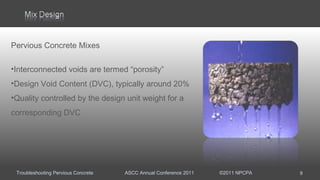

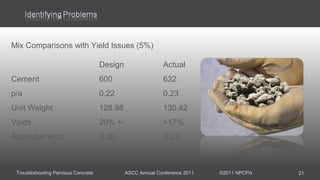

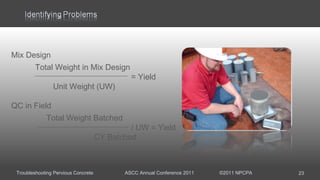

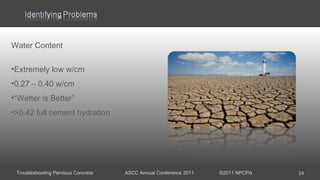

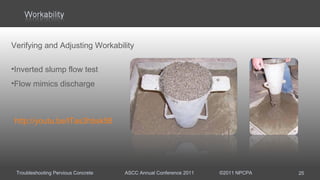

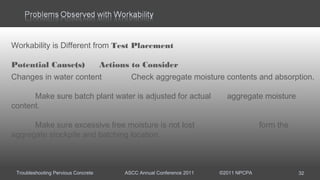

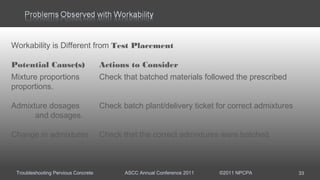

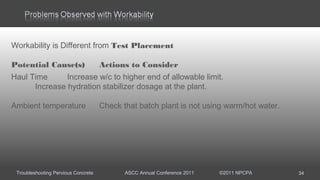

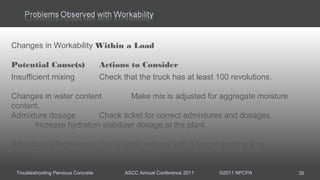

The document discusses troubleshooting pervious concrete mixtures and placements. It summarizes common issues such as changes in workability over time or between loads. Potential causes include changes in water content, mixture proportions, admixture dosages, and ambient temperatures. The document provides recommendations for actions like checking aggregate moisture, verifying batch proportions and admixture dosages, increasing hydration stabilizers, and adjusting water-cement ratios. The overall goal is to recognize and address issues in order to control mixture quality and prevent pervious concrete failures.