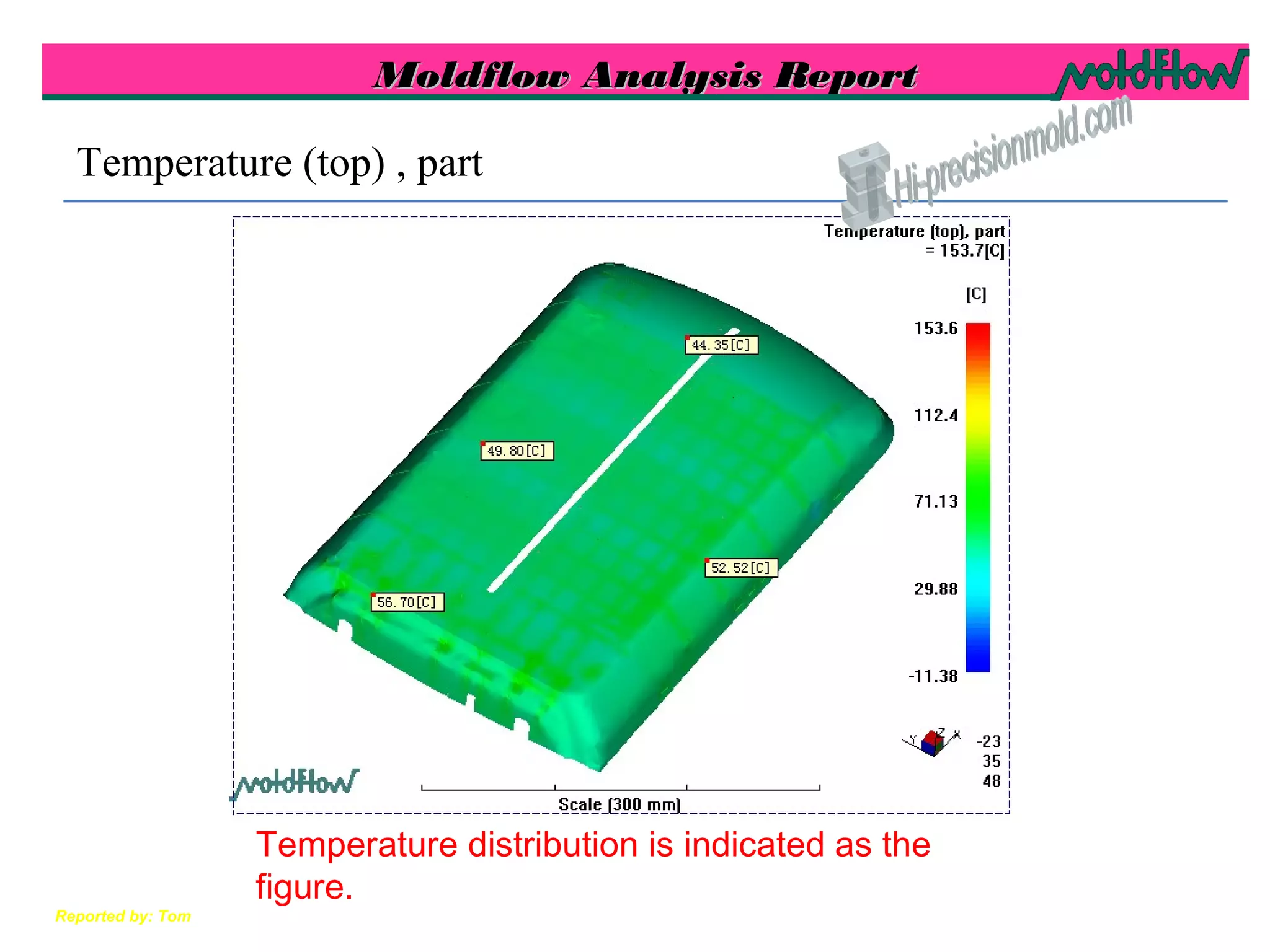

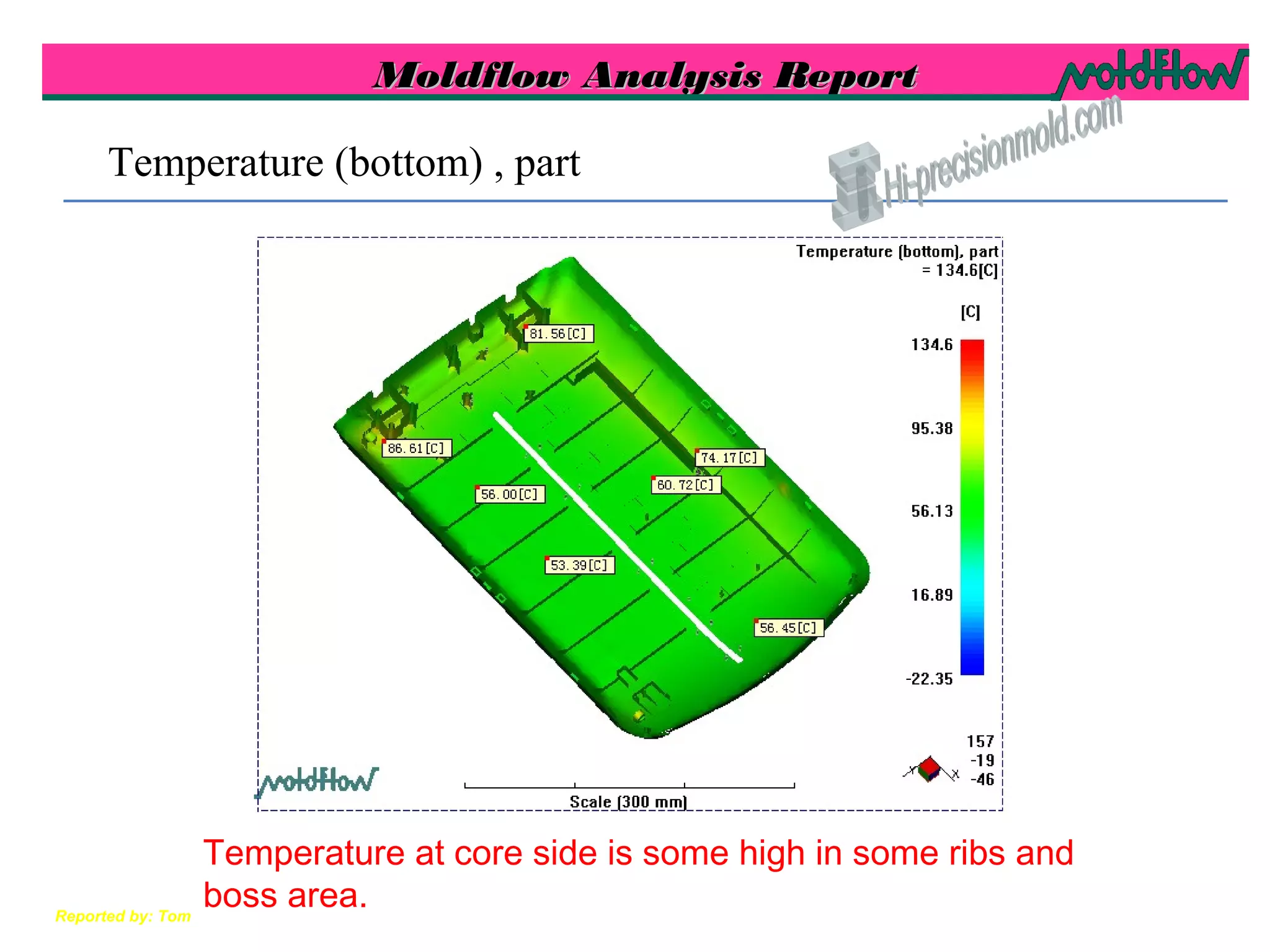

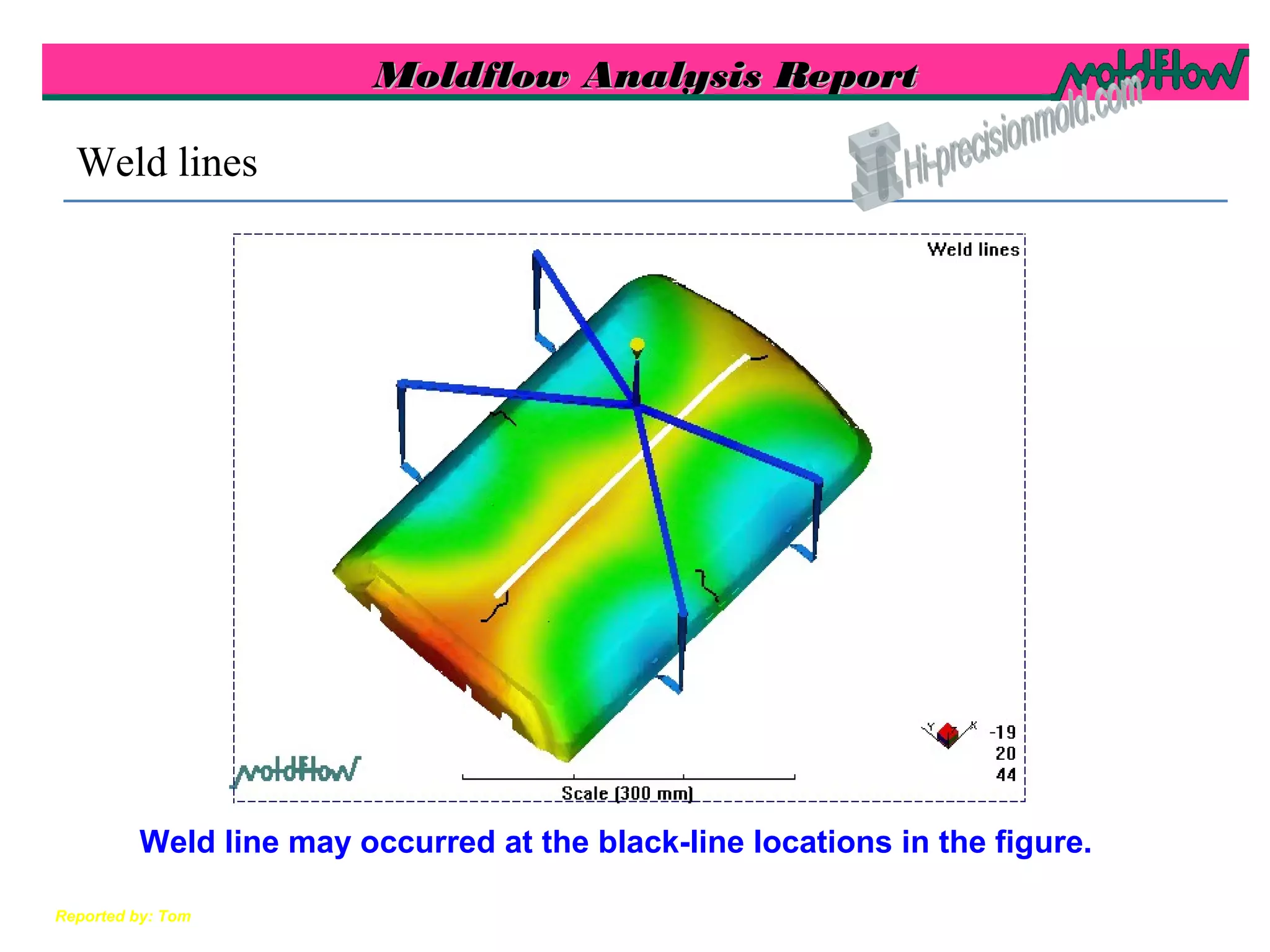

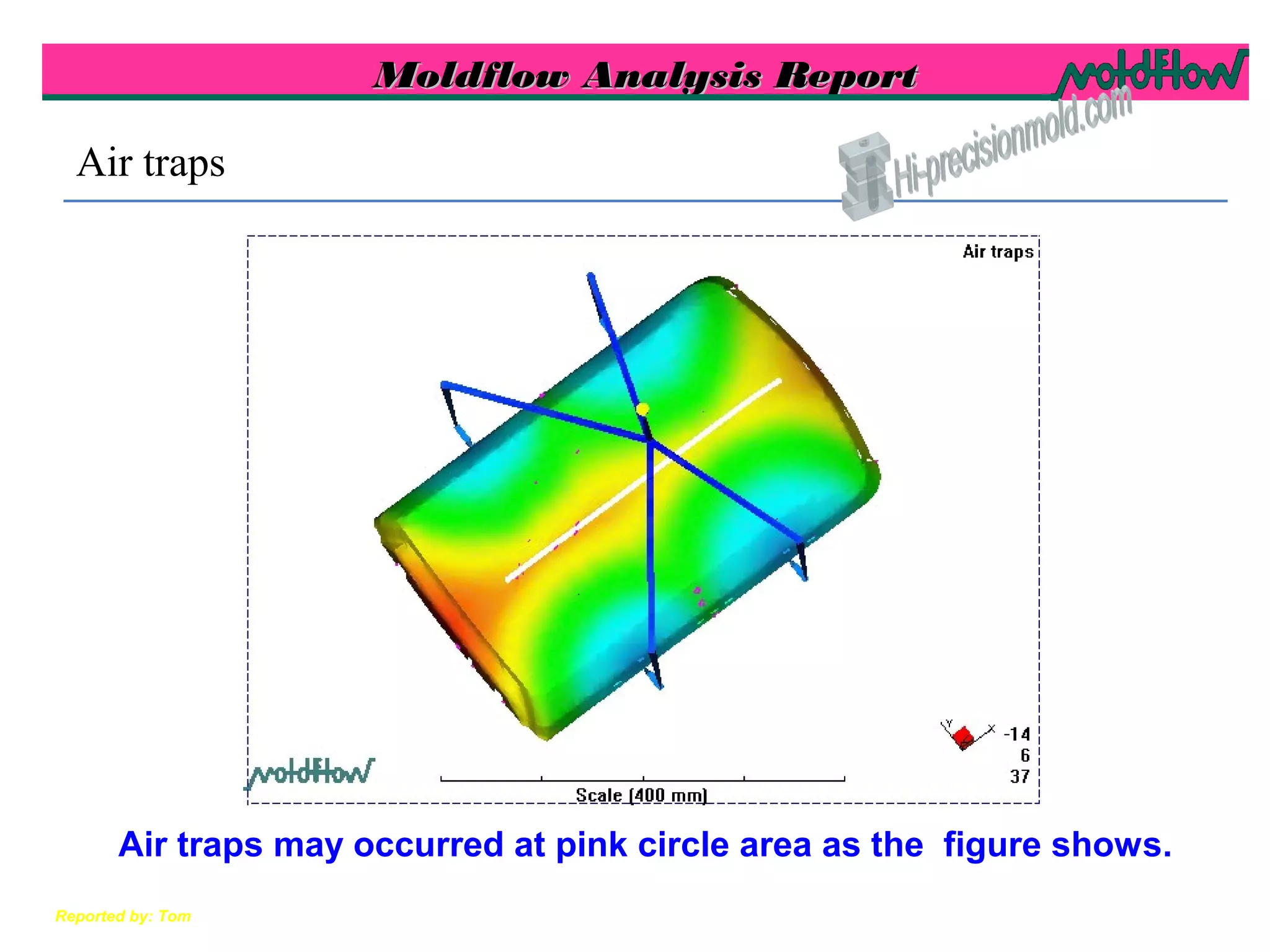

