This document details experiments conducted on temperature and concentration fields during combustion in a rapid compression machine, utilizing Rayleigh scattering and laser-induced fluorescence techniques. The study explores how these fields develop during combustion processes, particularly focusing on the exothermic decomposition of di-t-butyl peroxide, highlighting the effects of temperature stratification on reaction rates. The findings support improved understanding and modeling of combustion dynamics applicable to rapid compression machines.

![Temperature Fields During the Development of Combustion

in a Rapid Compression Machine

J. CLARKSON, J. F. GRIFFITHS*, J. P. MACNAMARA, and B. J. WHITAKER

School Of Chemistry, The University, Leeds, LS2 9JT UK

Temperature and concentration fields have been imaged by Rayleigh scattering in one-dimension on a line and

by laser induced fluorescence (LIF) of acetone in a 2-D sheet across the diameter of the cylindrical combustion

chamber in a rapid compression machine. Experiments were performed in non-reactive and reactive conditions.

To investigate the development of combustion, the exothermic decomposition of di-t-butyl peroxide vapor

diluted by inert gas was studied. This reaction is characteristic of a conventional thermal ignition. Acetone is

a major product. Inert gas mixtures, to study the temperature field in the absence of reaction, were seeded with

acetone. The evidence from the experimental results supports the following interpretation. As the piston of the

machine moves, it shears gas off the walls of the chamber. This probably creates a roll-up vortex, but more

importantly it also collects cool gas from the walls and moves this gas across the cylinder head pushing it forward

into a plug at the center. Once the piston stops, there is a stratified component at the center, which is slightly

colder than the bulk of the gas, and for a short time afterwards there is very limited mixing by bulk transport

of gas from one part to another, because the gas velocity is not very high. Diffusive transport will occur, but the

timescale is relatively slow, and the effect hardly shows before 20 to 25 ms after the end of compression. The

effect (on the combustion of di-t-butyl peroxide) of this “temperature stratification” at the core of the cylinder

is that the reaction develops more slowly in the center than elsewhere. The onset of reaction in a toroidal region

is shown unambiguously, and thermal runaway is initiated there. This is demonstrated by LIF measurements

through the central plane of the reaction cylinder. From the study of inert mixtures seeded with acetone, it is

shown also that the colder core lies just ahead of the piston crown, but it does not reach the central plane until

1 ms after the piston has stopped. Rayleigh scattering on a 1-D line in the central plane proved to be

insufficiently sensitive to show the presence of the cooler zone resulting solely from the physical compression.

However, the evidence for temperature stratification becomes unequivocal from Rayleigh scattering measure-

ments made in the later stages of the peroxide decomposition. Limits of sensitivity of the scattering technique

may be inferred from this. The physical characteristics of the compression are likely to be replicated in other

rapid compression machines and are relevant to understanding the spatial development of autoignition in such

systems, which has implications also for numerical modeling. There are rather more complicated consequences,

than is the case for thermal ignition, for chain-thermal interactions which involve development through the

negative temperature-dependent regimes, as occurs in combustion of the alkanes and that of other organic

compounds. © 2001 by The Combustion Institute

INTRODUCTION

The development of the temperature field in the

combustion chamber of rapid compression ma-

chines (RCM) has been a subject of interest

over many years and the way in which temper-

atures of gases develop during reaction after the

piston has stopped has been a matter of debate.

This is particularly relevant to the quantitative

validity of numerical modeling using compre-

hensive kinetic schemes because, in such cases,

the assumption of a spatially uniform tempera-

ture throughout the combustion chamber is a

pre-requisite [1, 2]. Such modeling is used for

the kinetic understanding of the onset of engine

knock [3], and experiments in rapid compres-

sion machines are important in their own right

for validation of these numerical studies.

Until recently the only thermometric infor-

mation, which could be extracted from experi-

mental measurements in RCMs related to an

average gas temperature determined from the

measured pressure [2, 4–6] Griffiths and co-

workers have asserted that fast compression

(such as at a piston speed of 10 m sϪ1

) is very

close to being adiabatic, so that at the end of the

compression stroke the temperature should be

uniform throughout the chamber, and they have

given indirect evidence for this [4]. Minetti and

co-workers, at Lille, have also established that

even when compression occurs at a lower rate,

there is a very substantial “core gas” which is at

the adiabatic temperature [5]. In either case,

during the post compression period heat loss to*Corresponding author. E-mail: johng@chem.leeds.ac.uk

COMBUSTION AND FLAME 125:1162–1175 (2001)

0010-2180/01/$–see front matter © 2001 by The Combustion Institute

PII 0010-2180(01)00236-X Published by Elsevier Science Inc.](https://image.slidesharecdn.com/temperaturefieldsduringthedevelopmentofcombustioninarapidcompressionmachine-150806102355-lva1-app6891/75/Temperature-fields-during-the-development-of-combustion-in-a-rapid-compression-machine-1-2048.jpg)

![the combustion chamber walls must cause the

core gas volume to contract. Exothermic oxida-

tion of reactive mixtures after the end of com-

pression competes with these losses, but there is

little known about the way in which the temper-

ature field evolves.

Recently, the Lille group have made direct

measurements of the temperature at the end of

and following compression using both single

point Rayleigh scattering from a laser beam and

thermocouple measurements [7, 8]. They traced

the thermal history of the core gas by both

techniques over a considerable post-compres-

sion period in a non-reactive gas, after its

compression to an adiabatic gas temperature of

about 700 K. The Rayleigh scattered signals

were calibrated from the signal/incident beam

intensity ratio at known, adiabatic, end-of-com-

pression temperatures and pressures, and the

(slower response) thermocouple measurements

were validated against these data. The temper-

ature field associated with combustion of 2.2.4

trimethyl pentane (iso-octane) was then ex-

plored using the thermocouple.

