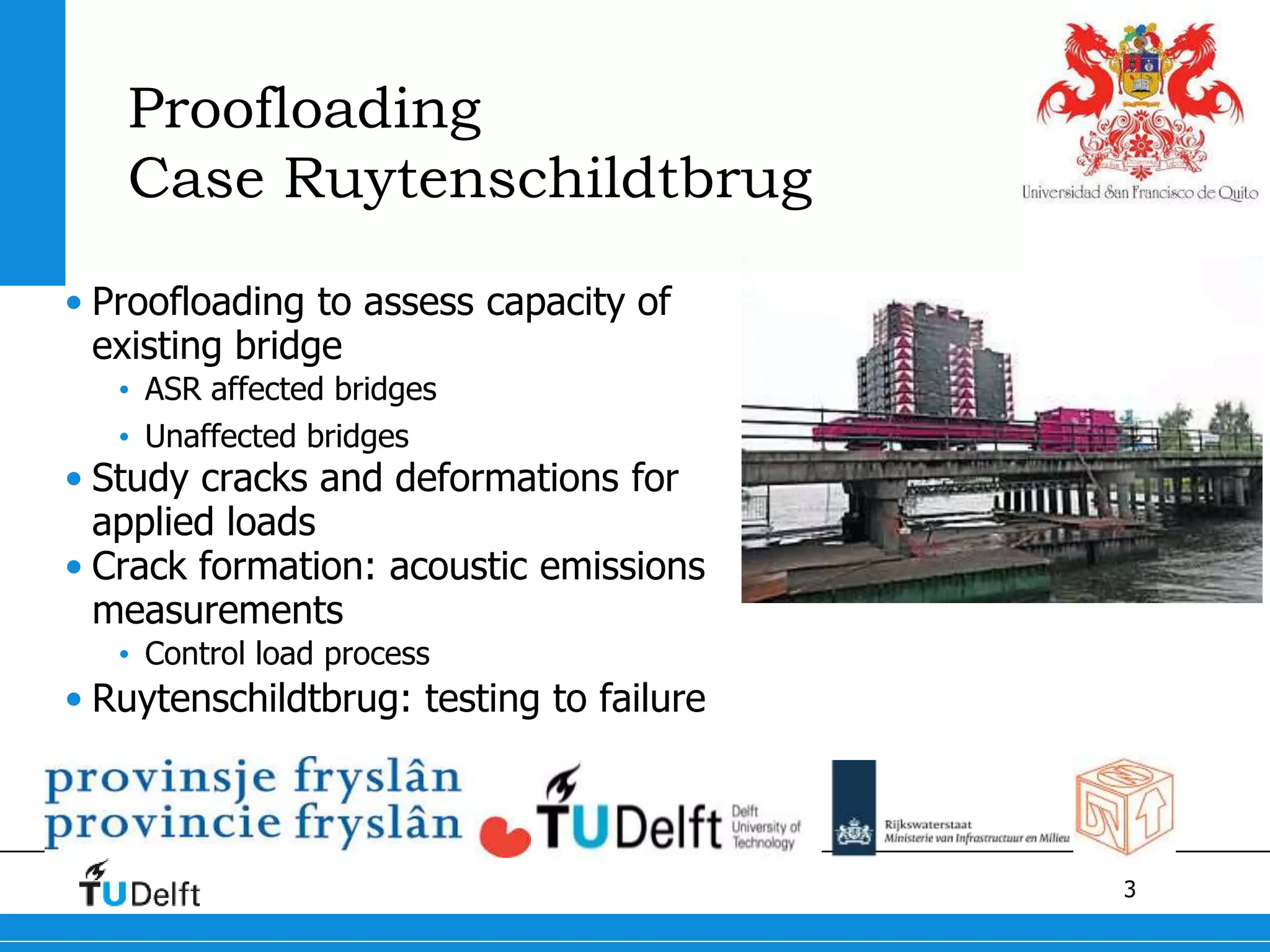

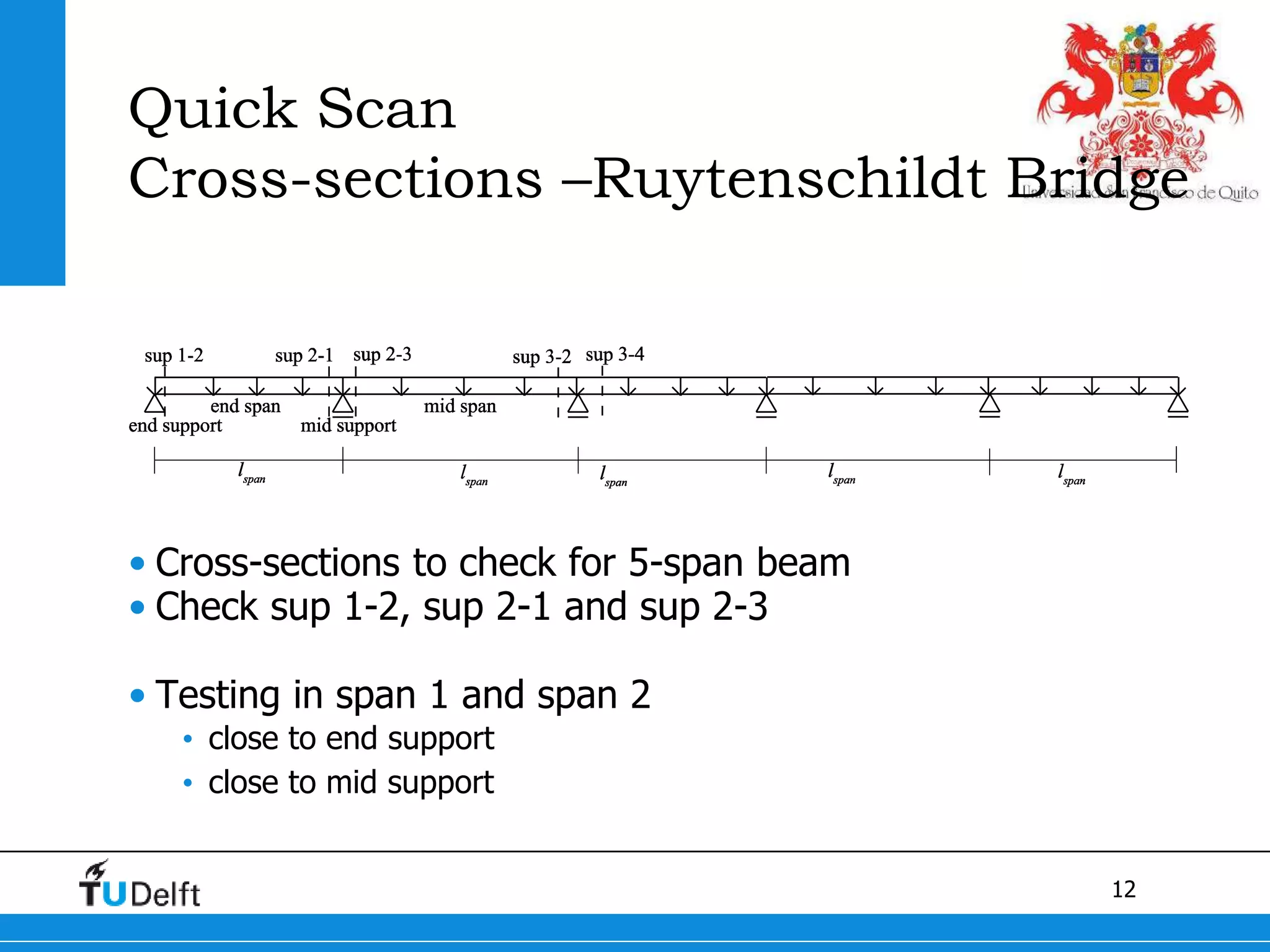

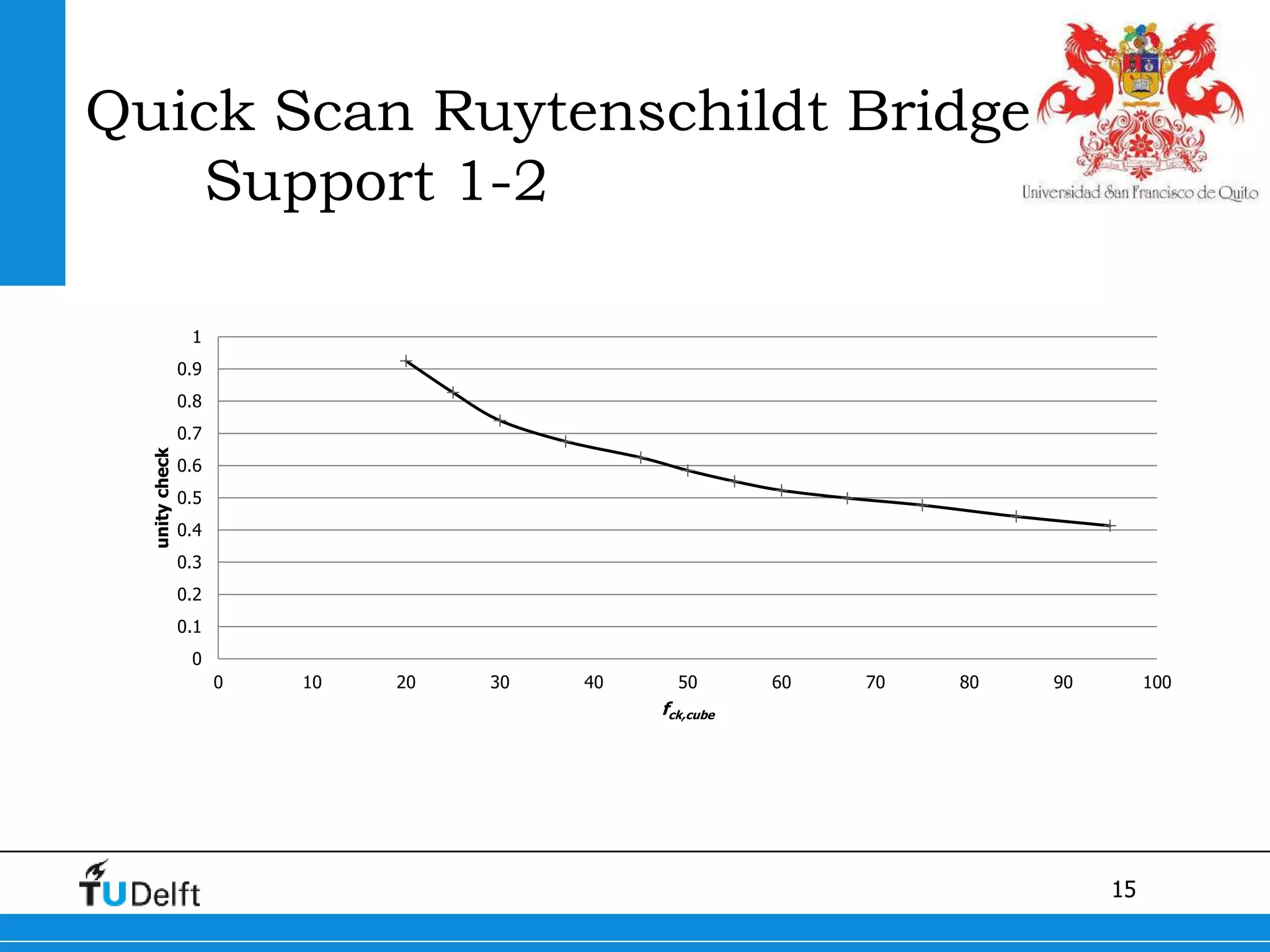

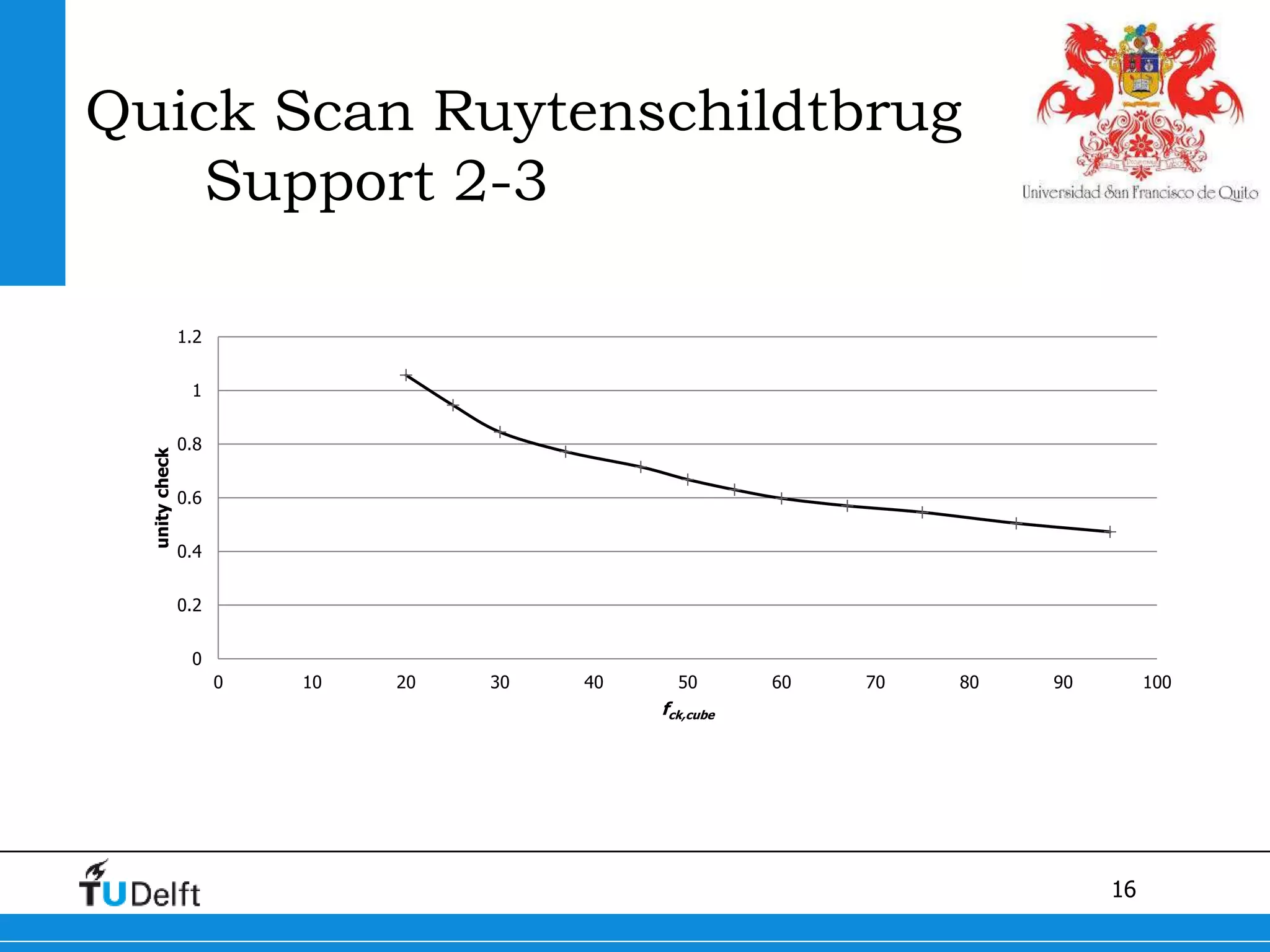

