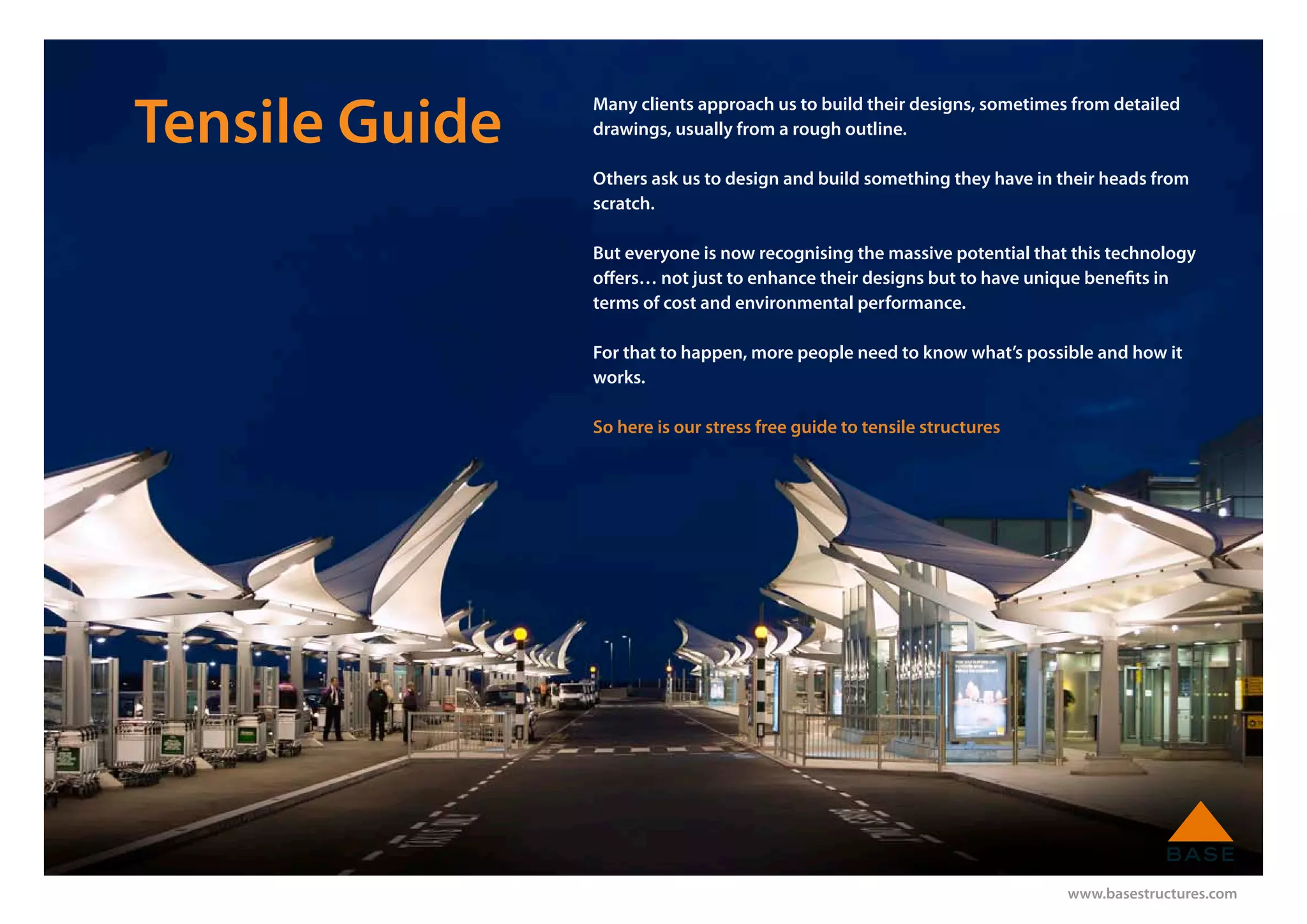

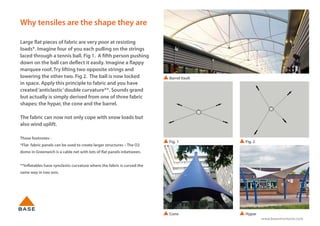

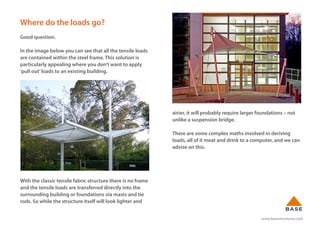

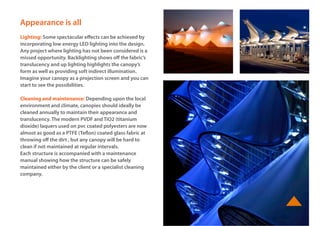

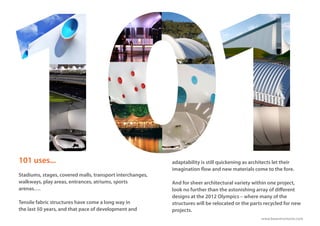

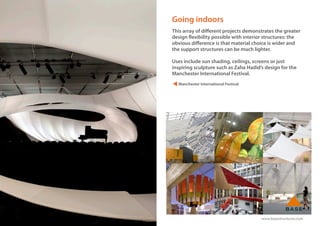

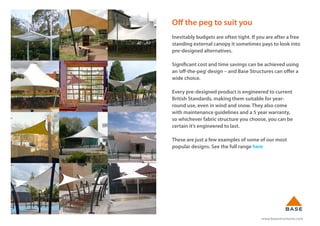

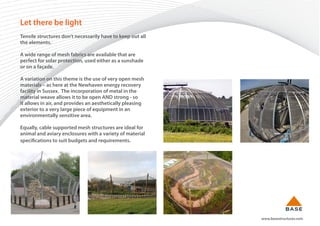

This document provides an overview of tensile fabric structures and guidance on their design and construction. It discusses how tensile structures derive their shape from fabric engineering principles and how their loads are transferred. It also outlines considerations for choosing fabrics, lighting, maintenance, and other factors. The document demonstrates the flexibility and many applications of tensile structures, from tents to stadium roofs, and how their design continues to advance through new materials and software.