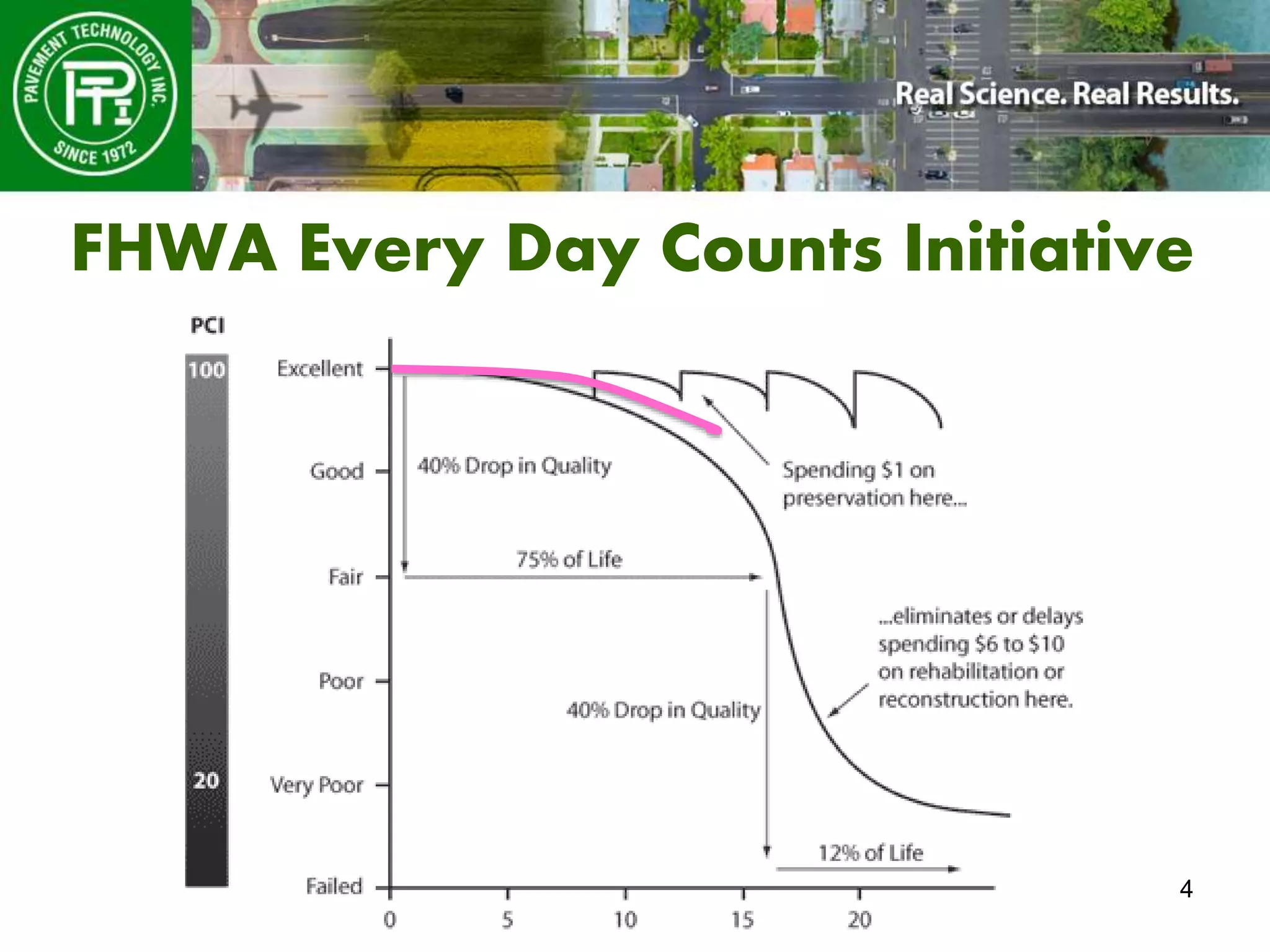

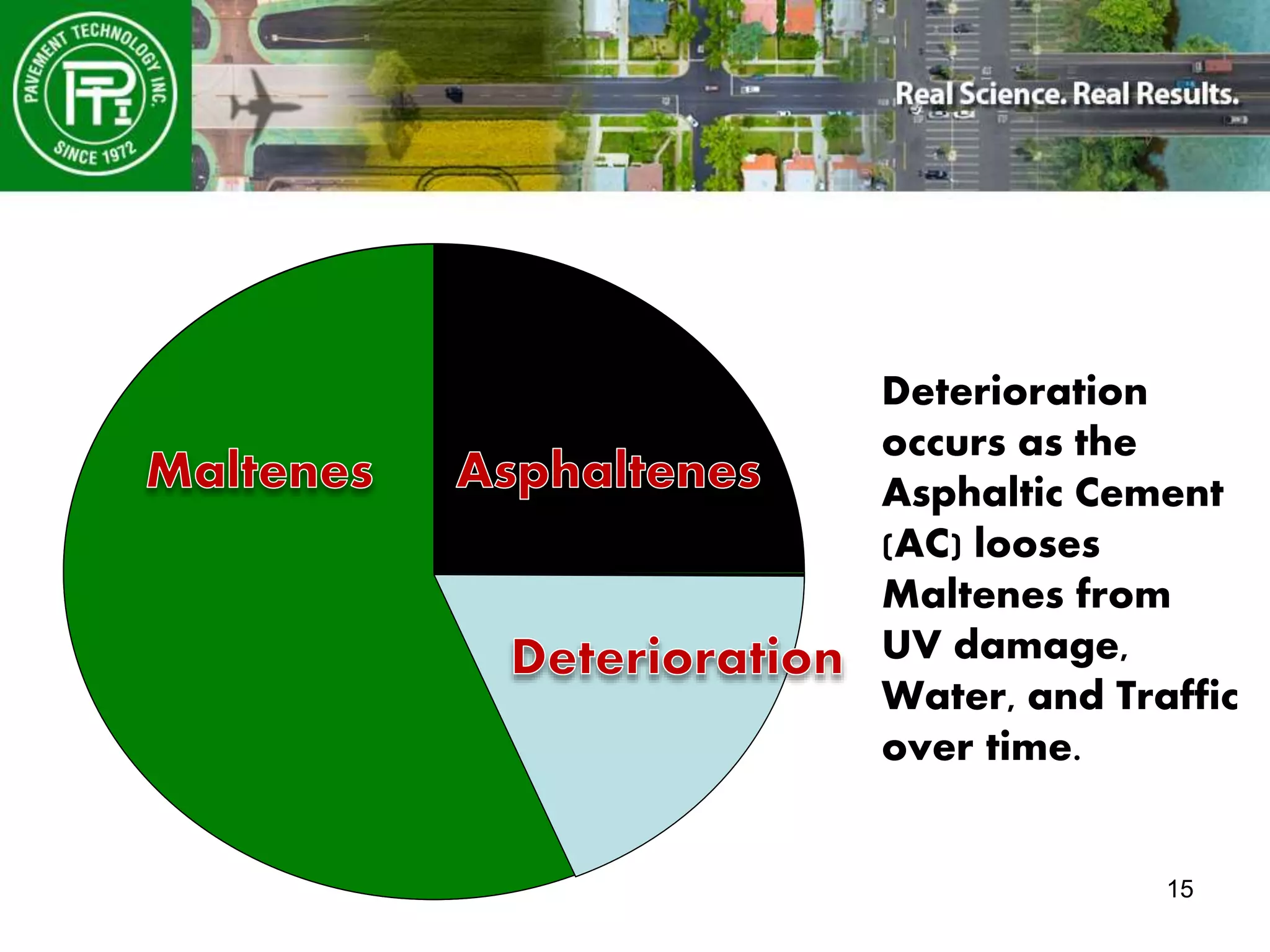

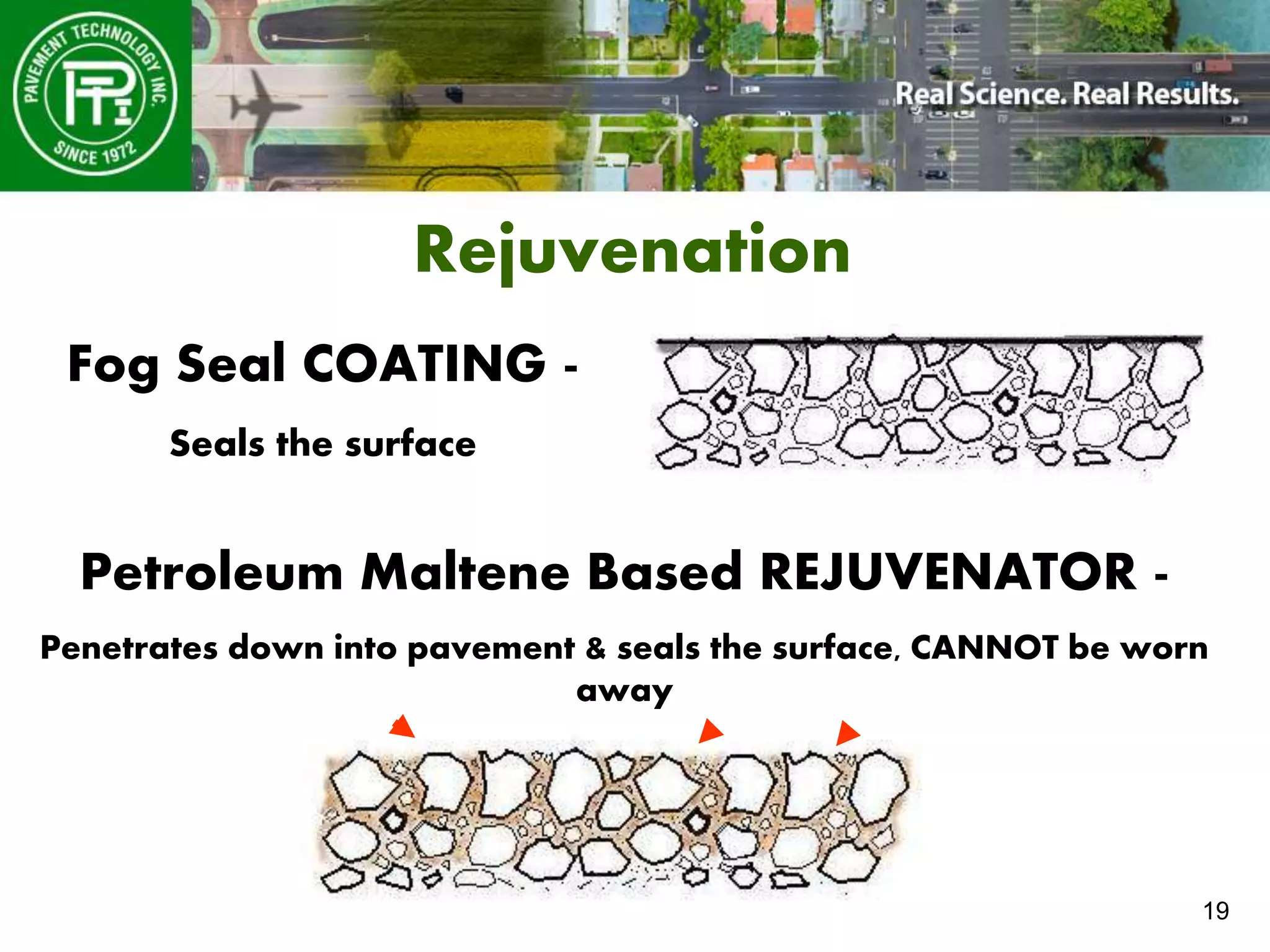

