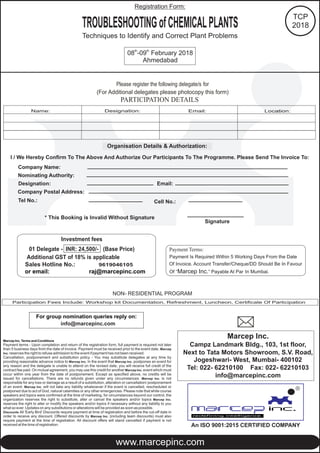

Marcep Inc. is hosting a two-day training workshop on troubleshooting in the chemical process industry in Ahmedabad on February 8-9, 2018. The program aims to equip participants with systematic approaches to identify and correct plant problems, featuring techniques for diagnostics and case studies, specifically tailored to enhance plant performance. Registration details and contact information for queries are provided for interested participants.