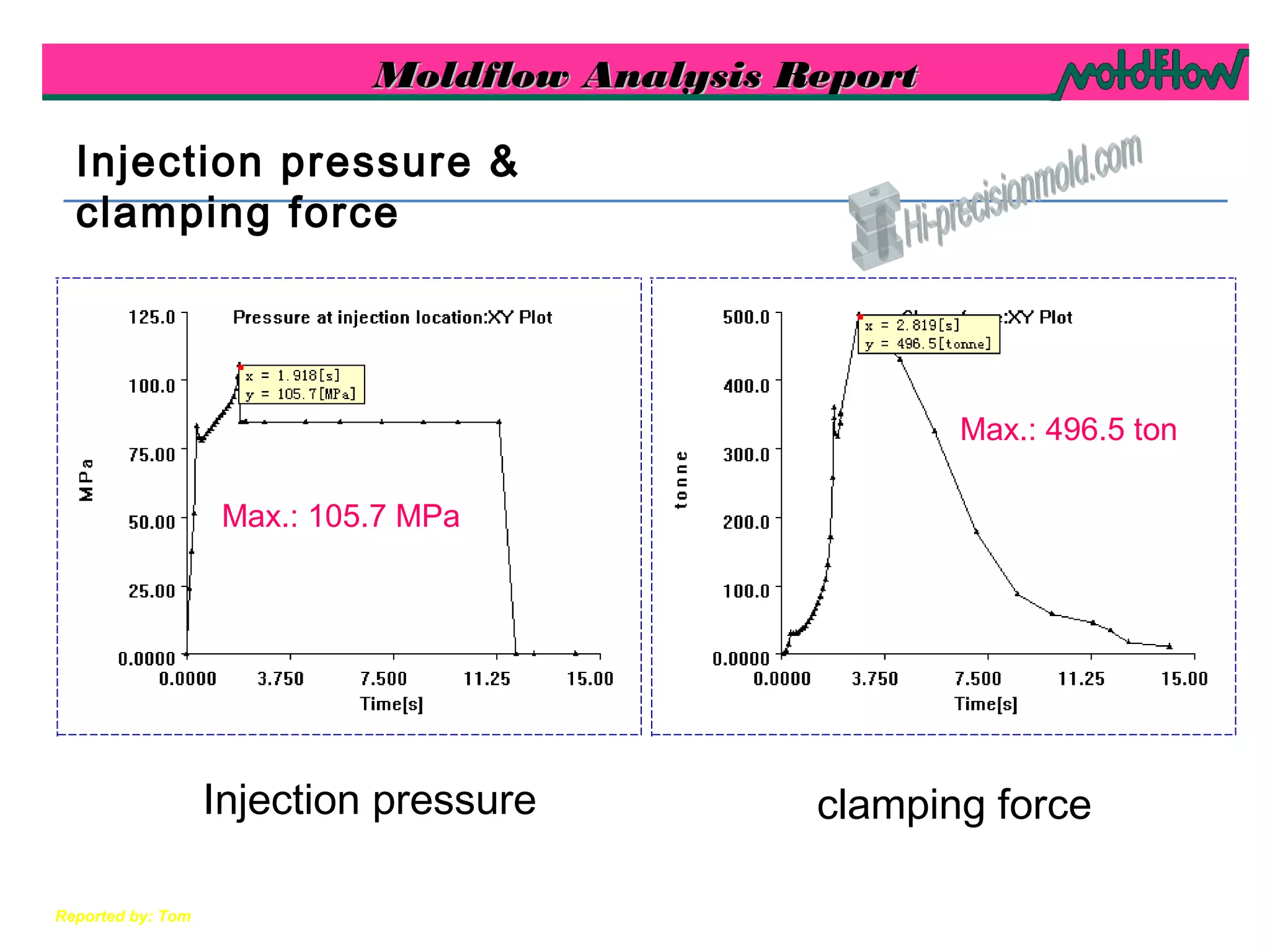

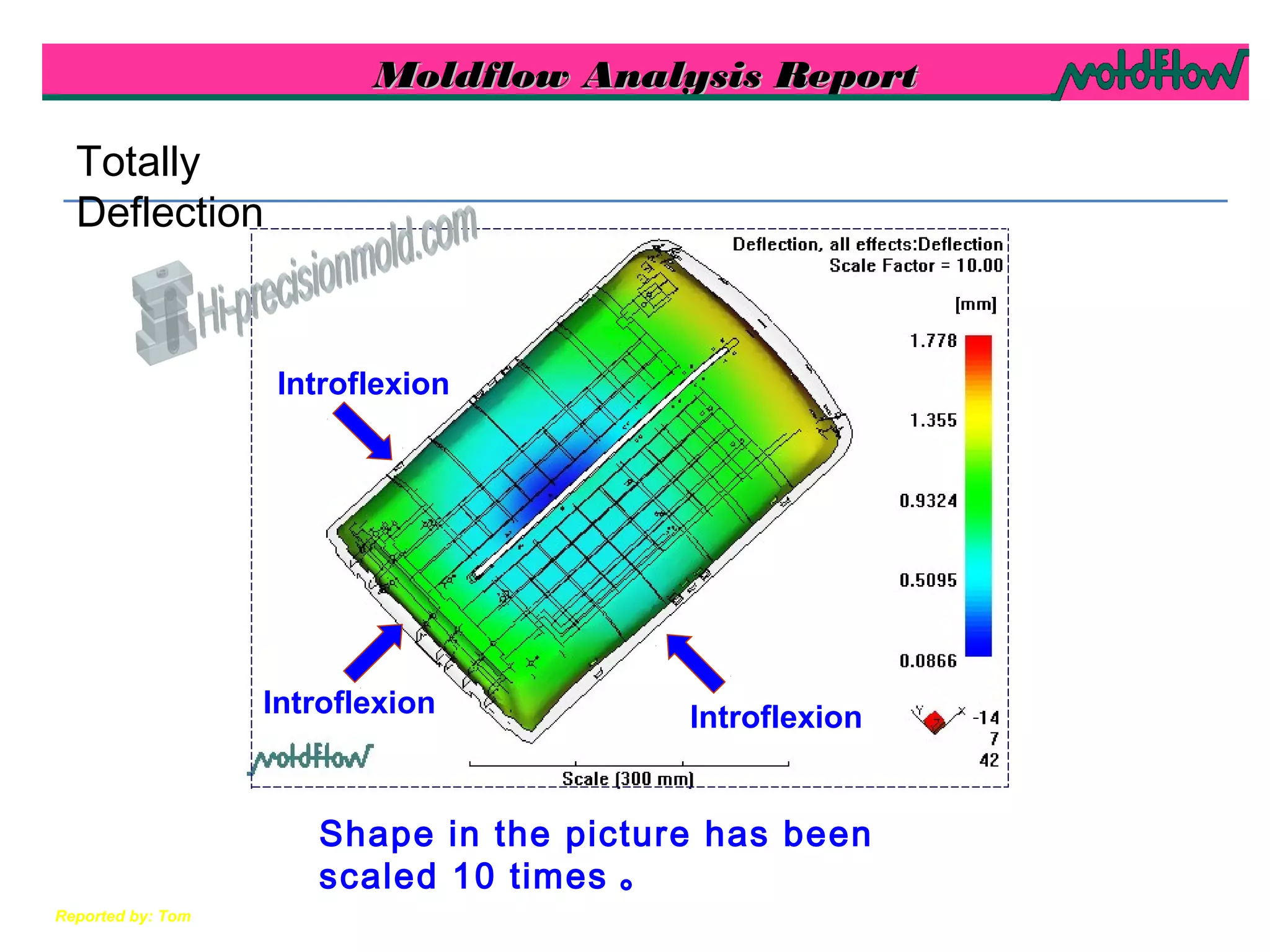

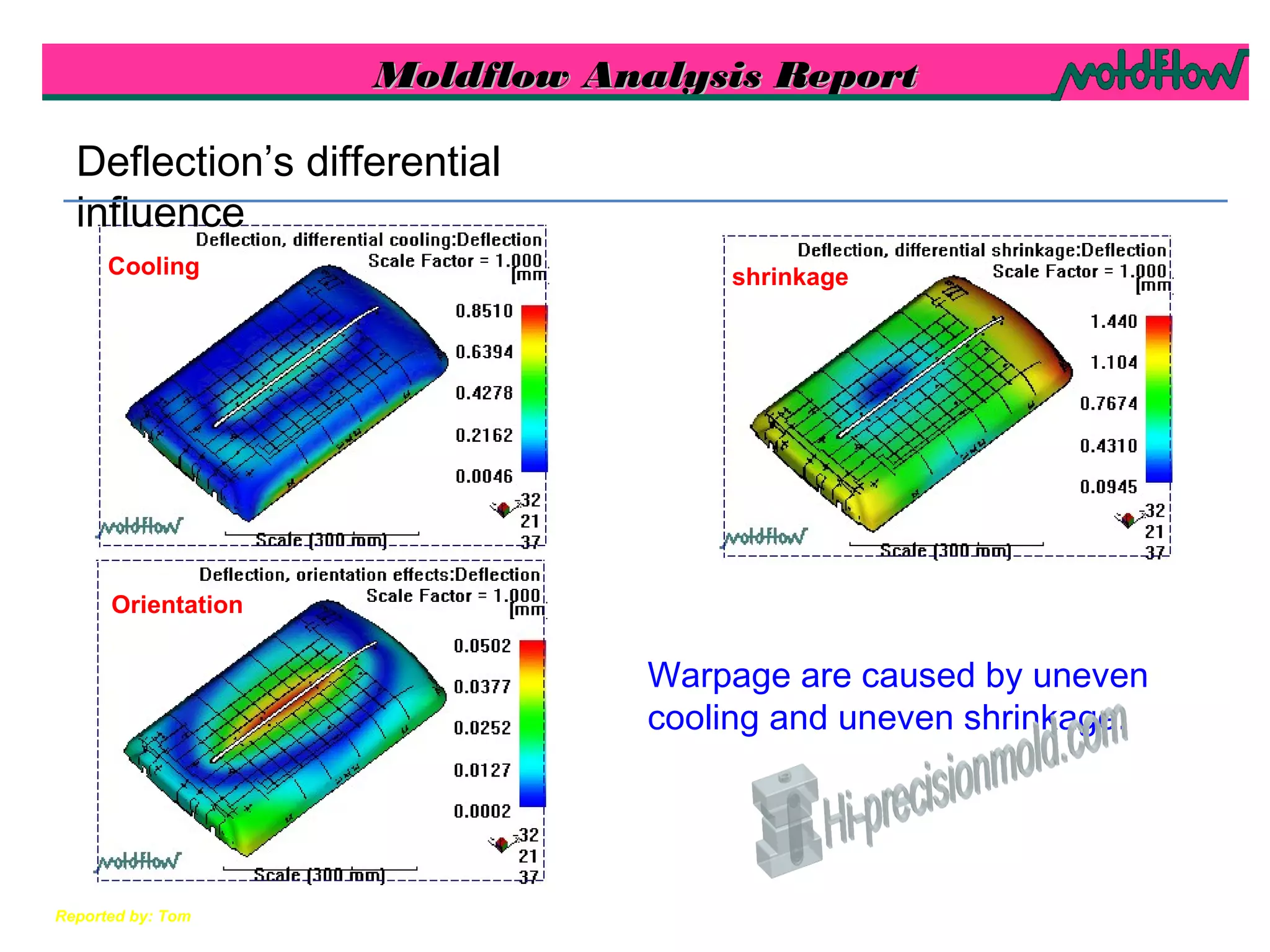

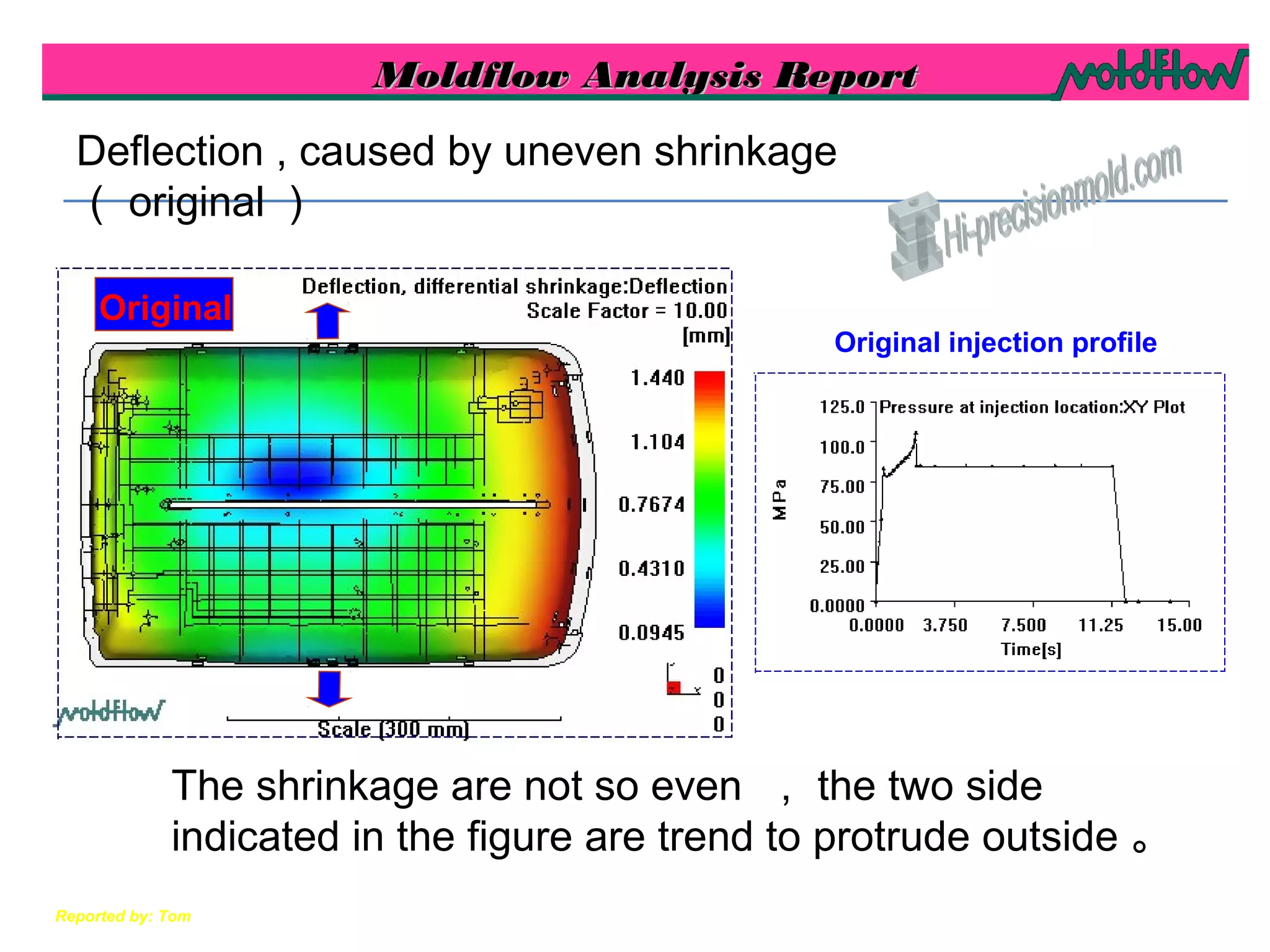