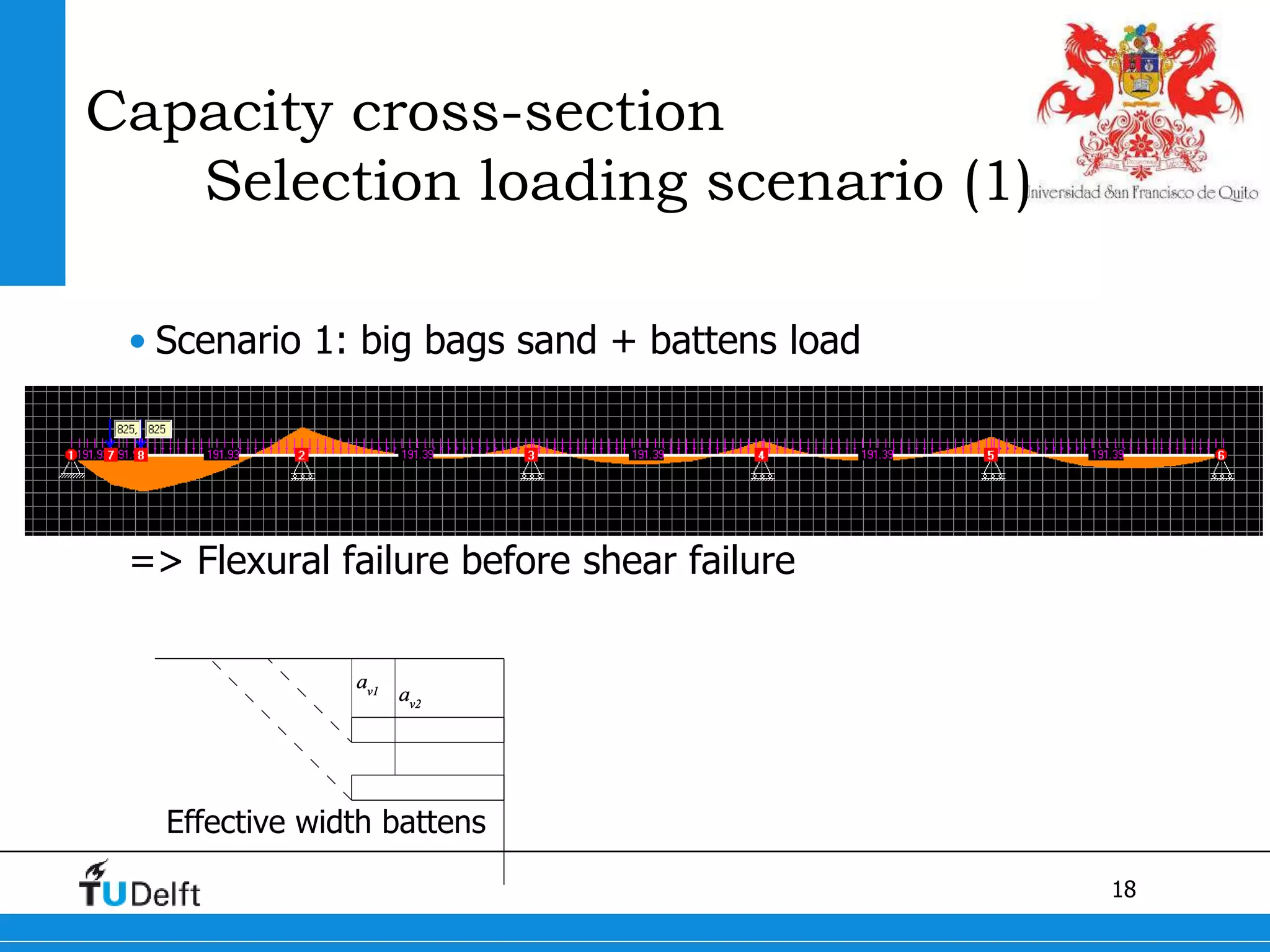

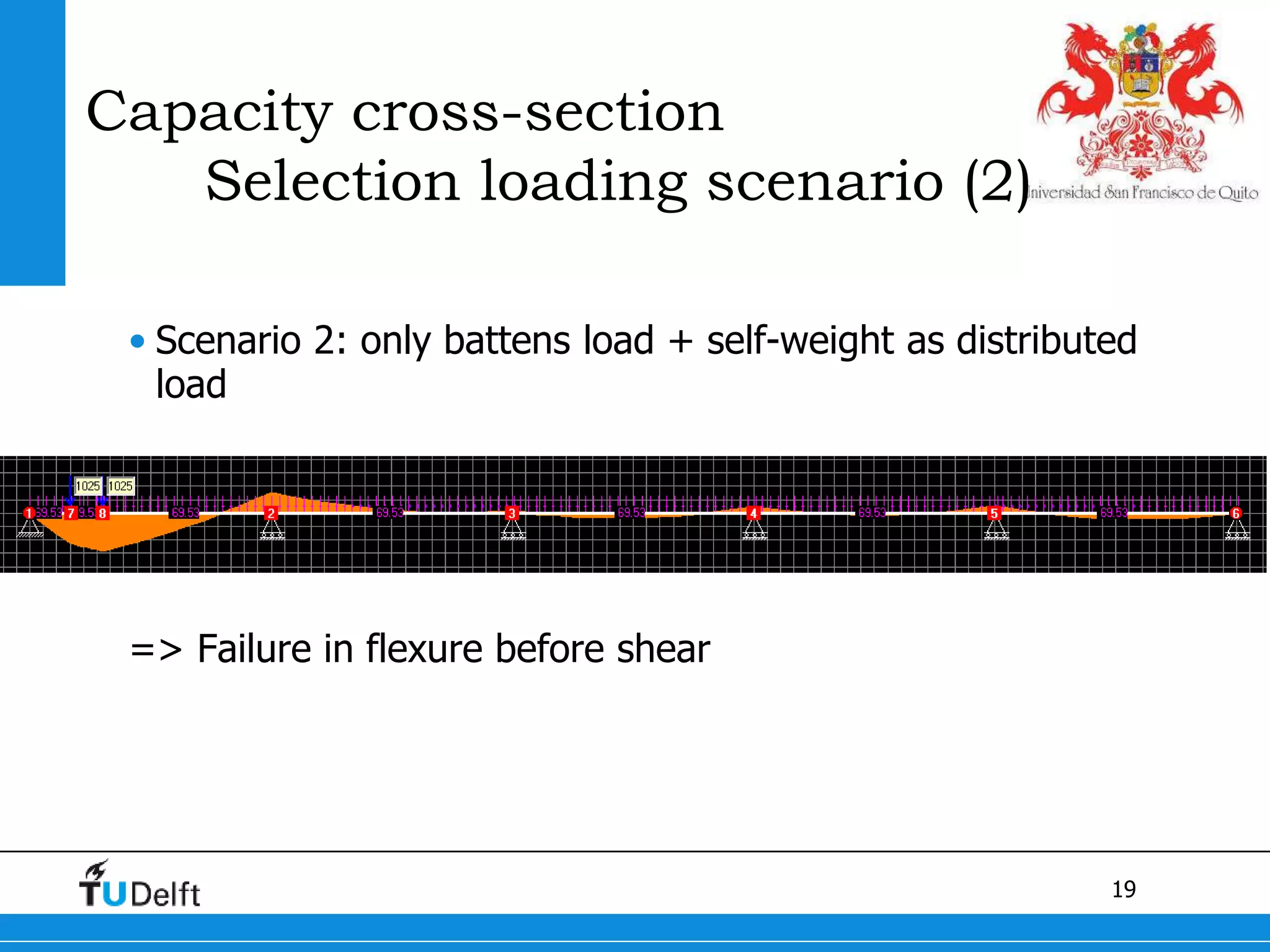

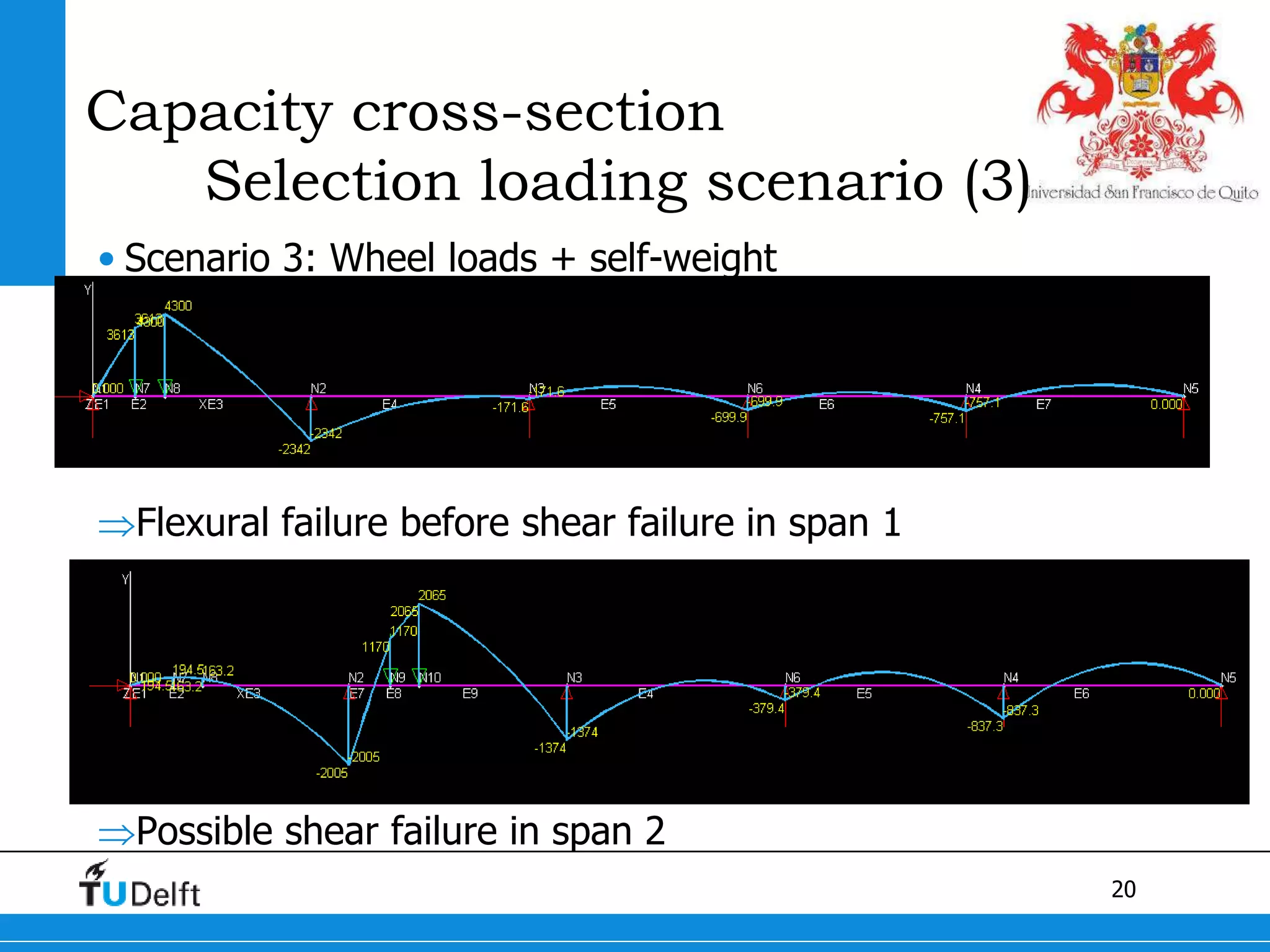

