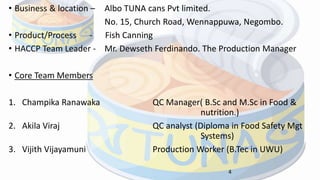

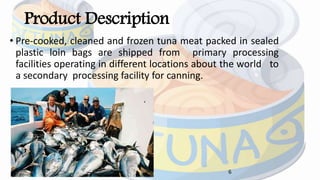

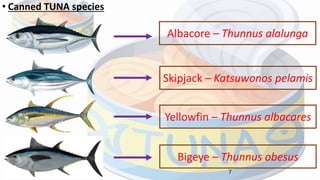

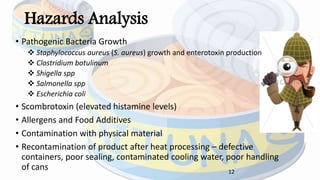

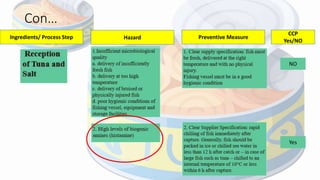

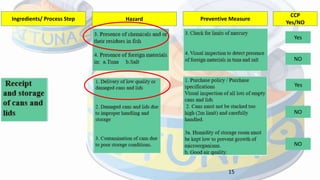

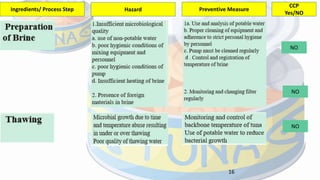

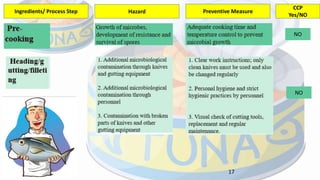

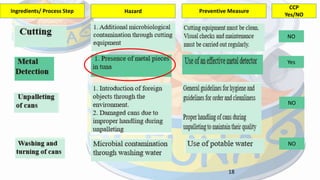

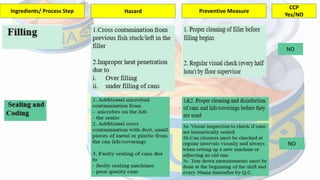

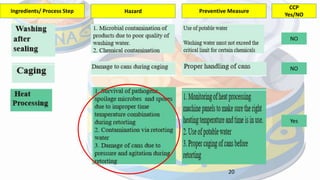

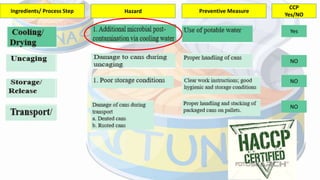

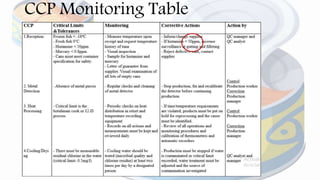

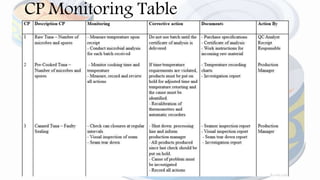

The document outlines the HACCP process and flow diagram for canned tuna production at Albo Tuna Cans Pvt Limited. It includes details on the HACCP team, product description, raw materials, hazard analyses including bacteria growth and contamination risks, and preventive measures. References for HACCP guidance and fish canning practices are also provided.