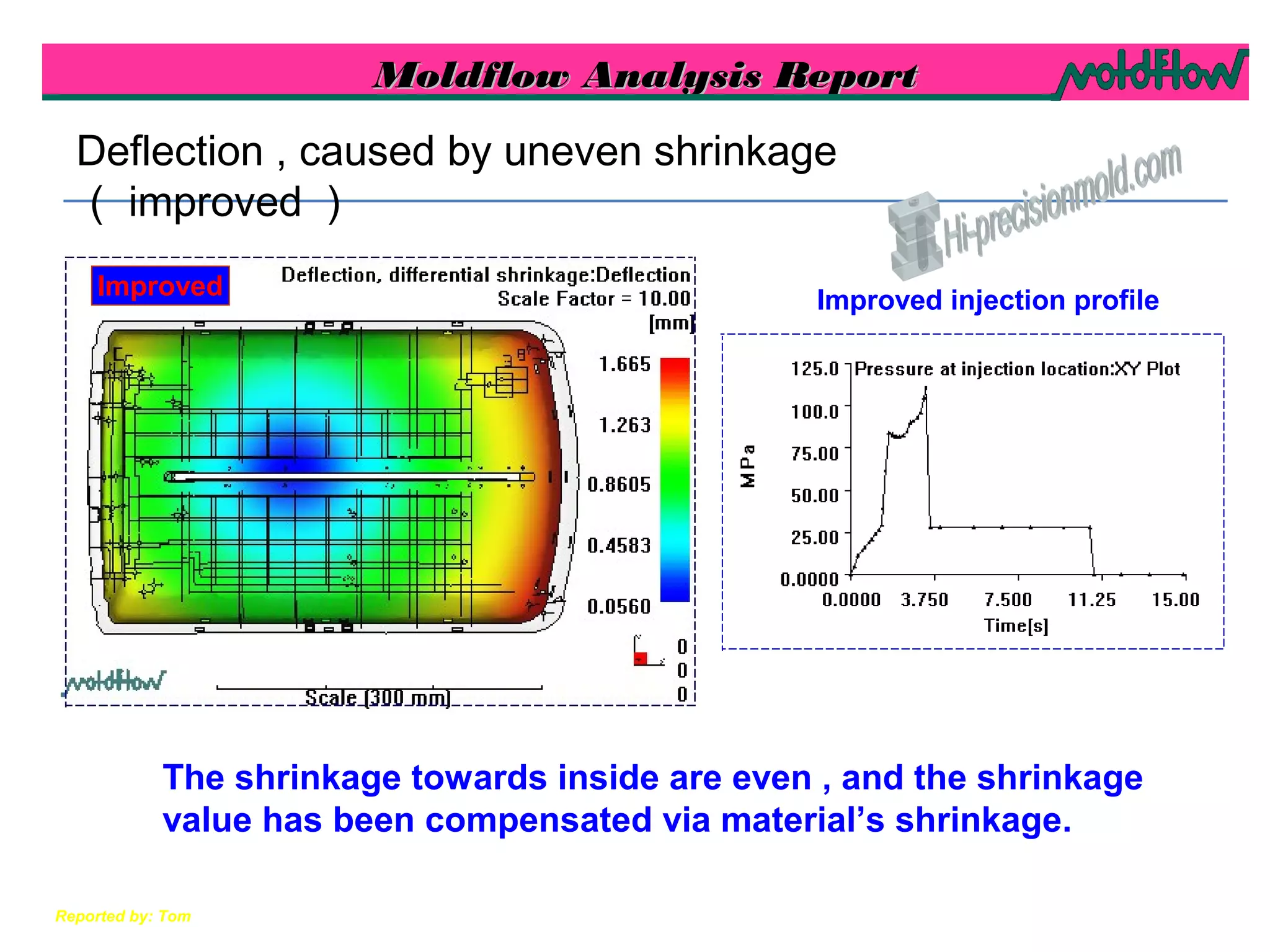

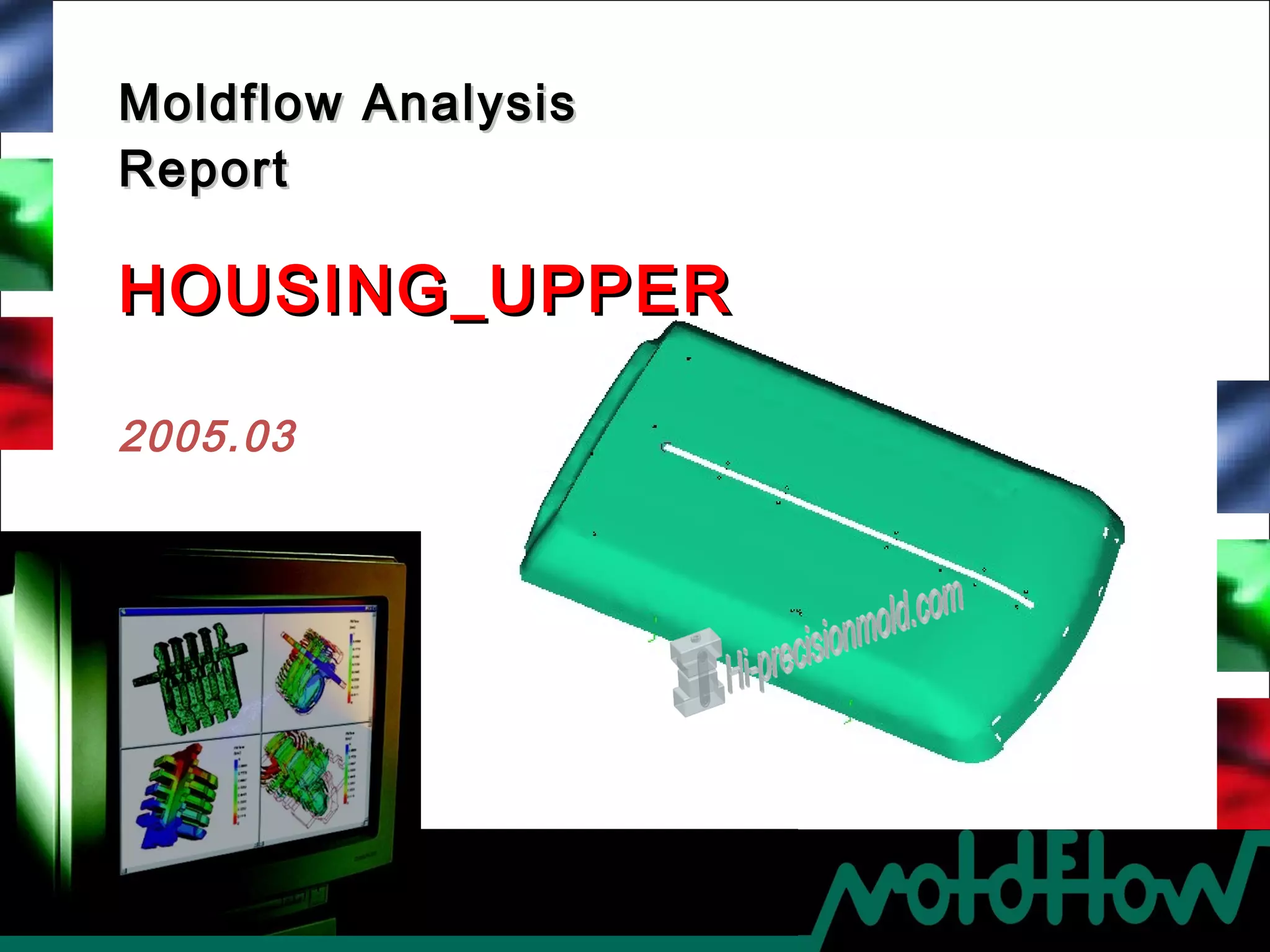

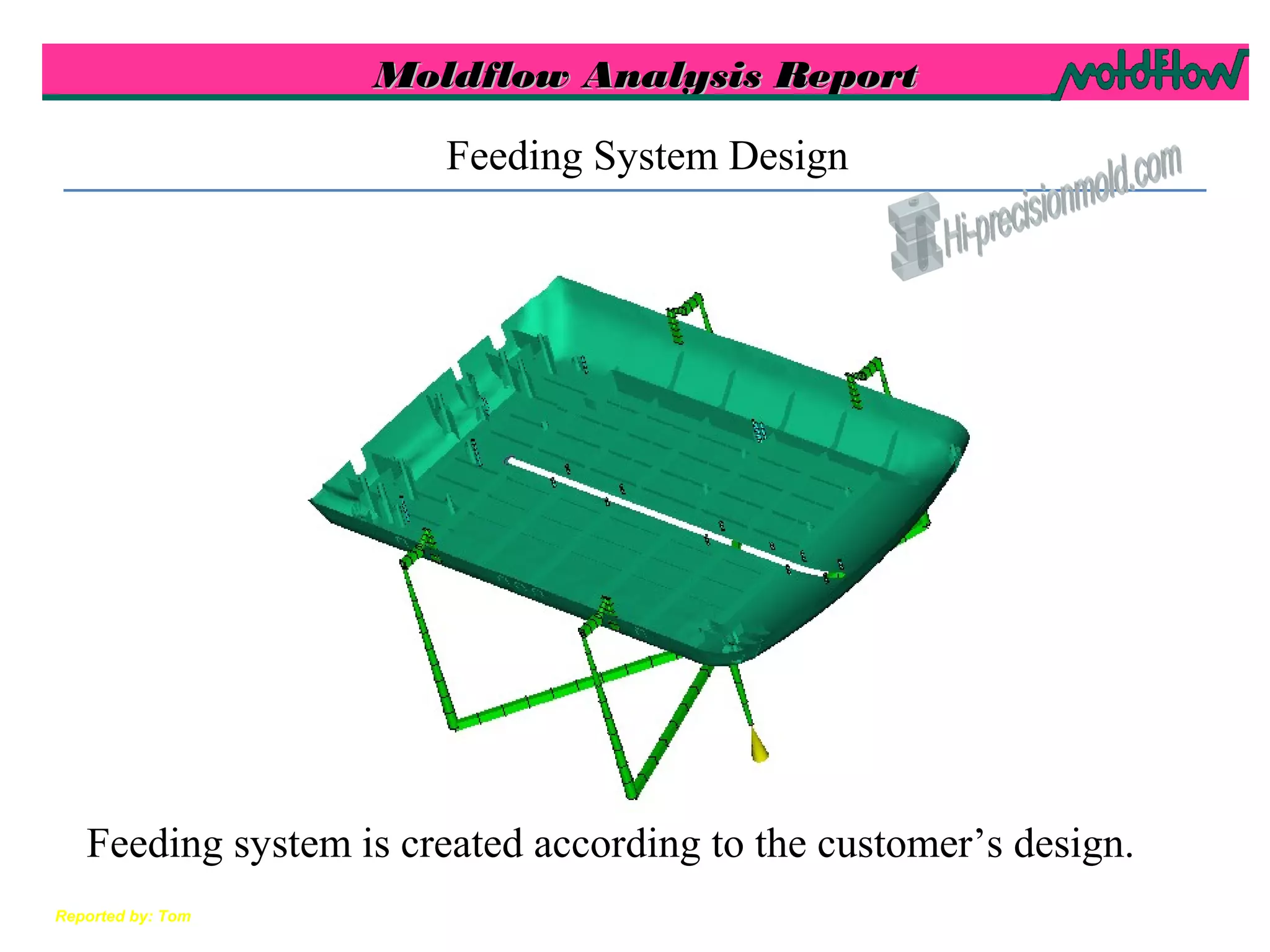

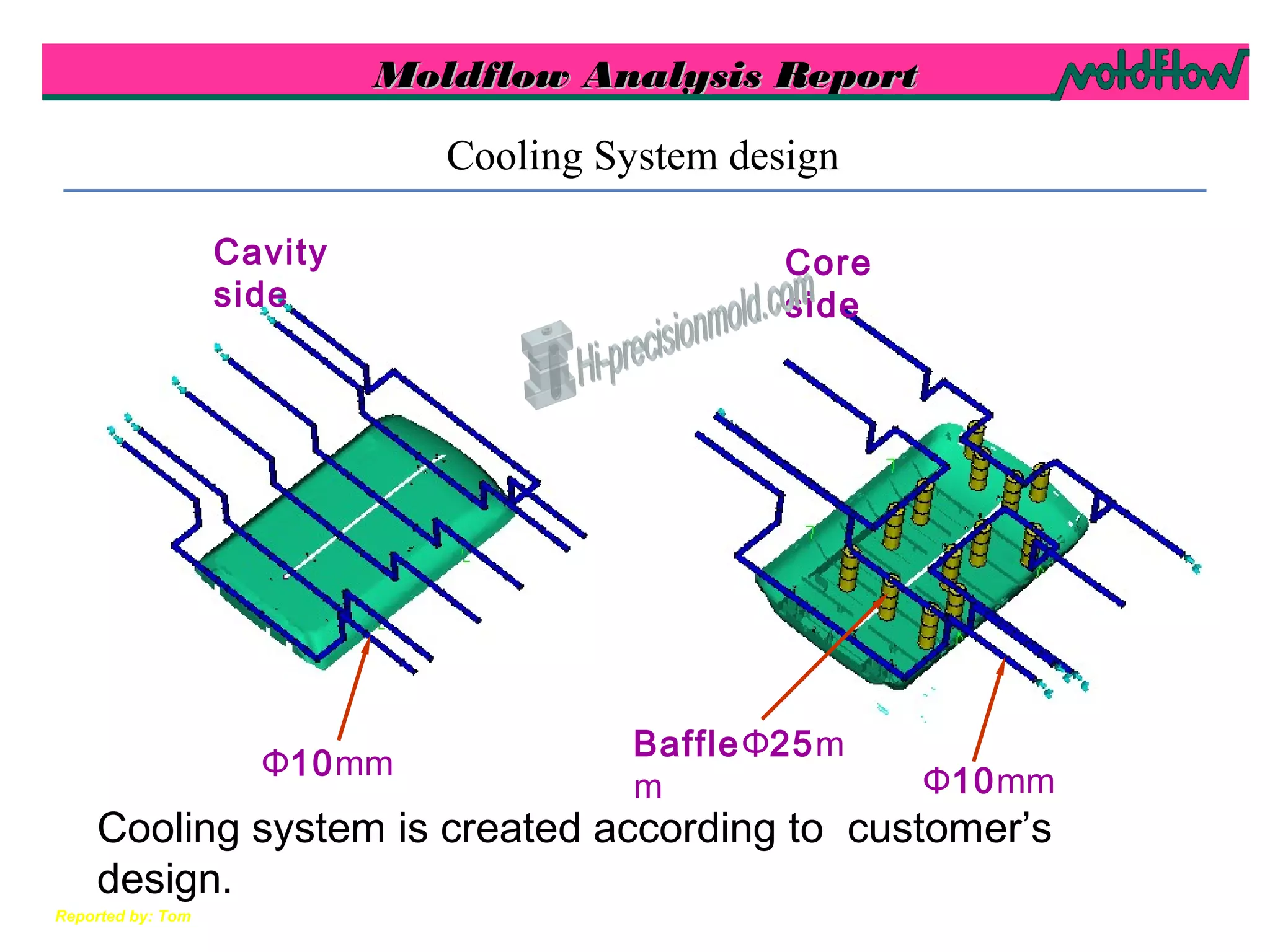

