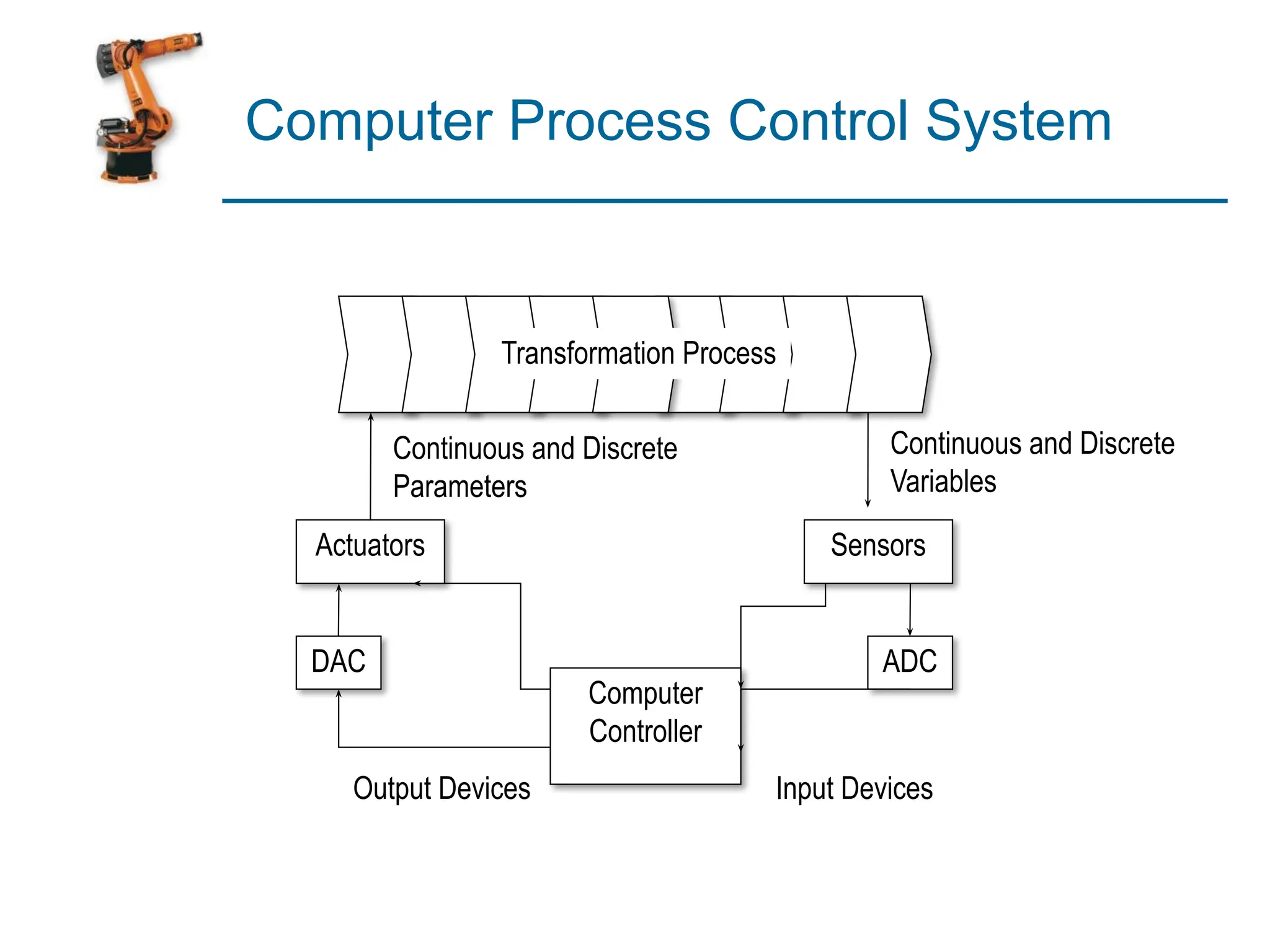

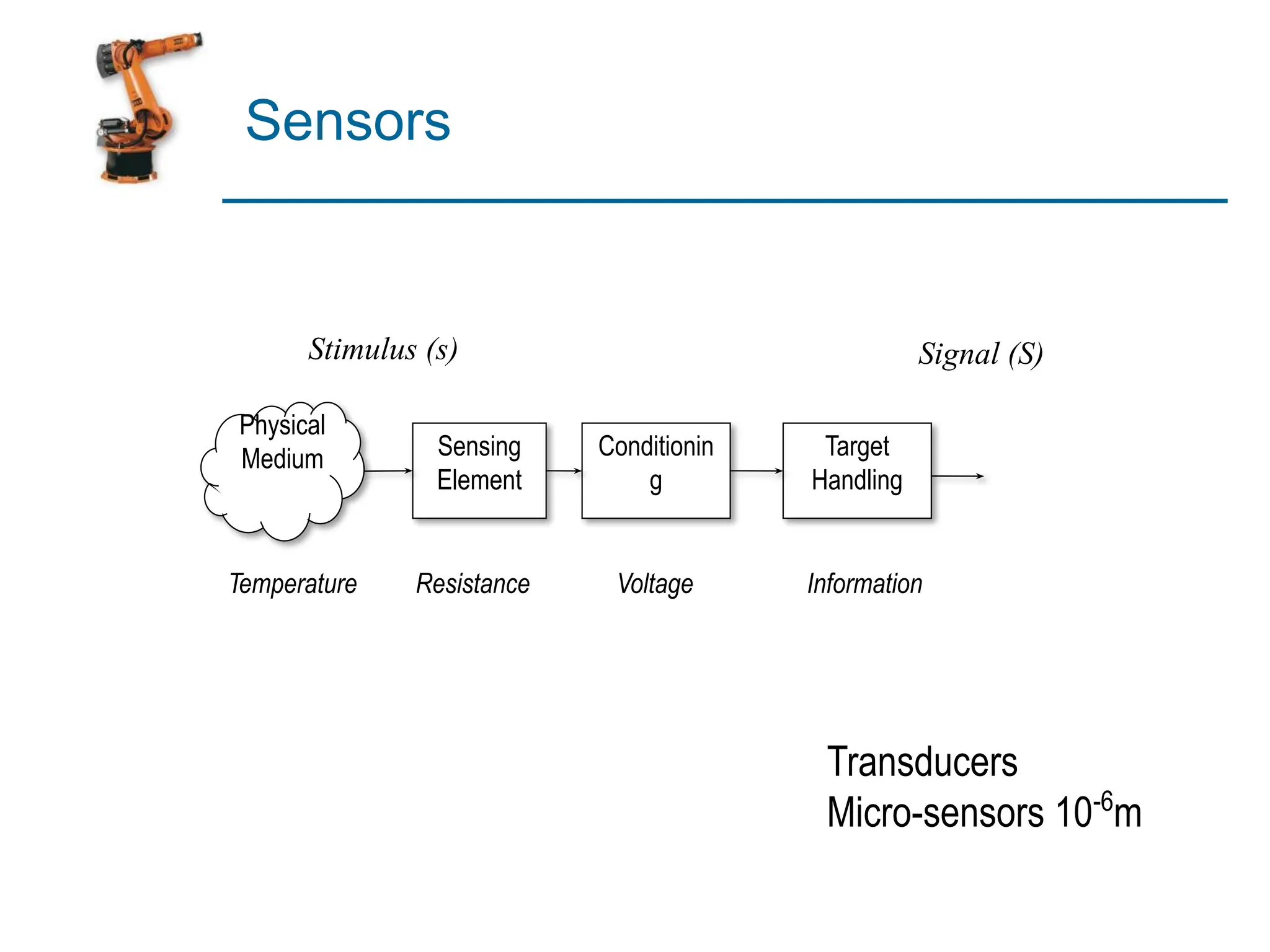

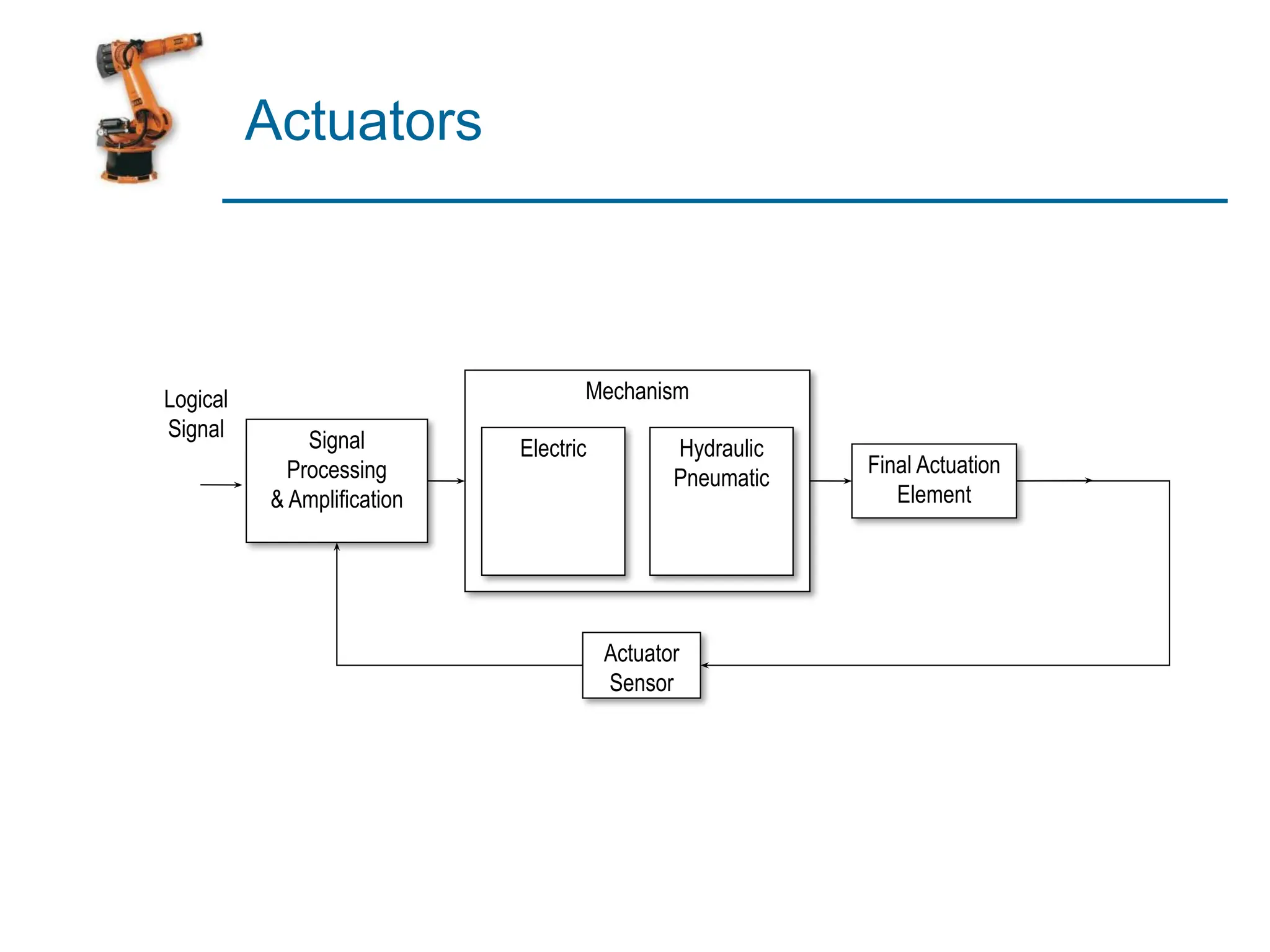

