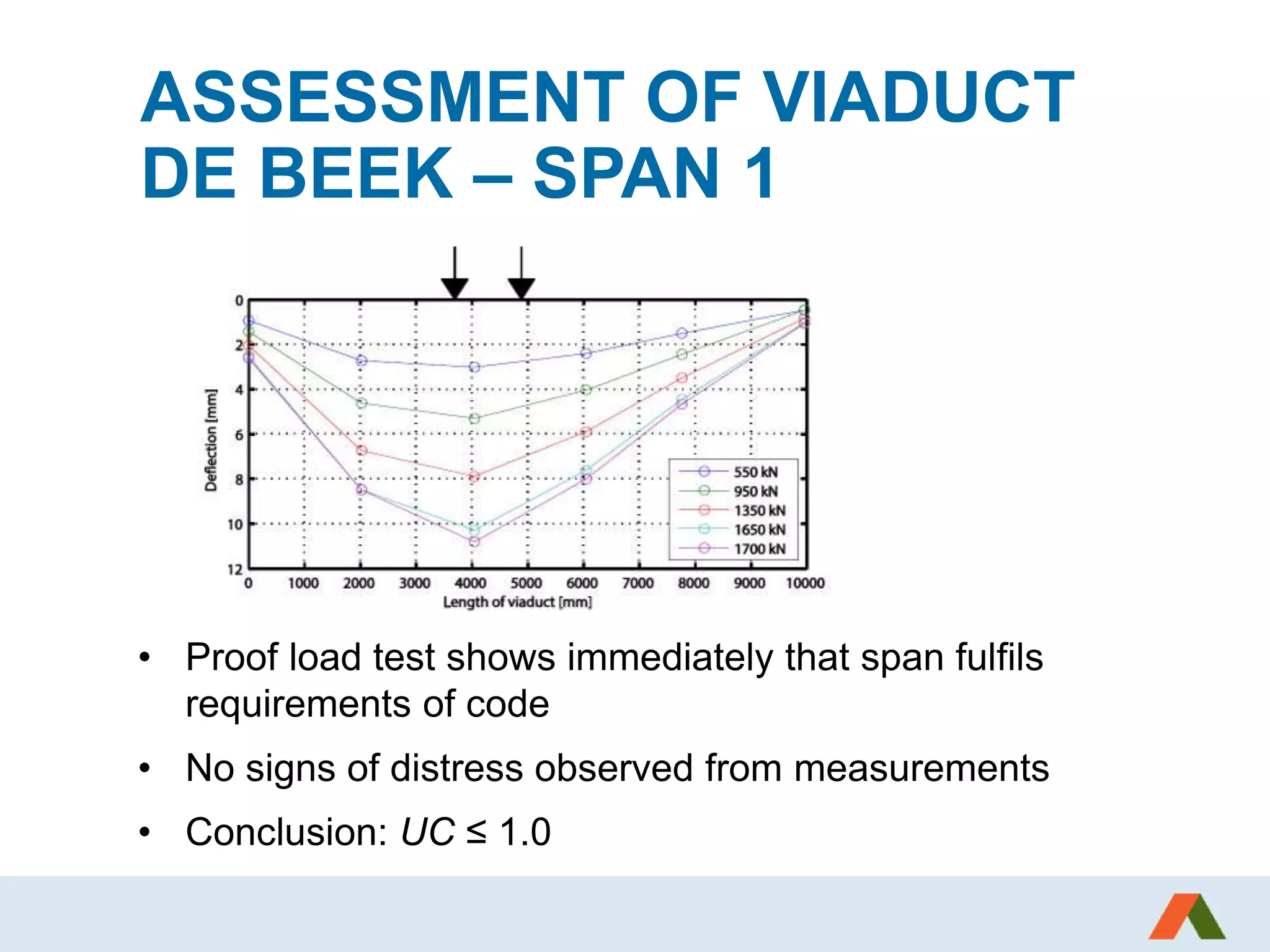

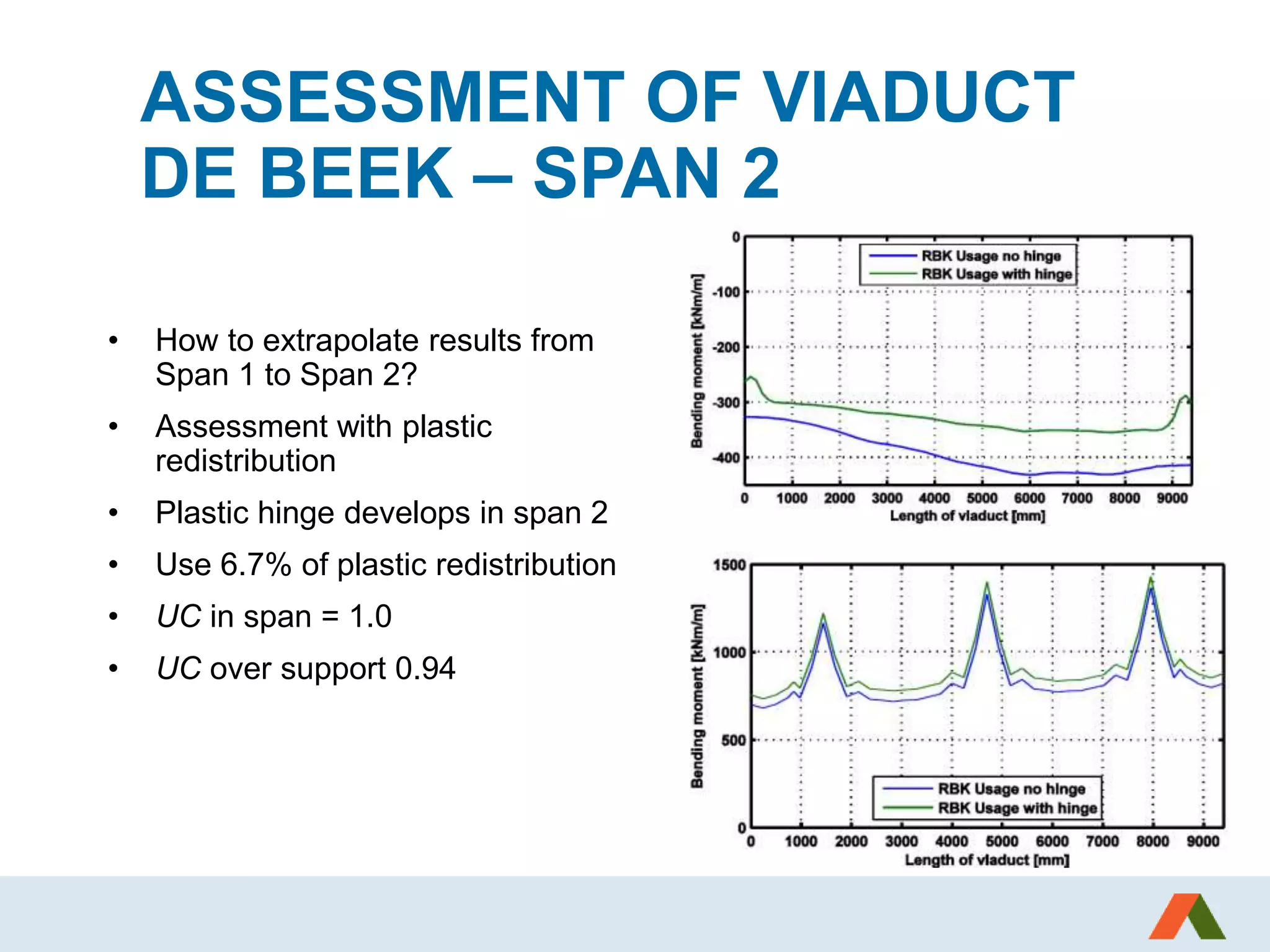

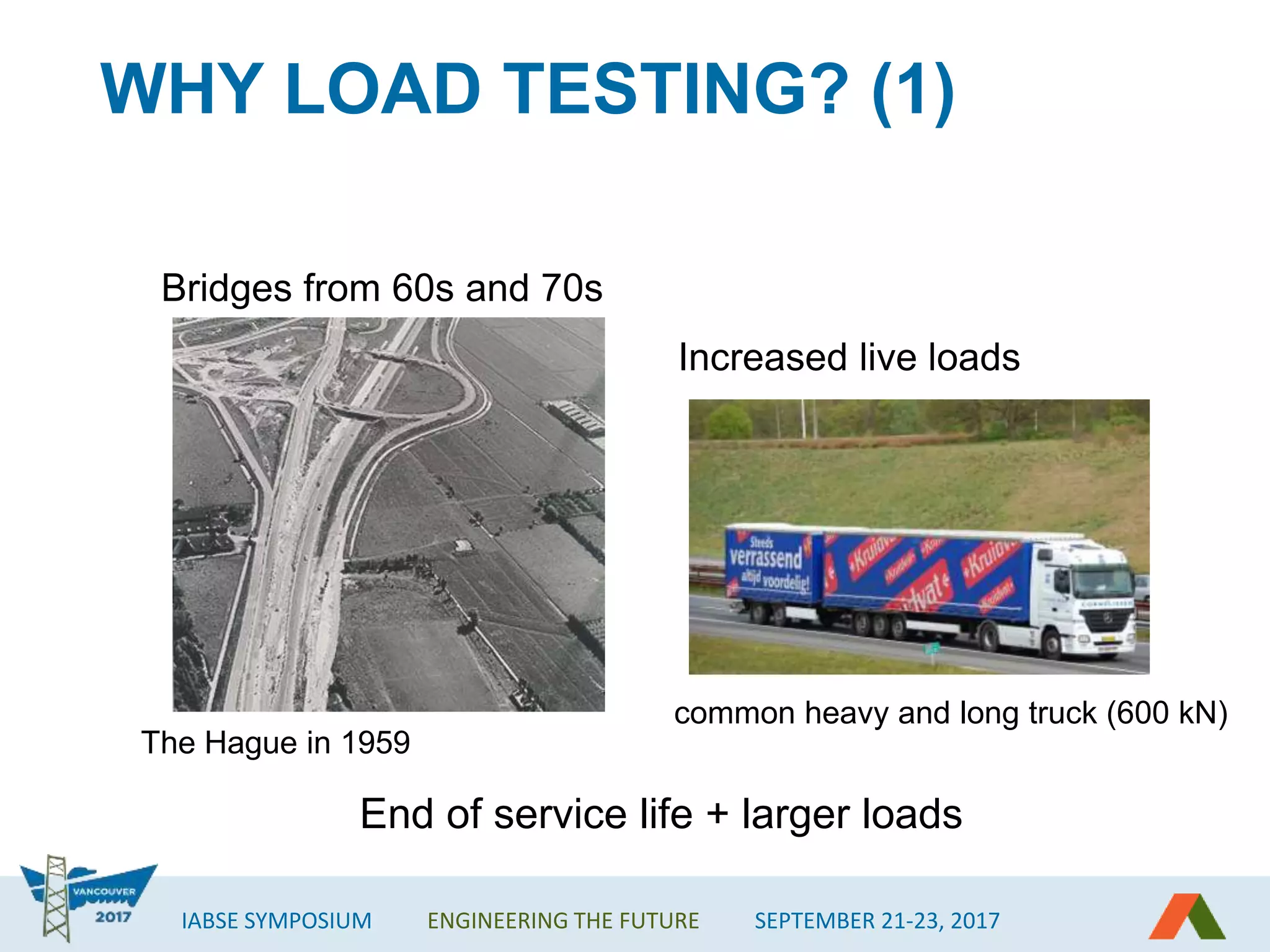

