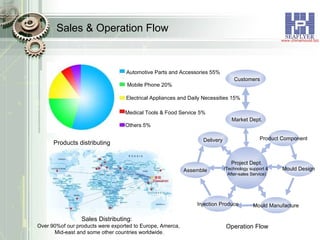

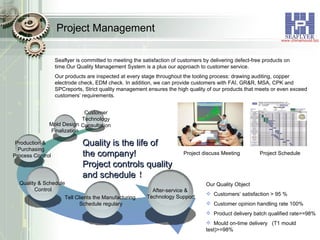

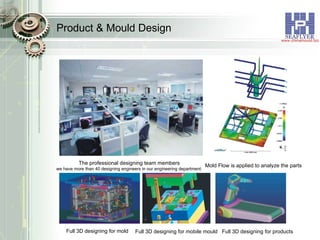

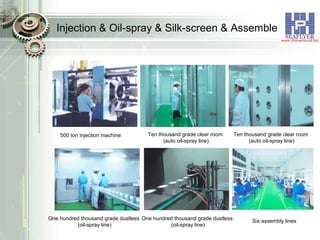

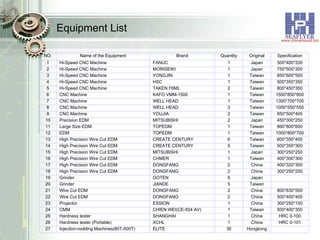

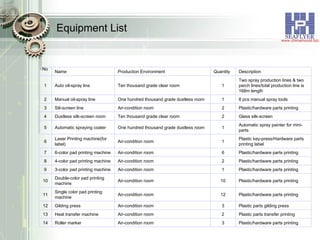

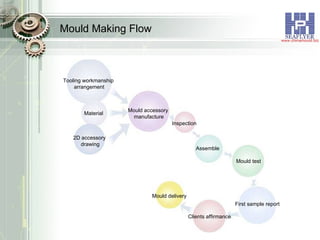

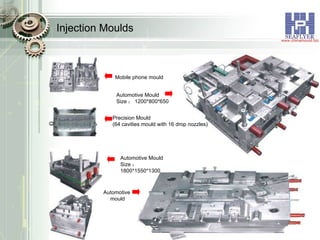

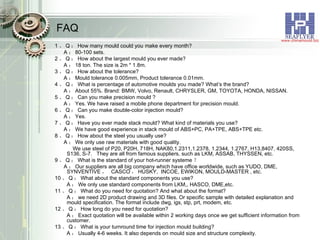

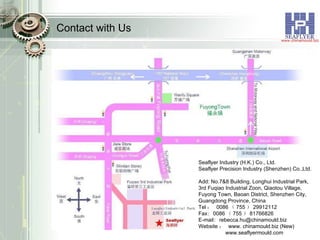

The document provides information about Seaflyer Precision Industry (Shenzhen) Co., Ltd., including its establishment, facilities, equipment, certifications, products, clients, and capabilities. Seaflyer has 800 staff including 300 engineers, and facilities covering 10,000 square meters. It focuses on injection molding and has advanced CNC, EDM, and other machining equipment.