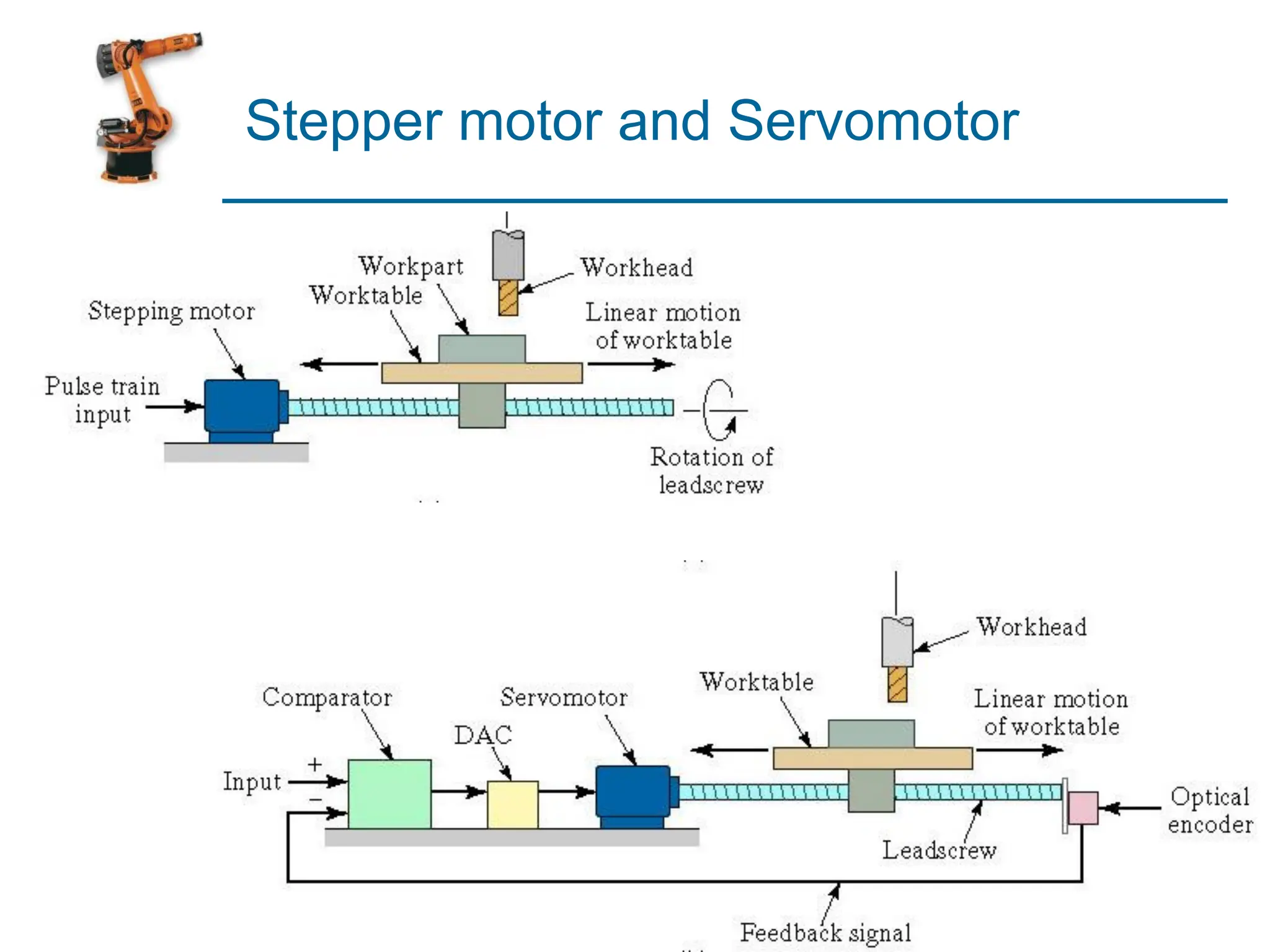

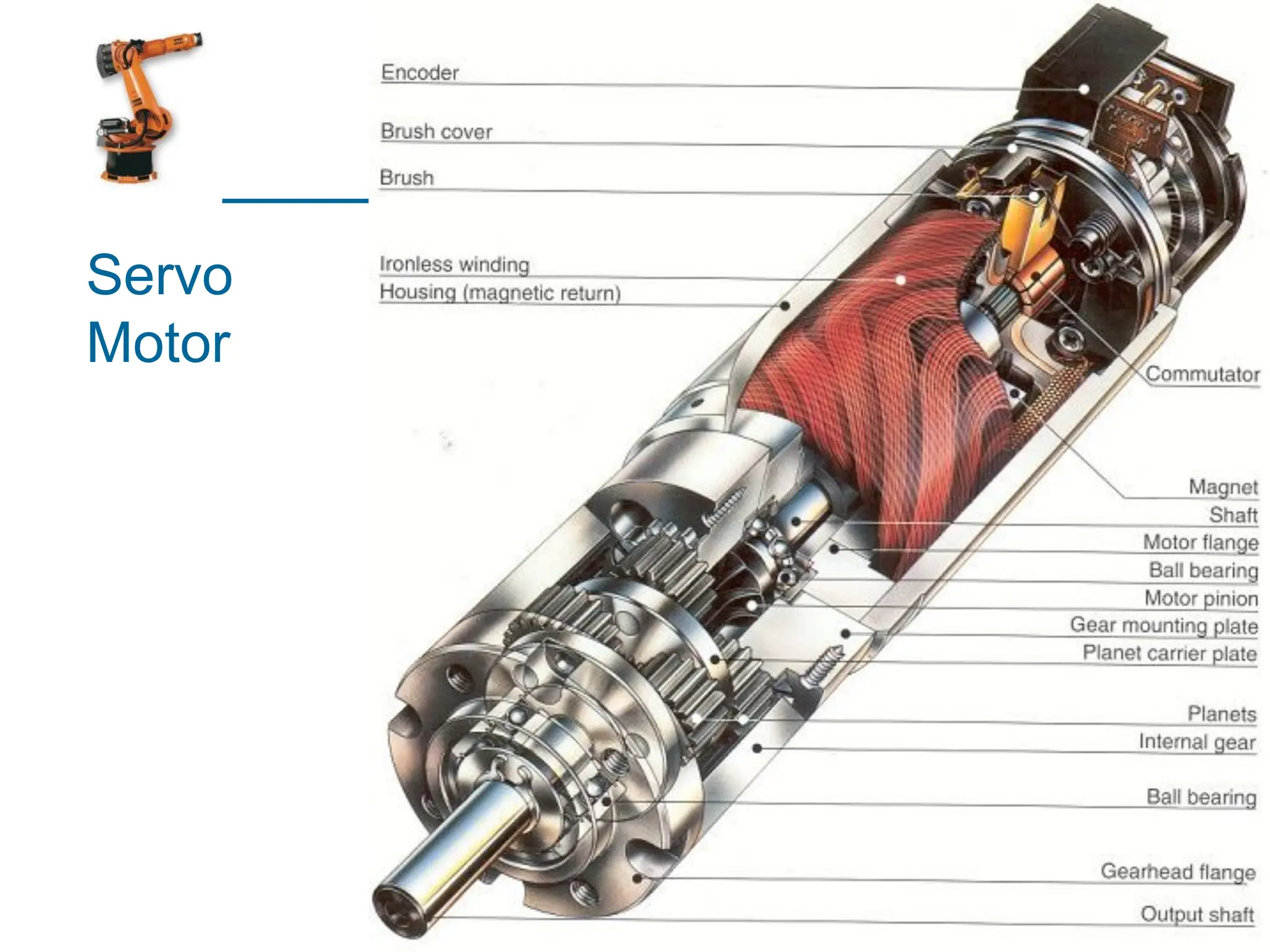

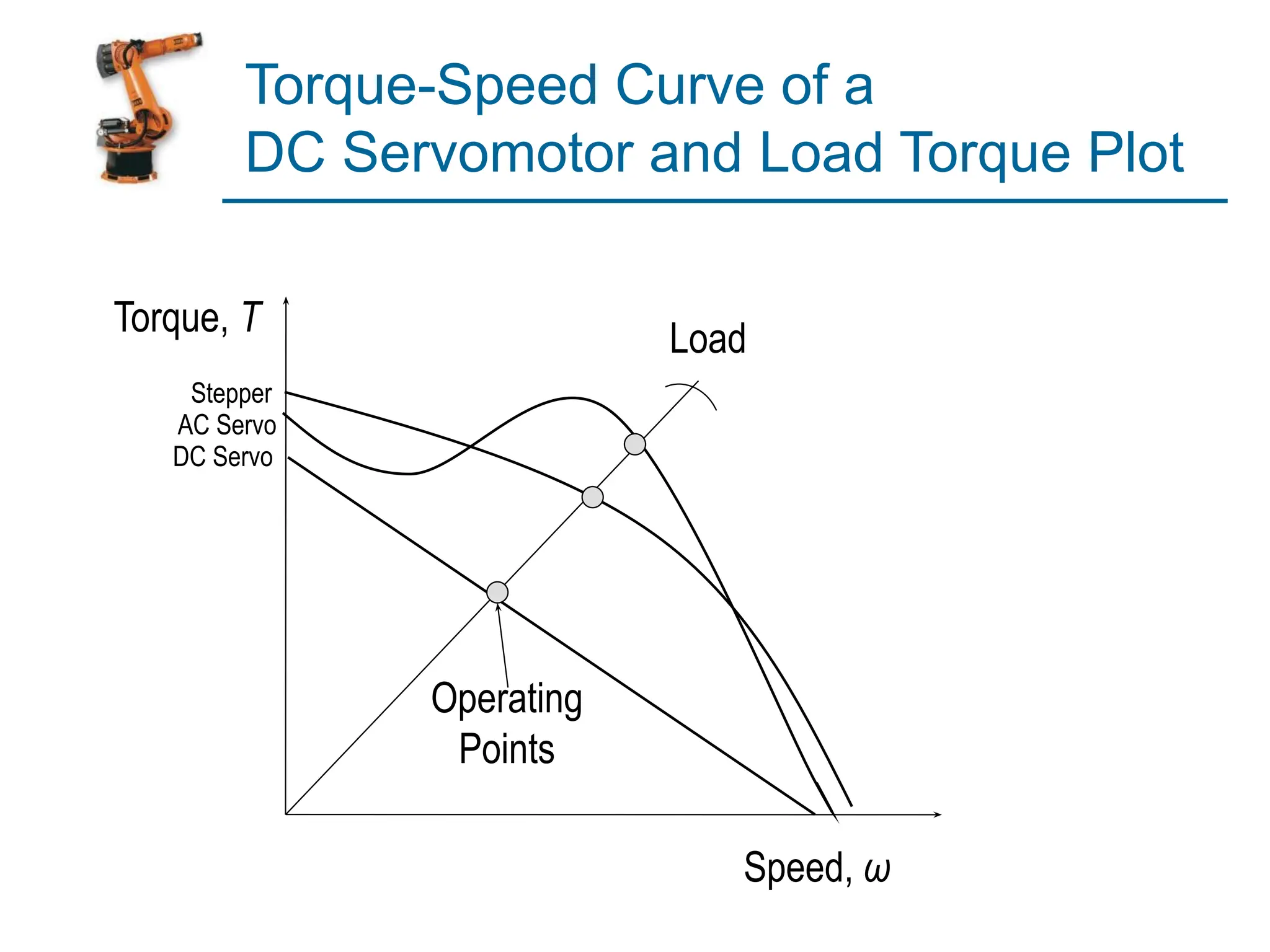