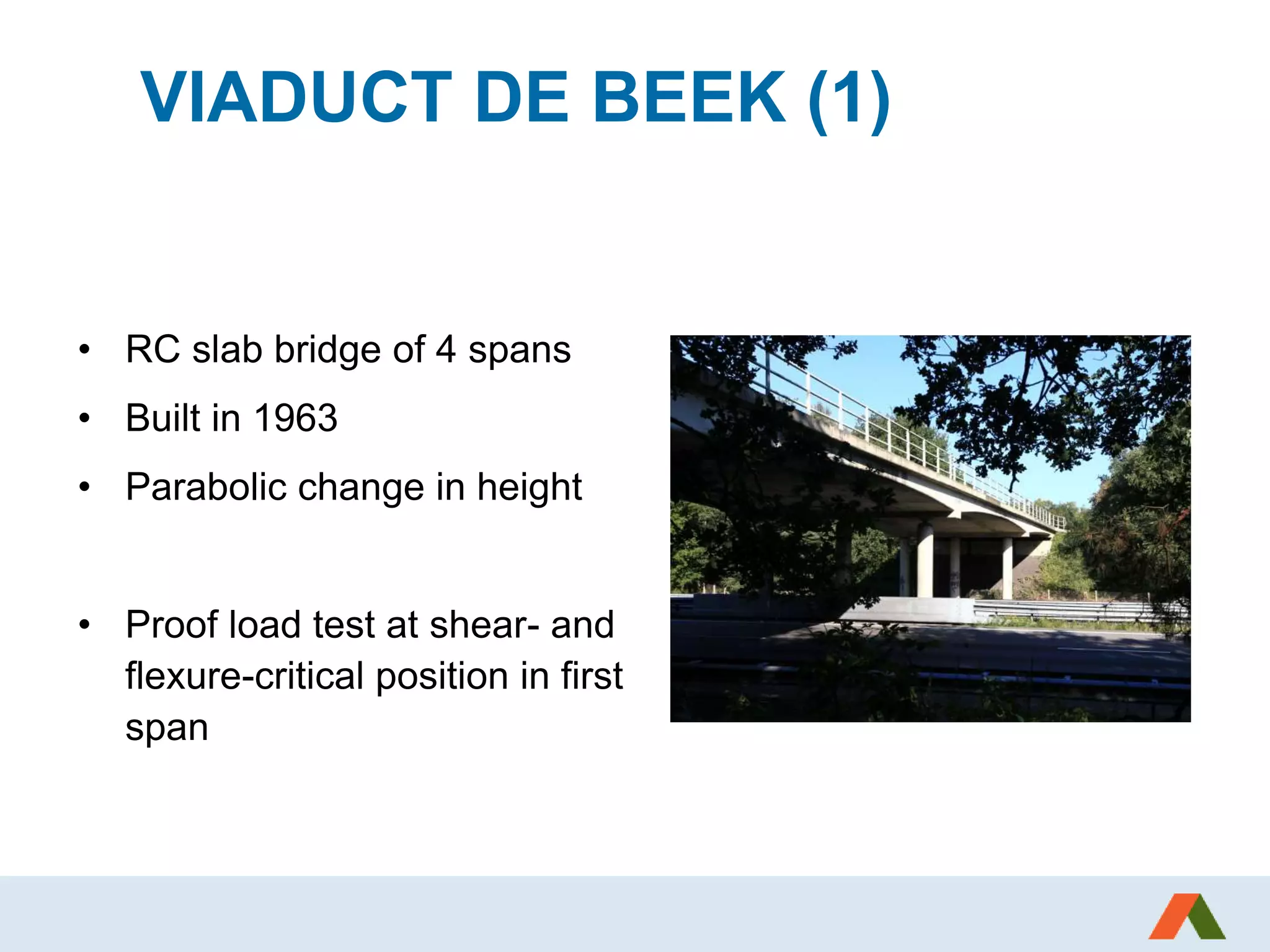

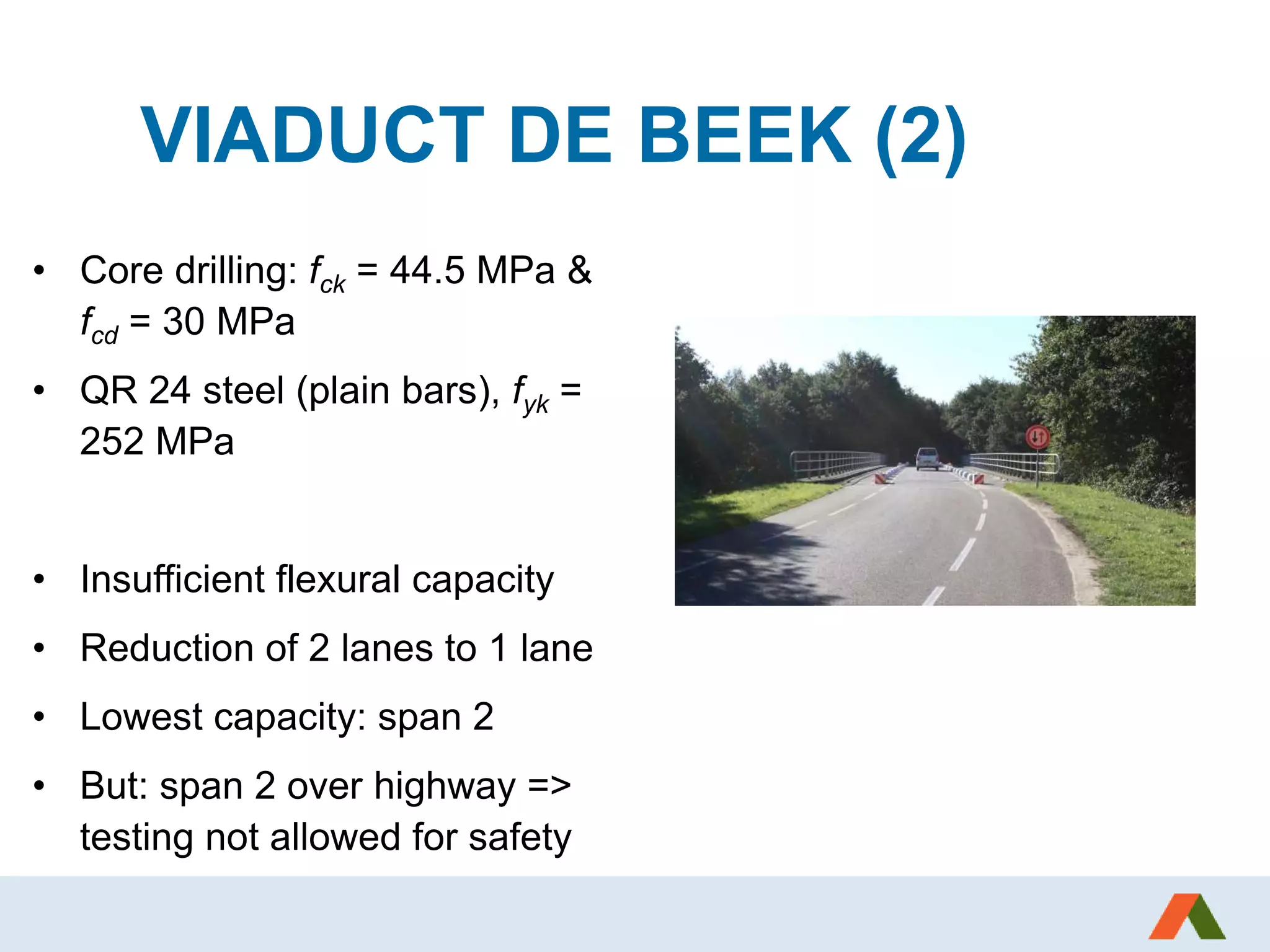

The IABSE symposium discusses the proof load testing of the viaduct de Beek, emphasizing the importance of evaluating aging bridges from the 1960s and 70s for safety under increased live loads. The document details the preparation, execution, and assessment processes of the proof load test, highlighting the use of sensors and a cyclic loading protocol. Ultimately, the viaduct demonstrated compliance with safety requirements, with recommendations for further inspections and traffic reopening.

