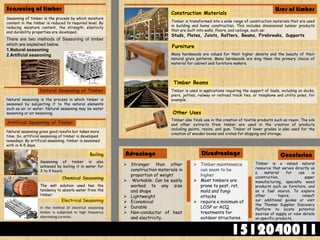

Wood has been used as a construction material for hundreds of thousands of years. Some of the earliest timber homes and structures date back over 10,000 years, and wood construction advanced significantly during the Roman Empire with the introduction of timber cranes. Today, wood is still widely used in construction for buildings, furniture, and infrastructure due to its strength, workability, light weight, durability, and renewability as a natural resource. While wood maintenance can be higher than other materials and it is prone to pest and rot damage, treatments exist to protect wood structures.