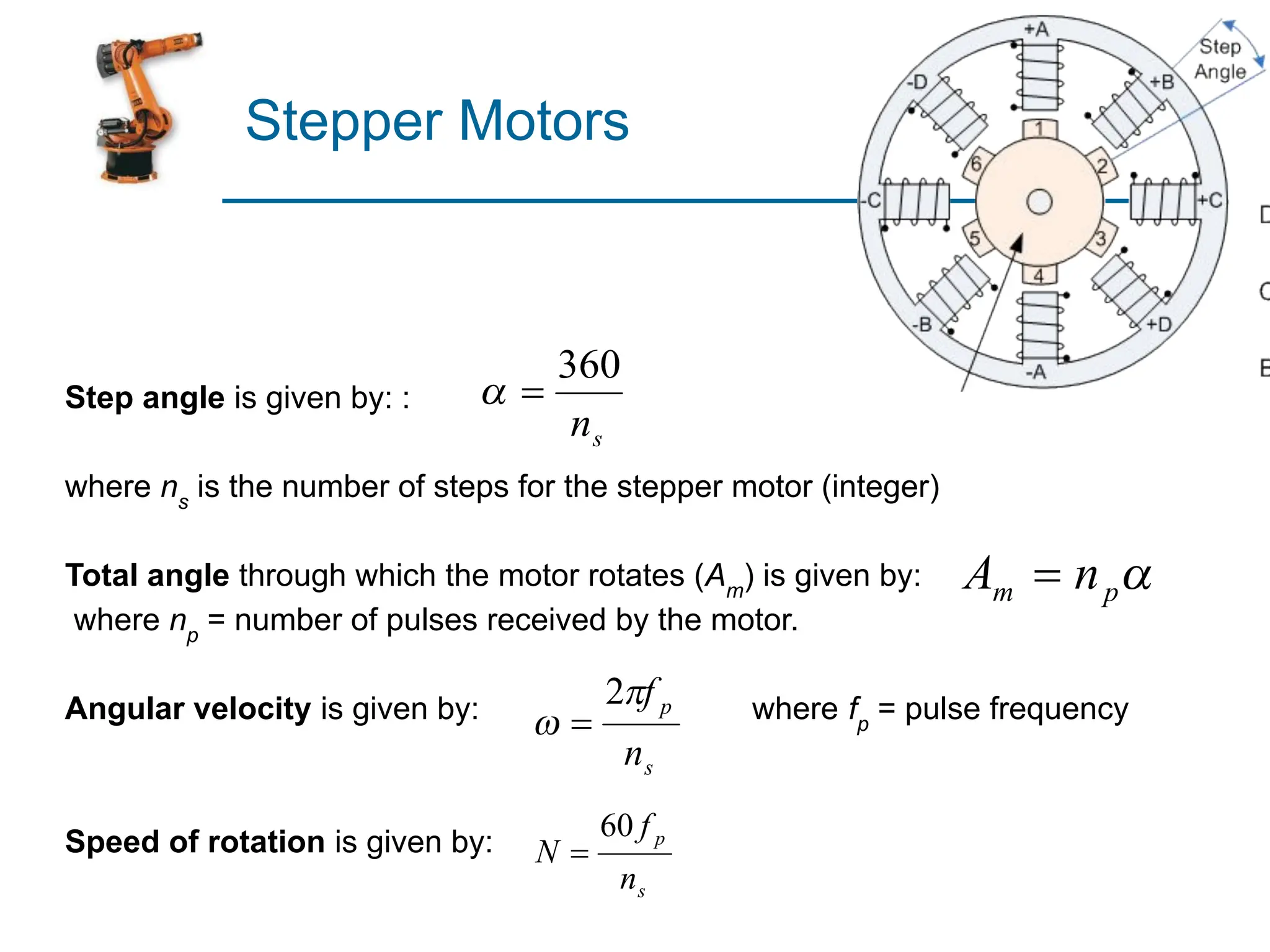

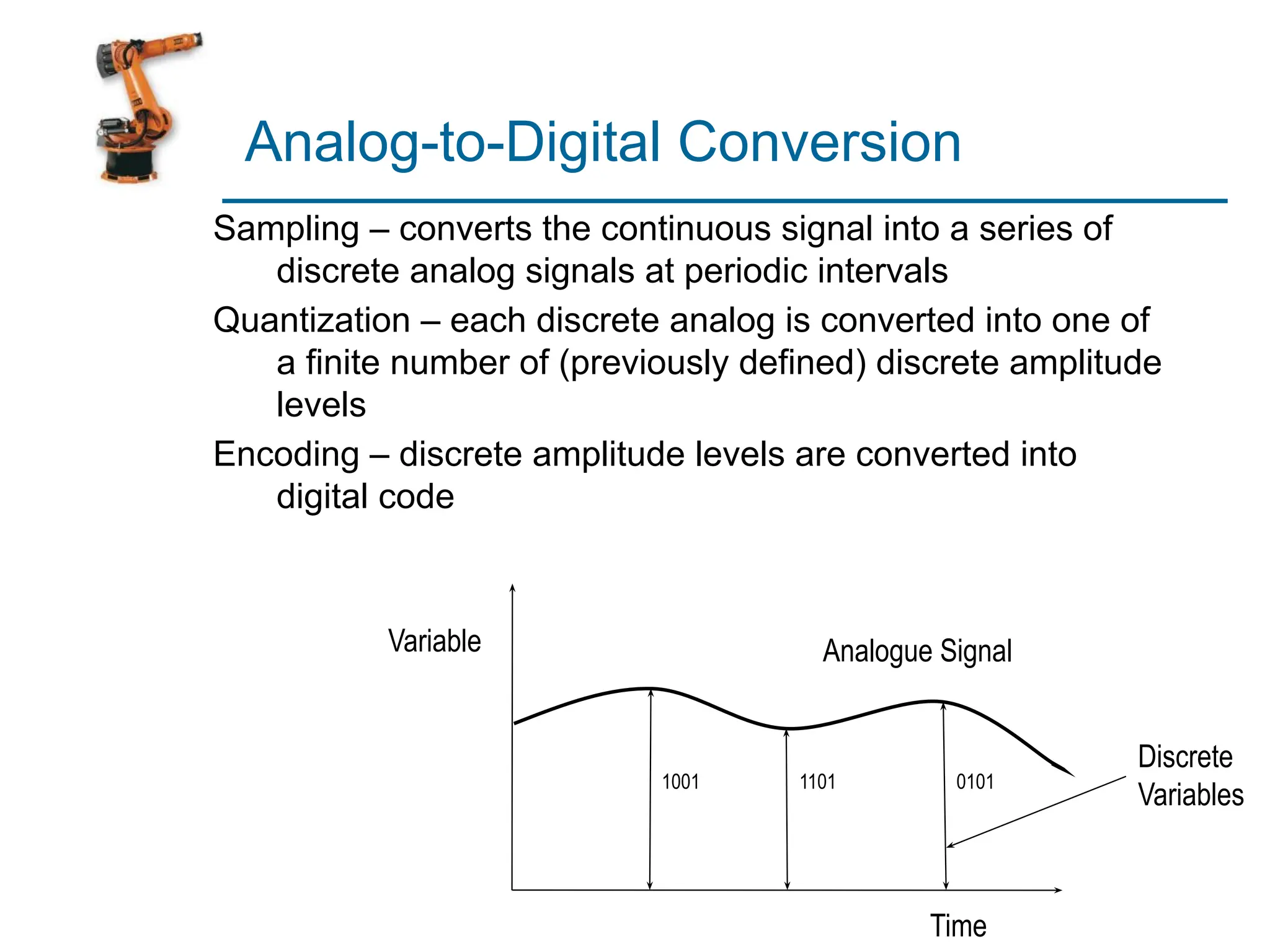

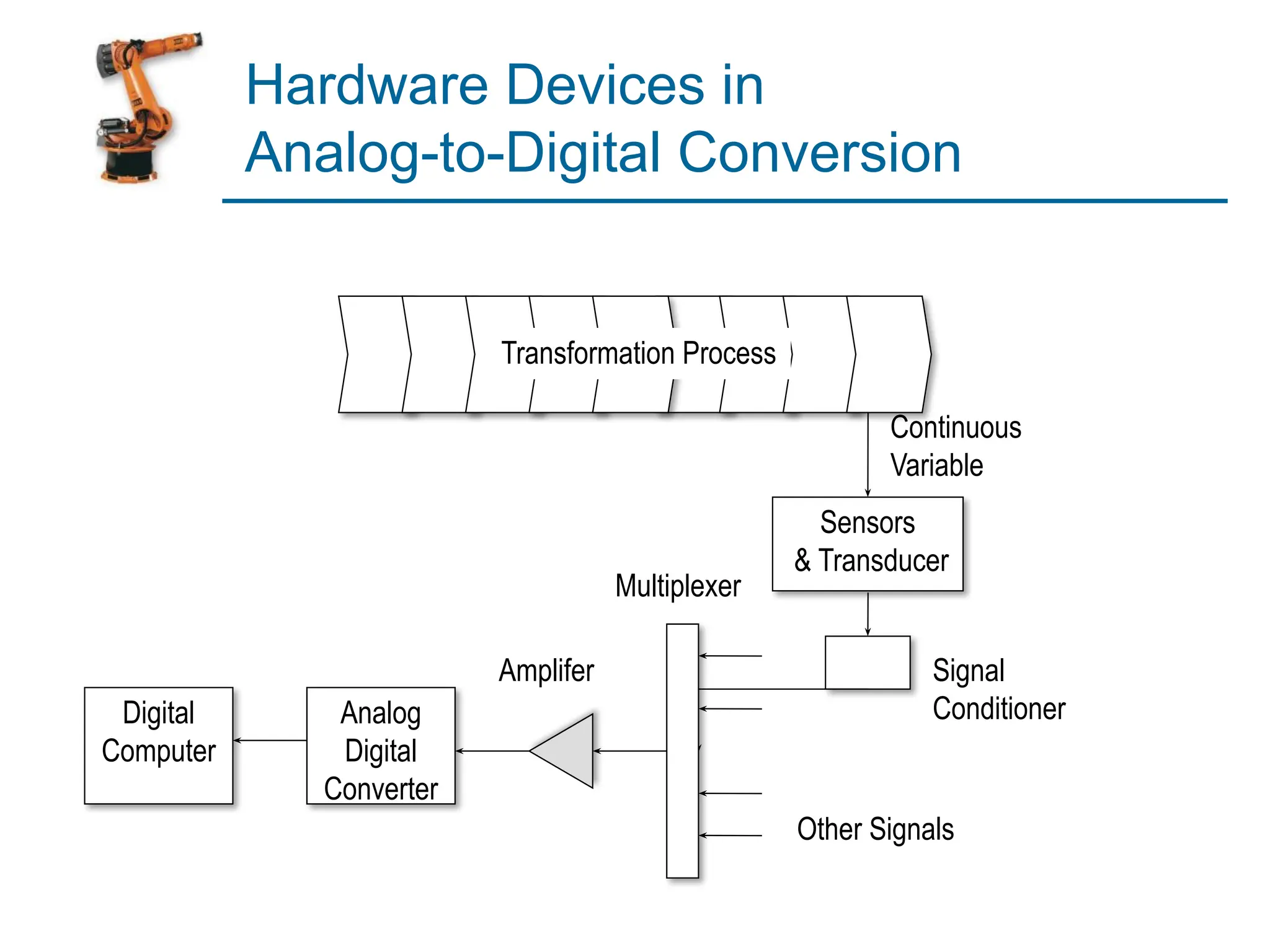