Laser Rayleigh scattering has, for some time,

been used as a combustion diagnostic tool but

commonly the technique has been applied to

open, low pressure flames [9]. Other than single

point measurements, there are relatively few

reports of its application to high-pressure sys-

tems such as engines [10]. However, 2-D, laser

sheet, Rayleigh scattering in a combustion

bomb has been described by Kim et al. [11].

Espey et al. [12] have reported planar Rayleigh

imaging of fuel vapor in a diesel jet and Koch et

al. [13] have applied UV Rayleigh imaging to an

automobile engine.

In the present work, the potential for Rayleigh

scattering as a diagnostic for temperature mea-

surement along a line spanning the central plane

of the cylindrical combustion chamber of an RCM

was further investigated. The major interference is

from Mie scattering and also from specular reflec-

tions of the incident laser light. The study of the

spatial development of the temperature fields in

the RCM by Rayleigh scattering, under both

non-reactive and reactive conditions, was sup-

ported by laser induced fluorescence (LIF) of

acetone (2-propanone) to characterize the tem-

perature and concentration fields.

The first order, exothermic decomposition of

di-t-butyl peroxide (DTBP), following compres-

sion to 0.6 MPa at temperatures of 530 K and

570 K, was exploited as the reactive medium

because this combustion process develops in a

“classical” thermal ignition mode. That is, reac-

tion is initiated from the hottest regions of the

compressed gas, thereby causing an augmenta-

tion of any temperature inhomogeneities.

Moreover, acetone is a primary product of

reaction. The LIF of acetone, at 266 nm, was

studied in a thin sheet in the vertical plane

across the central cross-section of the combus-

tion chamber. Acetone was seeded at 1% by

volume in inert gases to investigate the behavior

of non-reactive mixtures.

Neither Rayleigh nor LIF measurements

were fully calibrated so we cannot report quan-

titative data. Nevertheless, novel qualitative fea-

tures are evident from the experimental results

and the limits of sensitivity that might be ex-

pected of Rayleigh scattering in this environ-

ment are shown. We believe that the results may

have important implications for modeling stud-

ies and may enhance the understanding of spa-

tial development of autoignition in rapid com-

pression machines.

APPARATUS, EXPERIMENTAL METHODS

AND DATA PROCESSING

A full description of the RCM and its operation

can be found elsewhere [4, 14]. A diagram of the

apparatus is given in [15]. In summary, to attain

a range of compressed gas temperatures, fuel

vapor was pre-mixed with various proportions

of inert diluents (nitrogen, argon or carbon

dioxide) so that ␥ (ϭCp/Cv) could be controlled.

In the present work, DTBP decomposition was

studied in two mixtures comprising DTBP vapor

(3.3 mol %) in N2 ϩ CO2, to achieve a com-

pressed gas temperature of 530 and 570 K

respectively when the chamber wall was heated

to 315 K. The compression ratio was 10.50

(Ϯ 0.15).

Pressure-time data during the compression

stroke and throughout the post-compression

period were measured by a pressure transducer

(Kistler 601A, natural frequency 100 kHz).

High-resolution records of the pressure history

and the timing mark for the laser firing se-

1163TEMPERATURES IN RAPID COMPRESSION](https://image.slidesharecdn.com/temperaturefieldsduringthedevelopmentofcombustioninarapidcompressionmachine-150806102355-lva1-app6891/75/Temperature-fields-during-the-development-of-combustion-in-a-rapid-compression-machine-2-2048.jpg)

![quence were recorded on a digital oscilloscope

(Tektronix, TDS 220). The gaseous reactants

were admitted to the combustion chamber at an

initial pressure of 33 kPa, then compressed by a

piston driven by compressed air. The compres-

sion took 22 Ϯ 1 ms and the final, cylindrical

volume was about 30 cm3

, the combustion

chamber then being 4.5 cm dia. ϫ 1.9 cm depth.

To allow a laser beam to traverse the diame-

ter of the combustion chamber, two 1.0 cm

diameter, optically flat, fused silica windows

were located on opposite sides of the chamber.

The end of the chamber was fitted also with an

optically flat, fused silica window (5.0 cm diam-

eter ϫ 3.0 cm thick) which allowed a full view of

the chamber cross-section for imaging the scat-

tered laser light or the laser induced fluores-

cence. An intensified charge coupled device

(ICCD) camera (Princeton Instruments, 576-G)

was used to collect photons. The piston crown

was highly polished to an optically flat, mirror

finish. This gave less interference from scattered

light than a piston crown made from brushed,

black anodized, aluminum.

Particular attention was paid to the design of

the firing sequence to maintain a stable laser

mode of operation, via its continuous firing at a

constant repetition rate while coping with the

long duty cycle of the RCM and the shot-to-shot

variation (ϳ1 ms) resulting from the electro-

mechanical operation. The solution for compat-

ibility was to externally clock the laser flashlamp

and Q-switch at a constant 10 Hz. An “en-

abling” signal was generated from the initial

trigger of the RCM, which was used to activate

the machine simultaneously with the next laser

trigger pulse. Normally two or three laser shots

would occur during the machine operation. The

following laser shot would then take place

sometime during the chemical reaction period.

The external clock was intercepted at this stage

with a pre-set, variable delay to synchronize this

particular laser pulse to the required image

point. This pulse also triggered the ICCD gating

electronics so that the camera was exposed only

for the duration of the laser pulse as it passed

through the chamber (140 ns). Once the camera

had been triggered the external clock reverted

to the normal frequency of 10 Hz.

