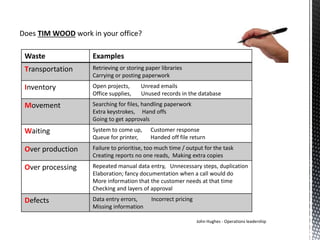

Lean principles can be applied to office environments to eliminate waste. The mnemonic "TIM WOOD" identifies common types of waste: transportation, inventory, movement, waiting, overproduction, overprocessing, and defects. Examples of waste in offices include unnecessary retrieval or storage of paperwork, open projects or unread emails, excess searching for files, waiting for responses, creating unnecessary reports, and data entry errors. Simple changes like organizing a desk efficiently, programming keyboard shortcuts, clearly labeling file cabinets, and managing electronic data can help reduce office waste.