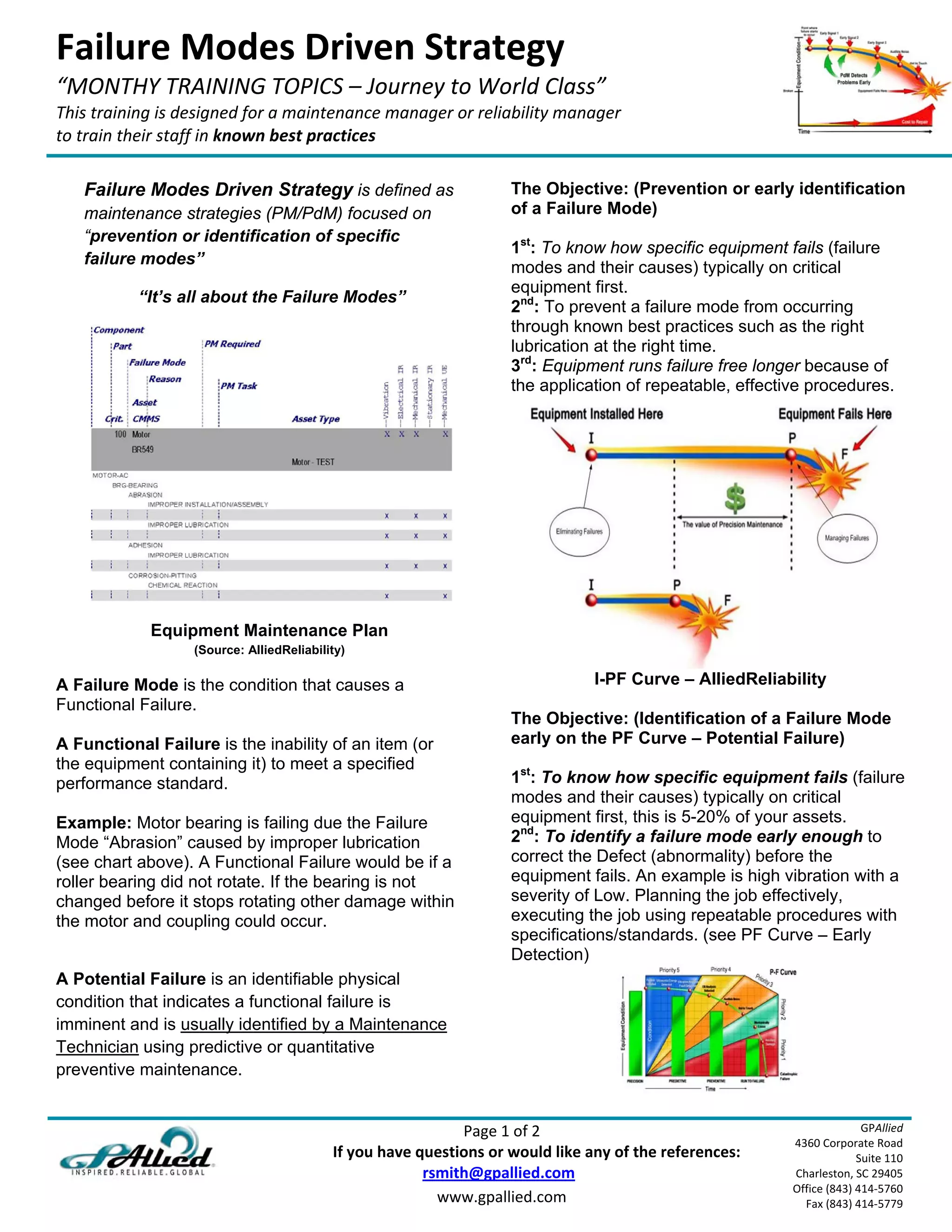

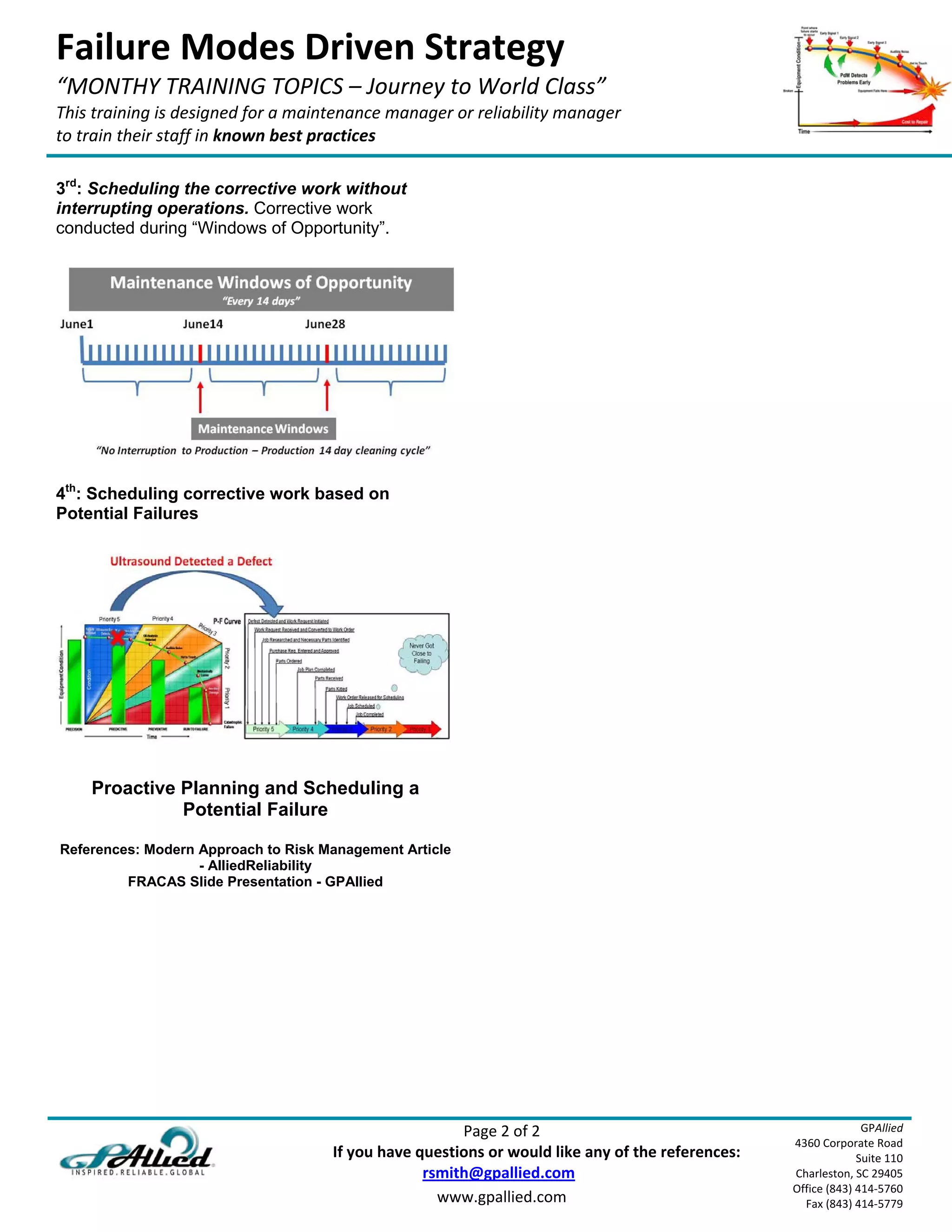

The document outlines a training program focused on failure modes driven strategy for maintenance and reliability managers to educate staff on best practices for preventing equipment failures. It emphasizes the importance of understanding failure modes, implementing preventive measures, and scheduling corrective work to ensure optimal equipment performance. Additionally, it provides examples of functional failures and highlights the significance of proactive planning in maintenance operations.