The laser system was a frequency doubled

Nd:YAG (Quantel 680) which had been retro-

fitted with a seed diode laser (Lightwave Elec-

tronics) so as to operate on a single longitudinal

mode. Single-mode operation and linewidth

(ϳ500 MHz) were monitored by means of a

high finesse etalon placed in a reflected portion

of the main beam. Typically, the laser output at

532 nm was 300 mJ pulseϪ1

, and pulse-to-pulse

fluctuations in the laser output were estimated

to be less than 1%.

There was always some condensation of reac-

tion products within the combustion chamber.

Consequently, before each experiment it was

essential to clean all surfaces scrupulously with

the windows removed. The laser beam was

realigned after their replacement to ensure a

laser beam path through the cell that was per-

pendicular to the windows.

Rayleigh Scattering from a 1-D Line

The main beam was steered into the combustion

chamber by three, high quality, dichroic mirrors

to remove any residual IR radiation in the

beam. A Galilean telescope arrangement was

used to condense the beam before it entered the

chamber. Each single-shot pass (6–7 ns) formed

a beam (ϳ100 m dia. at 1 ) in the horizontal

diameter of the combustion chamber close to its

central, cylindrical plane. Neutral density filters

placed in the beam path were used to control

the intensity of the beam, and a series of irises

were located along the beam path to reduce the

specularly scattered light entering the chamber.

For a fixed composition, the Rayleigh scattered

signal is an inverse function of gas temperature

[7–10].

To minimize the unwanted signal from Mie

scattering and specular reflections off the cham-

ber walls and the windows, a filtered Rayleigh

scattering technique was employed [16]. This

exploits the difference in Doppler line-broaden-

ing which arises from the differing speeds of

(potentially Mie scattering) particles and the

molecules themselves. Filtering out the peak of

the Gaussain in the scattered laser light inten-

sity and collecting only the Doppler-shifted light

from the extremity discriminates the molecular

scattering. By operating the Nd:YAG laser on a

single longitudinal mode it is possible to tune

the output of the Nd:YAG laser to coincide

with one of the absorption frequencies in mo-

1164 CLARKSON ET AL.](https://image.slidesharecdn.com/temperaturefieldsduringthedevelopmentofcombustioninarapidcompressionmachine-150806102355-lva1-app6891/75/Temperature-fields-during-the-development-of-combustion-in-a-rapid-compression-machine-3-2048.jpg)

![lecular iodine vapor which, thus, served admi-

rably as a filter. This was achieved by tuning the

frequency of the diode seed laser concomitantly

with the cavity length of the Nd:YAG oscillator.

In a temperature stabilized laboratory it was

then possible to hold the Nd:YAG laser output

on an I2 line for several hours before a mode

hop occurred. A heated glass cell 15 cm long ϫ

6 cm diameter containing resublimed iodine

vapor and fitted with good quality windows was

placed between the RCM end window and the

ICCD camera. A second smaller cell was used

on a portion of the main laser beam to check, by

means of the easily observed laser induced

fluorescence, that the laser was correctly tuned

to an I2 absorption feature.

The scattering cross-section is both tempera-

ture and composition sensitive. The cross-sec-

tions and their temperature sensitivity are

known for a range of substances, and from these

it would be possible to compute the overall

scattering cross-section for certain mixture (in-

deed this is often the case [11, 17]). In general,

such calculations for reactive mixtures are un-

likely to be very accurate, not only because

there are many molecular intermediates but

also because combustion processes evolve

through an extensive temperature range. This

limits the scope for calibration, although there

is some compensation to be gained from the

dominance of inert components (e.g., N2) when

combustion takes place in air. Because the

Rayleigh scattering cross-section depends on

the wavelength to the fourth power, the sensi-

tivity of our experiment would have been im-

proved by working with the fourth harmonic of

the Nd:YAG laser around 266 nm, if a suitable

molecular or atomic filter had been available.

For example, Golz and Andresen [18] have

employed Fe atoms as a filter for Rayleigh

imaging using the output of a tunable narrow

band KrF laser (248 nm).

The composition variation in the present

study is more simple than normally encountered

in combustion because the major components

were nitrogen and carbon dioxide, with the

reactant, DTBP, and the products ethane and

acetone being present at less than 10 mol% in

total at any stage of reaction. The scattering

cross-sections of the reaction components are

somewhat greater than those of N2 and CO2.

Although iterative calculations to match com-

position and temperature fields from measured,

or calculated, molecular polarizabilities and

their temperature dependences might be viable,

and could yield quantitative results, there are

particular complications in the present case.

That is, a falling scattering cross-section is likely

to accompany the conversion of DTBP to the

smaller product molecules, reducing the scat-

tered signal under isothermal conditions, and

the peroxide decomposition is accompanied by

heat release, which also reduces the overall

scattering cross-section as a result of the tem-

perature increase. However, this combination

has attendant benefits for interpretation of the

qualitative structure because changes of scatter-

ing cross-section, originating from these two

causes, have the potential to augment each

other and thereby enhance the signals that

identify the spatial variation in temperature

along the laser line.

LIF of Acetone from a 2-D Sheet

For the purpose of the LIF imaging, a laser

sheet (width 8 mm ϫ 100 m depth) was

formed by using a cylindrical beam expanding

telescope in conjunction with a spherical lens to

focus the beam in the horizontal plane with its

vertical face to the end window. For these

experiments the laser output at 532 nm was

further doubled using an external frequency

doubling crystal to obtain the fourth harmonic

of the Nd:YAG fundamental. No seeding by the

diode laser was necessary in these experiments.

The LIF signal is sensitive to temperature be-

cause the absorption cross-section falls as tem-

perature increases. At 266 nm there is a 50%

reduction in the fluorescence quantum yield

over the temperature range 500 to 800 K [19,

20]. There are two different types of response

from the LIF detection in the present work.

