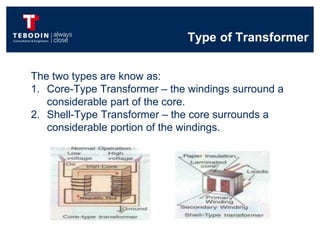

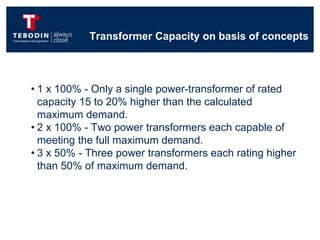

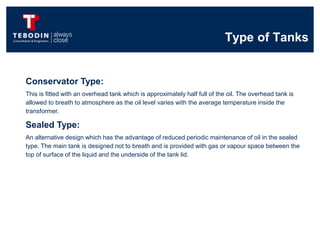

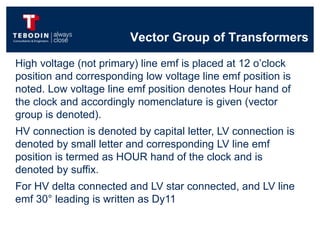

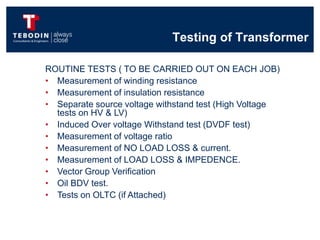

This document provides an overview of transformers, including their applicable standards, working principle, construction, types, sizing, and testing. Transformers are used to increase or decrease voltage for power transmission and distribution. They work by magnetically coupling two inductive coils to transfer power between circuits of different voltages. Common types include distribution, power, and phase shift transformers. Proper sizing involves considering the maximum demand plus spare capacity. Transformers are tested according to applicable standards to ensure safety and performance.