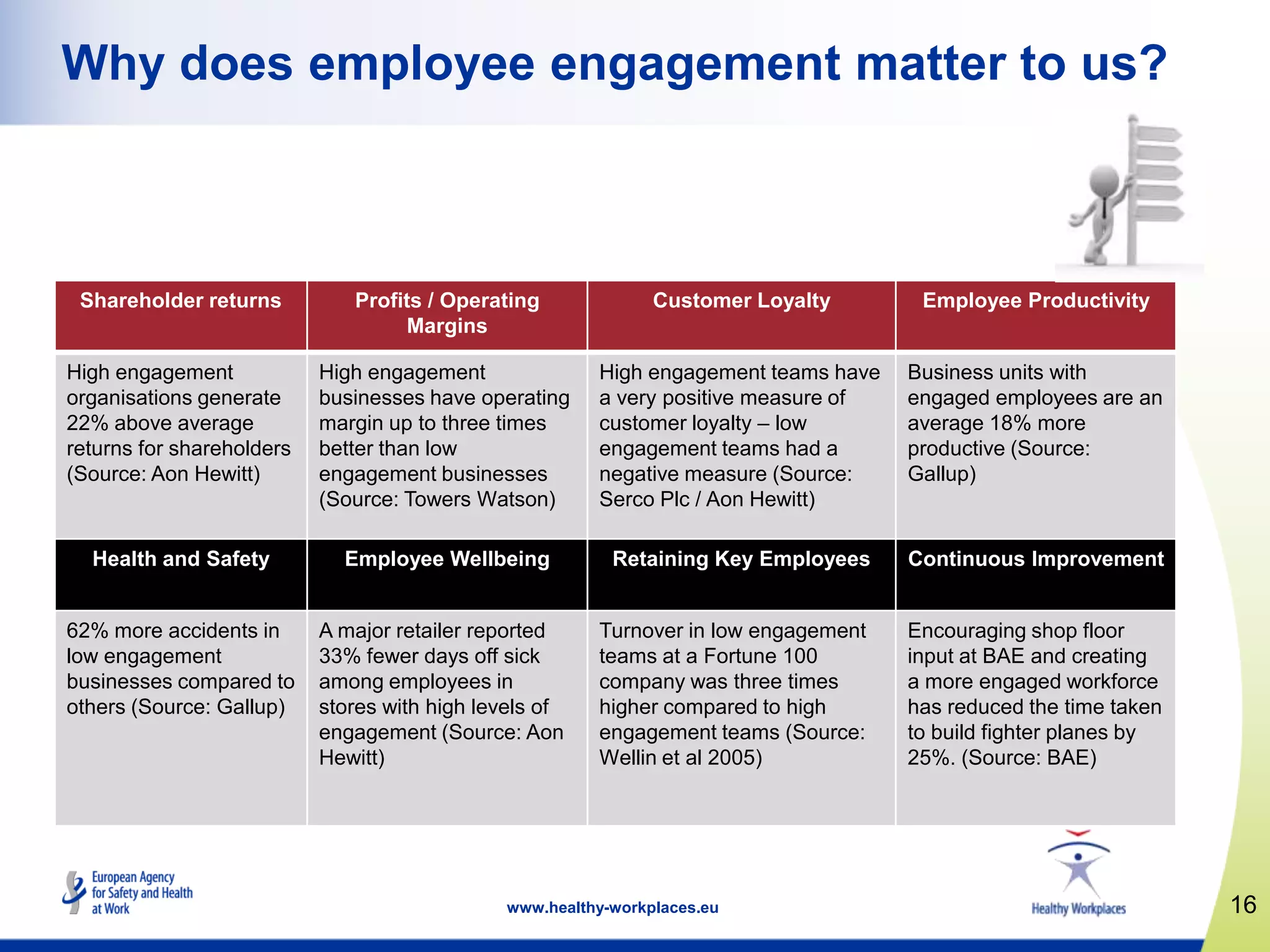

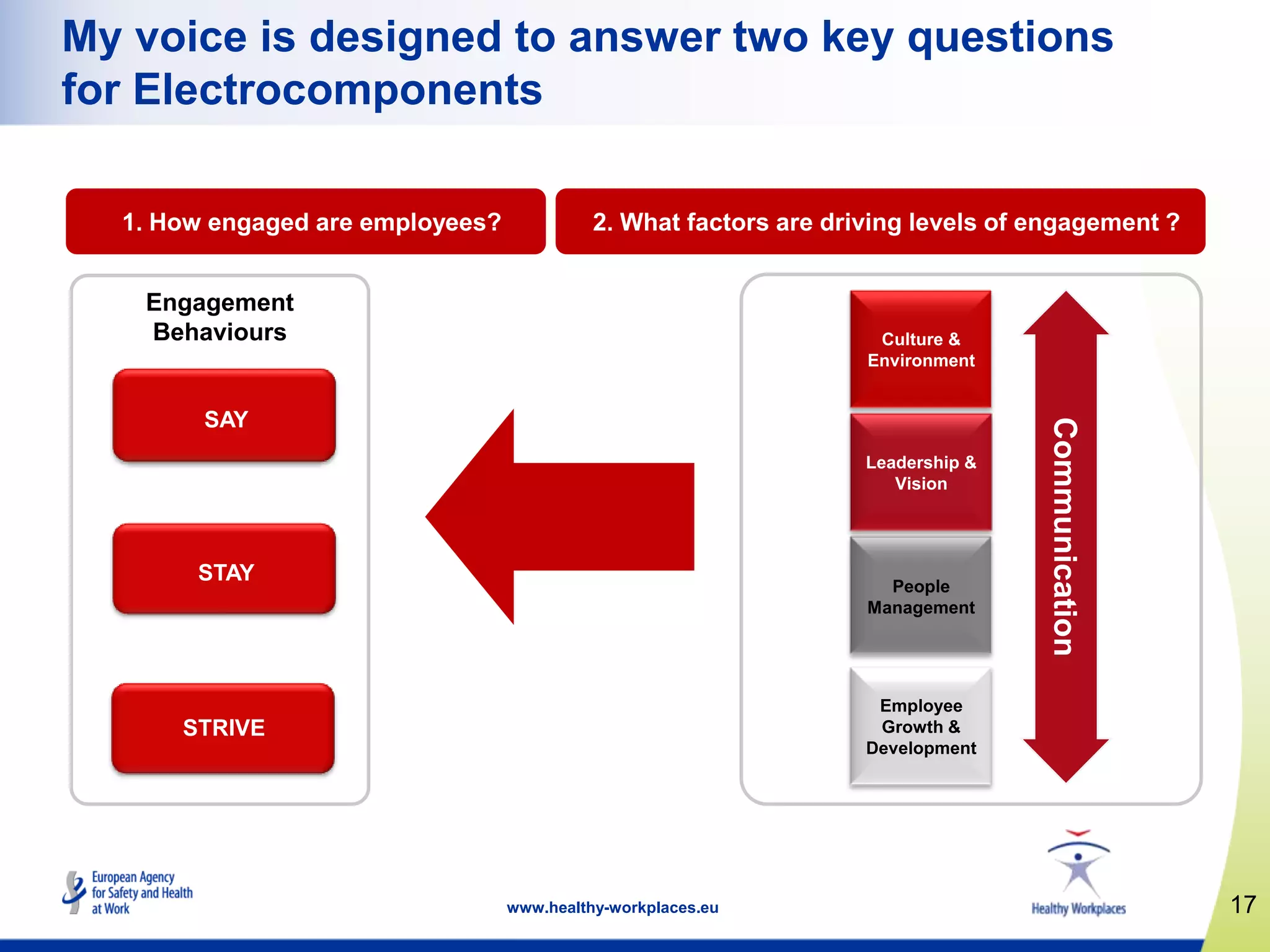

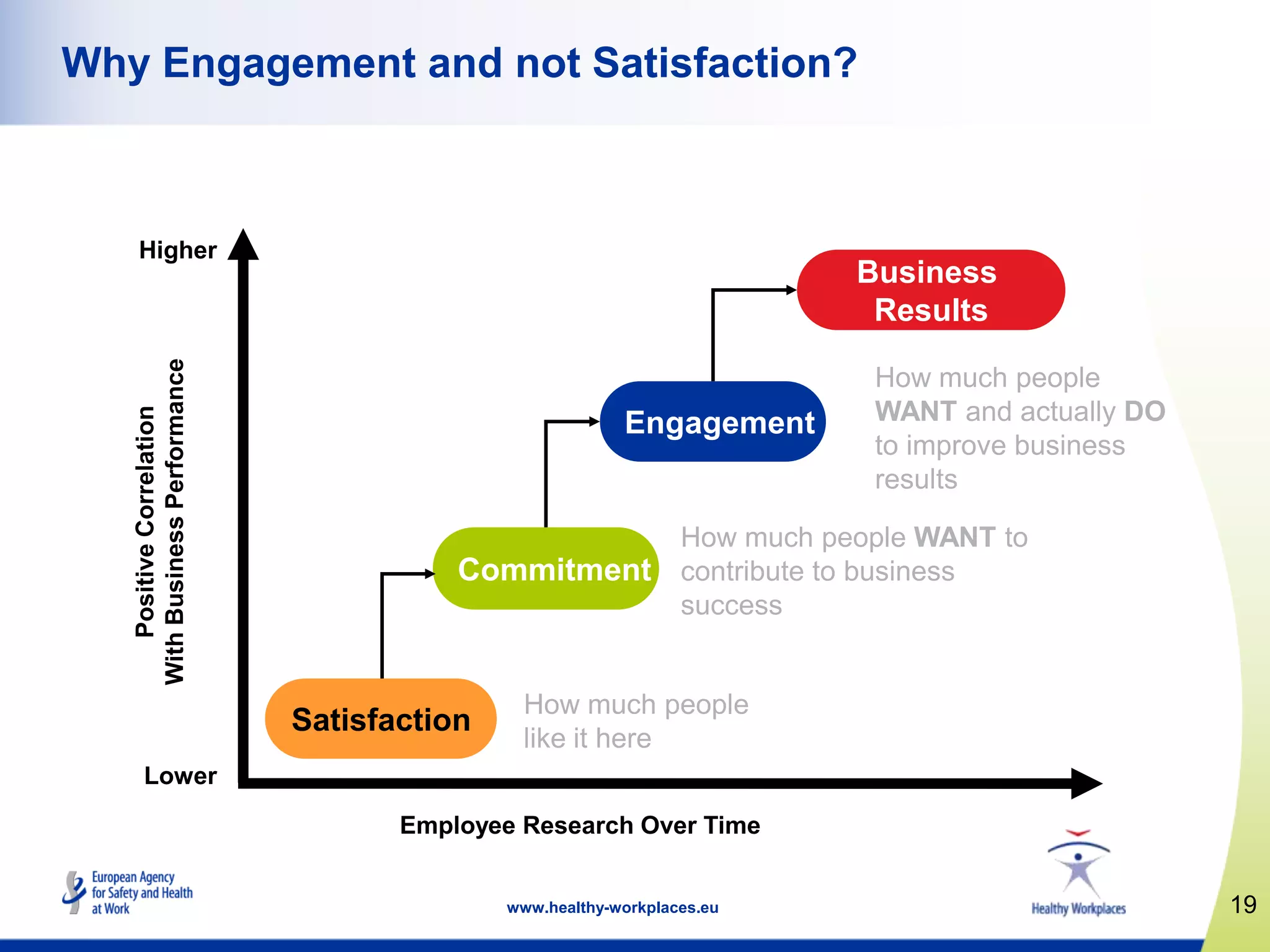