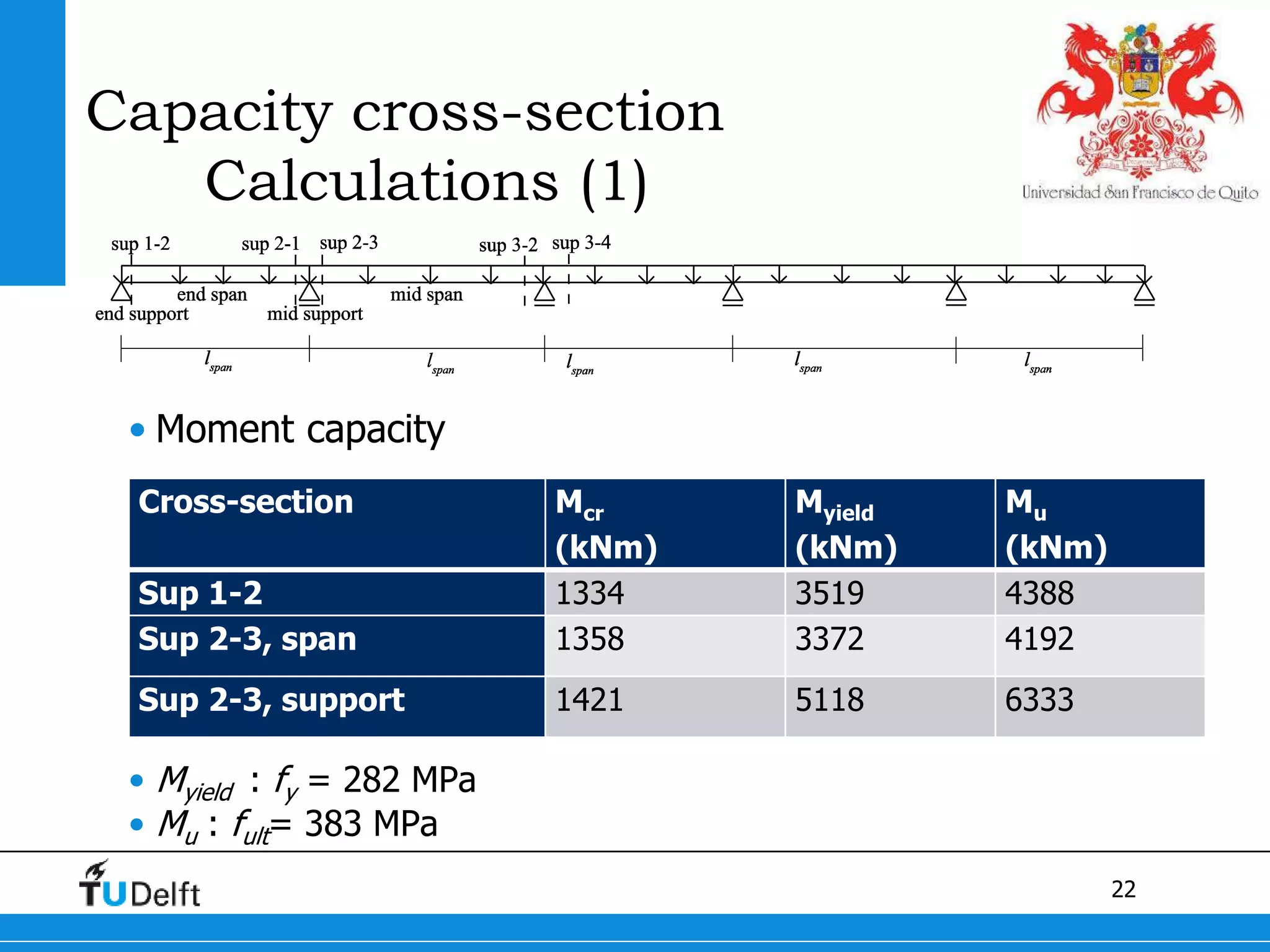

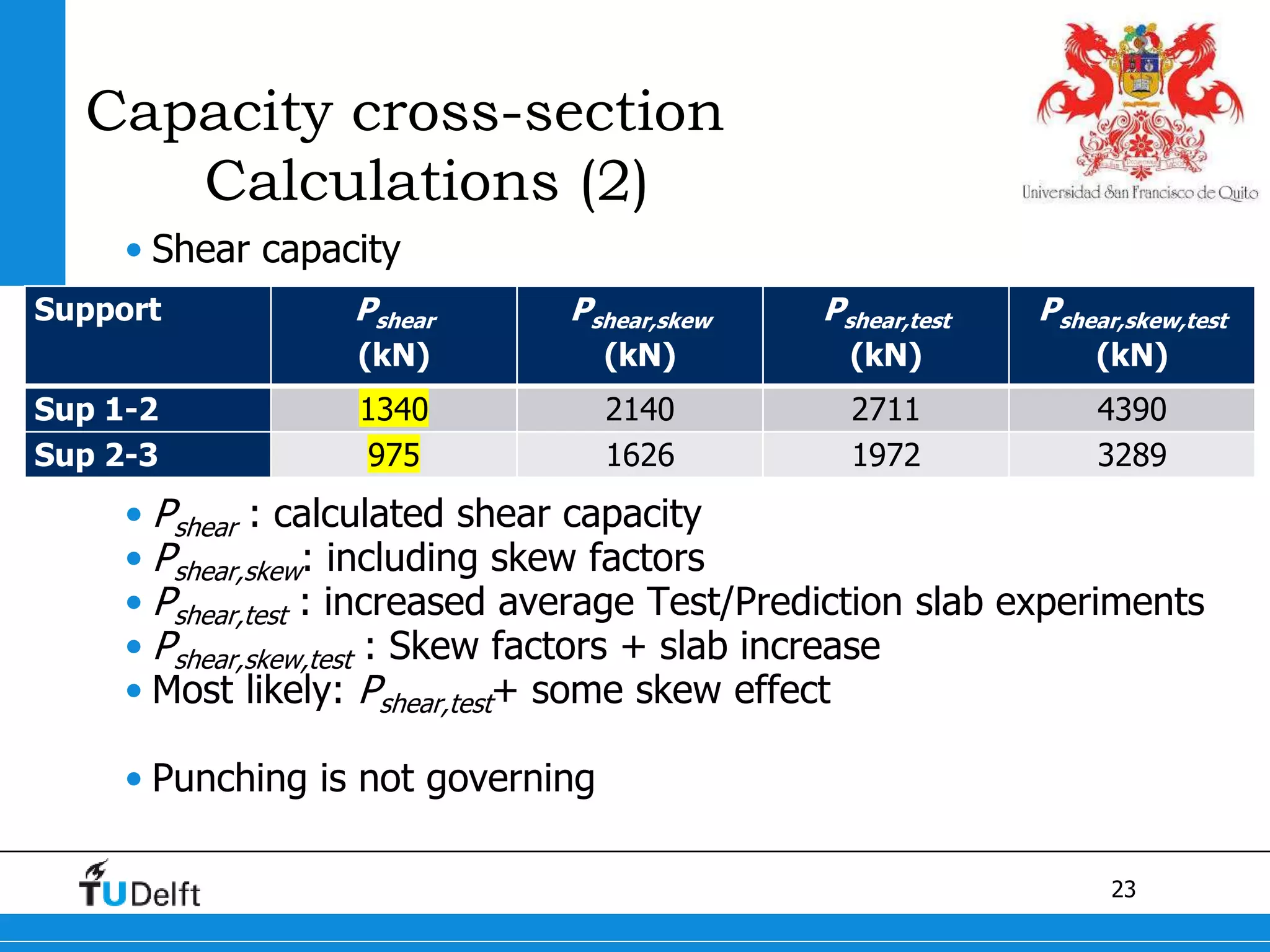

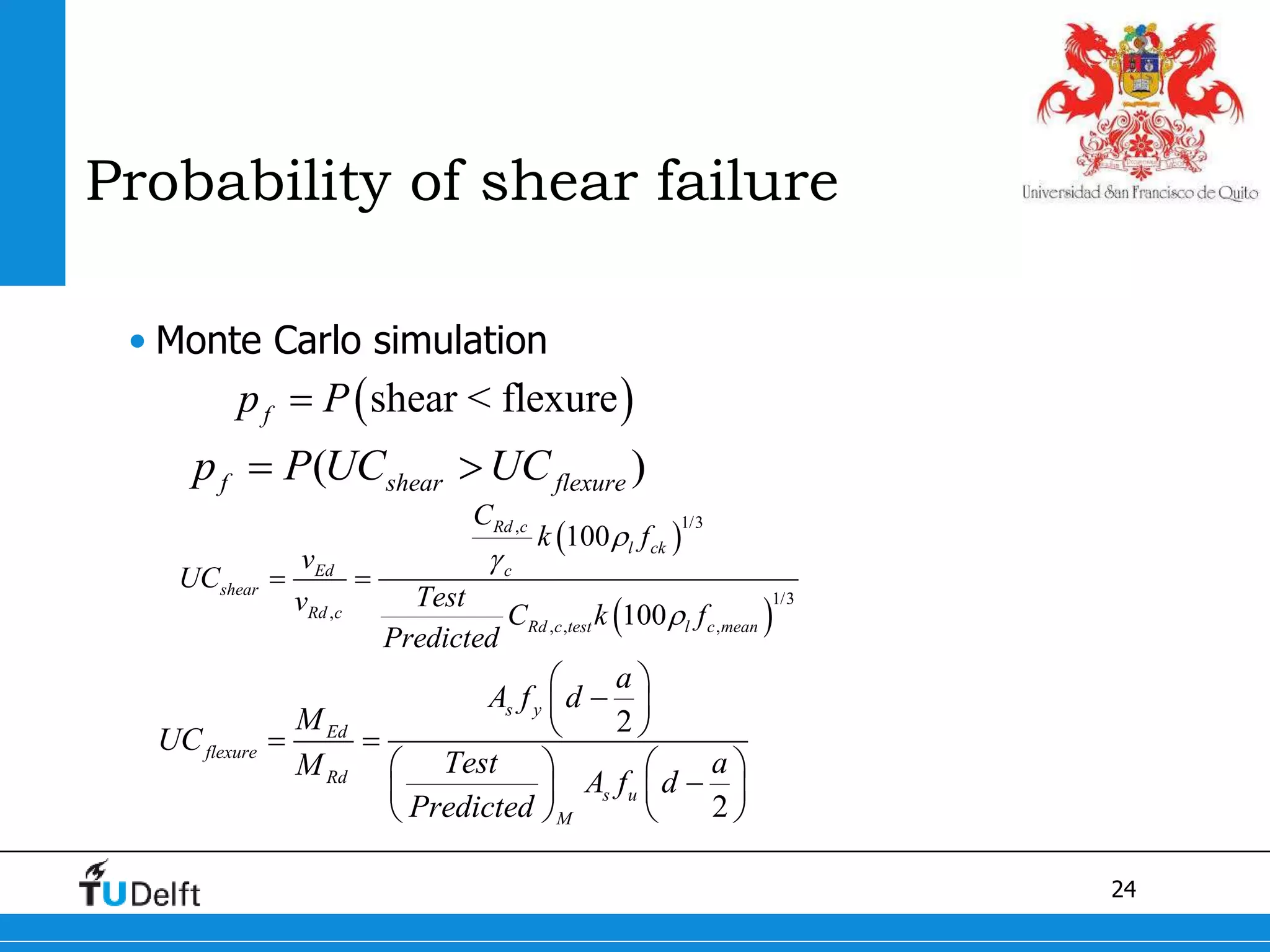

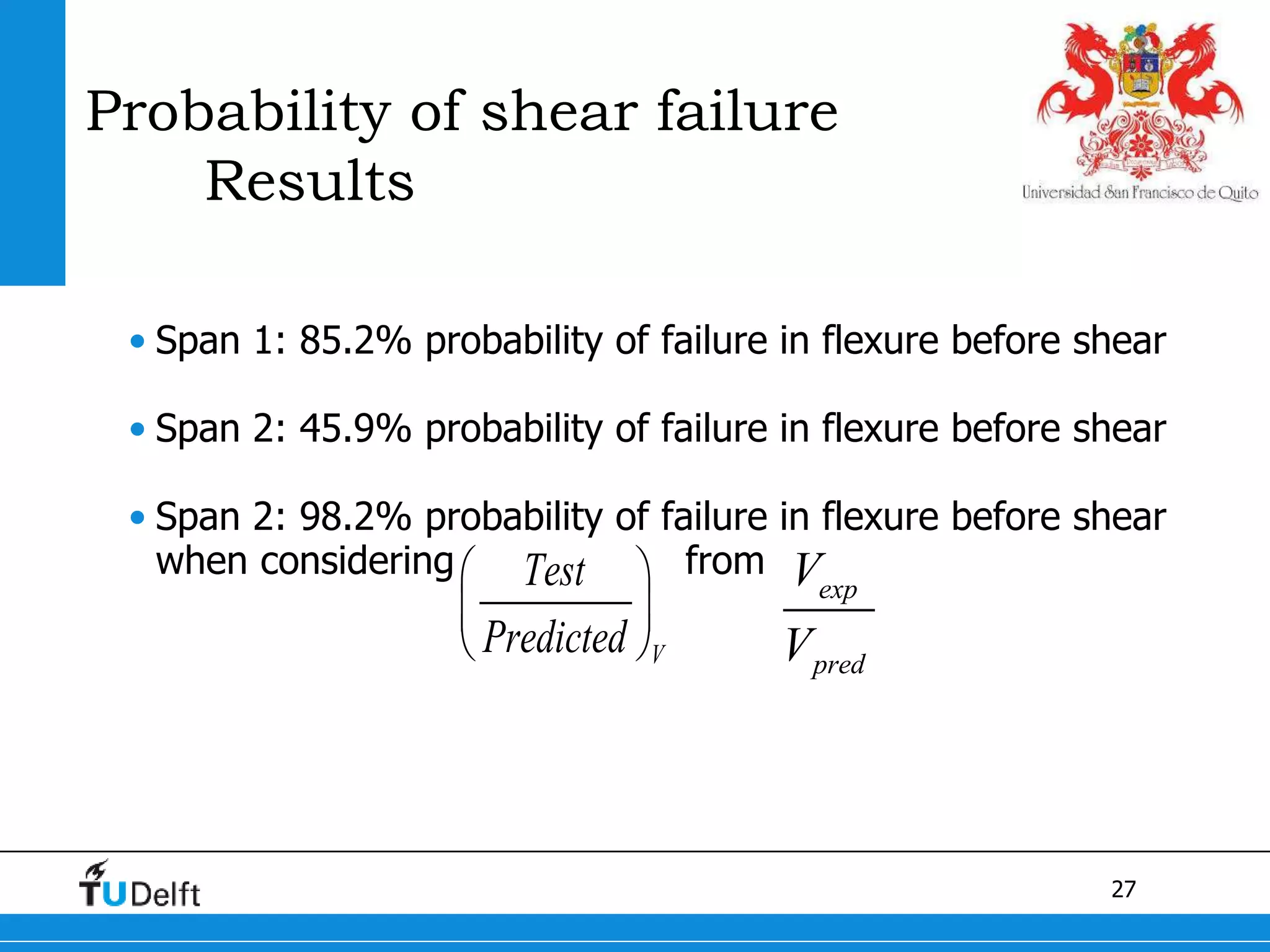

1) The Quick Scan analysis predicted failure by flexure in Span 1 and either flexure or shear failure in Span 2 of the Ruytenschildt Bridge.

