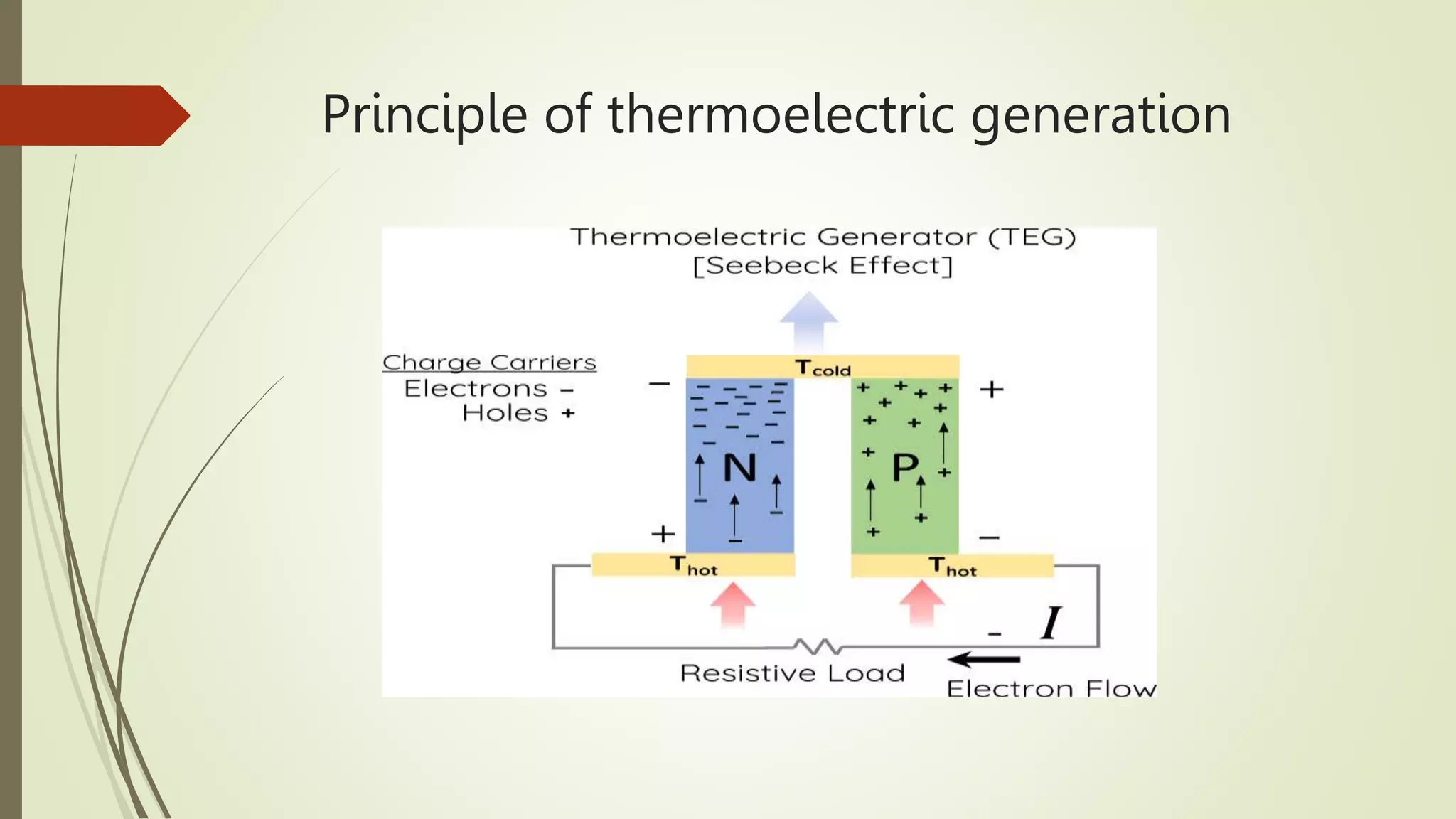

This document discusses thermoelectric generators (TEGs) and their ability to directly convert thermal energy into electric power through the Seebeck effect. It describes how TEGs work using three key elements: a heat exchanger to absorb heat, thermoelectric modules to generate electricity from a temperature difference, and a heat sink to dissipate additional heat. The document also examines common TEG materials like bismuth telluride and challenges like low thermal efficiency around 4%, as well as applications in recovering waste heat from power plants, automobiles, and other systems.