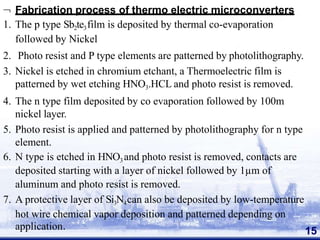

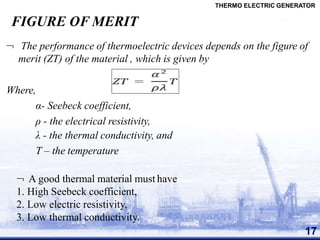

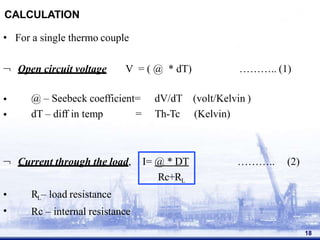

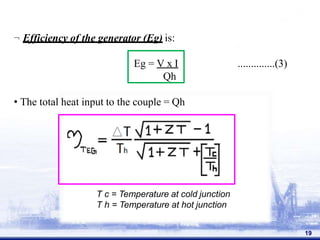

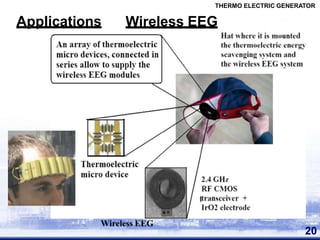

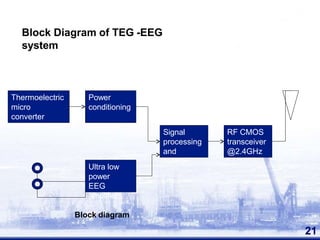

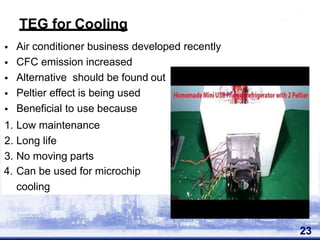

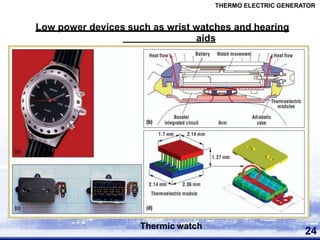

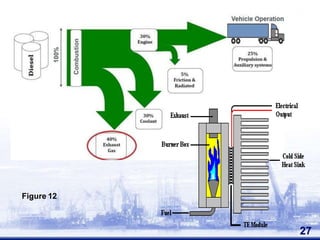

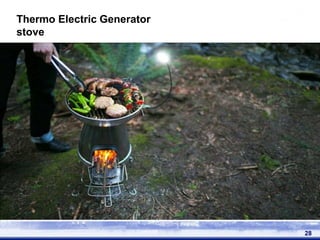

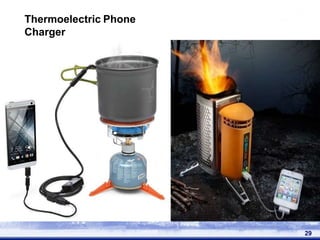

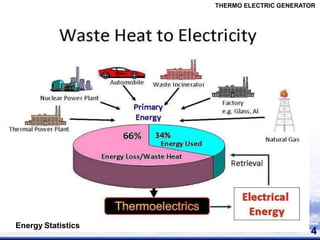

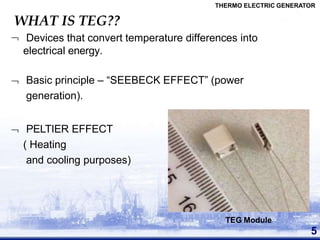

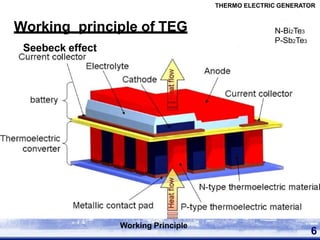

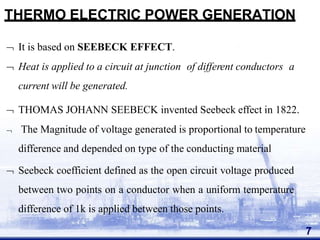

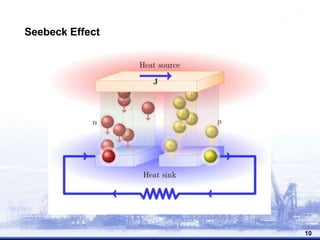

The document presents an overview of thermoelectric generators (TEGs), emphasizing their role in converting temperature differences into electrical energy through the Seebeck effect. It discusses the principles, applications, advantages, disadvantages, and fabrication processes of TEGs, highlighting their potential to harness waste heat for low-power electronics. While TEGs offer various benefits such as solid-state construction and maintenance-free operation, challenges include low efficiency and high costs.

![Thomas Johann Seebeck [ 1770 – 1831 ]

8](https://image.slidesharecdn.com/lalkrishntripathippt-240426064456-6ab6367f/85/lalkrishn-tripathi-Malvian-Seminar-Report-8-320.jpg)

![Jean Peltier [ 1785 - 1845 ]

12](https://image.slidesharecdn.com/lalkrishntripathippt-240426064456-6ab6367f/85/lalkrishn-tripathi-Malvian-Seminar-Report-12-320.jpg)