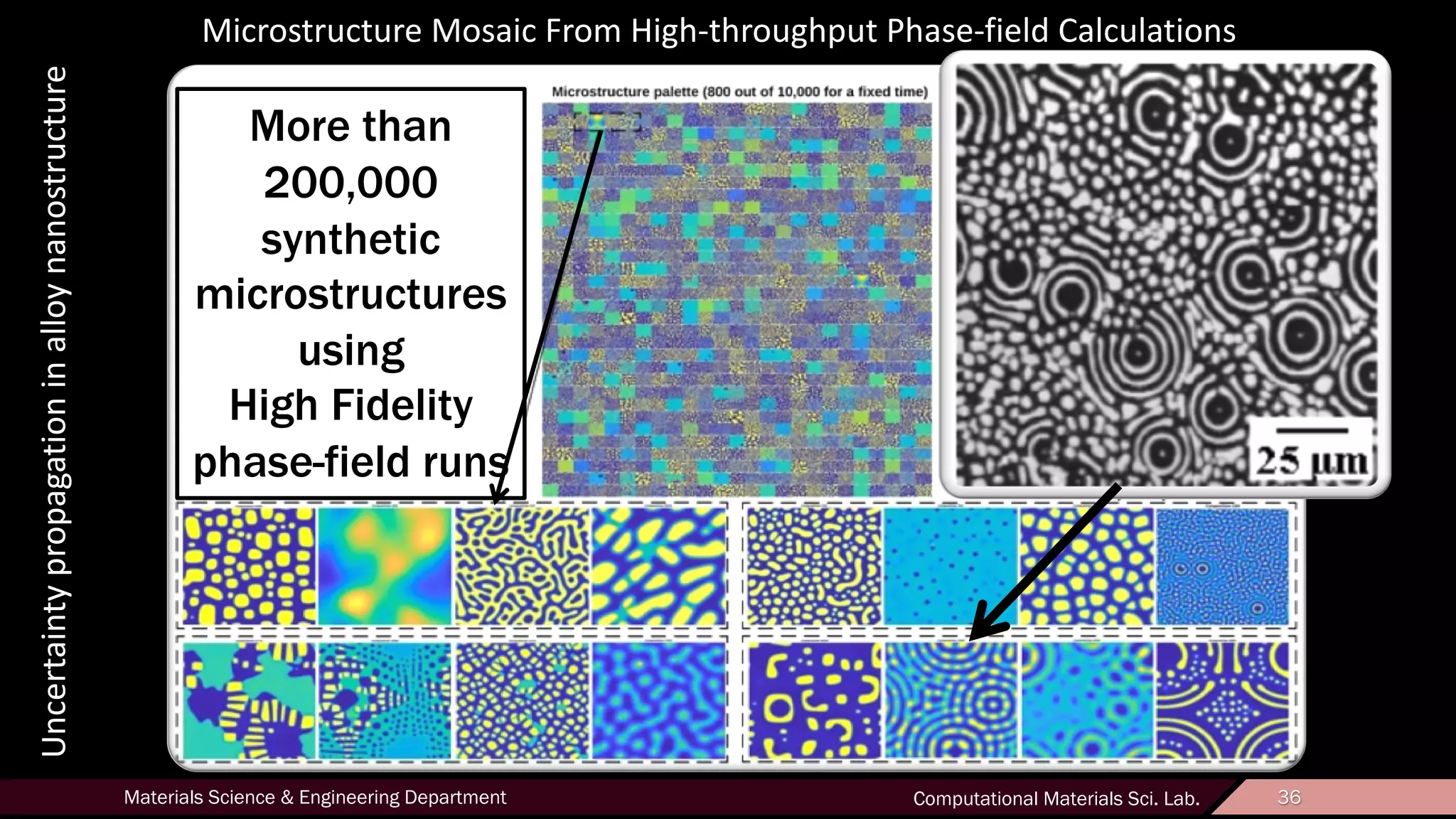

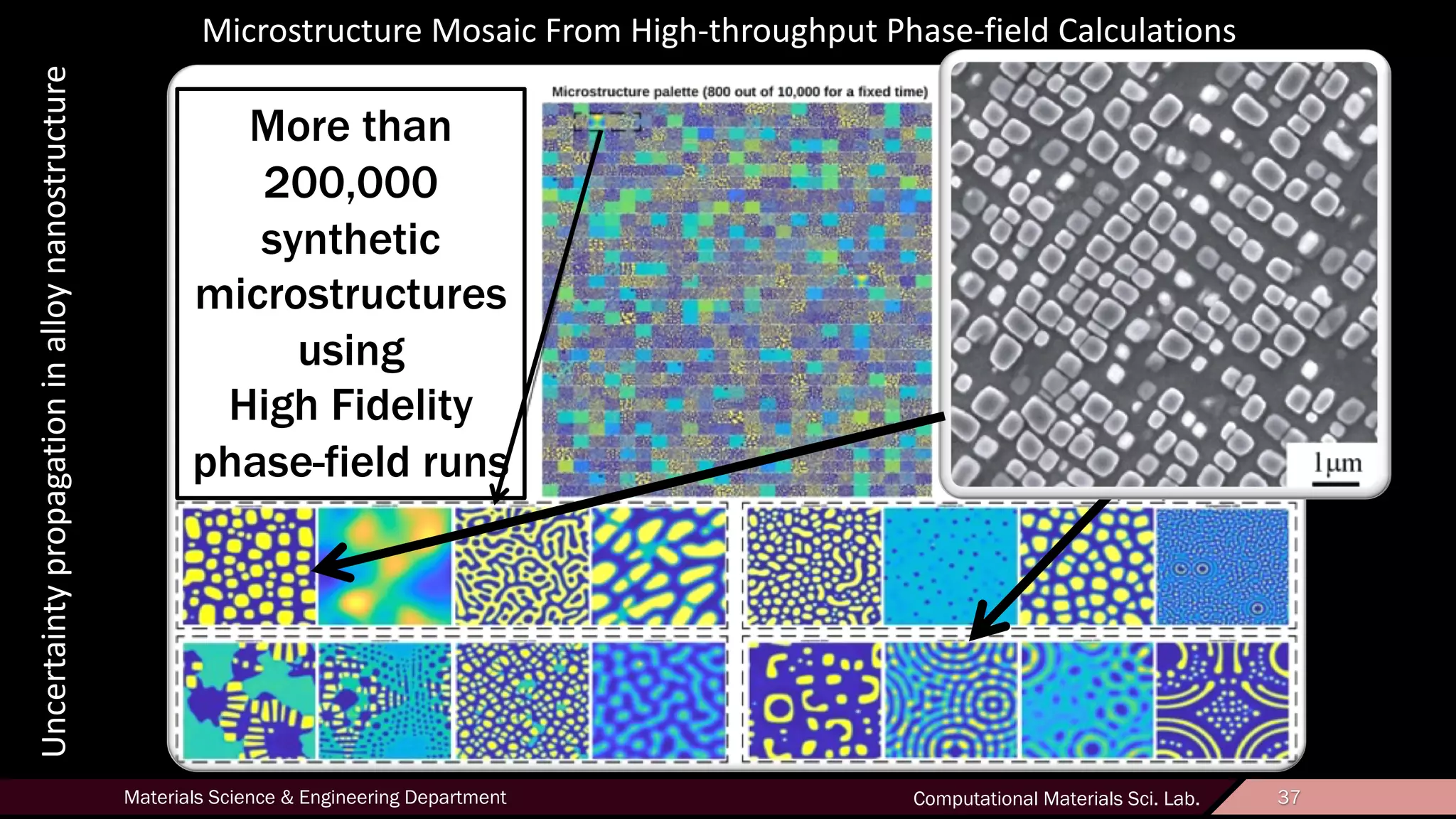

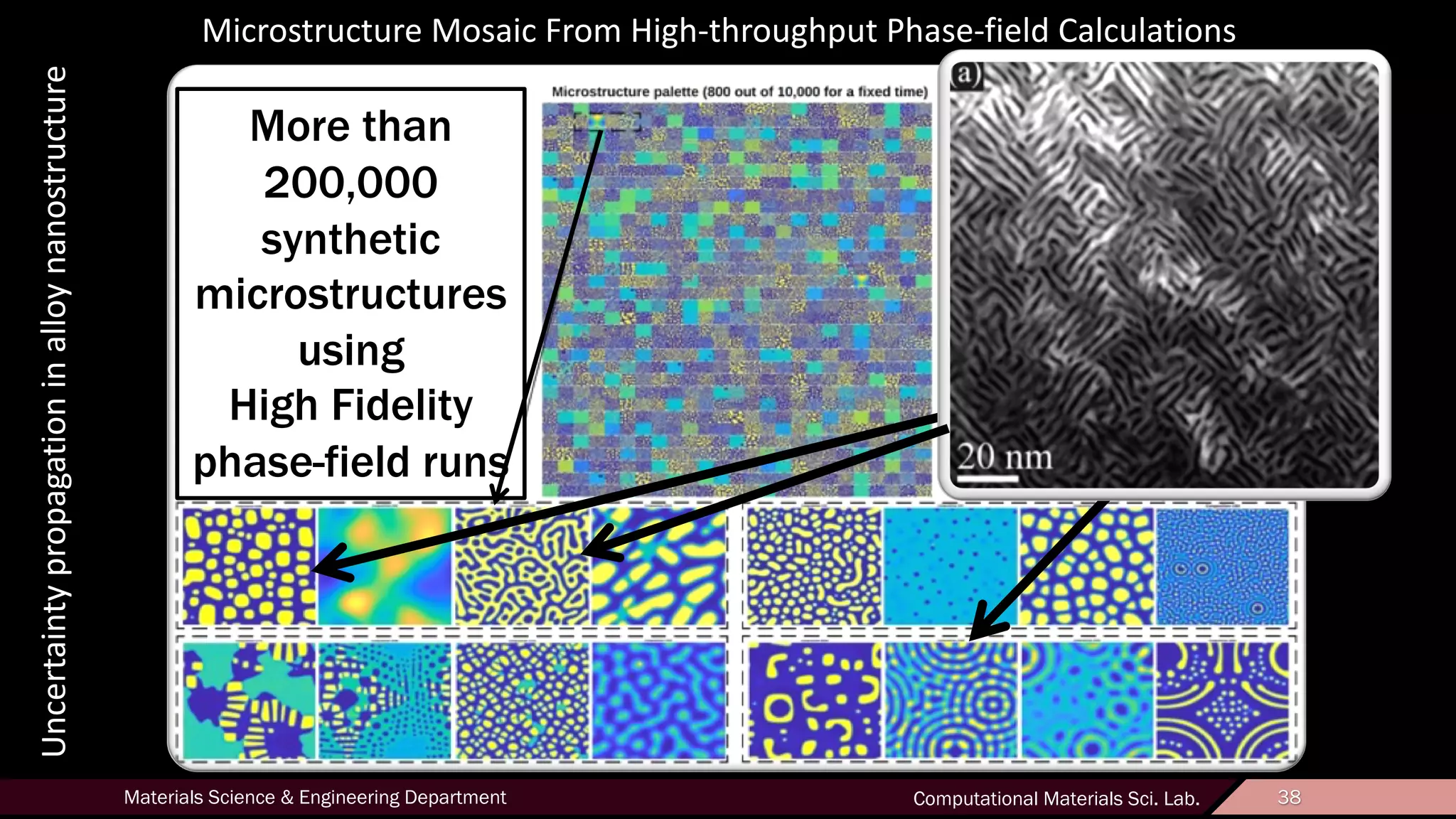

