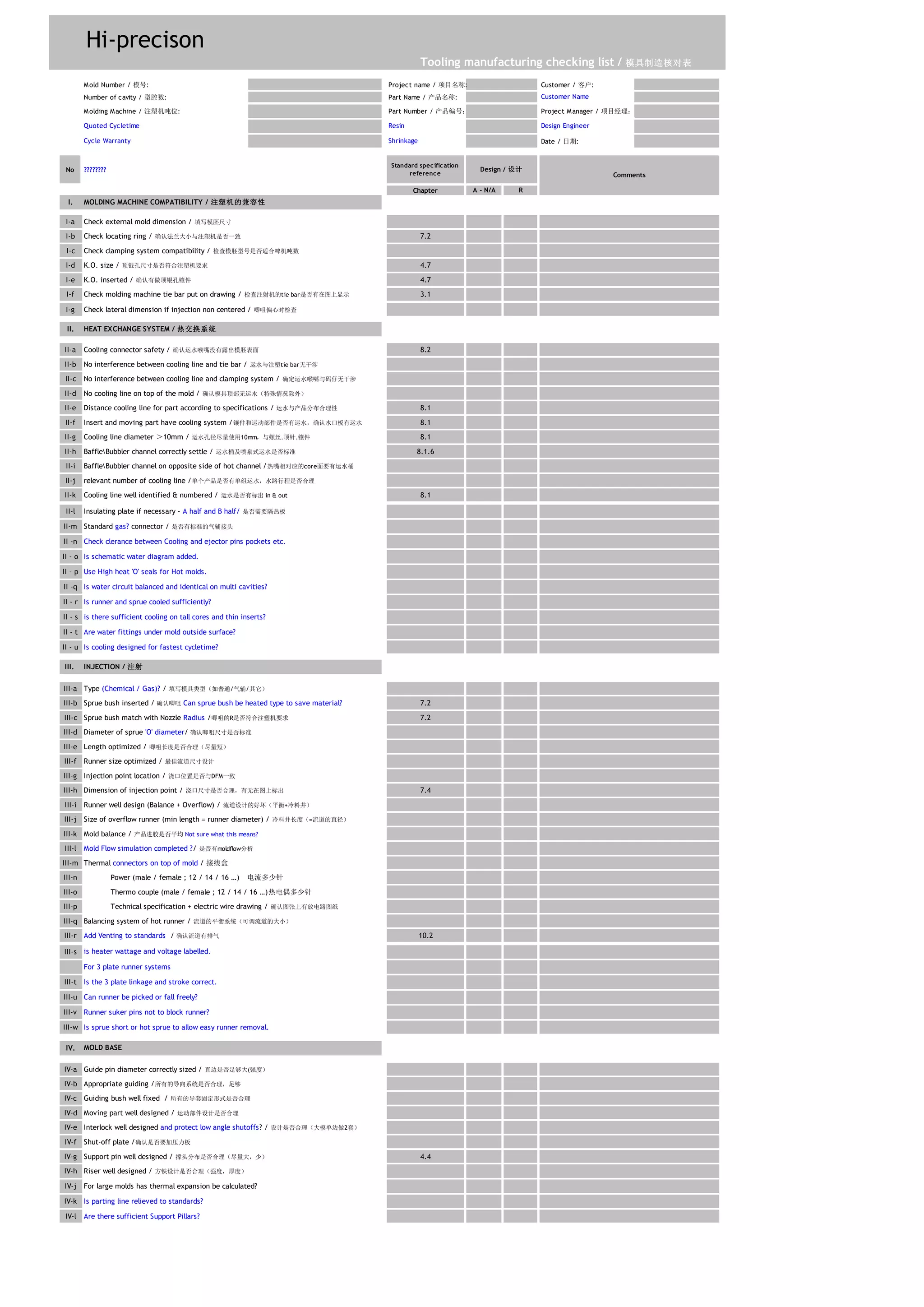

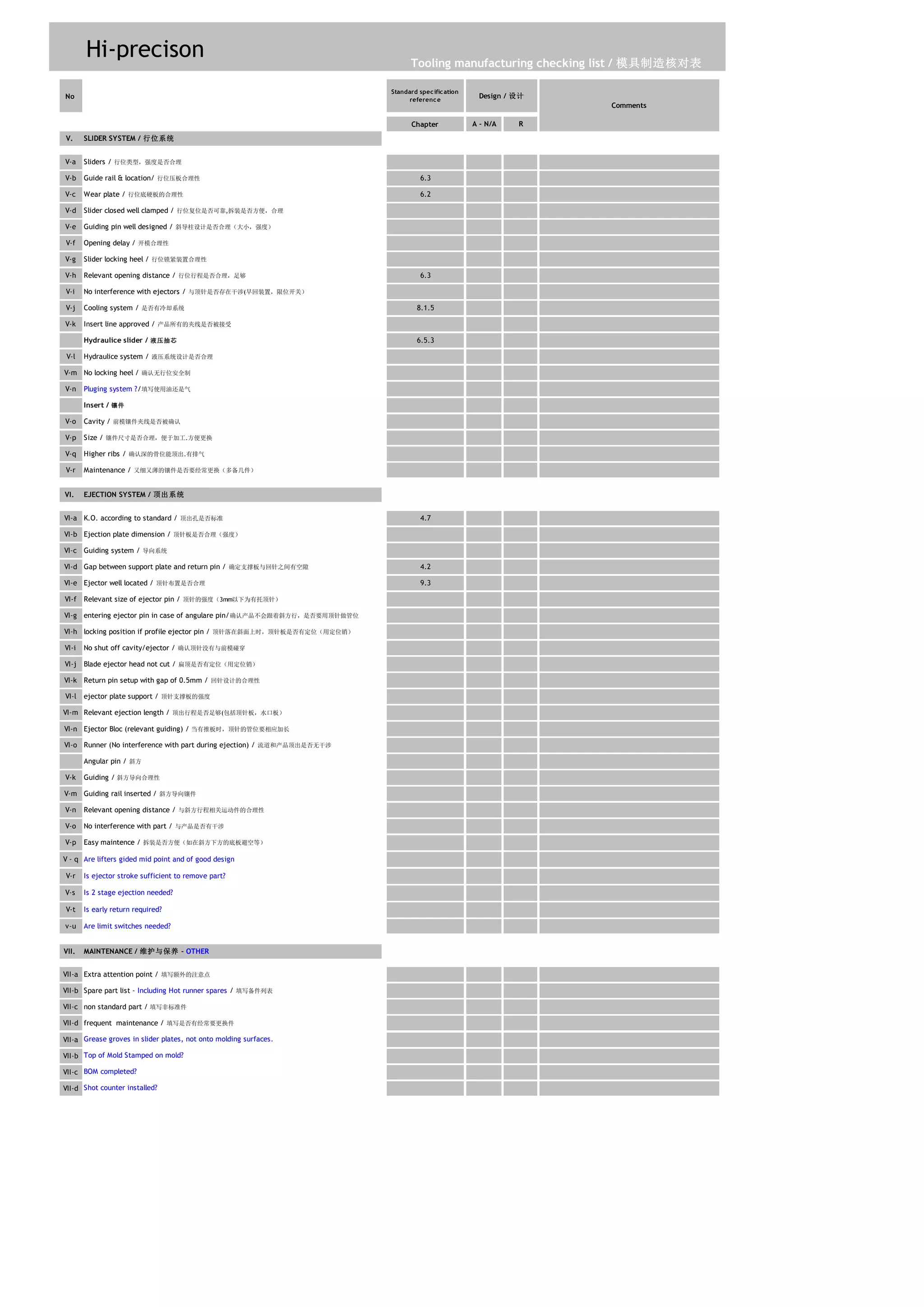

This document contains a checklist for reviewing the design of an injection molding tool. It includes sections on mold components like the cavity, cores, ejection system, cooling system, and more. For each component, it lists design requirements and considerations to ensure quality, manufacturability and performance of the tool. The overall checklist aims to capture all relevant aspects of the mold design to obtain design approval.