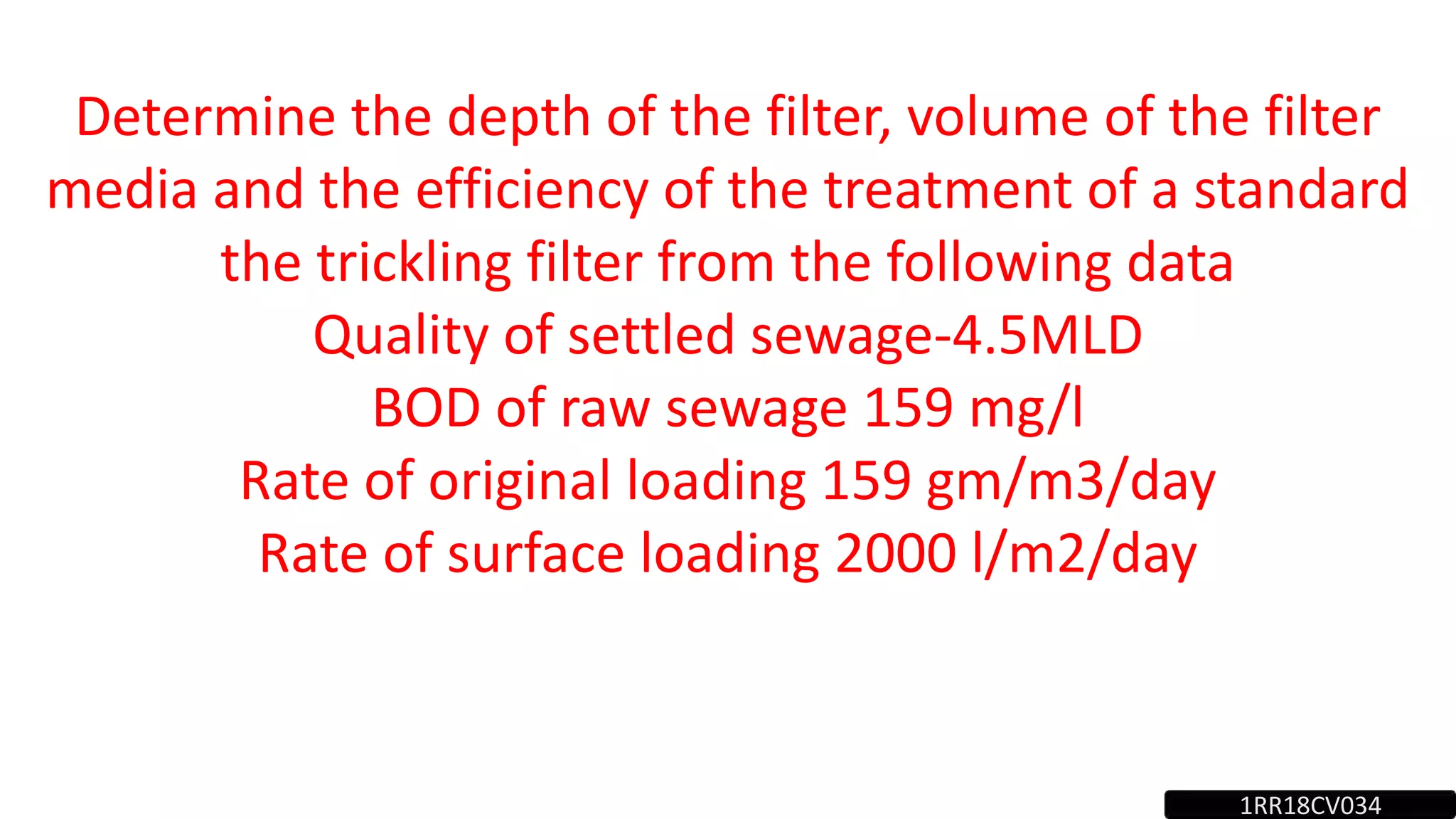

The document describes the working and construction details of a trickling filter system used for wastewater treatment, detailing its components such as the permeable media, rotary distributing arms, and underdrainage tank. It highlights common operational issues including high head loss, the necessity for primary treatment, and odor problems, while providing calculations for the filter's dimensions and efficiency based on sewage characteristics. The overall efficiency of the trickling filter is calculated to be approximately 85.44%.