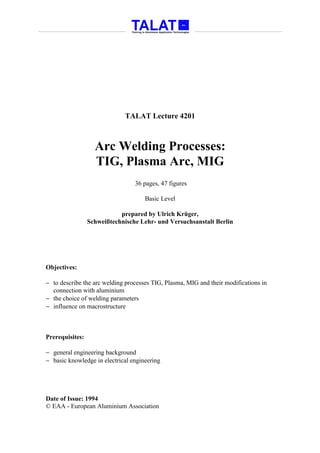

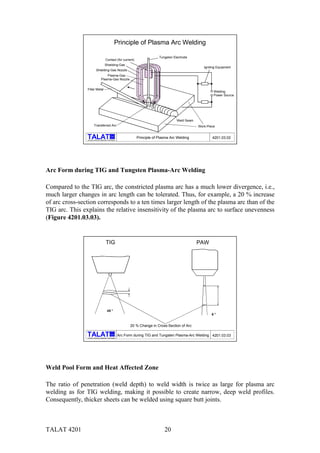

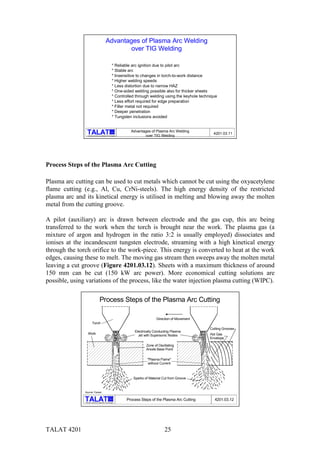

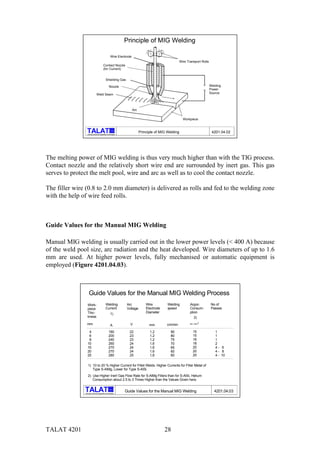

This document provides an overview of TIG, plasma arc, and MIG welding processes for aluminum. It describes the principles, equipment, parameters, and macrostructure outcomes of each process. The objectives are to explain TIG, plasma arc, and MIG welding and their modifications for aluminum, how welding parameters influence macrostructure, and the choice of parameters. It requires a general engineering background and basic electrical engineering knowledge. The document was created in 1994 and contains 47 figures to illustrate the concepts discussed over 36 pages.