Spatial variations in temperature that arise in

compressed inert gas seeded with acetone are

shown as a diminished fluorescence signal in

hotter regions. By contrast, regions in which

acetone is generated by reaction show an en-

hancement in the fluorescence intensity. This

signal is proportional to the concentration in

isothermal conditions. However, there is a tem-

perature increase associated with the formation

1165TEMPERATURES IN RAPID COMPRESSION](https://image.slidesharecdn.com/temperaturefieldsduringthedevelopmentofcombustioninarapidcompressionmachine-150806102355-lva1-app6891/75/Temperature-fields-during-the-development-of-combustion-in-a-rapid-compression-machine-4-2048.jpg)

![This enhanced fluorescence signifies that gas

resident in the central region at this time is

colder than that in the “toroidal” zone sur-

rounding it. The extent of the enhancement in

intensity is approximately 20%, which would

suggest a temperature difference of approxi-

mately 50 K between the center and the toroid

surrounding it [16]. On this basis the gradient

on the right hand side of the temperature

depression is approximately 50 K cmϪ1

. There is

also a left to right decay in intensity imposed on

the signal as a result of absorption of the beam

intensity. By 30 ms post-compression there is no

evidence of the central depression in the tem-

perature (Fig. 2c), but the fluctuations of the

LIF signal (which are somewhat greater than

those in Fig. 2b at a similar magnitude for the

integrated signal) may suggest that there is a

quite complex pattern of minor temperature

variation across the central plane of the com-

bustion chamber. At 30 ms there is also an

increase of the fluorescence intensity at the

right hand side of the chamber, which suggests

the development of a cool zone close to the

wall, but this cannot be clearly distinguished at

the point of entry of the laser beam on the left

hand side. The signal intensity in this and

subsequent figures are representative of the

number of scattered photons. However, the

incident laser was not calibrated and (minor)

variations of the intensity in successive experi-

ments were not taken into account. For this

reason the ordinate is reported in arbitrary

units. Nonetheless, for comparison, the values

do give a meaningful indication of the relative

signal strength of the figures.

Combustion of DTBP Vapor at a Compressed

Gas Temperatures of 530 and 570 K and 0.6

MPa

The combustion of DTBP (3.3 mol %) was

investigated in two mixtures comprising 1.00

C4H9OOC4H9 ϩ 7.00 N2 ϩ 22.30 CO2 and 1.00

Fig. 2. The LIF signals from an acetone tracer (1 mol %) in

N2 imaged in a sheet across the central plane of the

combustion chamber. An ICCD image and the photon

count is shown. (a) Cold, compressed gas. (b) 1.1 ms

post-compression. (c) 30 ms post-compression. The ordi-

nate represents the photon count integrated across the

width of the beam, and is given as arbitrary units because

the intensity of the incident laser beam was not calibrated.

The pixel number on the abscissa is related to the position

in the field of view across the diameter of the chamber.

4™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™™

1167TEMPERATURES IN RAPID COMPRESSION](https://image.slidesharecdn.com/temperaturefieldsduringthedevelopmentofcombustioninarapidcompressionmachine-150806102355-lva1-app6891/75/Temperature-fields-during-the-development-of-combustion-in-a-rapid-compression-machine-6-2048.jpg)