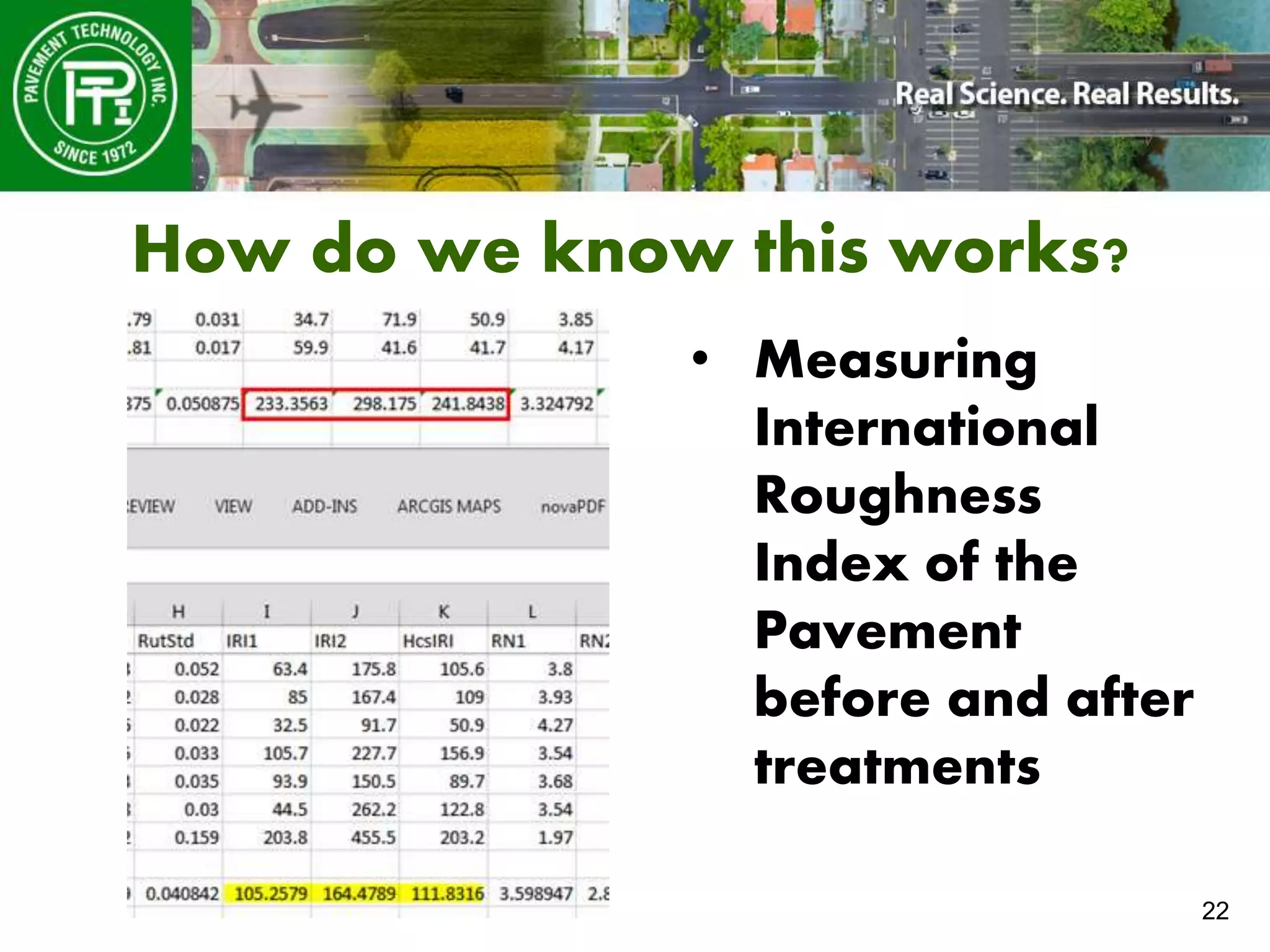

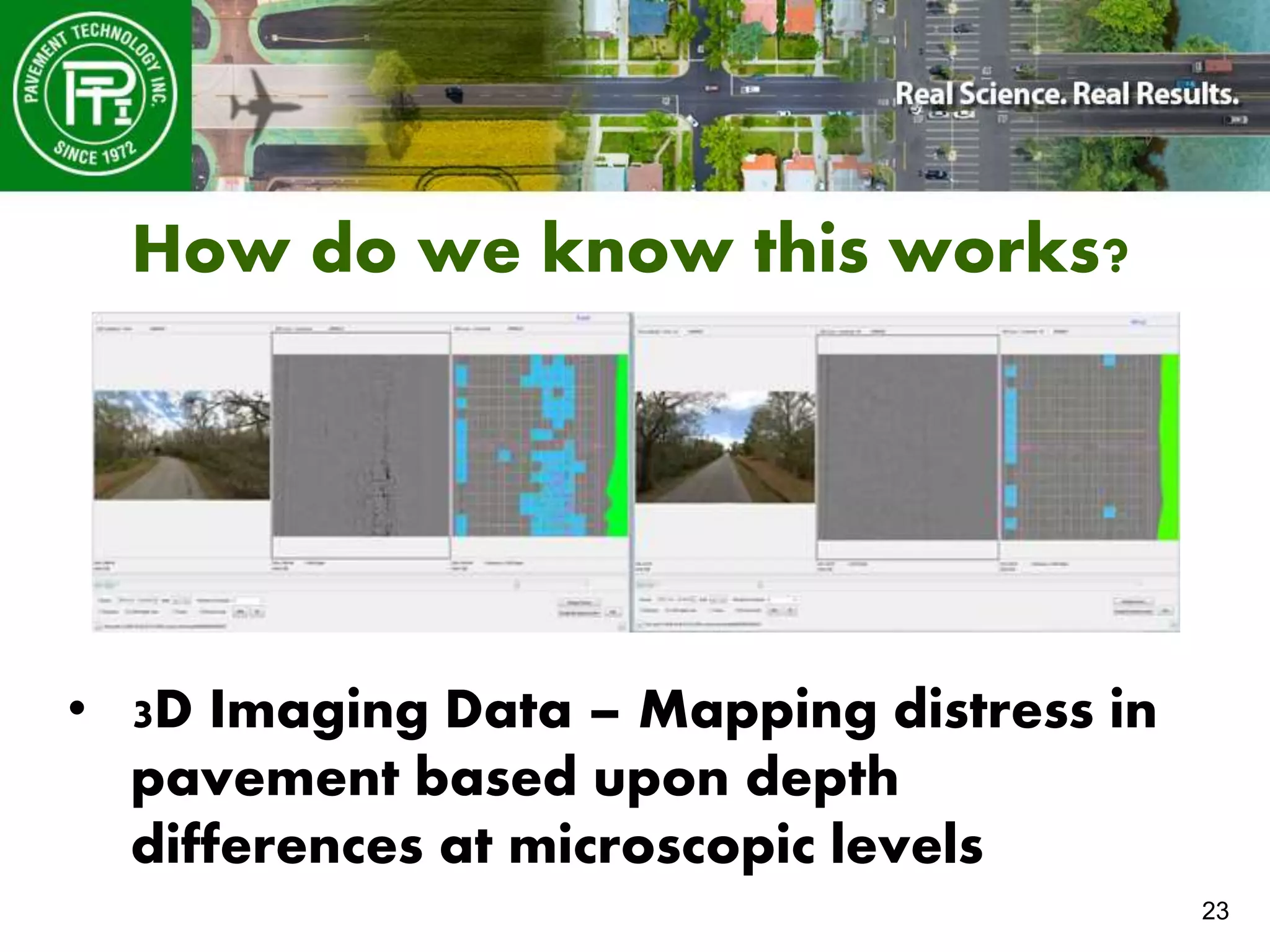

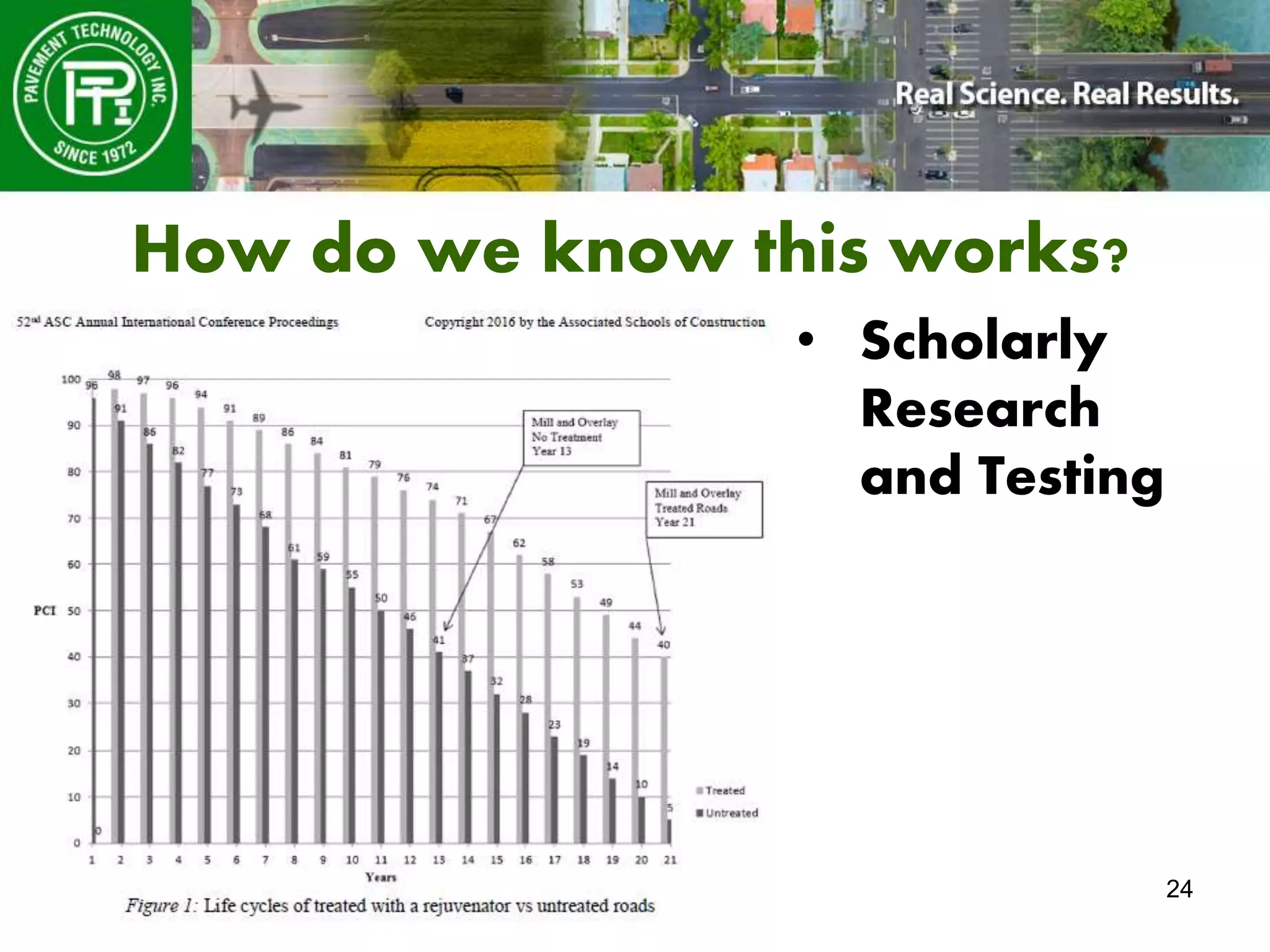

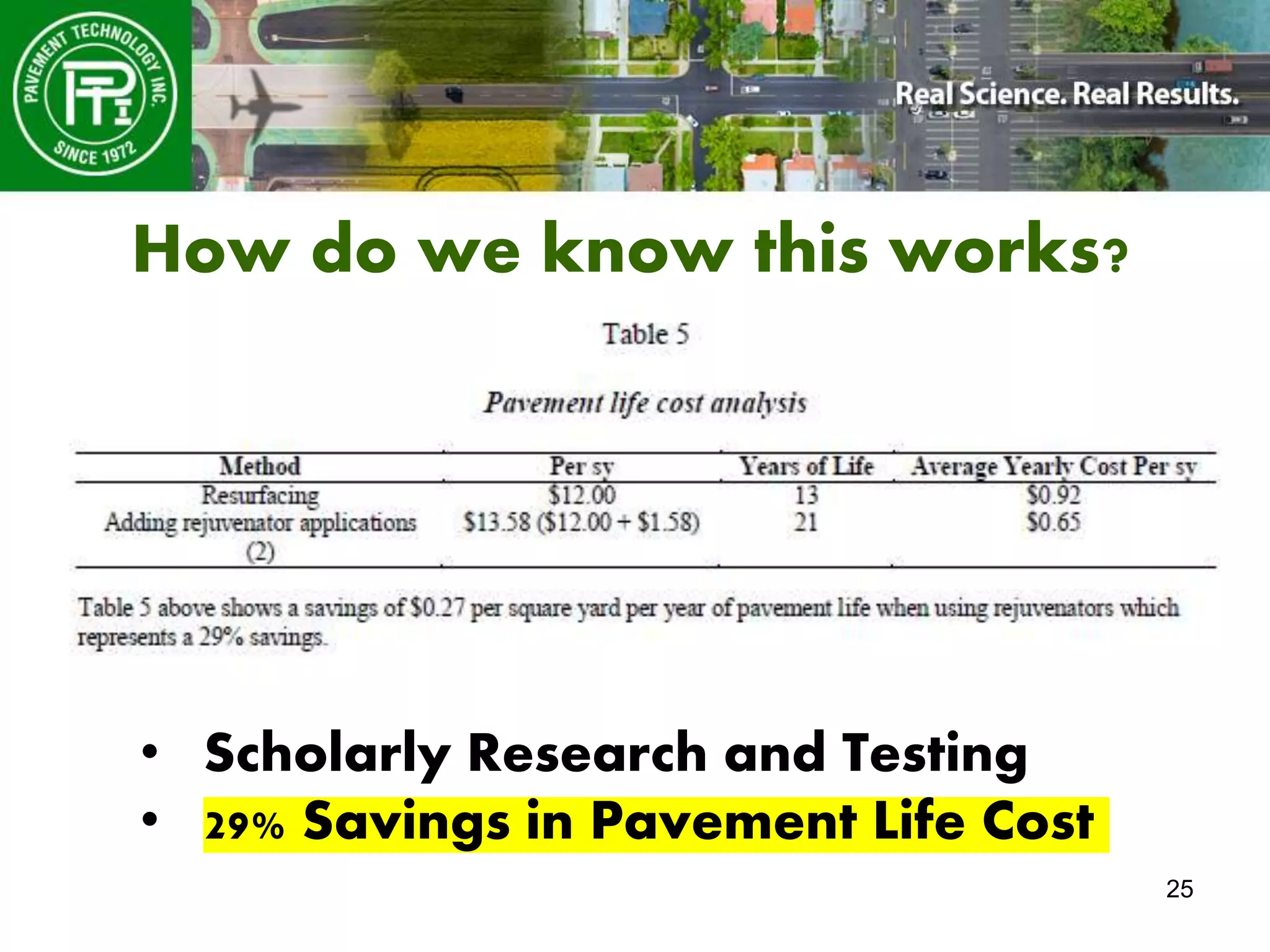

