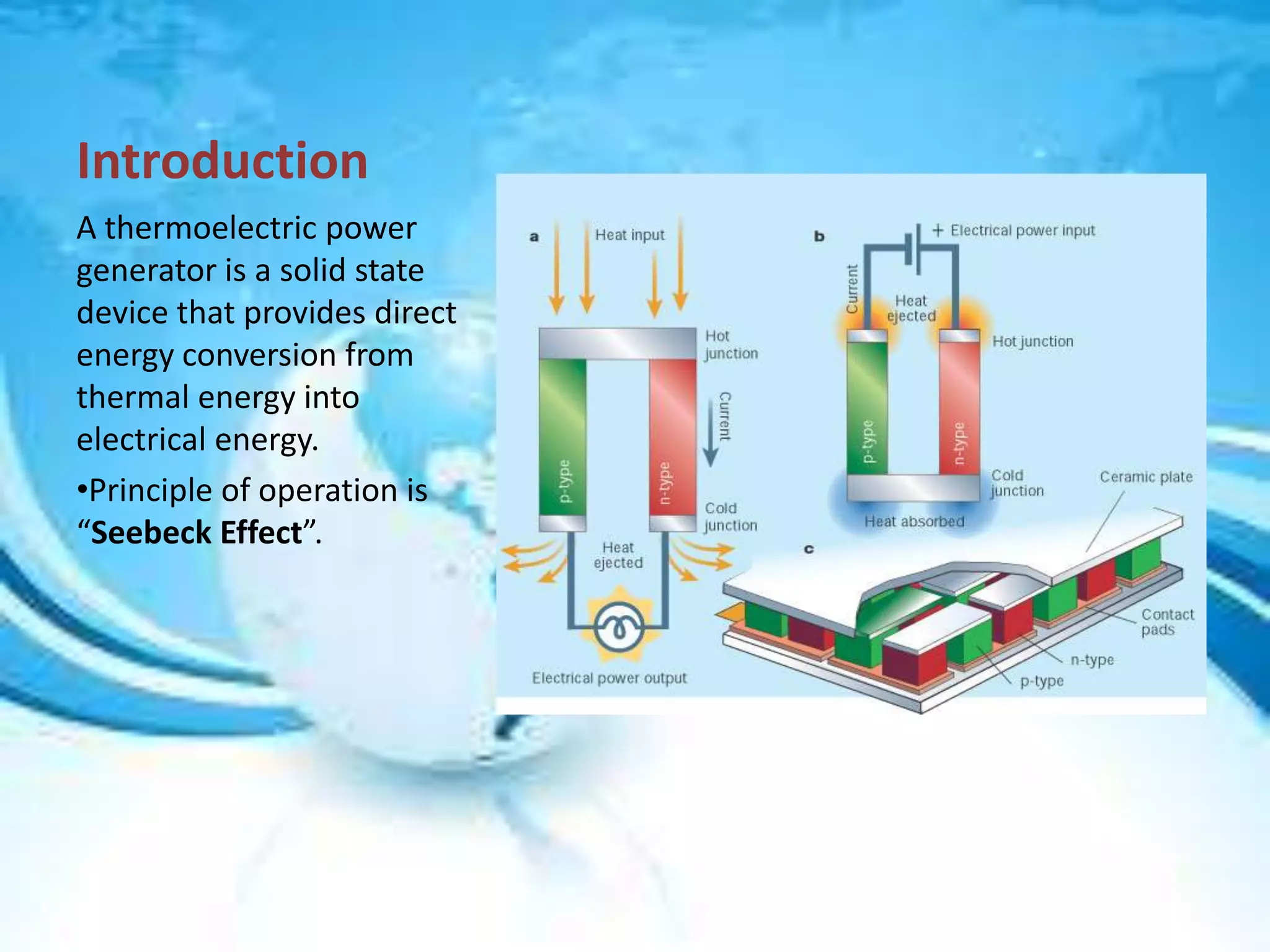

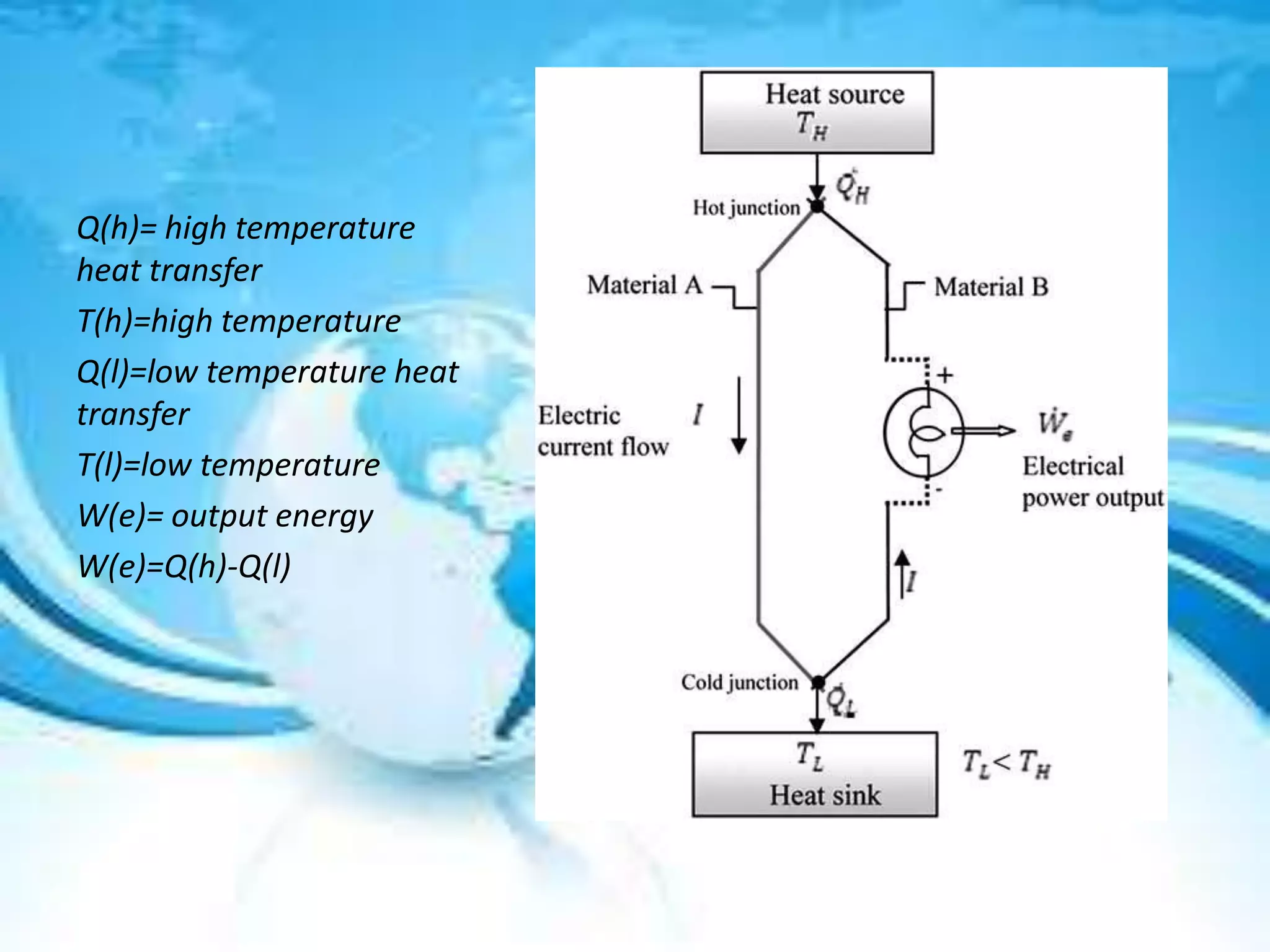

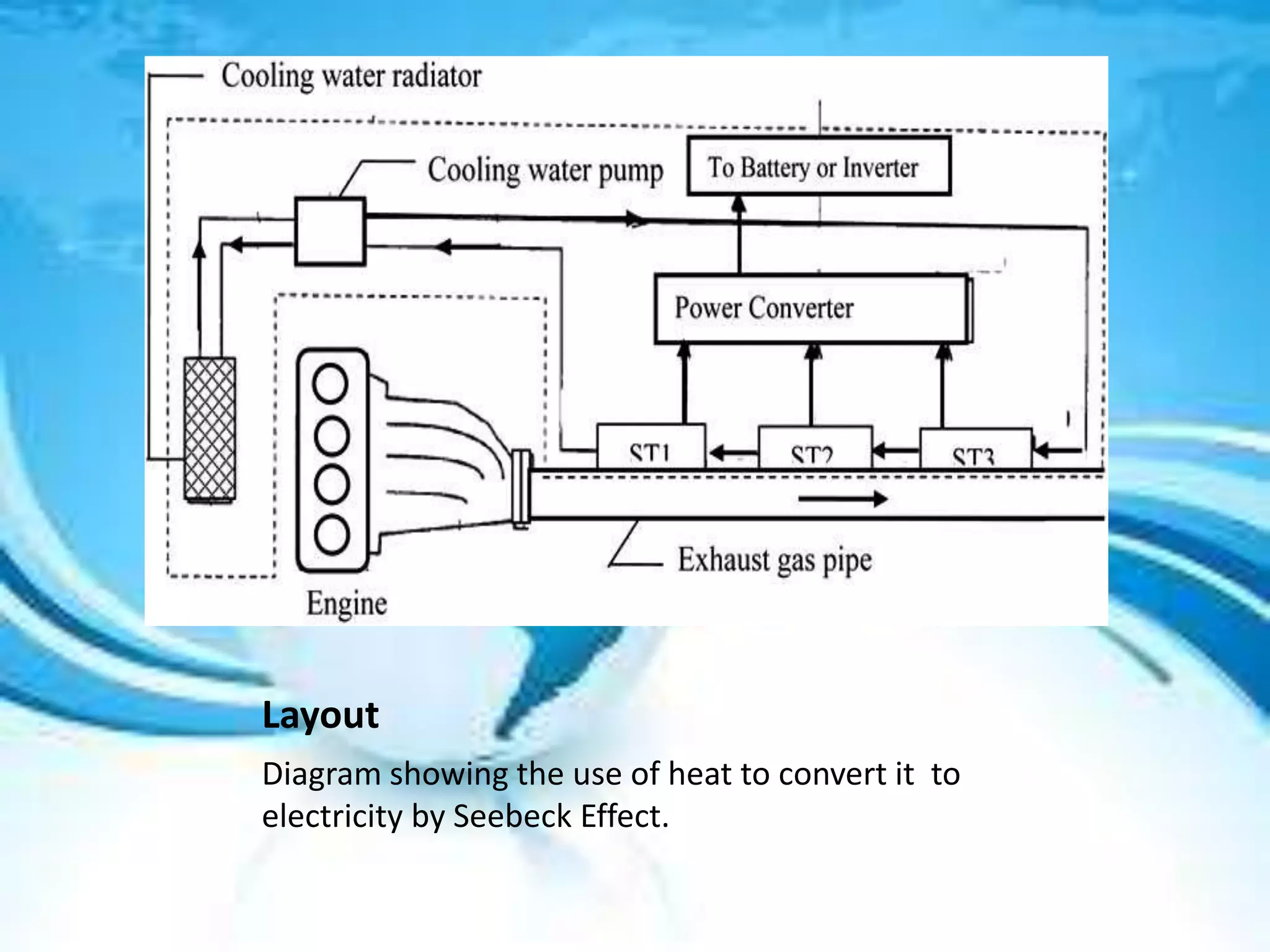

This document discusses thermoelectric power generators. It begins by introducing thermoelectric power generation and the Seebeck effect. The Seebeck effect produces voltage when two dissimilar conductors are joined and experience a temperature difference. The document then provides specifications for conventional thermoelectric devices and describes their components and arrangement. It discusses the performance factors for thermoelectric materials, including figure of merit and conversion efficiency. The document outlines the materials used in thermoelectric generators, including semiconductors, and categorizes conventional and novel materials. It provides examples of applications, such as automotive waste heat recovery and industrial waste heat utilization.