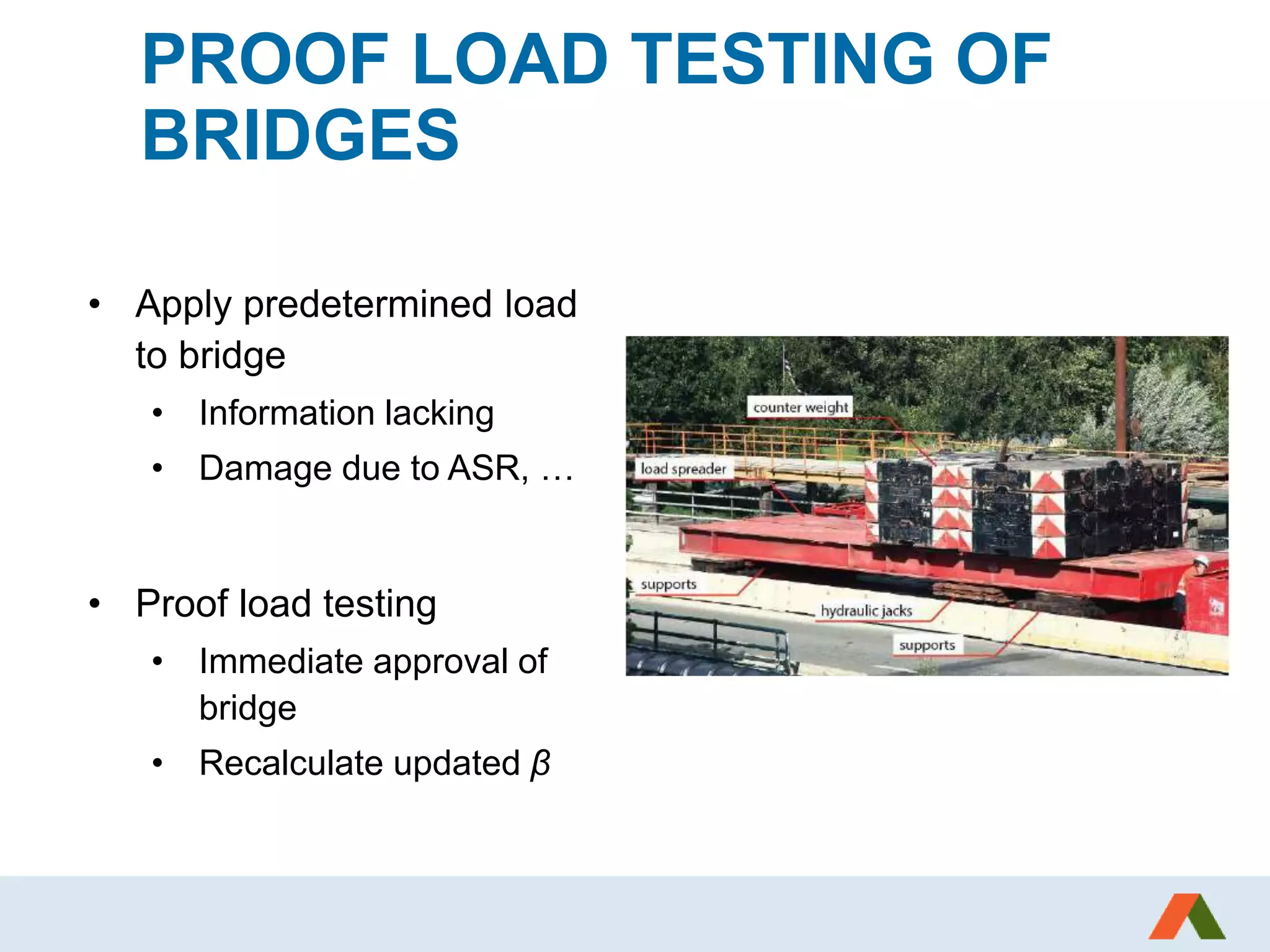

![PREPARATION OF LOAD

TEST – TARGET PROOF LOAD

Reliability level β Pb

[kN]

Ps

[kN]

EC ULS 4.3 1656 1525

RBK Design 4.3 1649 1516

RBK Reconstruction 3.6 1427 1311

RBK Usage 3.3 1373 1262

RBK Disapproval 3.1 1369 1257

EC SLS 1.5 1070 976

• Find target proof load that results in same sectional moment or

shear as load combination of code

• With LFEA

• Load combination with load factors depending on safety level

• Exception γDL = 1.10](https://image.slidesharecdn.com/iabsedebeek2017-06-23-170925210309/75/Proof-load-testing-of-the-viaduct-De-Beek-7-2048.jpg)