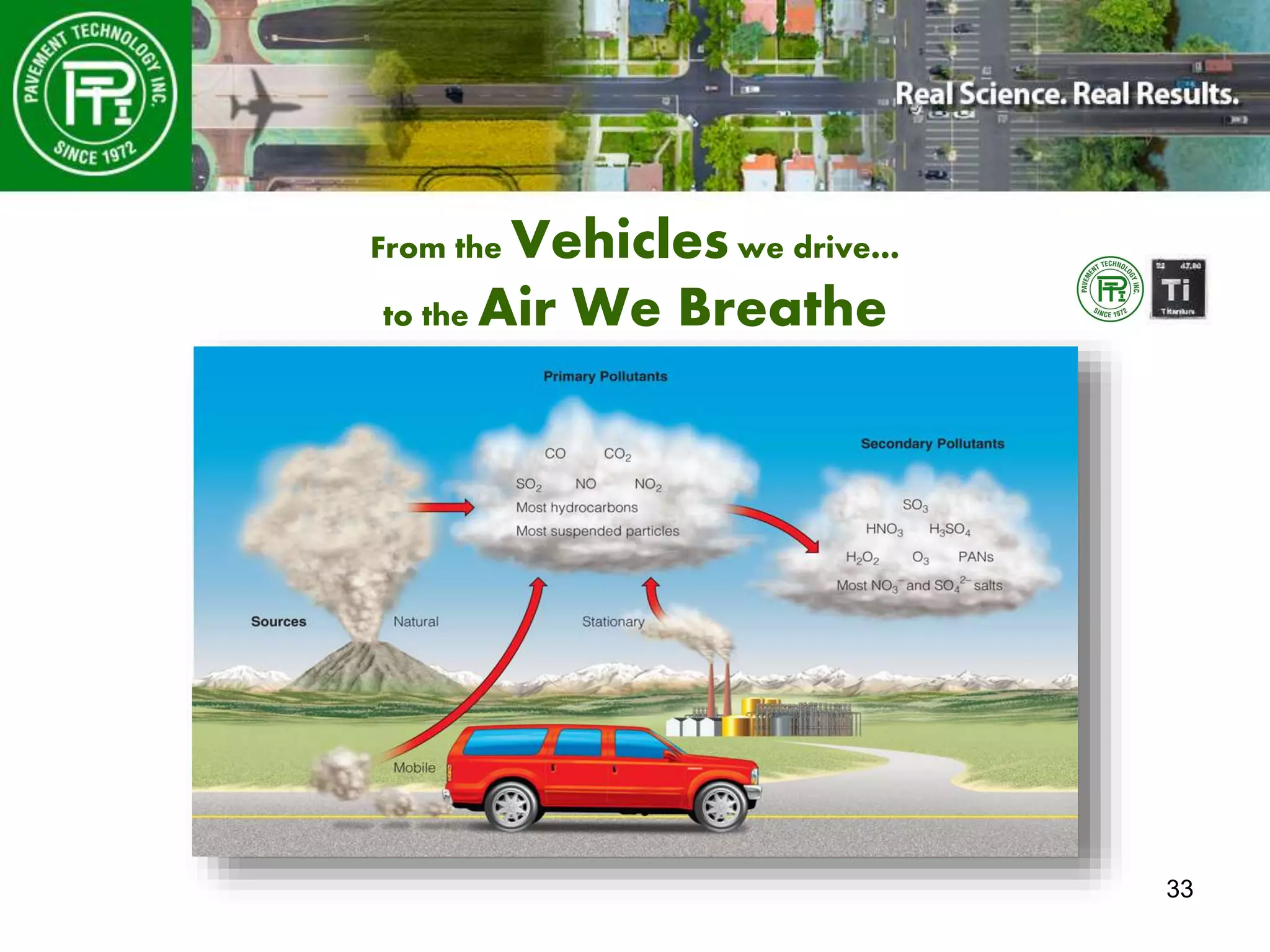

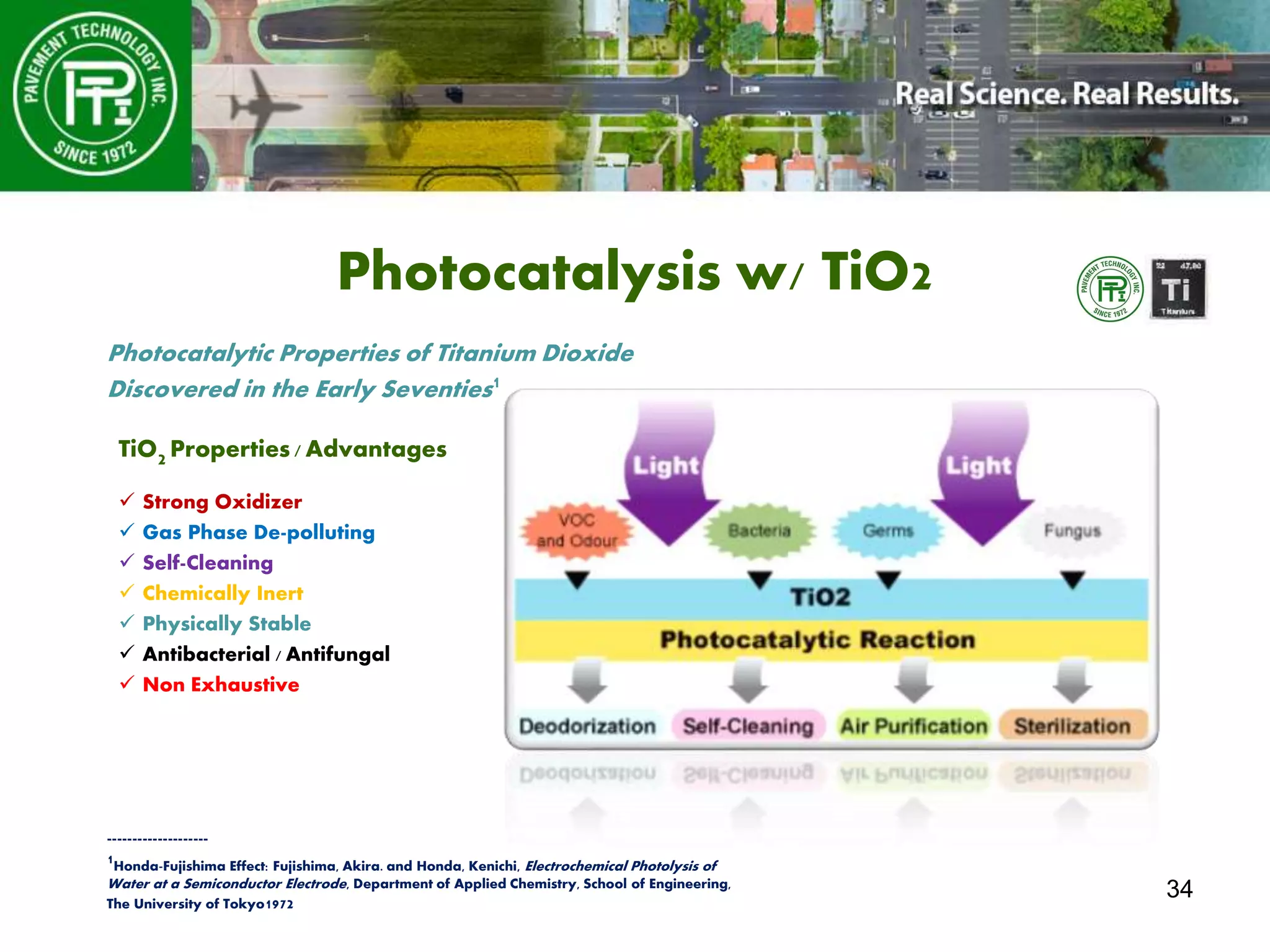

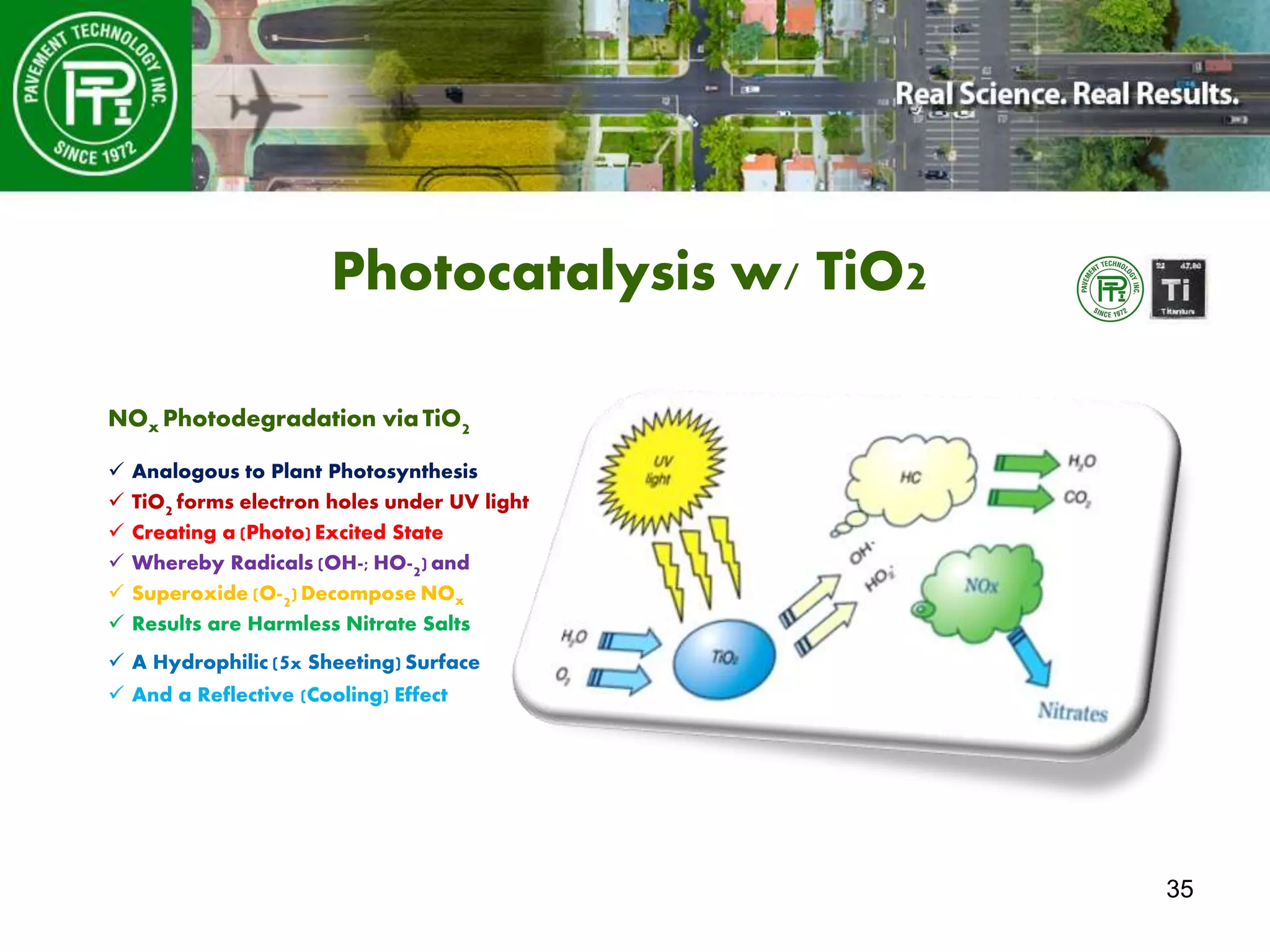