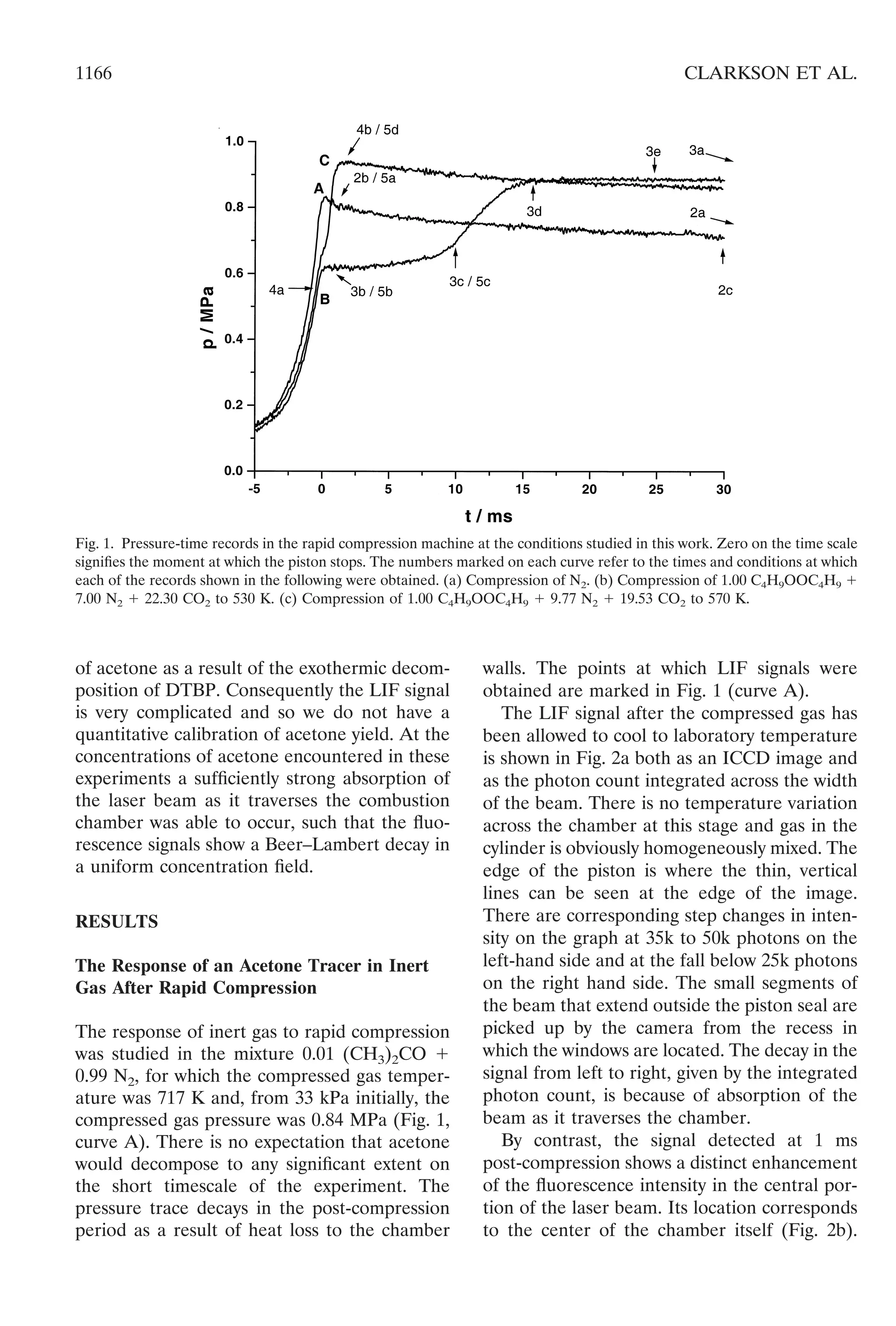

![C4H9OOC4H9 ϩ 9.77 N2 ϩ 19.53 CO2. On the

basis of adiabatic compression at CR ϭ 10.5,

these compositions ensured compressed gas

temperatures of 530 K and 570 K at the end of

compression when the cylinder is heated to 310

K. These conditions correspond to those used in

previous work [14]. The pressure records are

shown in Fig. 1 (lines B and C). Also marked in

each case are the points at which LIF images of

acetone (product) fluorescence in the 2-D plane

and thermal imaging by Rayleigh scattering on a

1-D line were obtained. Each of the optical

measurements were made in separate experi-

ments at the prescribed conditions.

The reaction developed in a single stage in

the post-compression period at both of the

selected compressed gas temperatures, but the

timescales were significantly different. The de-

velopment was relatively slow at the lower tem-

perature, the maximum pressure in the constant

volume chamber being reached only after about

15 ms (Fig. 1, curve B). The overall change in

mole numbers is relatively small (ca 6%) so this

pressure change is attributable almost entirely

to the temperature change resulting from the

exothermic reaction.

The compression is sufficiently rapid that

most of the temperature increase occurs within

the final few milliseconds of the compression

stroke and, unless excessive gas motion is arti-

ficially created [21], there is hardly any heat loss

associated with the compression stage [4]. Heat

loss in the post-compression period is inevitable

[5, 22], but the residual gas motion is not

sufficiently vigorous that the whole system could

be approximated to a spatially uniform, “well-

stirred” system [14]. Nevertheless, from the

extent of the post-compression pressure rise at

15 ms post-compression, on an ideal gas basis

the average increase in the gas temperature is

approximately 80 K.

The reaction occurred much more rapidly

when the compressed gas temperature was

raised to 570 K, with some decomposition being

possible even before the piston had stopped

(Fig. 1, curve C). In this case the maximum

pressure was reached ca 1 ms after the end of

compression. The average temperature rise cal-

culated from the pressure change is approxi-

mately 190 K, which is close to the predicted

adiabatic temperature rise for the mixture. Heat

losses over 1 ms post-compression would be

relatively insignificant. This rate of development

of the decomposition with thermal feedback is

to be expected since the half-life is 3 ms at 600

K, and by 650 K, t1/2 has diminished to less than

0.5 ms.

The respective LIF images of acetone gener-

ated as a reaction product following compres-

sion to 530 K are shown in Fig. 3. These are also

displayed both as the primary sheet image as

well as the statistical photon count integrated

across the image width. The cold, compressed,

reaction products cause a very strong Beer–

Lambert absorption because of the uniform

concentration of acetone that has been gener-

ated (Fig. 3a). The fluorescence signal intensity

is considerably stronger than that of the tracer

acetone in CO2 (Fig. 2a) because the concen-

tration of the product is much higher (ca. 6 mol

%) and the product has cooled to laboratory

temperature. The thin line of the piston seal is

just detectable on the right hand side of the

image, but it is masked by the window reflec-

tions on the beam entry side.

Although there has been no enhancement of

the gas pressure in the chamber at 1.1 ms

post-compression, there is already sufficient ac-

etone formed to create a weak fluorescence

signal (Fig. 3b). There is evidence in this result

that rather less acetone has been formed in the

center of the chamber as a consequence of the

reduced reaction rate in this cooler zone. The

pressure has begun to increase by 10 ms post-

compression (Fig. 1, line B) and, commensurate

with this development of reaction, there is a

somewhat stronger LIF signal from acetone

(Fig. 3c). The reduced intensity at the center is

clear, and (presuming that the temperature field

is qualitatively similar to that of the non-reac-

tive system) this signifies a lower temperature

simply because hardly any acetone has been

formed. We are not able to infer any magnitude

for the temperature variations across the cham-

ber because there are conflicting variations on

the intensity of the fluorescence signal owing to

changes both in the acetone concentration and

the gas temperature. The reaction is well devel-

oped at 15 ms post-compression and there is a

much greater fluorescence from acetone in con-

sequence (Fig. 3d). The effect of the laser beam

absorption, from left to right, is evident in the

1168 CLARKSON ET AL.](https://image.slidesharecdn.com/temperaturefieldsduringthedevelopmentofcombustioninarapidcompressionmachine-150806102355-lva1-app6891/75/Temperature-fields-during-the-development-of-combustion-in-a-rapid-compression-machine-7-2048.jpg)

![signal, but there is still a marked inhomogeneity in

the acetone concentration close to the center of

the chamber. Even at 25 ms post-compression,

although somewhat diminished in volume, there is

still a cooler core relative to that of the reactants

and products in the surrounding region (Fig. 3e).