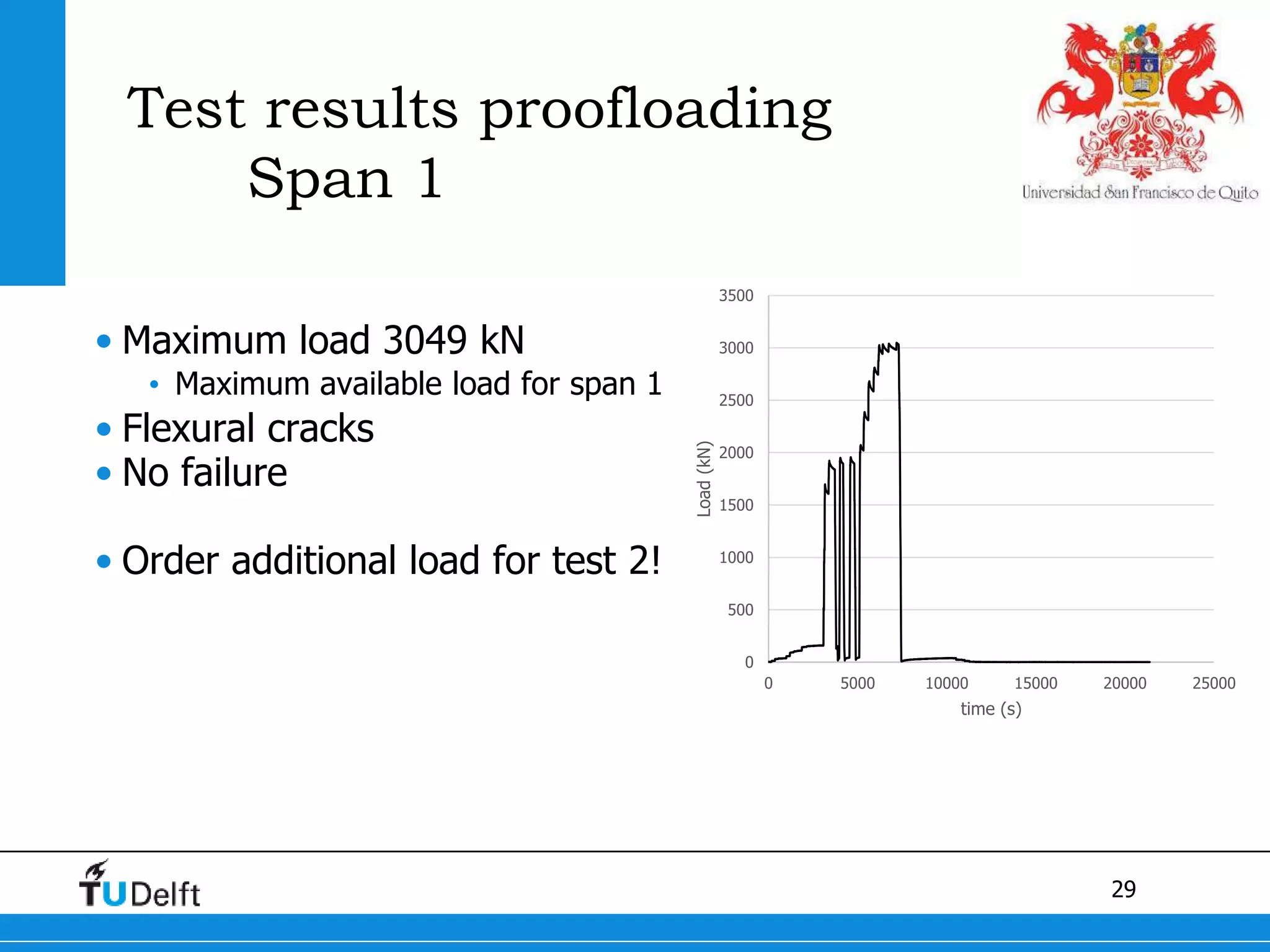

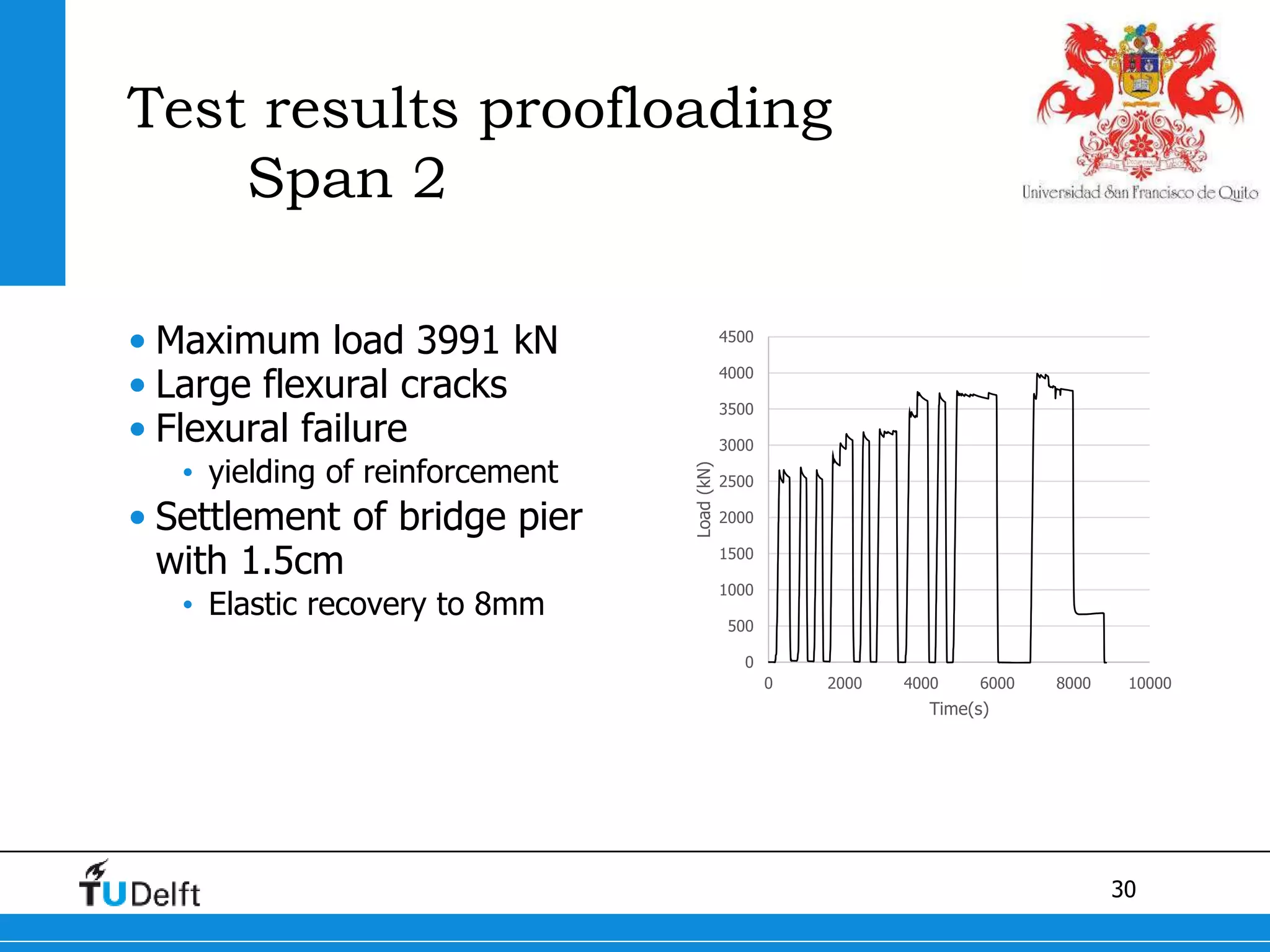

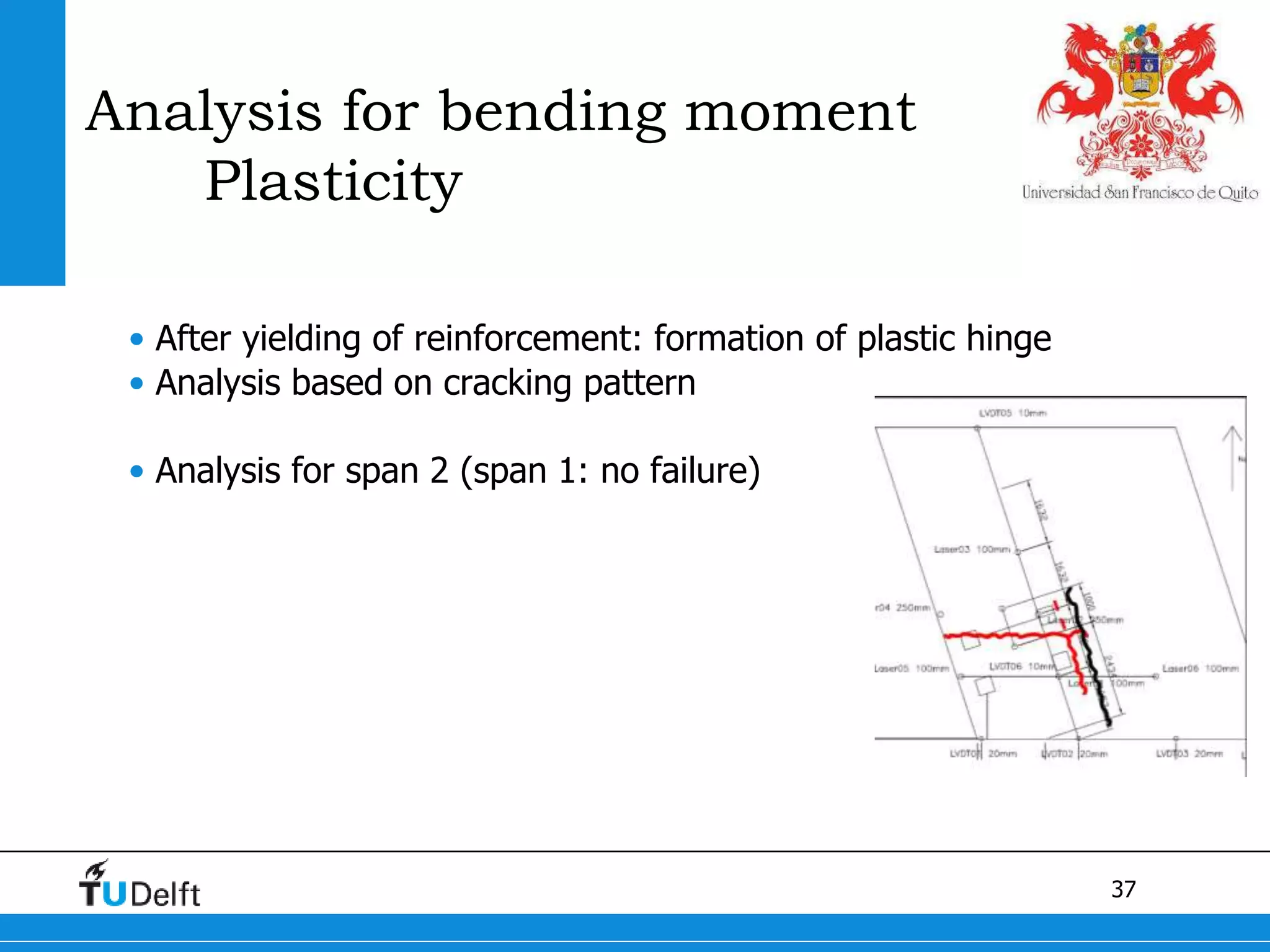

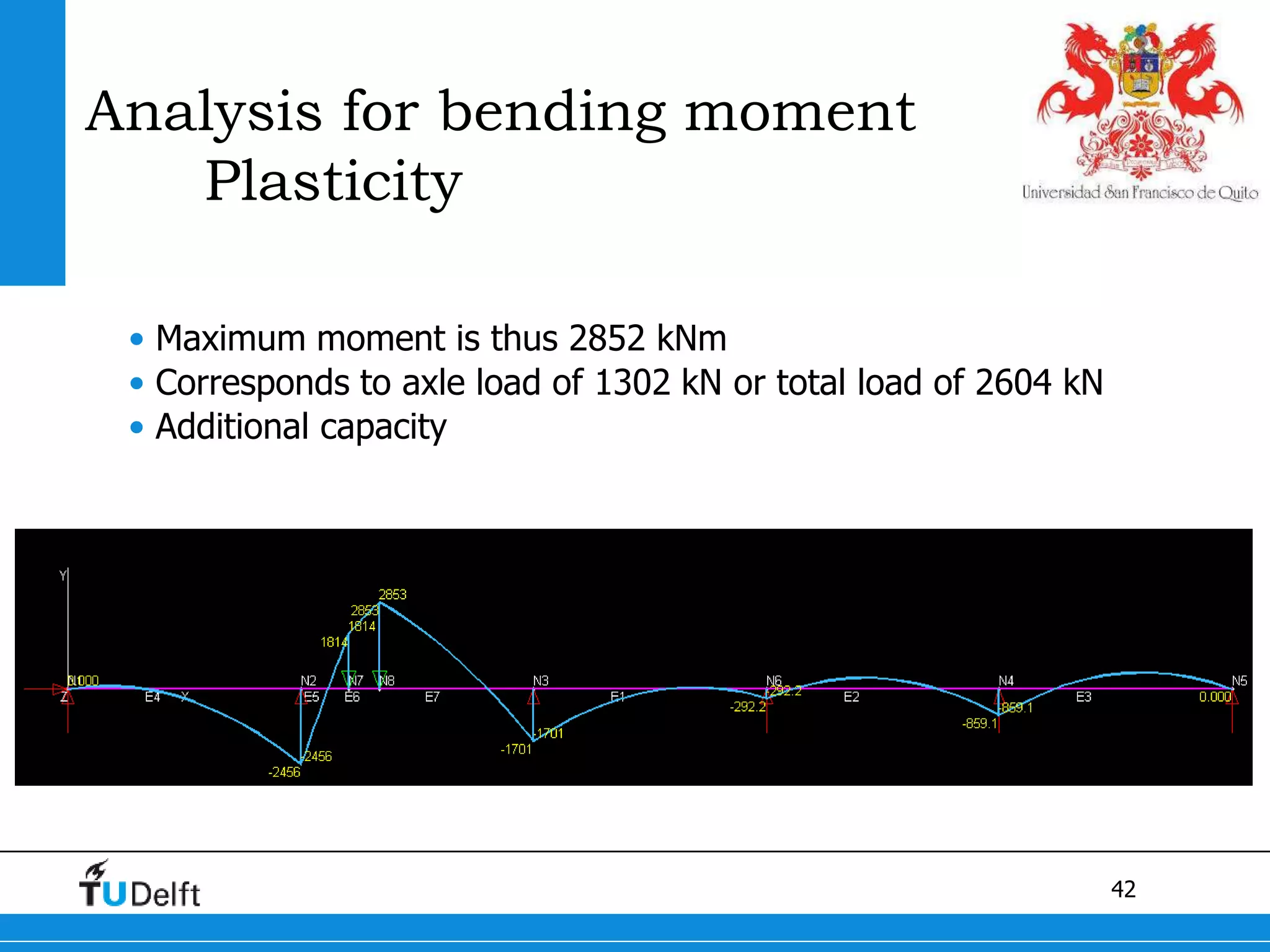

2) Proofloading tests showed flexural cracking in Span 1 without failure, and flexural failure in Span 2 through yielding of reinforcement.

