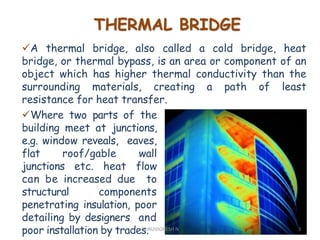

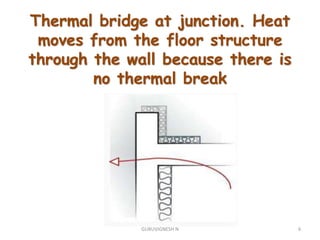

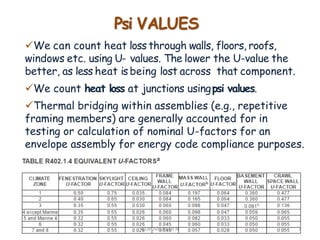

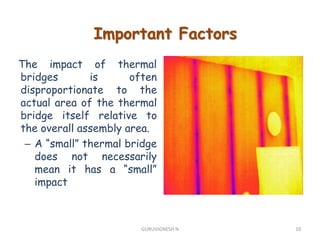

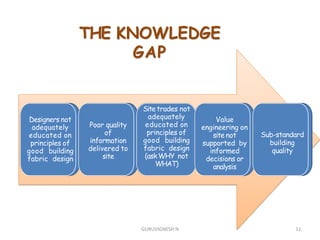

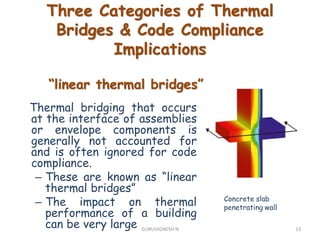

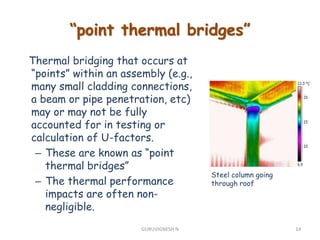

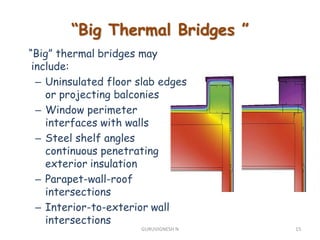

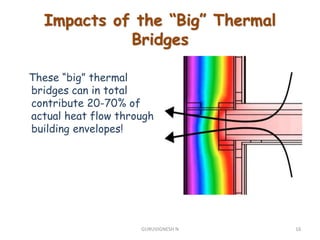

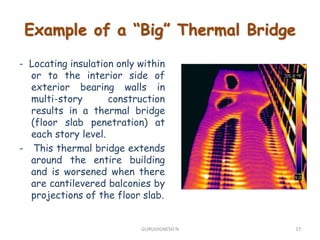

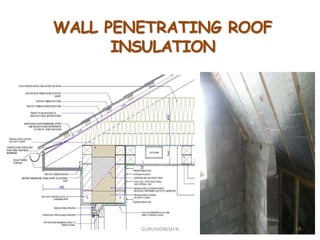

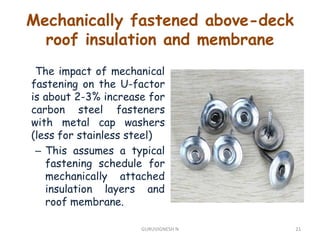

This document discusses thermal bridging in low energy buildings. Thermal bridging occurs where building materials with high thermal conductivity create paths of least resistance for heat transfer. This can occur at junctions where insulation is compromised. Infrared thermography is used to identify thermal bridges. While small bridges may have small impacts, larger bridges like uninsulated slabs can account for 20-70% of heat transfer. Proper design and insulation techniques can help mitigate thermal bridging to improve building energy efficiency.