Tom analyzed the molding process for a housing part according to the customer's design. The analysis examined flow, cooling, warpage conditions and optimized the runner and cooling systems. It determined processing parameters, identified potential weld lines and air traps, evaluated warpage and sink marks, and provided recommendations to improve the design.

![Moldflow Analysis ReportMoldflow Analysis Report

Reported by: Tom

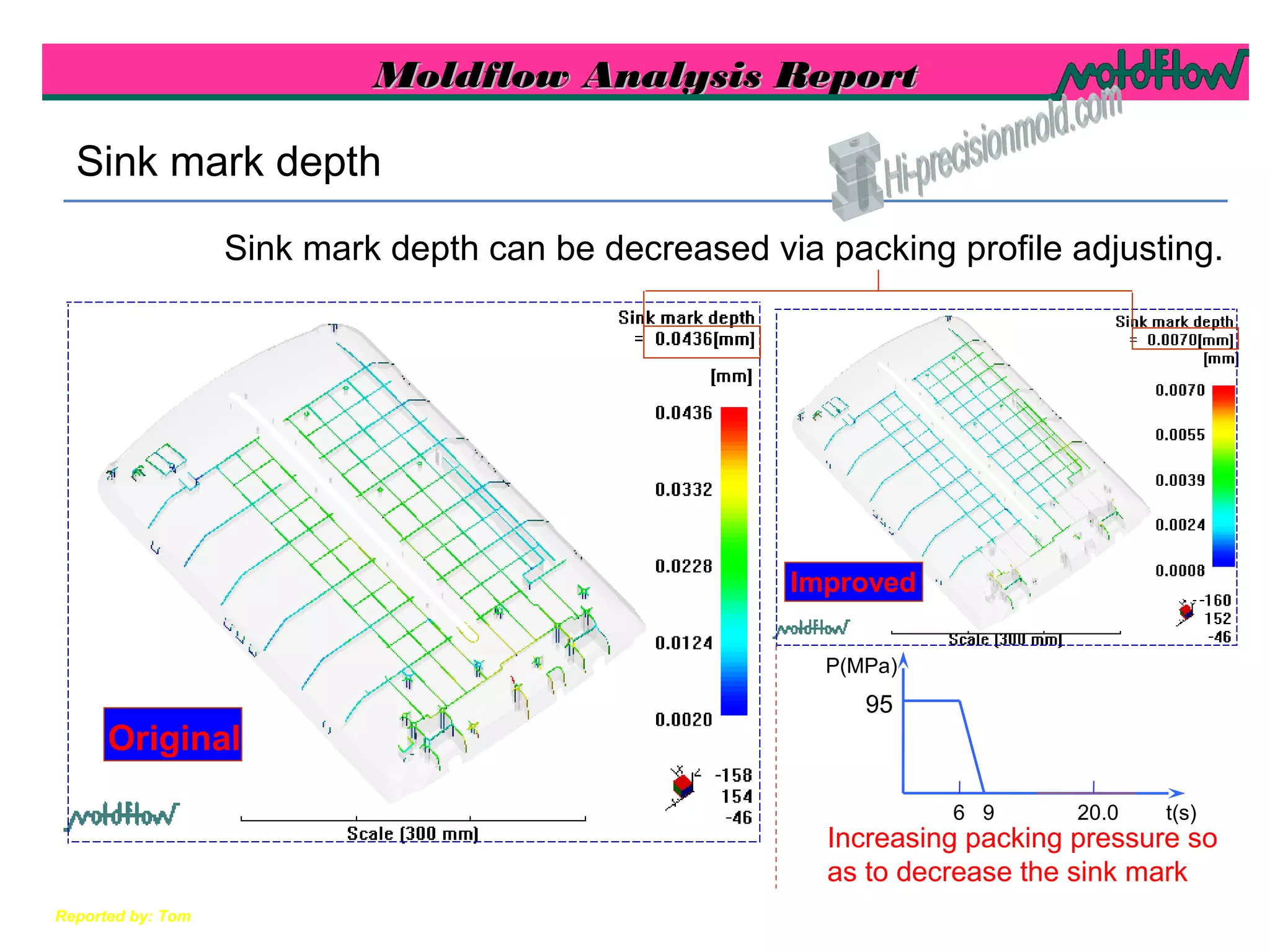

9 20.0 t(s)