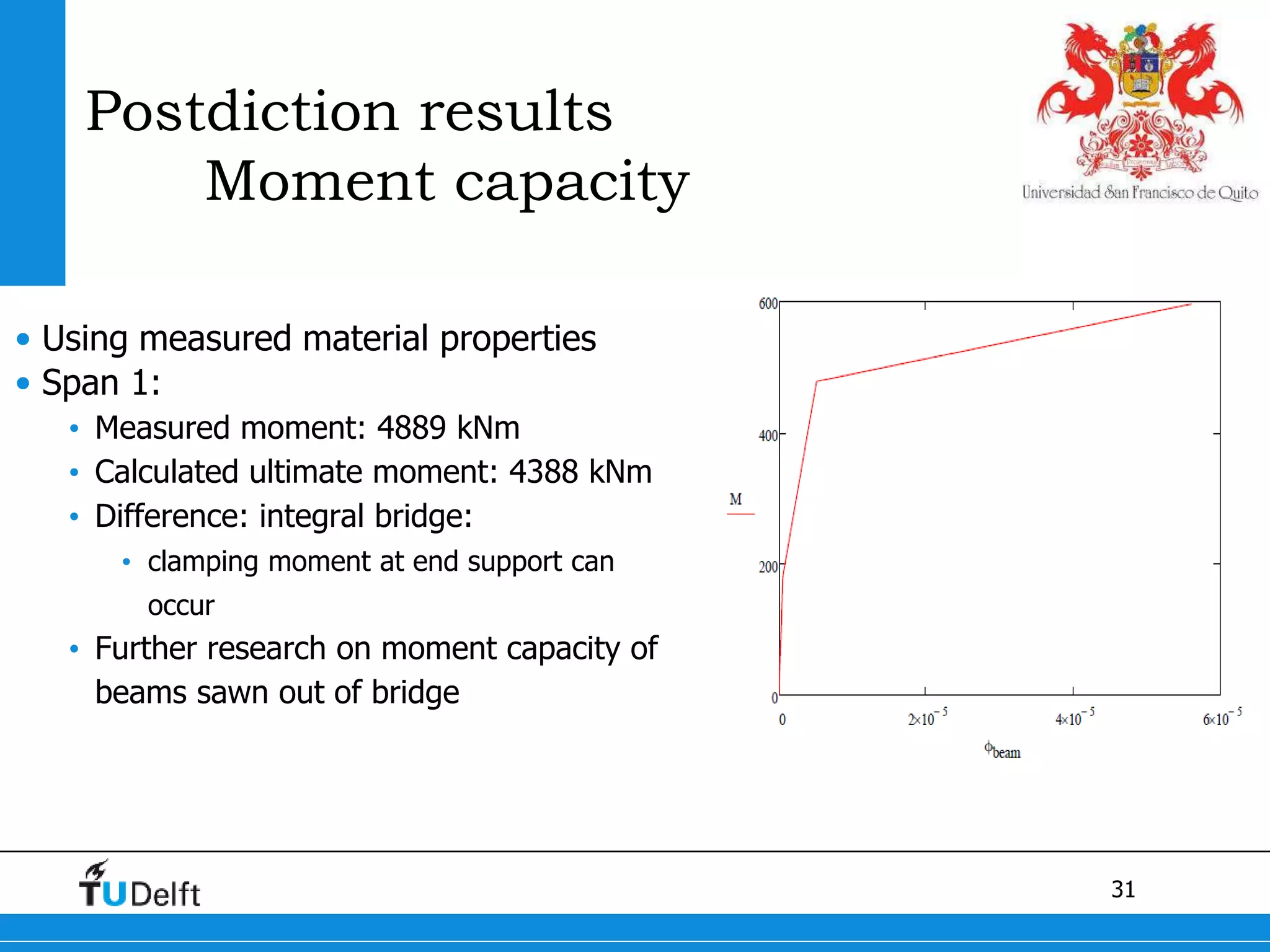

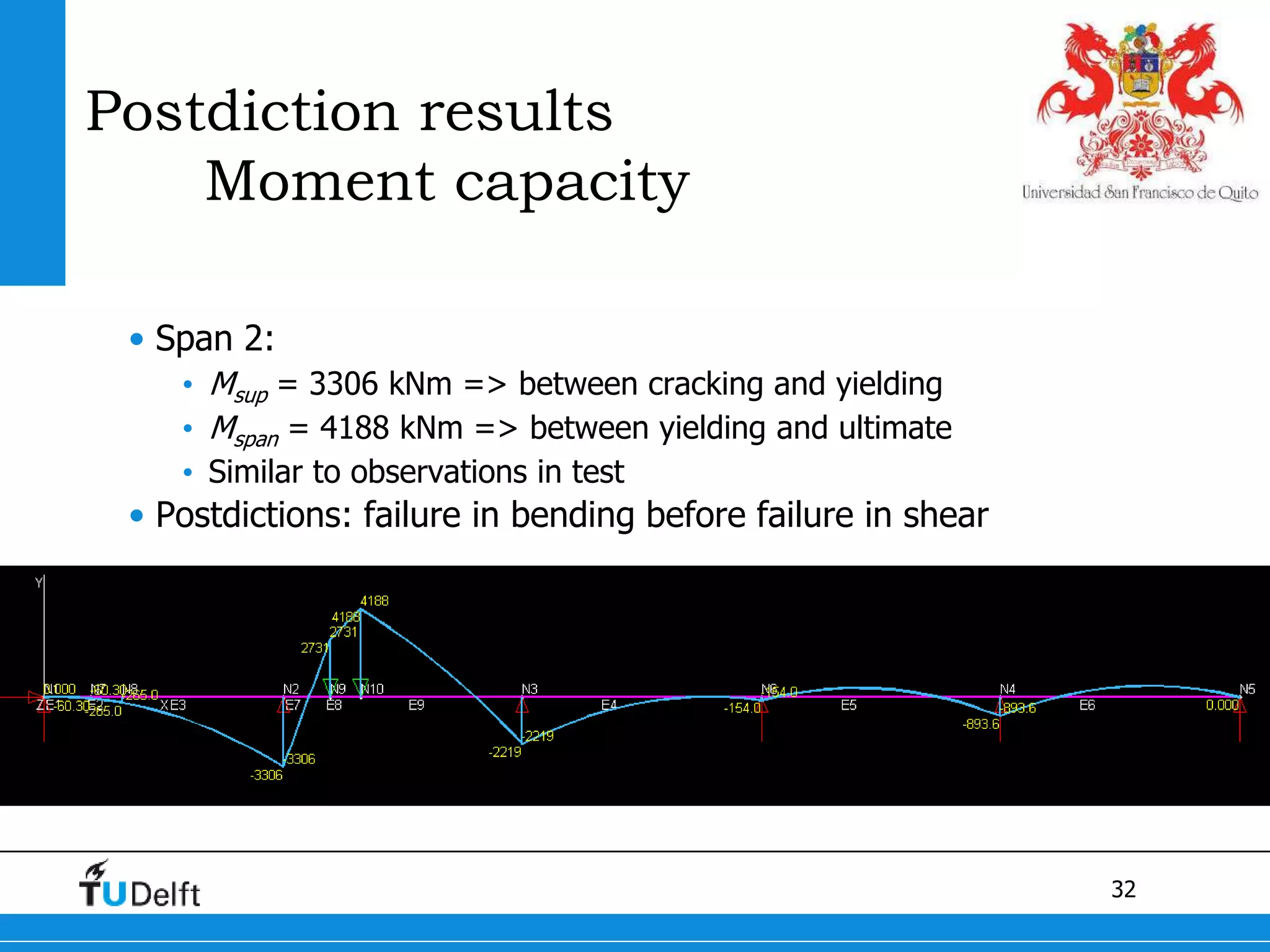

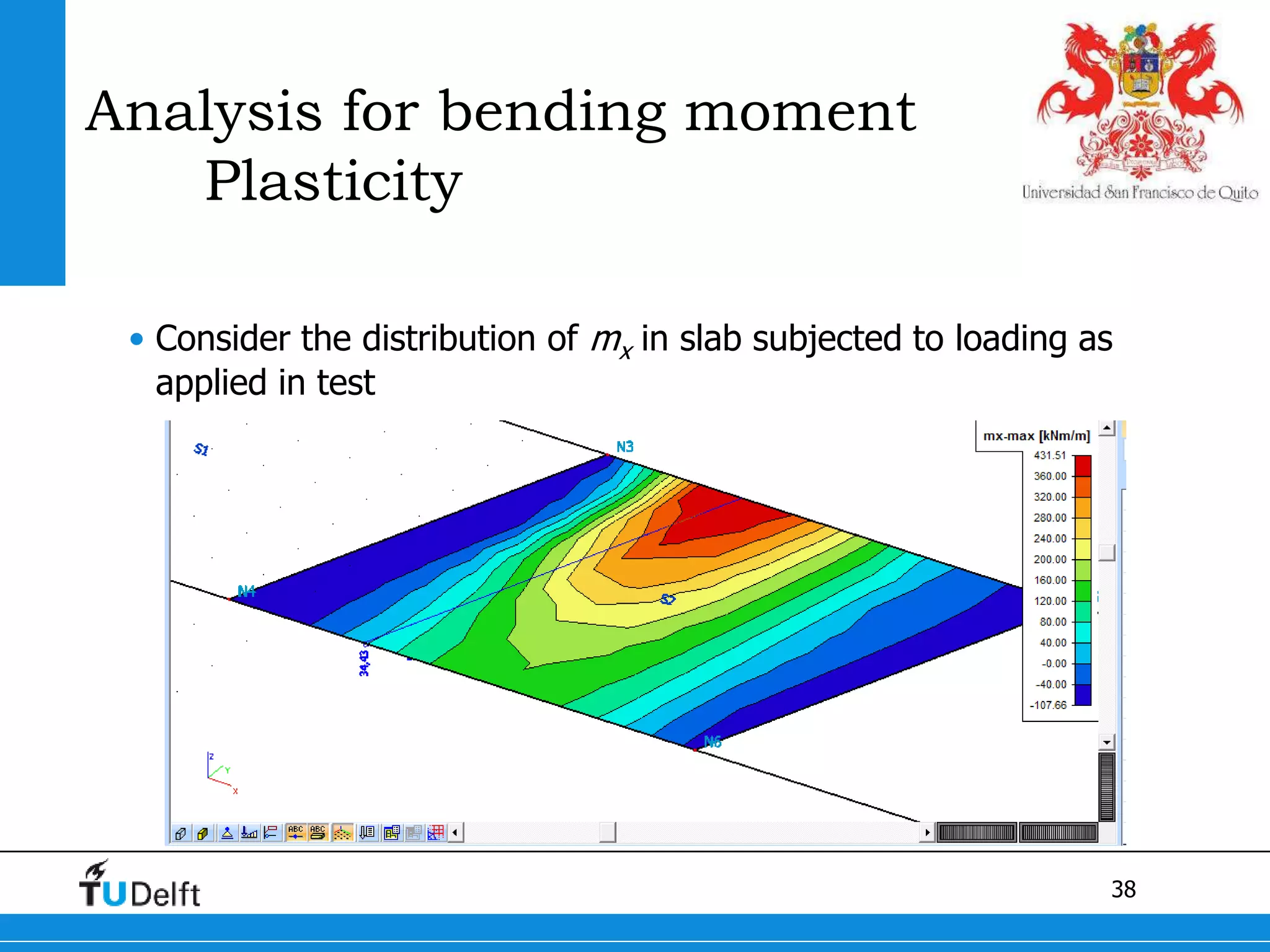

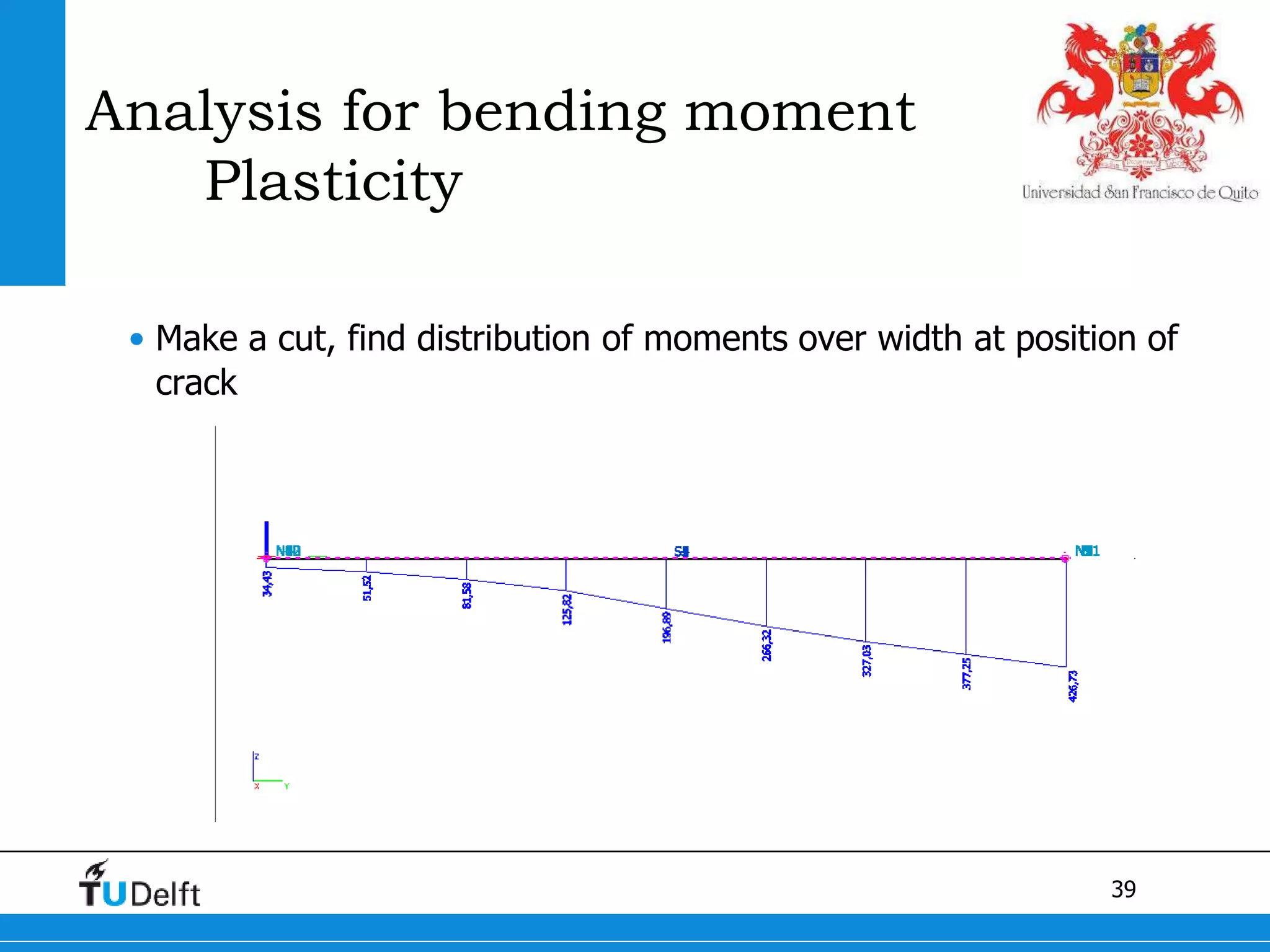