The acetone LIF signals during reaction at a

compressed gas temperature of 570 K are

shown in Fig. 4. It is likely that some reaction

has taken place even in the final stages of the

compression stroke because there is a very weak

LIF signal from acetone just before the end of

compression (Fig. 4a). However, there is no

indication that the cold core has penetrated to

the center plane of the chamber by that stage.

By 1.1 ms after the piston has stopped, the

chamber pressure is fully developed and the

reactants are at their highest average tempera-

ture (Fig. 1, line C). There is a substantial

fluorescence signal from the acetone produced

(although of lower photon count overall be-

cause of the high gas temperatures) and the

much weaker signal at the center confirms the

existence of the appreciably cooler core gas in

the central plane of the combustion chamber

(Fig. 4b). The photon count of the fluorescence

signal at the center integrated across the beam

width is approximately 40% of that in the region

either side of it. A slight increase in the image

intensity to the far left suggests that inhomoge-

neities following compression may be such that

the hottest gases reside quite close to the pe-

riphery of the chamber and that a gradient has

been created toward the cooler core region.

This would be commensurate with the forma-

tion of a roll-up vortex [23,24].

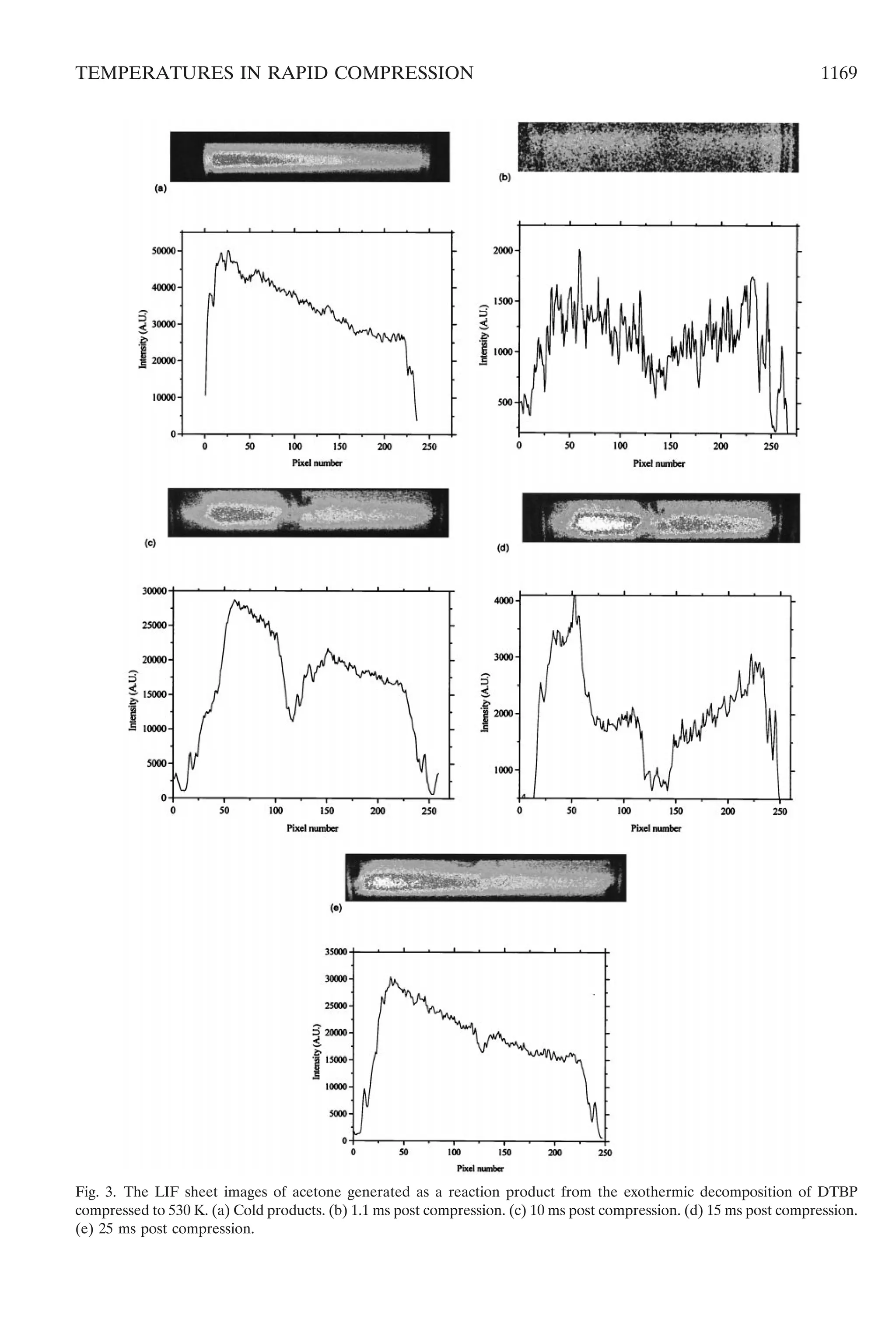

Rayleigh Scattering from a 1-D Line on the

Horizontal Radial Axis at the Central Plane

Rayleigh scattered signals from the horizontal

radial axis are shown in Fig. 5 both as the

primary image and the statistical count of pho-

tons on the central pixel line of the image,

scaled to the full range of photon counts (216

,

ϳ65k). The conditions are those for an inert gas

(N2) and also for the decomposition of DTBP at

530 and 570 K at 1.1 ms post-compression. The

edge of the piston crown and gap where the

p.t.f.e. seal fit can be seen clearly in Fig. 5a as a

thin, dark cylindrical section. There is some

scattered light detected beyond the chamber

itself and these reflections lead to spurious

signals just inside the circumference of the

chamber. Reflections are also visible at certain

locations inside the chamber owing to imperfec-

tions of the piston crown. Some artifacts also

appear as a result of imperfections of the iodine

filter cell. These could all be easily identified

and distinguished from the primary signal. A

limited amount of Mie scattering was also un-

avoidable. It was particularly difficult to obtain a

uniformly high quality of all images, the main

criteria being the cleanliness of optical align-

ment of the laser beam. Nevertheless, as shown

Fig. 4. The LIF sheet images of acetone generated as a

reaction product from the exothermic decomposition of

DTBP compressed to 570 K. (a) 0.5 ms before the end of

compression. (b) 1.1 ms post compression.

1170 CLARKSON ET AL.](https://image.slidesharecdn.com/temperaturefieldsduringthedevelopmentofcombustioninarapidcompressionmachine-150806102355-lva1-app6891/75/Temperature-fields-during-the-development-of-combustion-in-a-rapid-compression-machine-9-2048.jpg)

![spatial variations. The decomposition of DTBP

has some relevance also because it was the

subject of a computational fluid dynamic analy-

sis of reaction in the RCM, 7 years ago [14],

some aspects of which are discussed next.

In Fig. 6 we reproduce a simulation from a

KIVA II [24] calculation of the temperature

field in the Leeds RCM. This represents the

plan view of an axisymmetric section of the

chamber of the rapid compression machine

derived on a relatively coarse (20 ϫ 20) grid.

Results published elsewhere show the output

using a more refined mesh, but with very similar

qualitative features [14]. Although it is not

intended that the result in Fig. 6 is to be

interpreted in a quantitative way, it illustrates how

a cooler gas region may penetrate the core of the

reaction zone as a result of gas being swept from

the sidewall of the combustion chamber, with an

attendant roll-up vortex adjacent to the piston

crown and circumference of the chamber. This is

