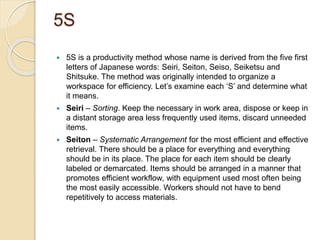

This document discusses methods for continual quality improvement including Six Sigma, Lean, and Lean Six Sigma. It emphasizes that management should play a role by establishing an organization-wide quality council, providing support, and scheduling progress reviews. Customers' needs are always changing, so improvement must be continual rather than a one-time effort. The 5S method is introduced as a productivity technique involving sorting, systematic arrangement, shining, standardizing, and sustaining the workspace. Finally, the document outlines a structure for quality improvement including establishing a quality council and developing responsibilities.