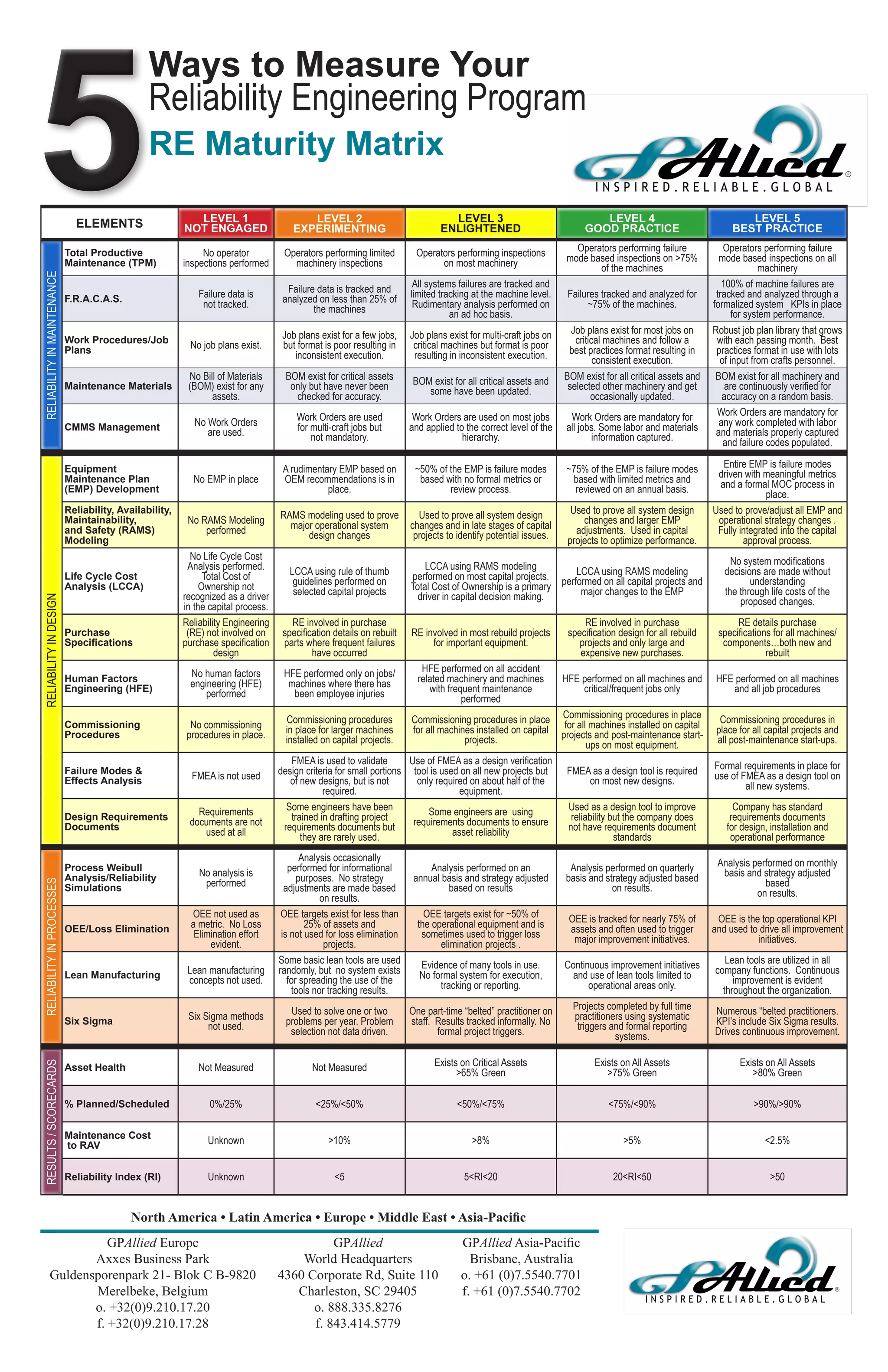

This document outlines a reliability engineering maturity matrix with 5 levels to measure a company's reliability program. It includes elements such as total productive maintenance, failure tracking systems, work procedures, equipment maintenance plans, and reliability metrics. Level 1 indicates a program that is just getting started, while level 5 represents industry-leading best practices across all elements. The goal is to help companies assess their current reliability practices and identify areas for improvement.