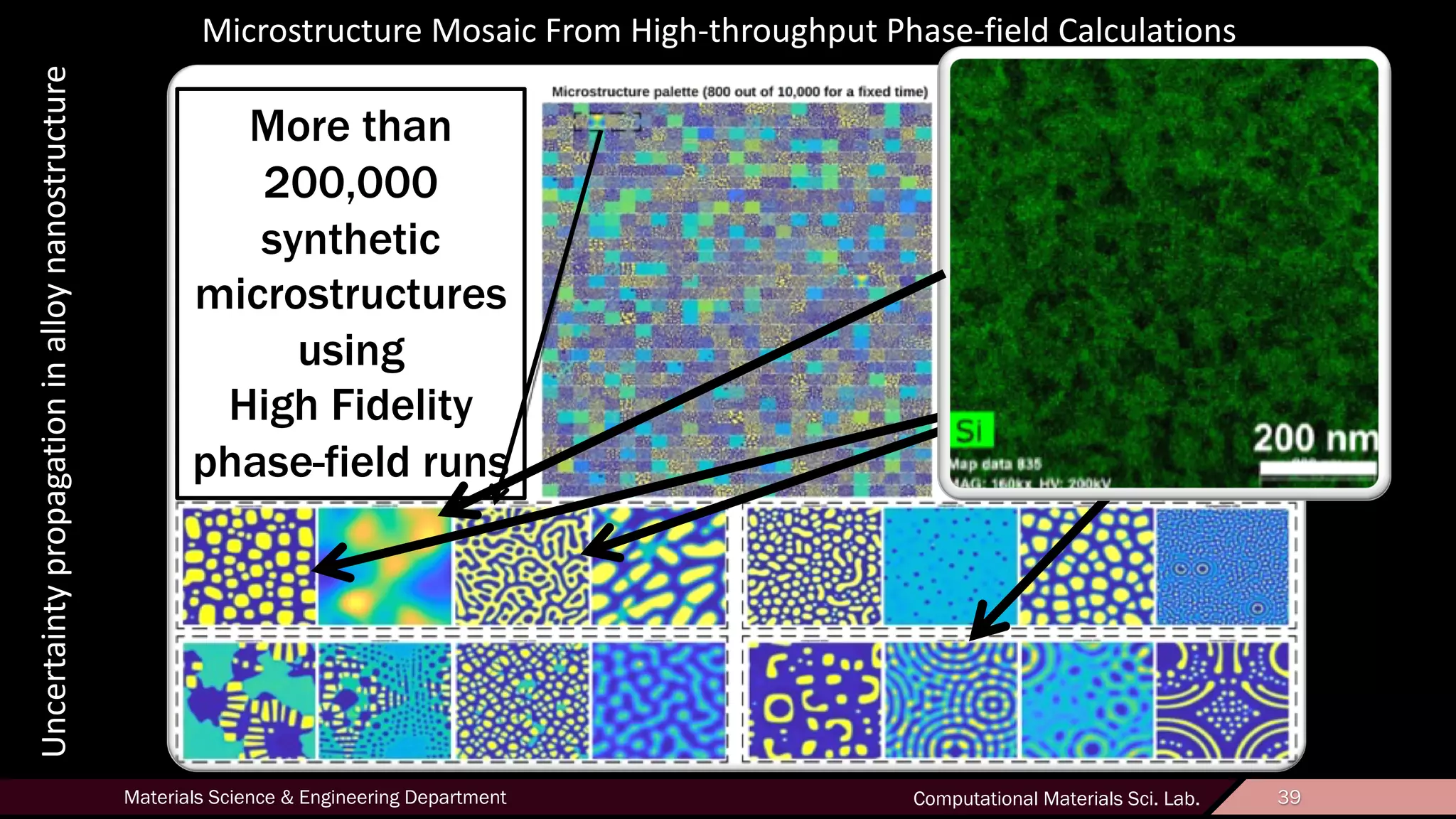

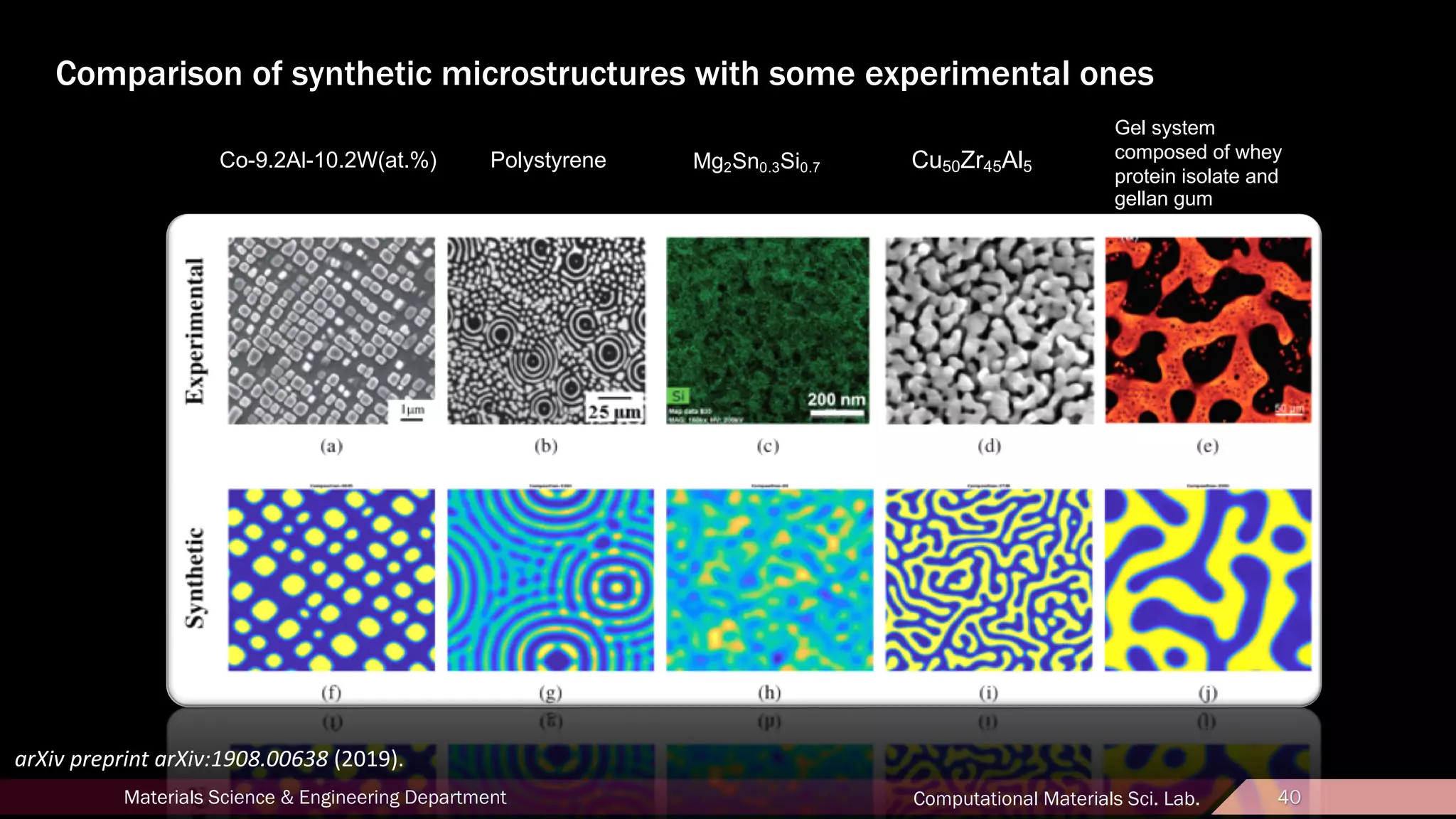

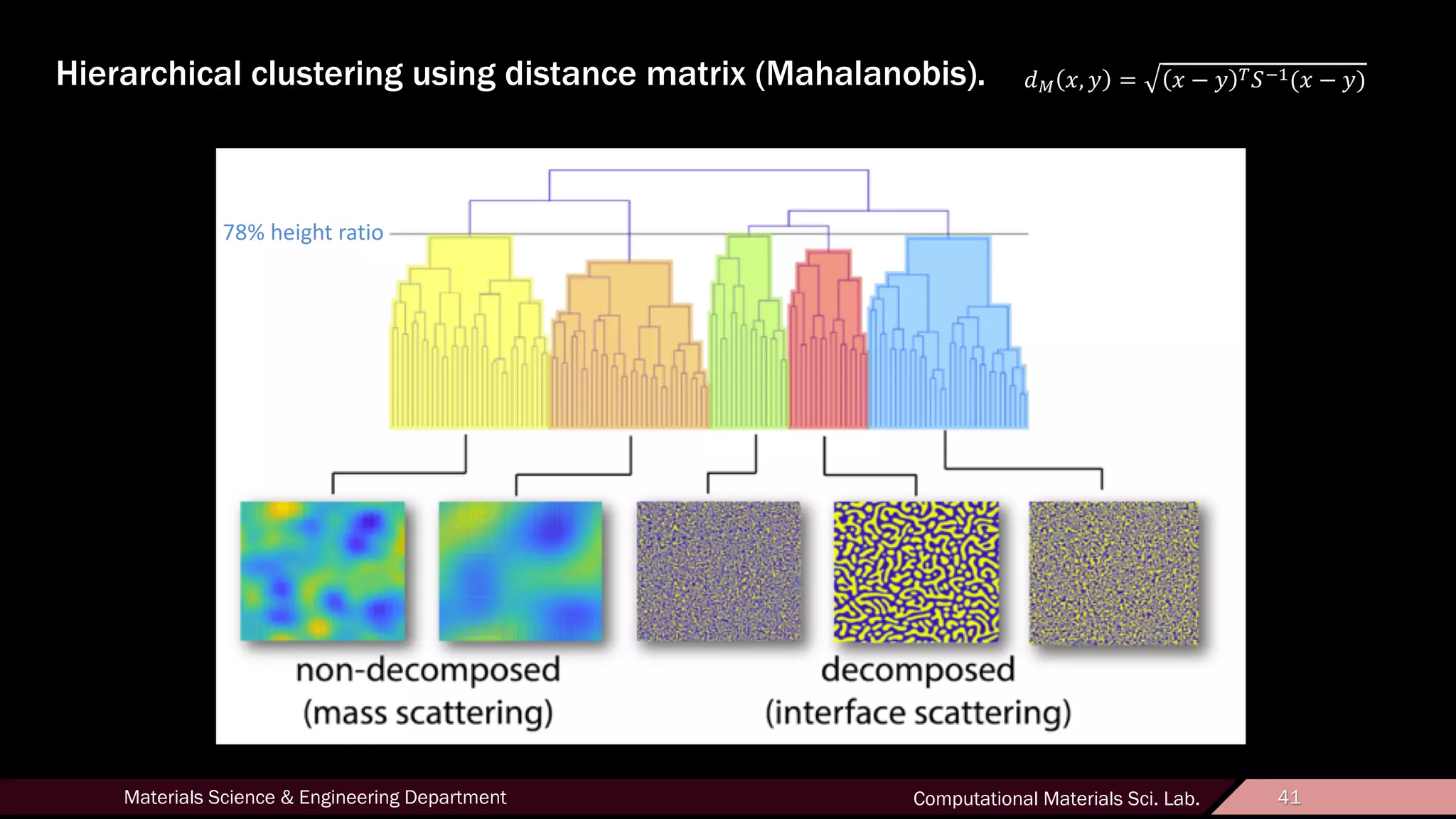