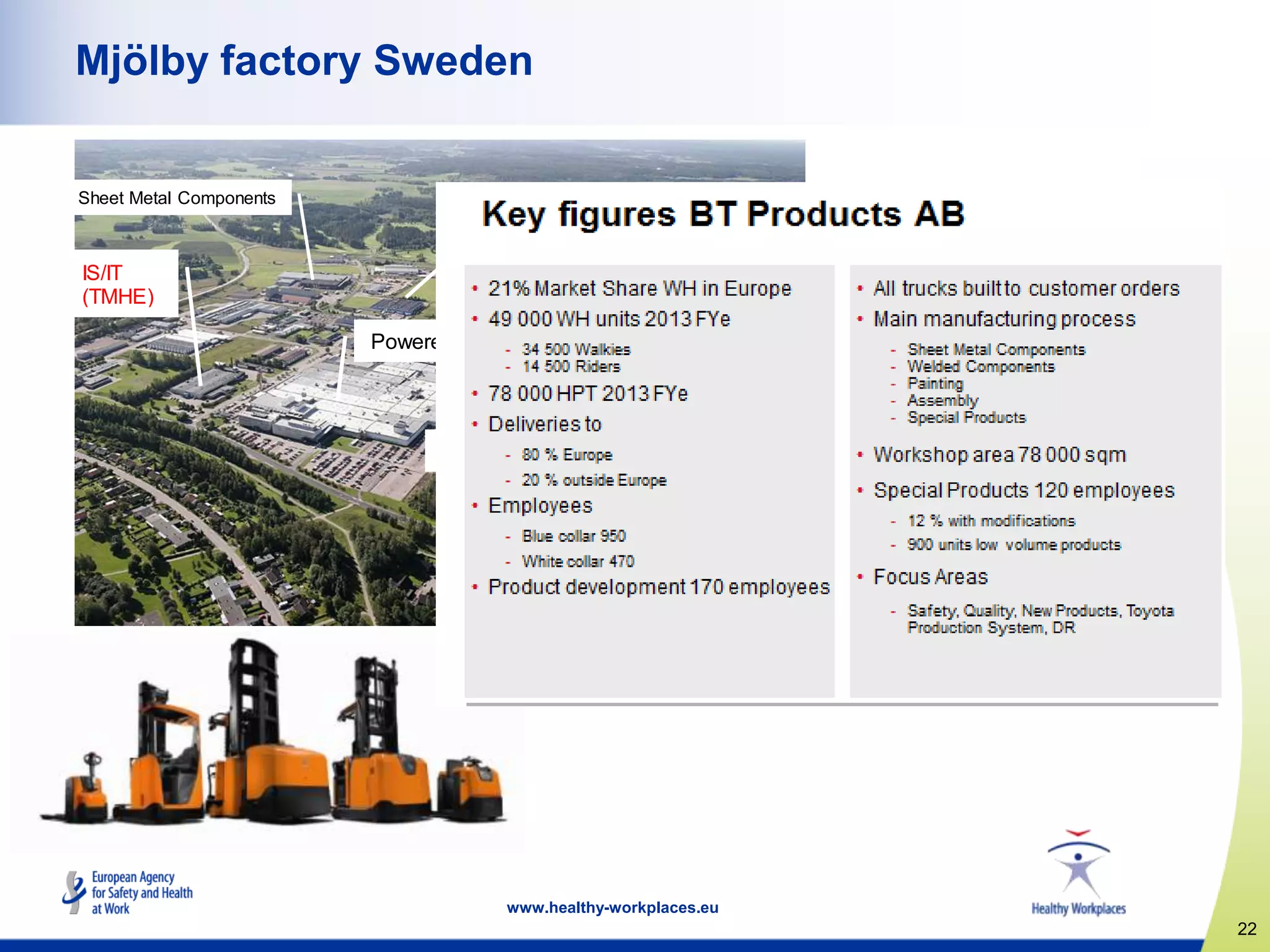

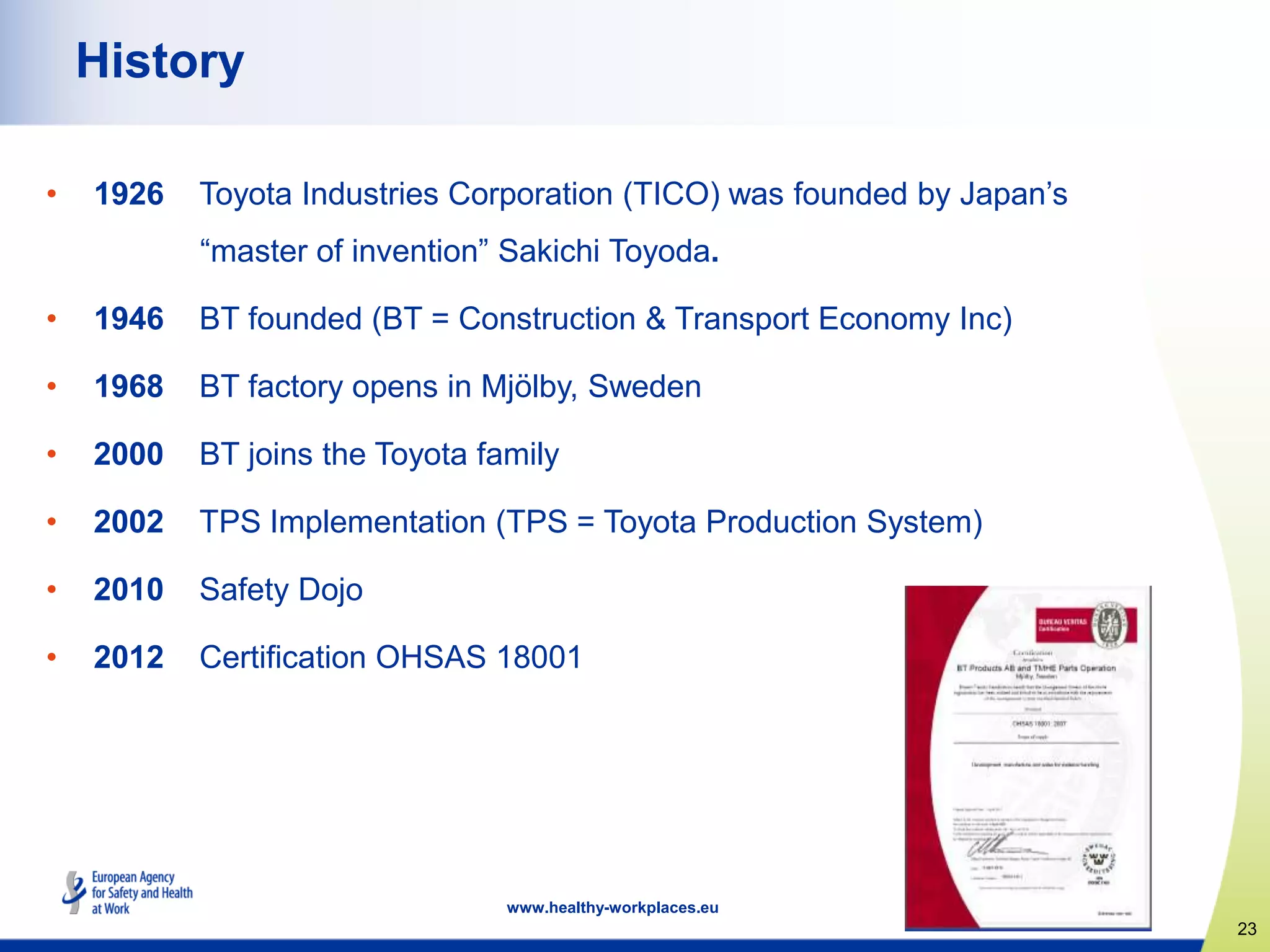