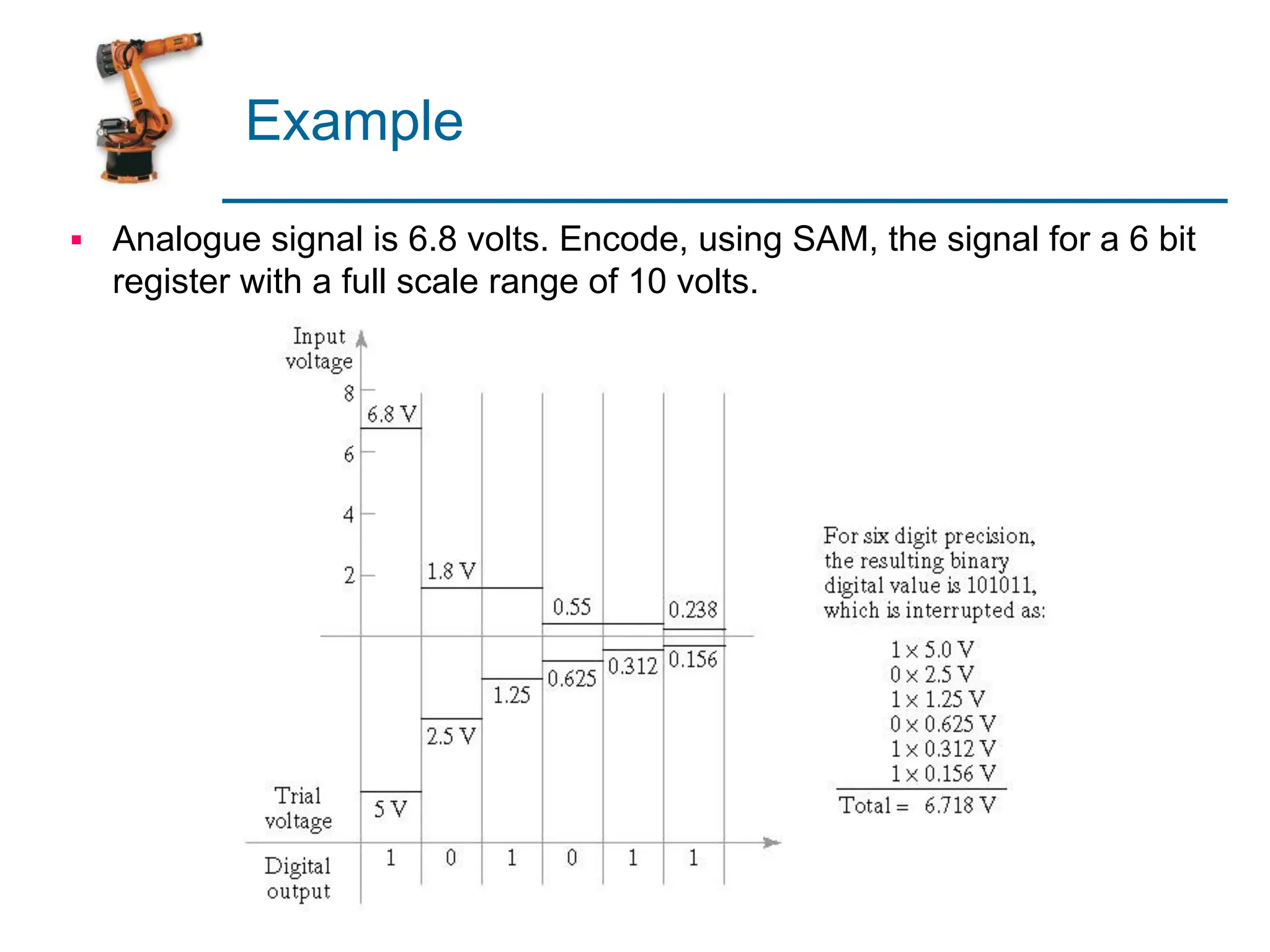

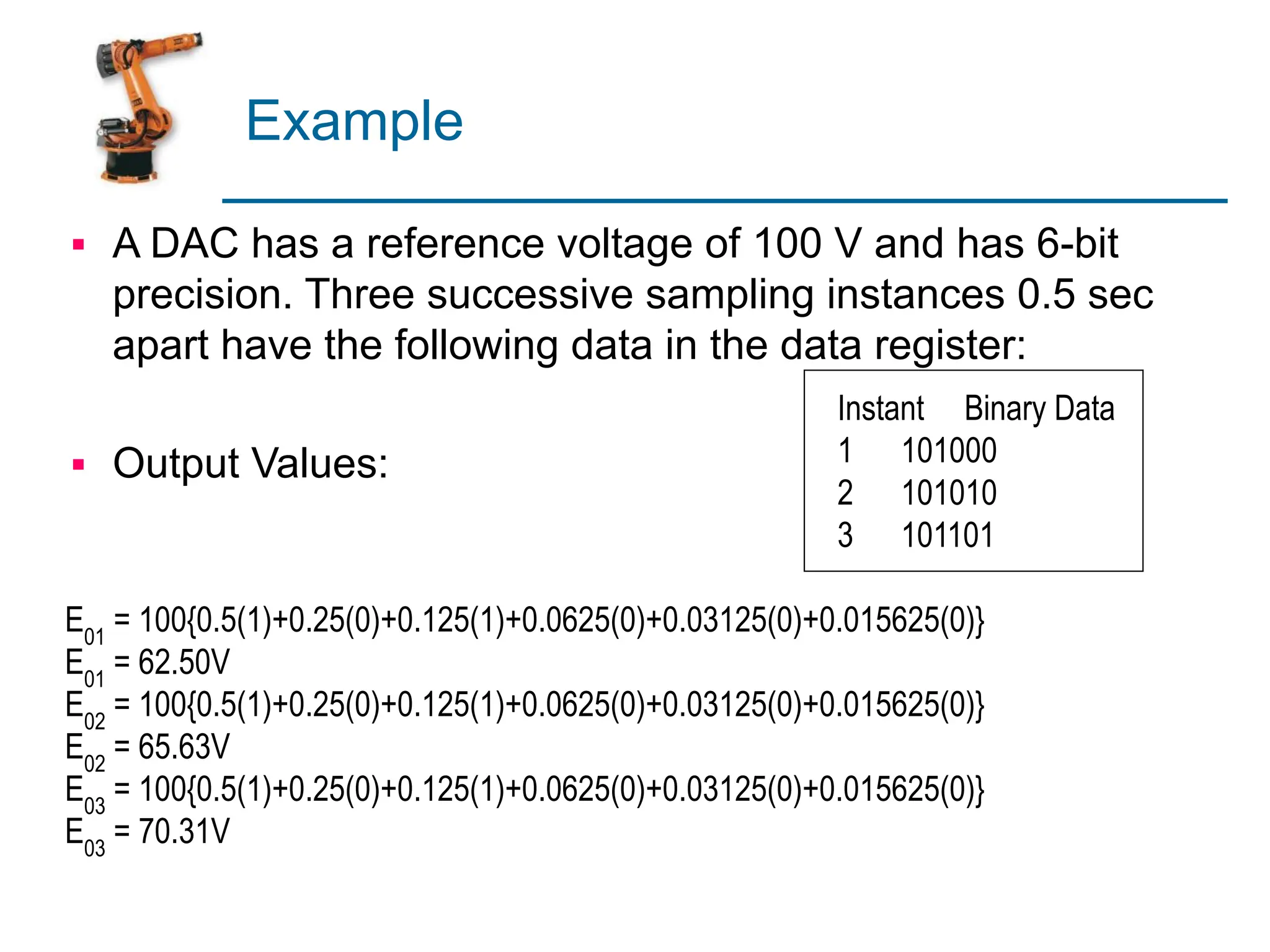

The document discusses the essential components for process control systems, including the roles of sensors, actuators, and data conversion methods such as analog-to-digital and digital-to-analog conversions. It elaborates on the types of sensors and actuators used, along with specific examples like thermocouples and motor types. Additionally, it covers technical details regarding the operation and characteristics of these devices, including calculations for transfer functions and quantization errors.