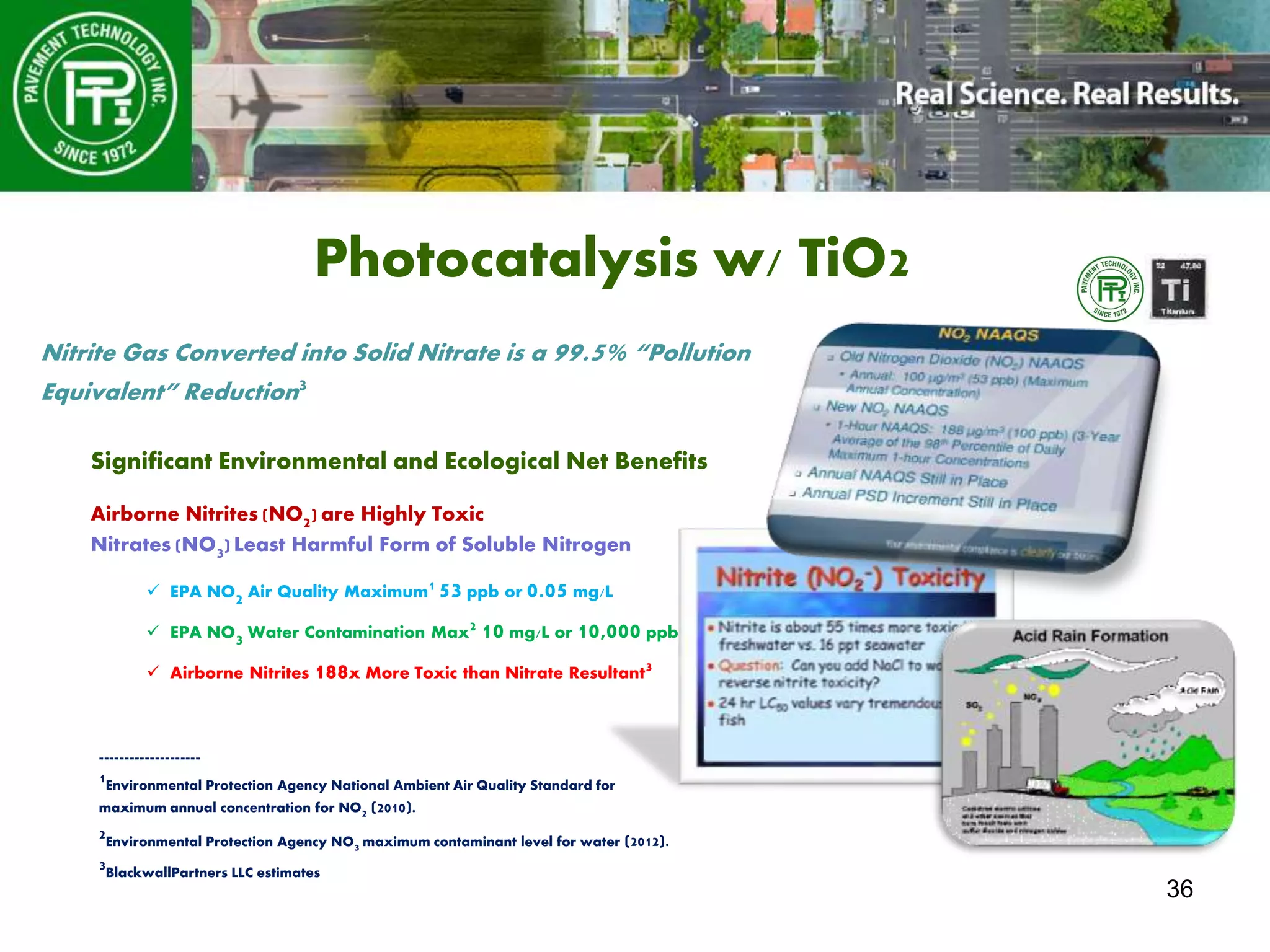

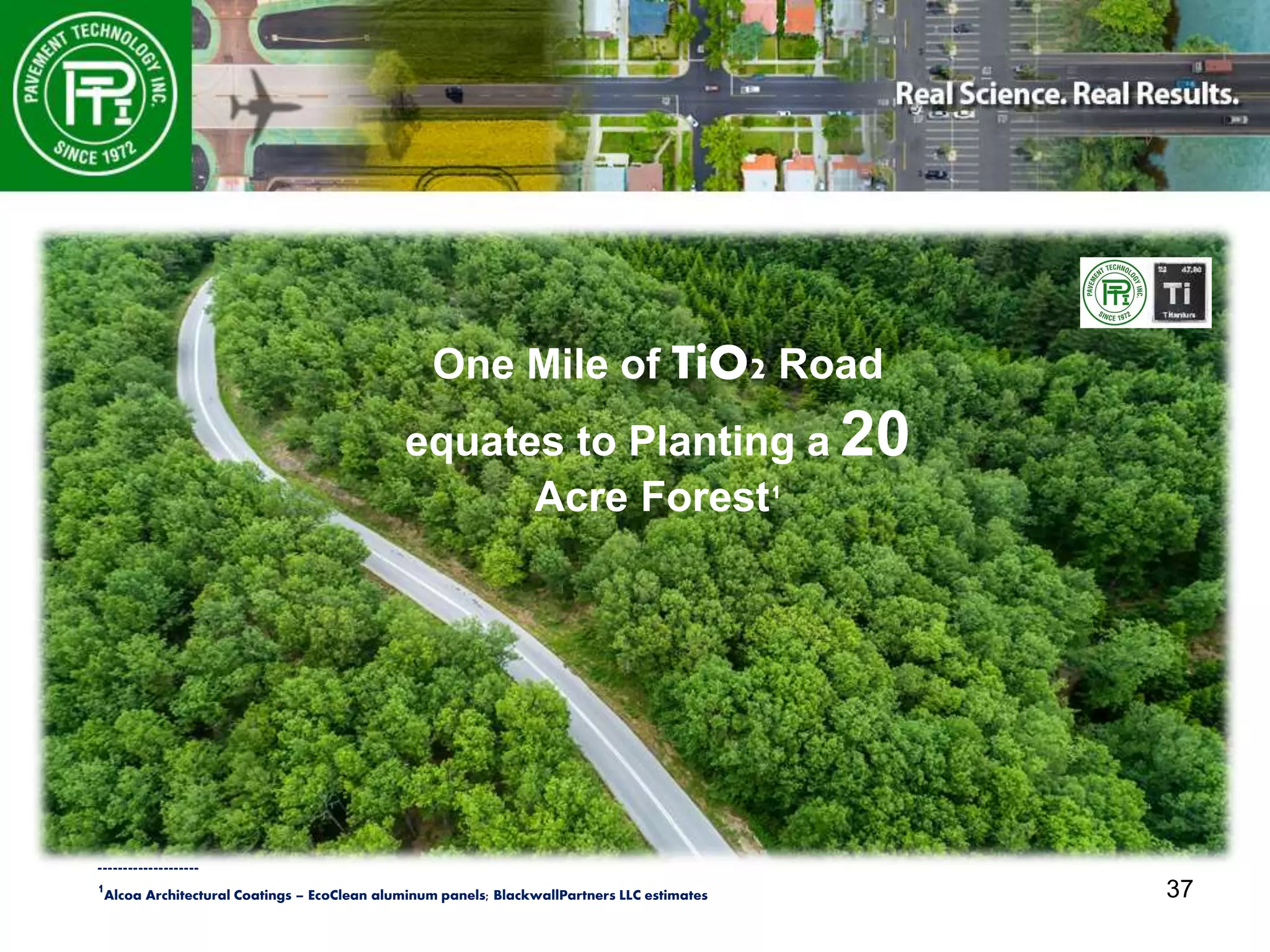

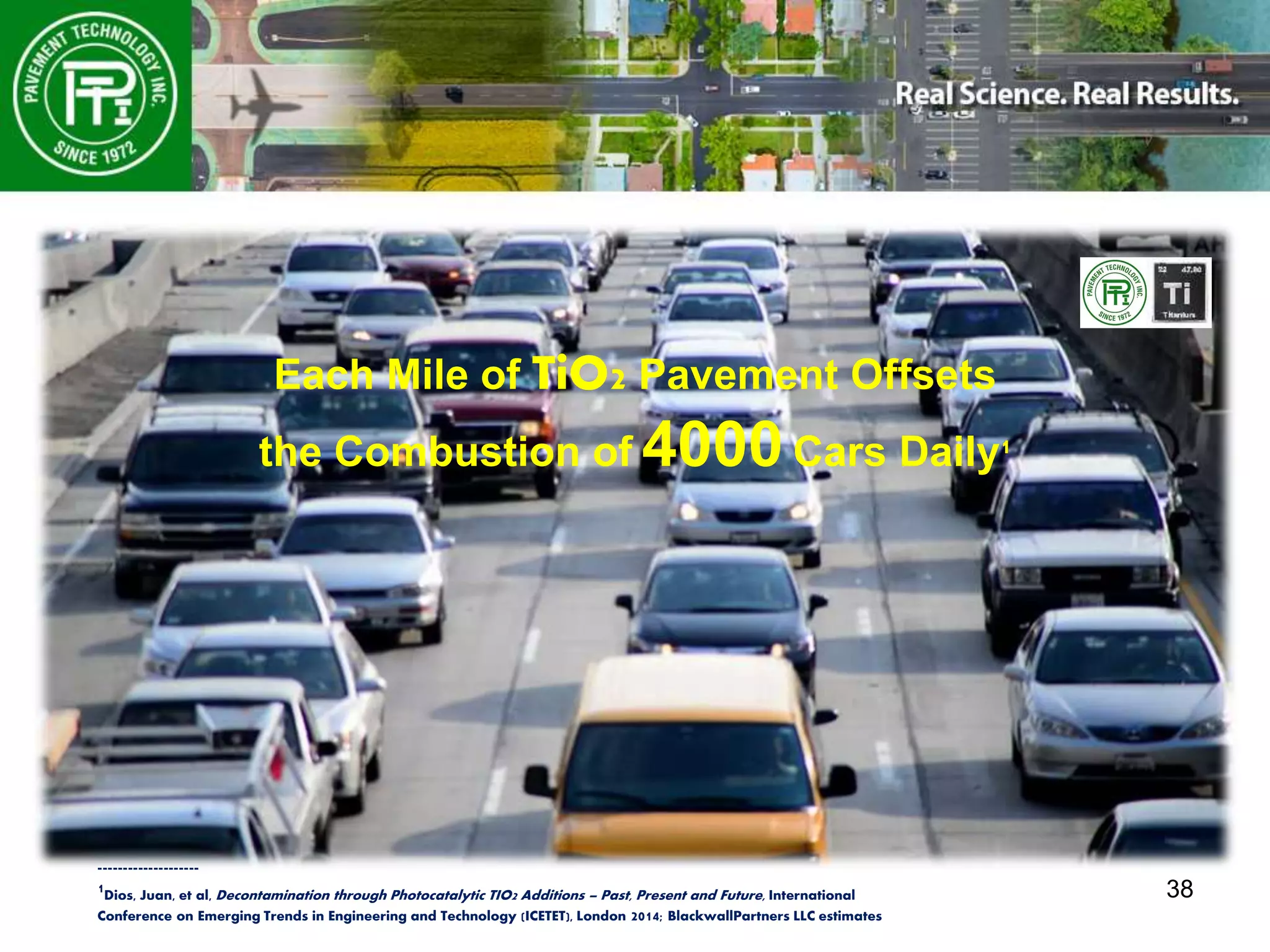