P(MPa

)

84.5

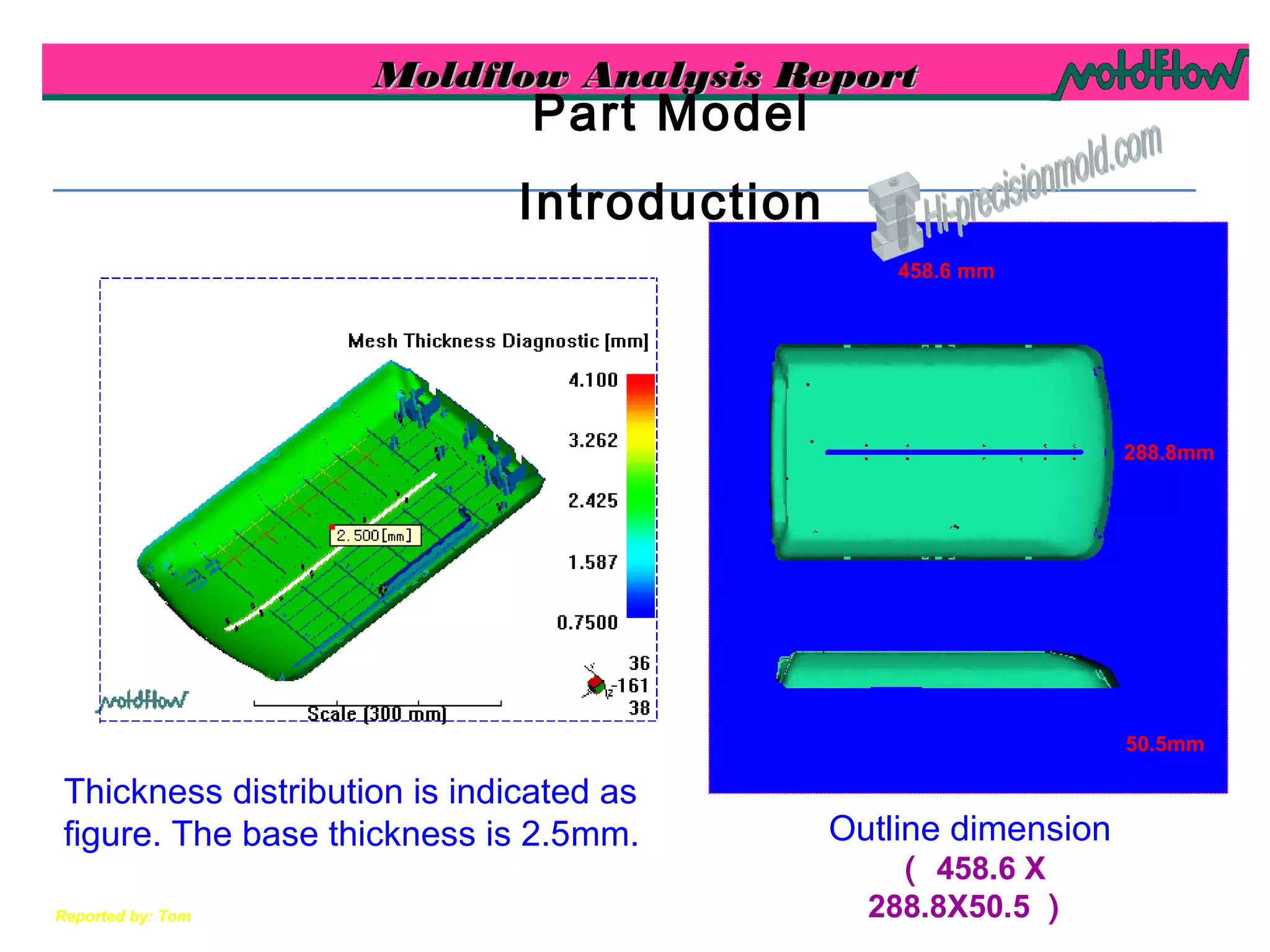

Processing conditions

Filling Conditions :

Mold temperature : 44.00 deg.C

Melt temperature : 235.00 deg.C

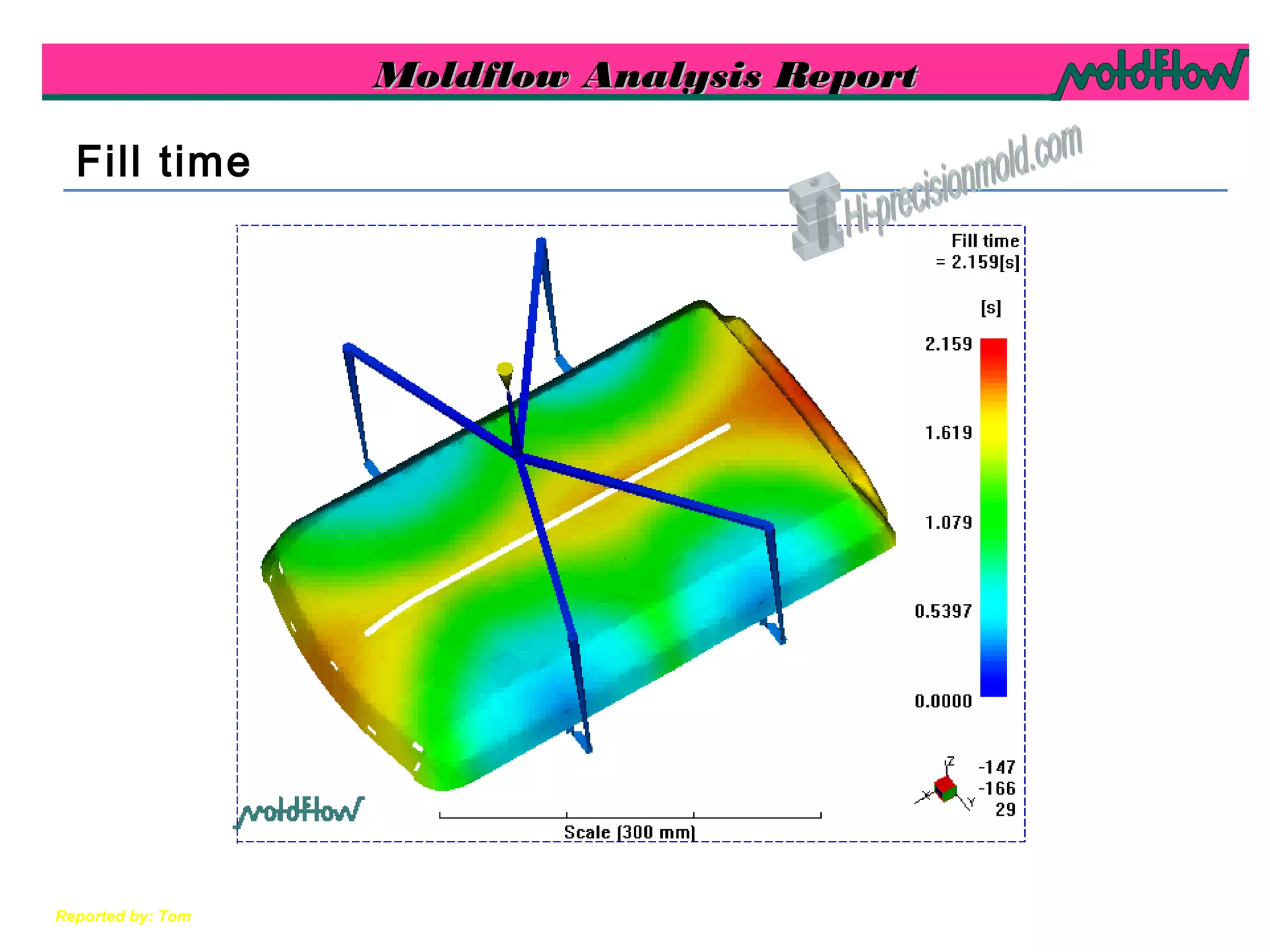

Injection time : 2.2 sec

Cooling Conditions:

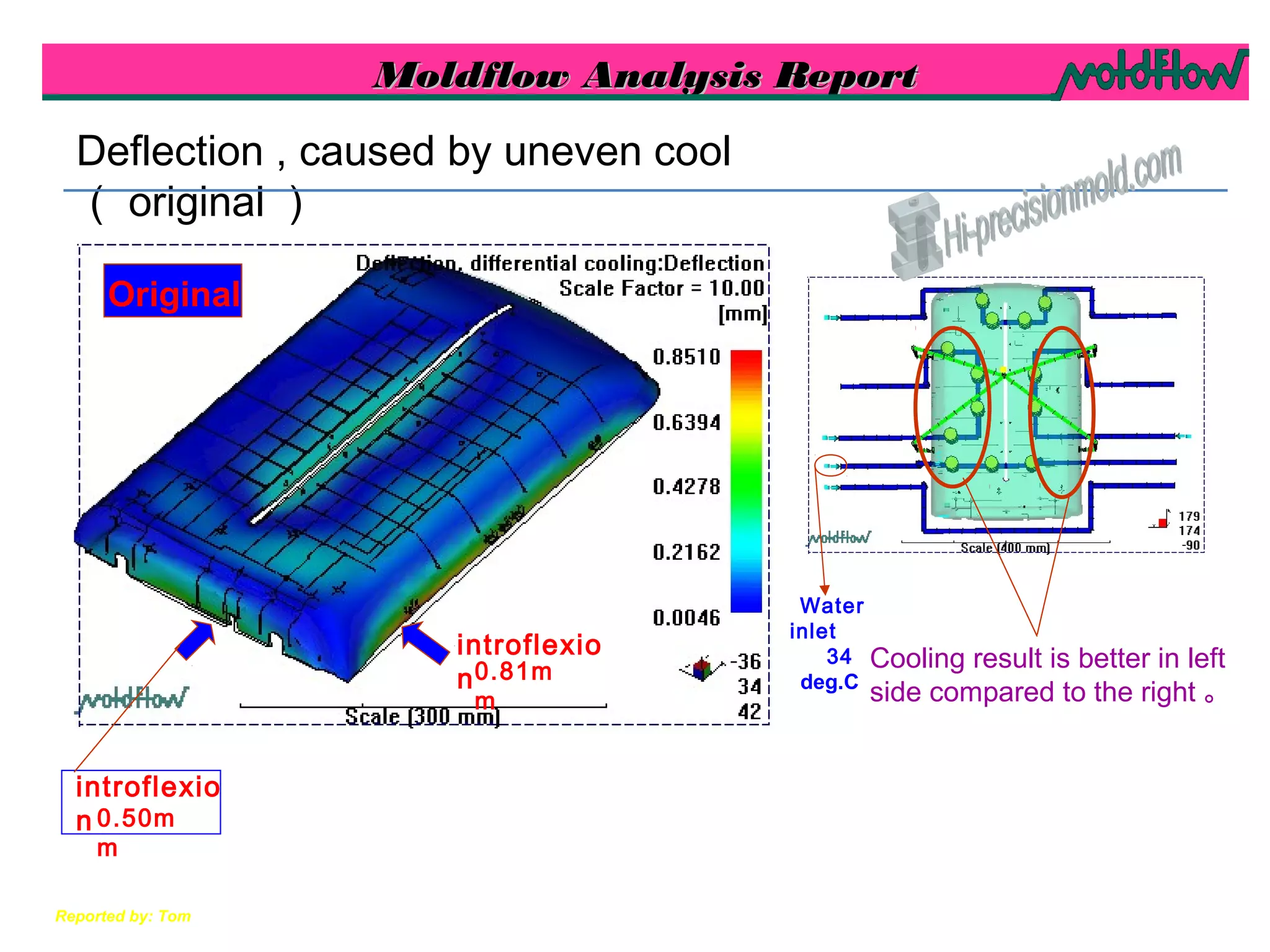

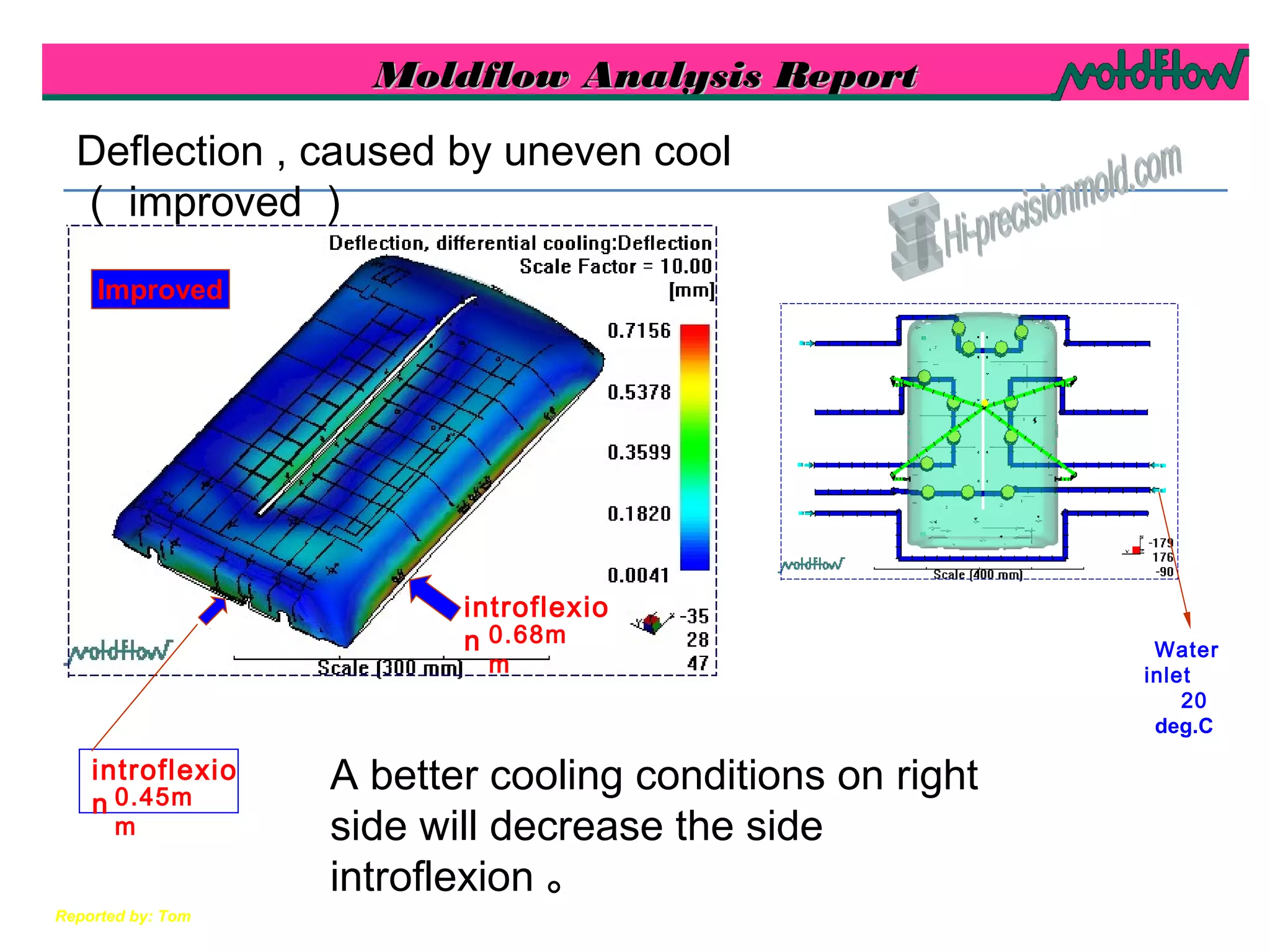

Coolant Temperature(Cavity) 34 deg.C

Coolant Temperature(Core) 34 deg.C PRESSURE[MPa] STEP DURATION [sec]

84.5 0.0

84.5 9

Packing is 80% max

injection pressure

Packing profile :](https://image.slidesharecdn.com/moldflowfromhi-precision-160730052156/75/Mold-flow-from-hi-precision-7-2048.jpg)