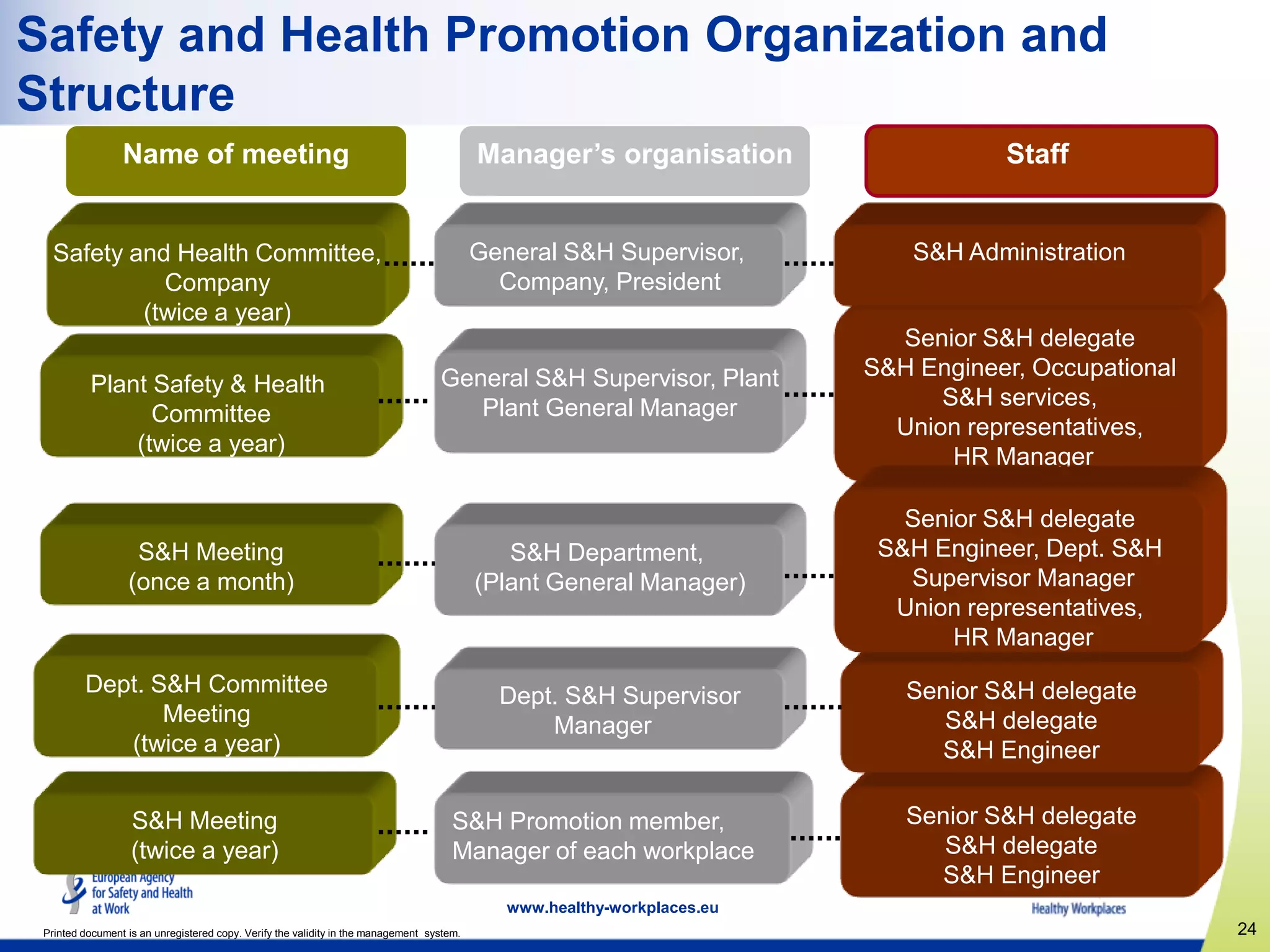

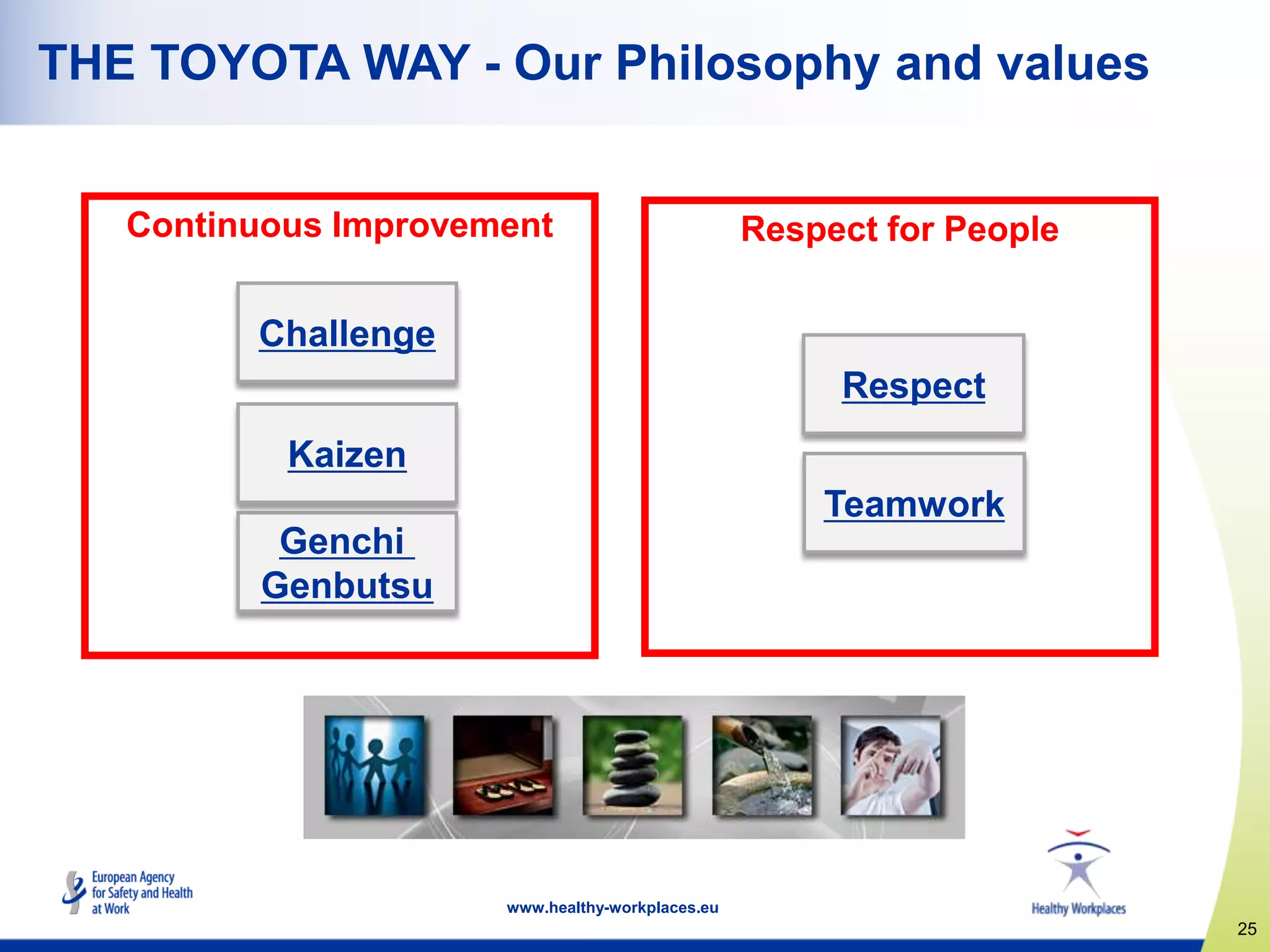

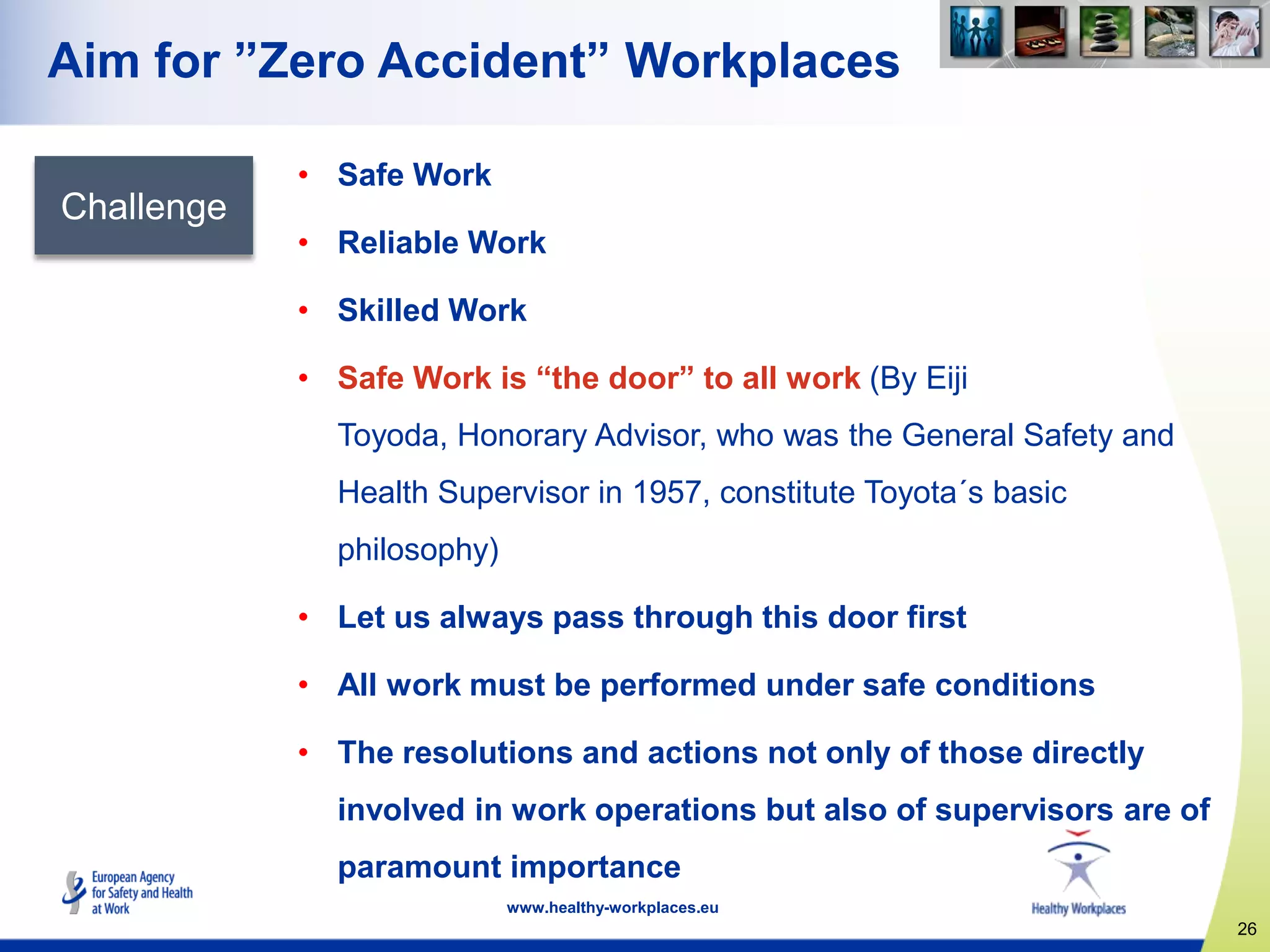