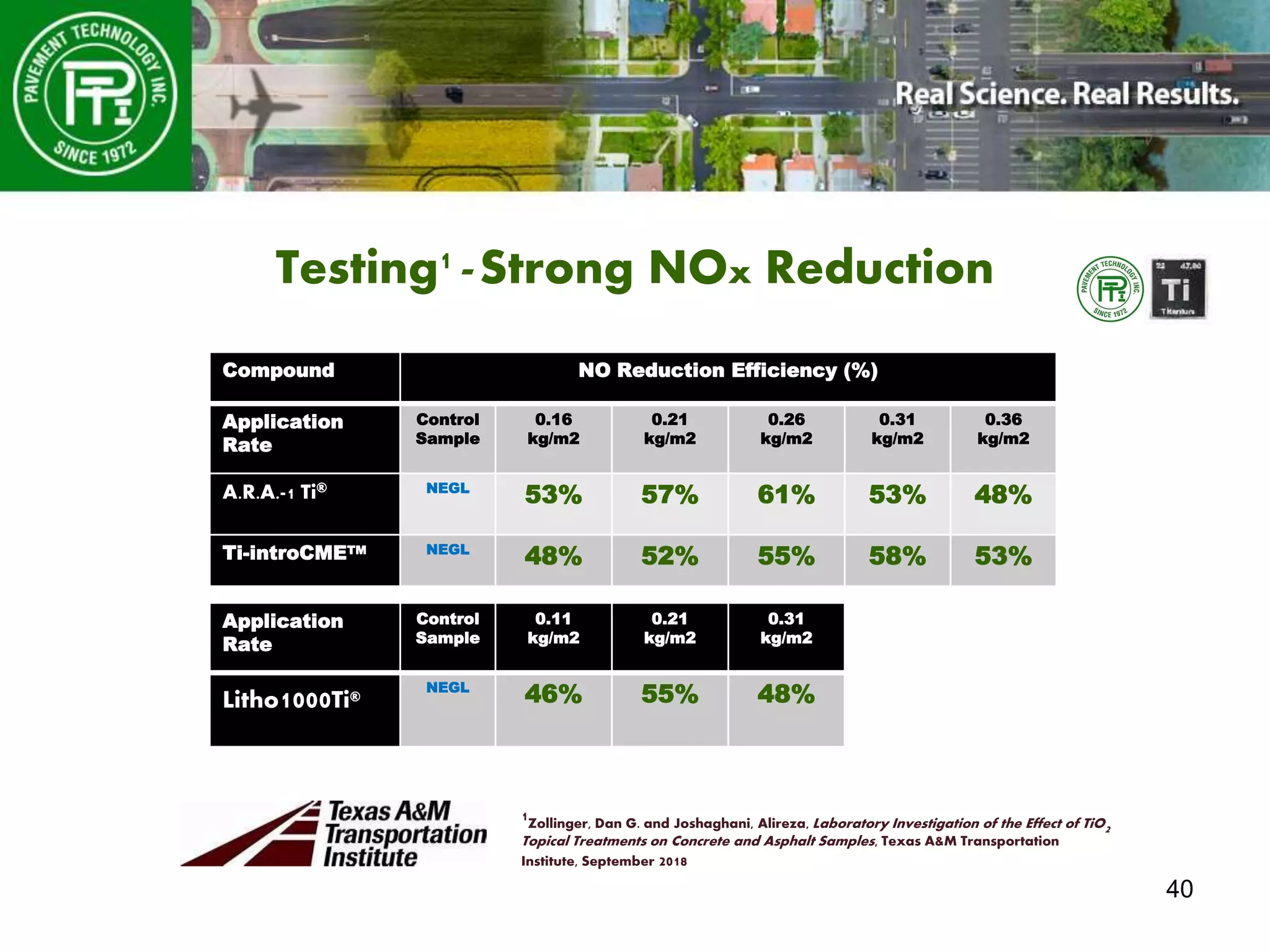

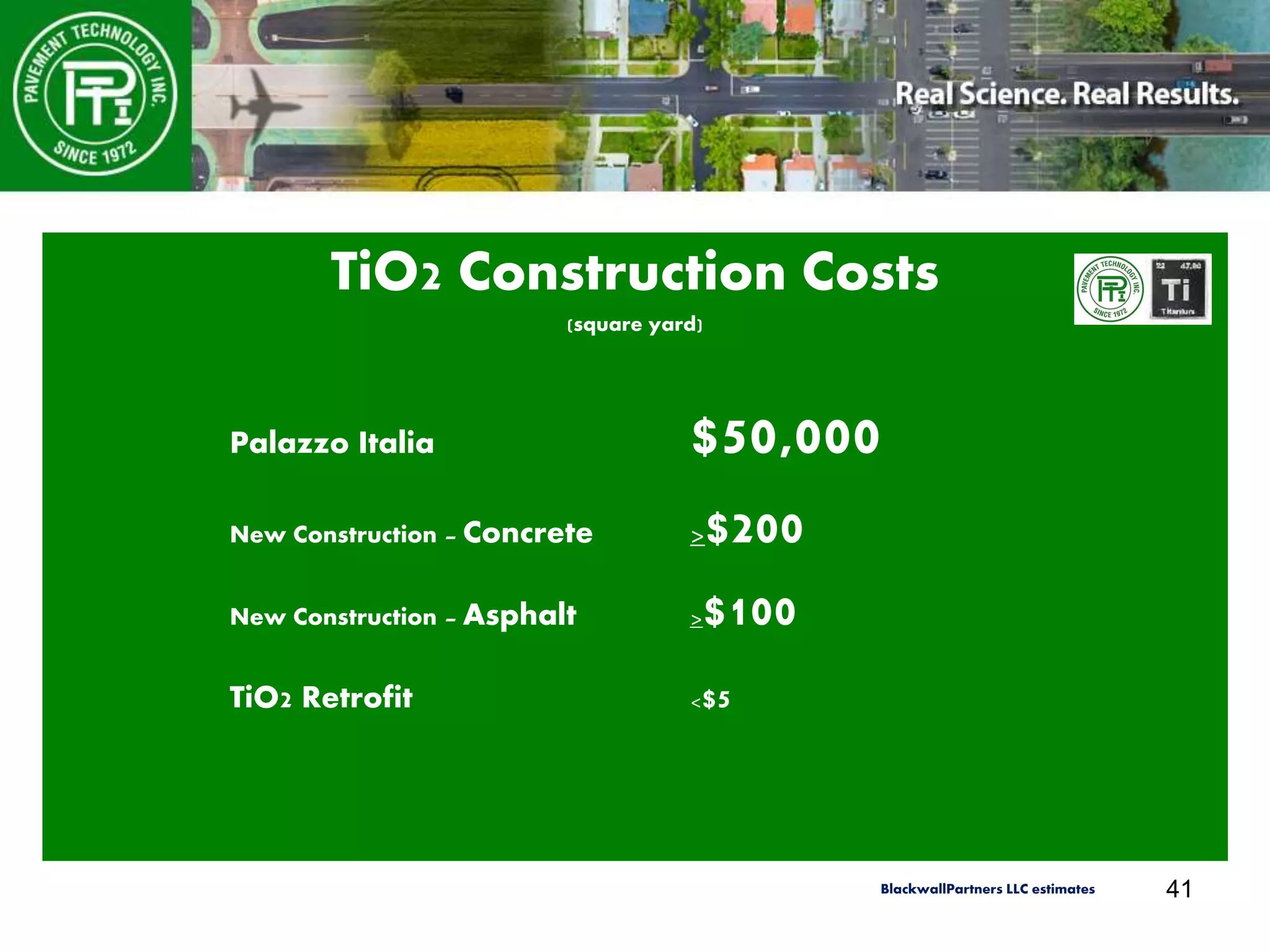

The document discusses asphalt preservation techniques, focusing on rejuvenators that extend pavement life and enhance safety while being cost-effective. It highlights the importance of maltenes in asphalt and techniques to replace them to limit deterioration, alongside methods for evaluating the effectiveness of rejuvenators. The potential environmental benefits of photocatalytic materials, such as titanium dioxide, for air pollution mitigation are also explored.