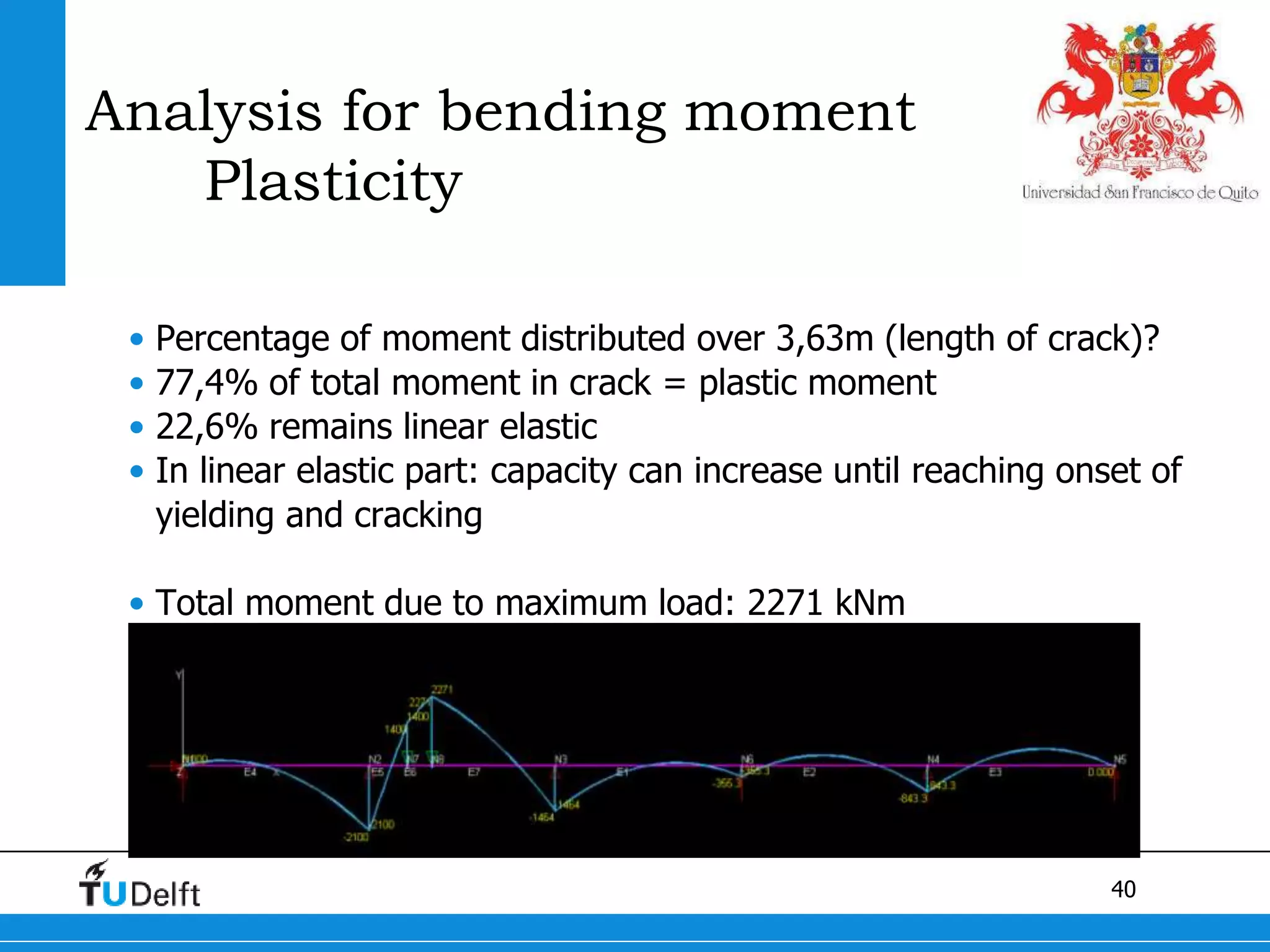

3) Postdiction analysis using material test results matched the failure modes observed and showed the bridge moments were below the calculated capacity.