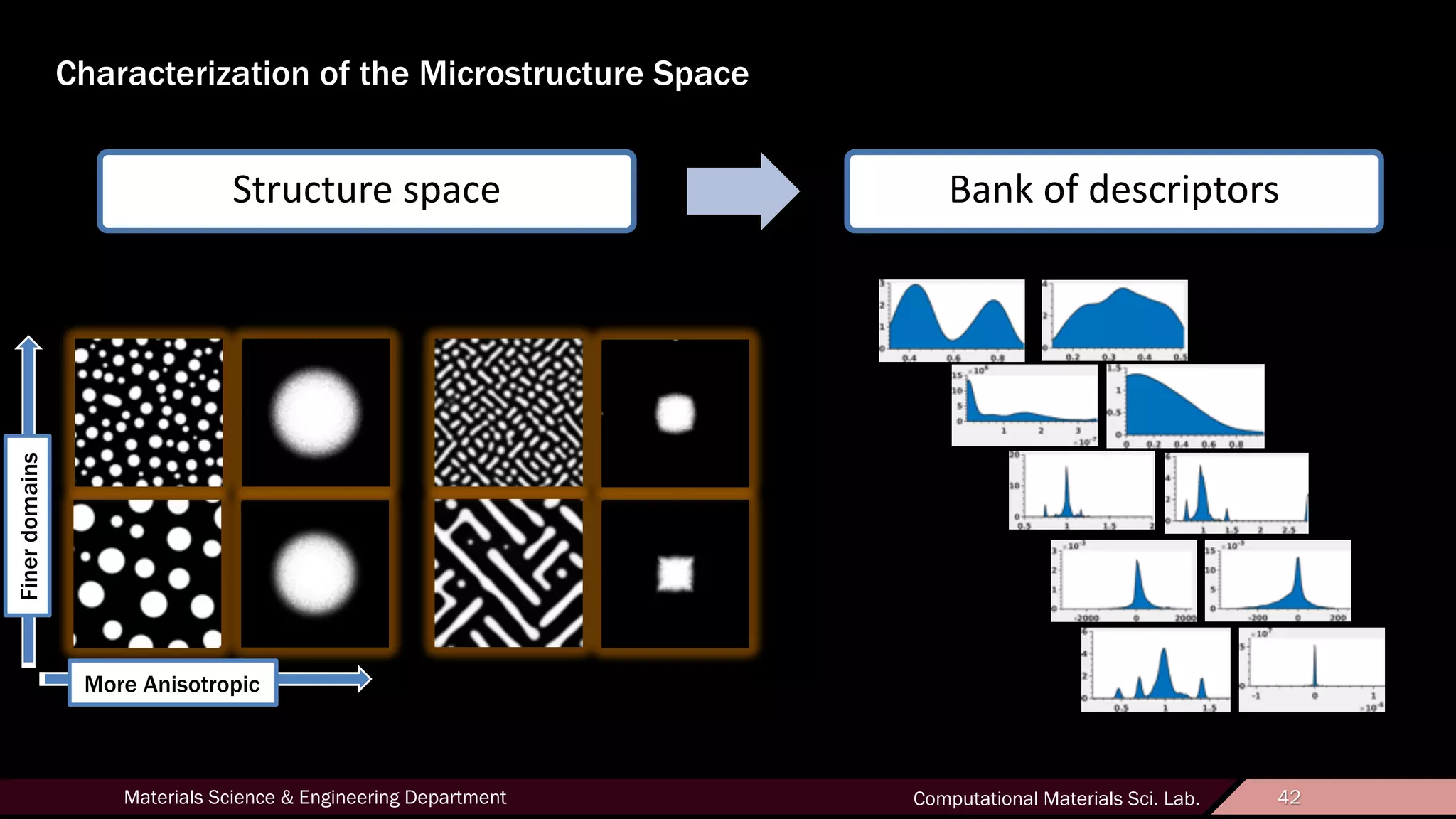

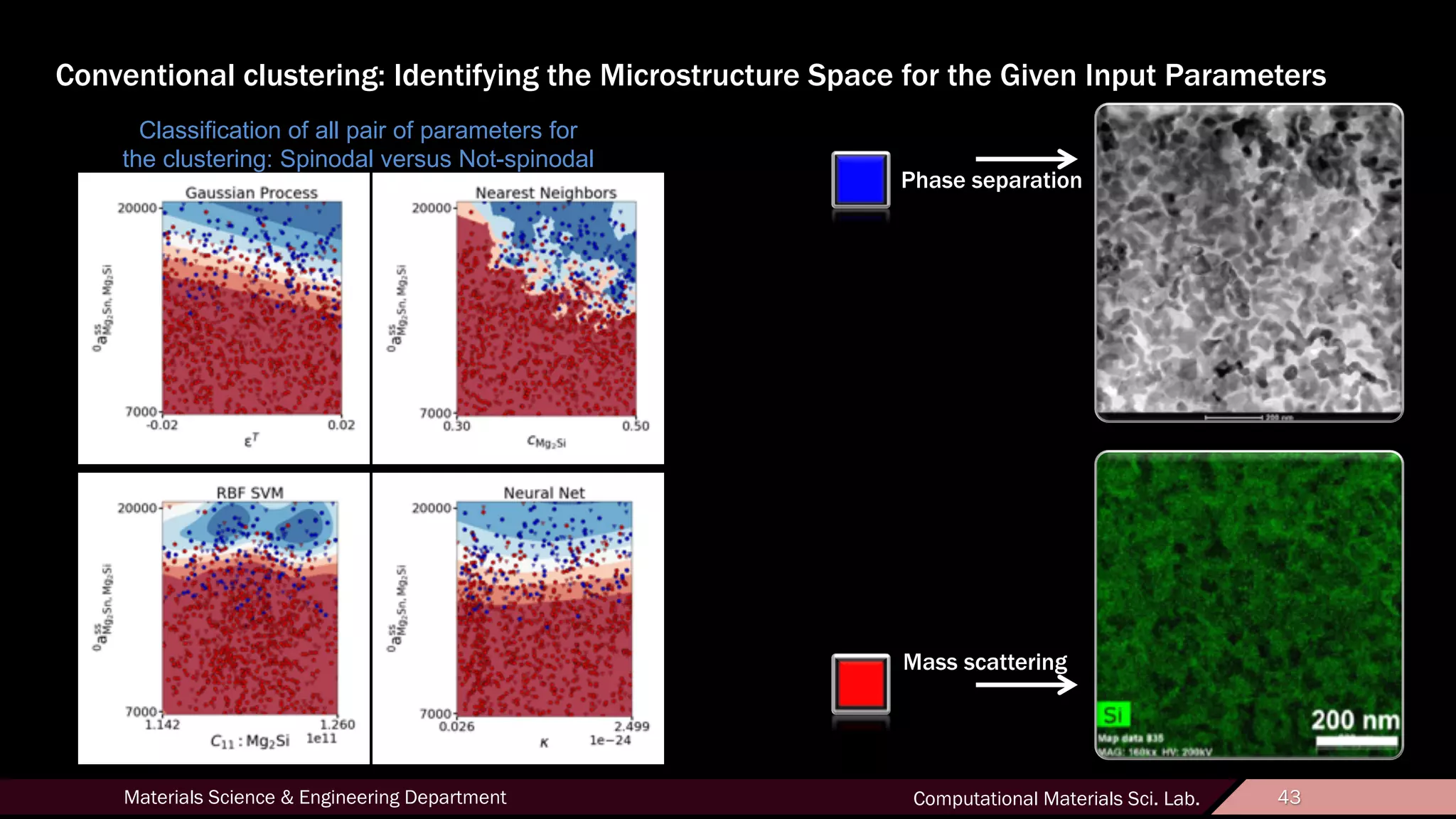

This document summarizes research on modeling microstructure evolution and properties in materials. It discusses three case studies: (1) modeling the growth of intermetallic compounds in Cu/Sn/Cu interconnects during processing, (2) using phase-field simulations and experiments to determine material parameters, and (3) developing thermoelectric Mg2SixSn1-x alloys through processing techniques. The document emphasizes that non-equilibrium processing can significantly alter material properties and discusses using thermodynamics, elastochemical modeling, and uncertainty quantification to predict phase stability and design microstructures for optimal performance.