consistent with the pattern of development shown

by Tabaczinski et al. [23] and in more recent,

related work by Lee and Hochgreb [25].

Consequences of the “Cold Core” on

Exothermic Chemistry that Exhibits a Positive

Temperature Dependence

There is clear evidence in this study that at the

end of compression a cold plug of gas is swept

across the piston face and is able to penetrate

the center of the adiabatically heated core gas.

This creates a spatially non-uniform tempera-

ture field during a post-compression time inter-

val that is relevant to the development of spon-

taneous ignition of reactive mixtures. The

temperature difference between the center and

the surrounding toroid may exceed 50 K. As a

result of thermal feedback, an exothermic

chemical reaction that exhibits a positive tem-

perature dependence enhances the spatial vari-

ations in temperature, and the hottest points

become the sites at which ignition would natu-

rally develop. A full development of ignition

does not follow in the decomposition of DTBP

(as studied here) because it is not strongly

exothermic (⌬Uo

298 ϭ - 165 kJ molϪ1

). Never-

theless, the temperature reached in the hottest

zones approaches the adiabatic temperature

change when the reactants are compressed to a

sufficiently high temperature for a fast develop-

ment of reaction (see Fig. 1, curve C). These are

the first experimental results to show how the

non-uniform temperature field following rapid

compression may affect the chemical develop-

ment.

Consequences of the “Cold Core” on

Chemistry that Exhibits an Overall Negative

Temperature Dependence

As is well known, the combustion of many

organic compounds, and alkanes in particular,

exhibit a negative temperature dependence (or

negative temperature coefficient, ntc) of the

overall chemical reaction rate through temper-

atures over the approximate range 750 to 850 K

[6]. The underlying chemistry is reasonably well

established now in a quantitative way [26].

When thermal feedback occurs in non-isother-

mal conditions, reaction may develop to give

oscillatory cool flames and complex ignitions, as

in closed vessels and stirred flow reactors [27].

Single or two-stage ignitions occur in devices

such as rapid compression machines [1, 2, 4, 5].

The two-stage ignition development itself exem-

plifies the occurrence of the ntc, insofar that the

reaction accelerates through the initial stage but

then decelerates as the onset of the second

stage is approached. It is at this point that the

reactant temperature has, on average, ap-

proached about 850 K [4]. The thermokinetic

Fig. 6. The temperature field that was predicted to develop

by 5 ms post compression, simulated in a combustion

chamber corresponding to that of the Leeds RCM, using

KIVA 11. The range of temperatures is 500 K to 570 K, with

contour lines at 10 K intervals.

1172 CLARKSON ET AL.](https://image.slidesharecdn.com/temperaturefieldsduringthedevelopmentofcombustioninarapidcompressionmachine-150806102355-lva1-app6891/75/Temperature-fields-during-the-development-of-combustion-in-a-rapid-compression-machine-11-2048.jpg)

![interactions that cause the onset of the second

stage are discussed elsewhere [28–30].

The relevance of these features is that a

system that exhibits an ntc of rate in a certain

temperature range, is capable of responding to

an inhomogeneous temperature field in a dif-

ferent way from that seen in the present exper-

iments. That is, reaction may be more vigorous

in the colder gas, which thus serves to smooth

out temperature differences, and the system

moves to a more uniform temperature field in

the later stages as a consequence of the negative

feedback. However, if gas mixing is not very

significant on the timescale of evolution of

ignition, the composition field does not become

uniform because different extents of reaction

will have occurred at different spatial locations

during the course of this development. This has

implications for the way in which the second

stage of ignition then evolves because regions

may then exist that are chemically more active

than others. These effects are to be discussed in

a later paper.

