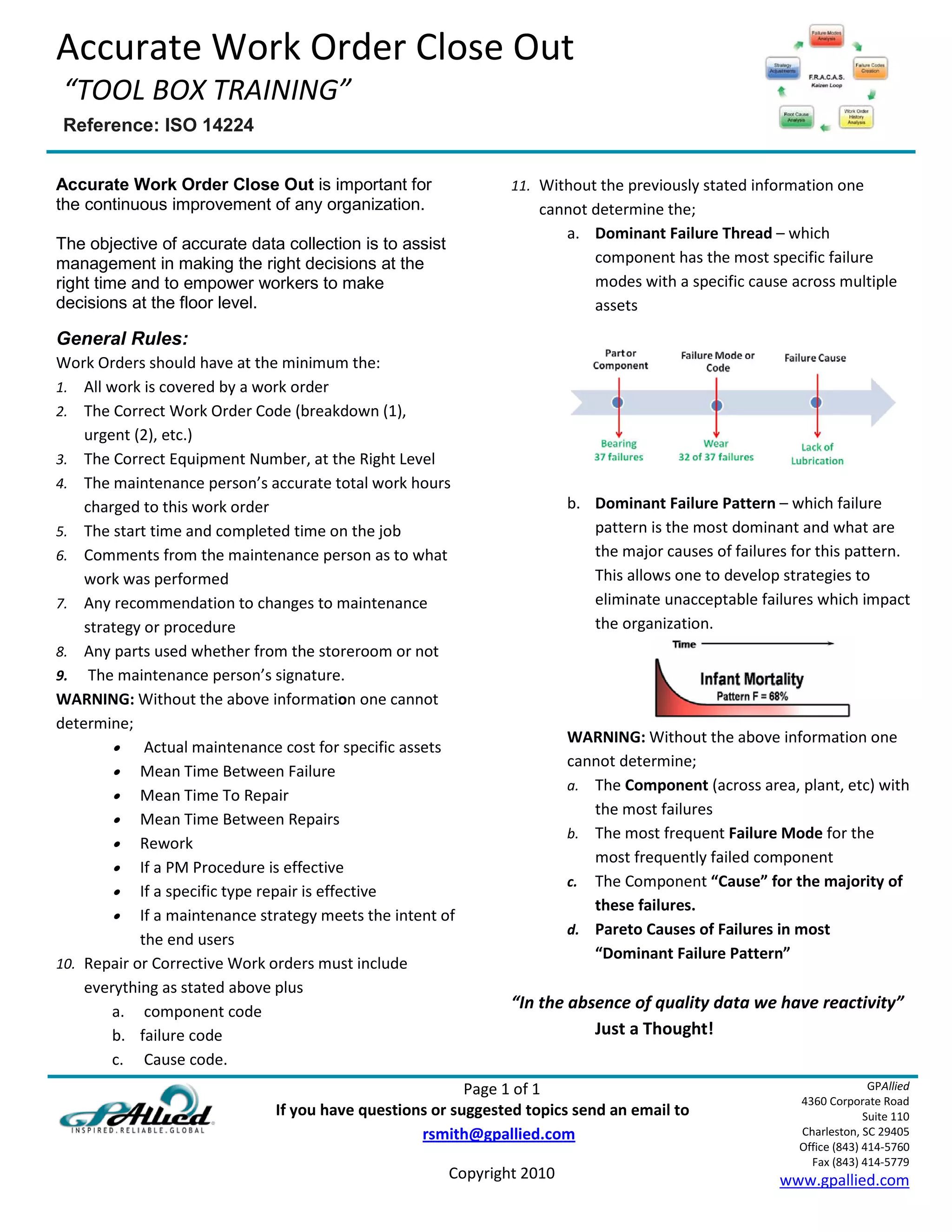

Accurate work order closeout is essential for continuous organizational improvement and effective decision-making. Key elements include the correct documentation of work orders, dominant failure patterns, and maintenance strategies to prevent failures. Without this information, organizations cannot assess maintenance costs, failure rates, or the effectiveness of repair procedures.