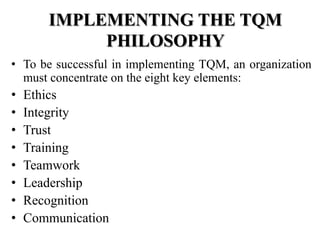

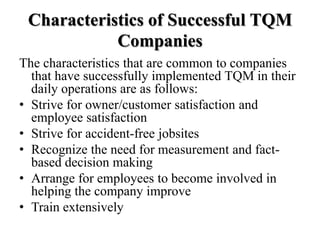

TQM is a management philosophy focused on meeting customer needs through continuous improvement. It emphasizes quality in all aspects of an organization and empowering all employees. Key elements include ethics, training, teamwork and leadership. Successful TQM companies strive for customer and employee satisfaction through measurement, employee involvement, communication and continuous improvement.