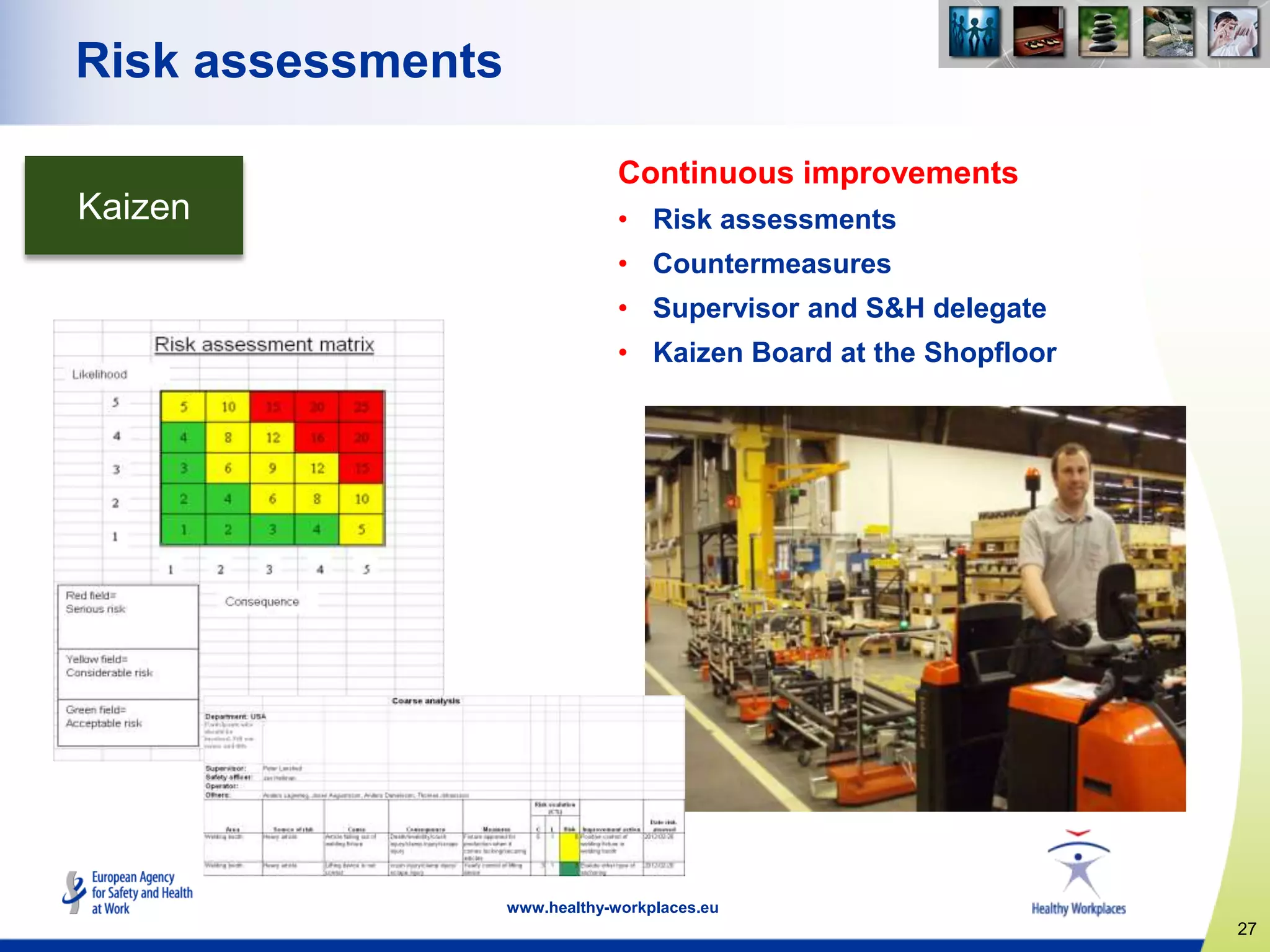

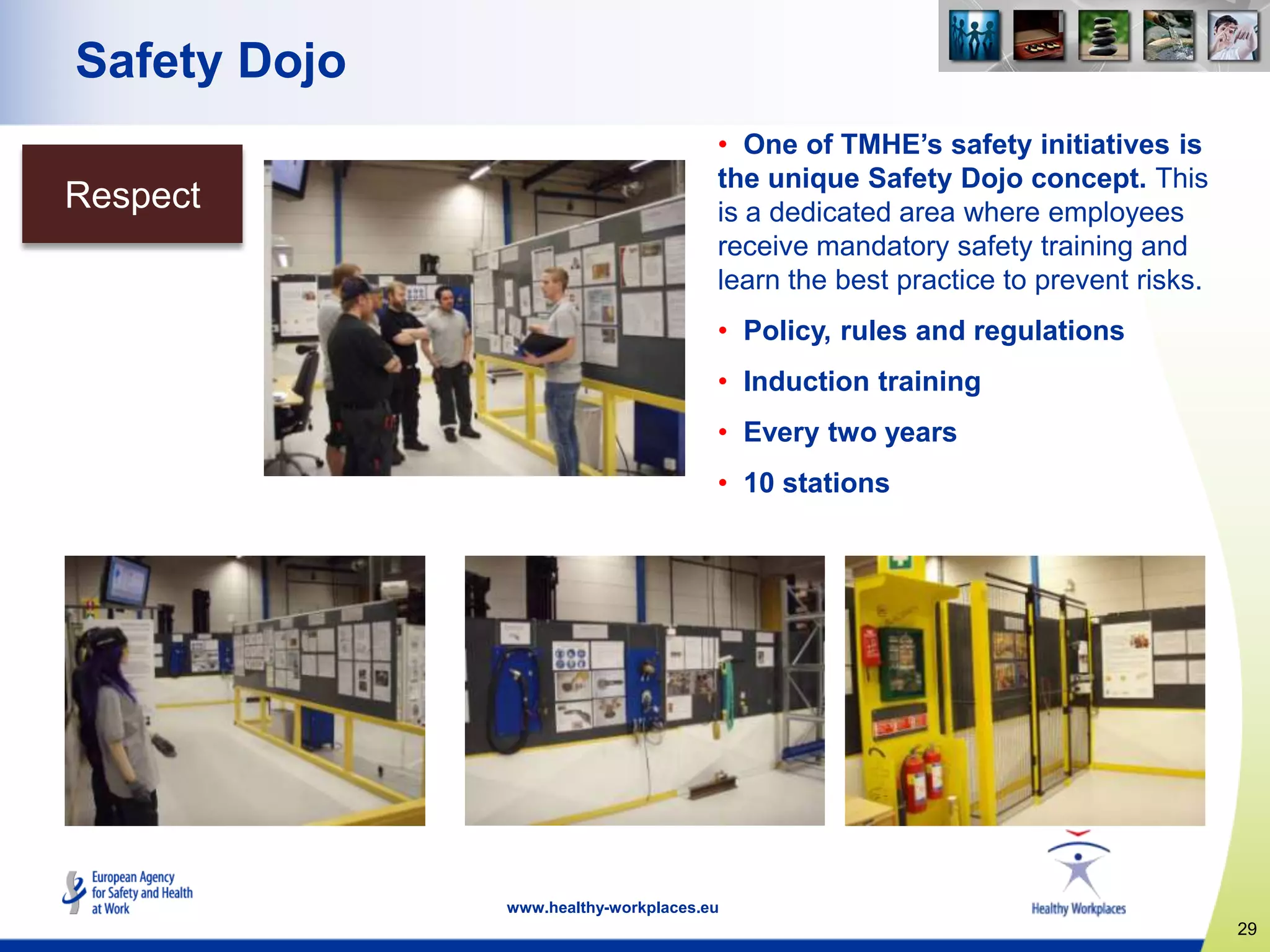

The document discusses the importance of safety and health culture within organizations, highlighting the roles of Electrocomponents and Toyota in fostering a positive environment. It emphasizes employee engagement as a key factor in driving business performance and reducing accidents, supported by case studies and metrics on the benefits of high engagement. Various strategies, including leadership involvement and continuous improvement practices, are explored as means to enhance safety culture.