A Critique of Experimental Methods for

Identifying Spatial Structure in Rapid

Compression Machines and their

Consequences

Acetone LIF serves well to identify spatial

variations in temperature in the RCM when it is

used as a marker in non-reactive gases up to

temperatures of about 900 K. Thereafter, its

own decomposition could become troublesome

on relatively short timescales. The system can be

calibrated because the temperature dependence

of the absorption cross-section is known [19,20].

Although we have not pursued our own calibra-

tion, the data provided by Thurber et al. [19, 20]

show that, by 1 ms post-compression, the tem-

perature difference between the cooler core gas

and the surrounding toroid, illustrated in Fig.

2b, might be as high as 50 K. This appears to be

supported in the calculations by Griffiths et al.

[14], as also exemplified in Fig. 6. The genera-

tion of a laser sheet is easy and, with greater

optical access than in the present chamber, an

extensive temperature field could be mapped.

In an active free radical environment an acetone

tracer not only presents a chemical perturbation

but also it is susceptible to reaction, so would

not be a viable route to studying the tempera-

ture field. In the case of DTBP decomposition,

the LIF of acetone can also been used to

identify the composition field represented by

the final product formation. However, unlike

the thermal calibration, there is no correspond-

ing, simple quantitative relationship for the

concentration vs. LIF intensity when acetone is

formed because it is being generated under

non-isothermal conditions. In both of these

applications there is a sufficiently strong (Beer–

Lambert) absorption of the excitation laser

beam for a correction for asymmetry of the LIF

signal to be required if quantitative analyses are

to be sought.

Our complementary study of Rayleigh scat-

tering on a one-dimensional line shows this

technique to be rather less sensitive for thermal

imaging than the acetone tracer LIF measure-

ments. This limitation of Rayleigh scattering, in

these typical combustion mixtures where nitro-

gen is present in high proportion, caused the

cooler core gas not to be identified in the

immediately post-compression interval. Thus

we would infer that any spatial variation in

temperature that is less than about 60 K is

unlikely to be distinguishable from background

noise in the Rayleigh scattered signal. Without

that awareness there is the risk of misinterpre-

tation of the qualitative structure, as is exempli-

fied when the results for the Rayleigh scattering

during the onset of DTBP decomposition fol-

lowing compression to 530 K (Fig. 5b) are

compared with the related LIF measurement

(Fig. 3b). However, a very clear, qualitative

distinction became evident when the tempera-

ture difference was amplified to approximately

200 K, as shown in Fig. 5c. This is an optimal

result because the temperature difference exists

at the center of the chamber. In most experi-

ments, the scatter of light close to the windows

in the chamber wall precludes an unambiguous

interpretation. Nevertheless, from the result

shown in Fig. 5c, it may be inferred that tem-

perature gradients at the edge of the chamber

are very steep.

Rayleigh scattering studies in the chamber of

a rapid compression machine, by Desgroux et al.

[7, 8], yielded single point temperature mea-

surements with a higher accuracy than assessed

from this 1-D line study, namely Ϯ 30 K.

1173TEMPERATURES IN RAPID COMPRESSION](https://image.slidesharecdn.com/temperaturefieldsduringthedevelopmentofcombustioninarapidcompressionmachine-150806102355-lva1-app6891/75/Temperature-fields-during-the-development-of-combustion-in-a-rapid-compression-machine-12-2048.jpg)

![Although they did not investigate spatial varia-

tions, even at this precision and given the scatter

that was reported for a series of measurements,

it is debatable whether or not they would have

been able to distinguish the development of a

“toroidal” temperature field of the kind seen in

the present work. In any event, the compression

was considerably slower in the apparatus that

was used by Desgroux et al., taking 60 ms for a

similar stroke, so somewhat different spatial

and temporal temperature evolution would be

expected in the post compression period. The

subtleties of the temperature history are cer-

tainly machine specific, and significant differ-

ences may be realized under different operating

conditions or in chambers of different design.

Lee and Hochgreb [25] have shown theoreti-

cally how attention to the design of the piston

crown and rings can suppress the formation of a

roll-up vortex and thereby reduce or eliminate

the effects that are reported in the present

paper.

Ignition delays measured in different appara-

tus cannot usefully be compared directly with-

out reference to the dependences on the indi-

vidual equipment. Foremost is the effect of heat

loss, but more subtle consequences of gas mo-

tion that induce spatial temperature variations,

as exposed here, may also be relevant. As has

been illustrated with respect to di-t-butyl perox-

ide decomposition [14], the existence of temper-

ature inhomogeneities also has considerable

bearing on the relationship between experimen-

tal measurements of ignition and numerical

simulations using detailed, zero-dimensional

thermokinetic models. However, there are mit-

igating circumstances with respect to the mod-

eling of alkane combustion, whereby kinetic

systems that exhibit a negative temperature

dependence of reaction rate are capable of

smoothing out the spatial variations that may

have been created in the combustion system, as

noted in the preceding subsection and in earlier

publications [8, 31, 32].

The authors are grateful to EPSRC for support

of this project under grant GR/K97189. The au-

thors wish to thank Drs M. Schreiber and J. Meyer

for permission to publish the results shown in Fig.

6, which were preliminary calculations for the

work described in [14].

REFERENCES

1. Cox, A., Griffiths, J. F., Mohamed, C., Curran, H. J.,

Pitz, W. J., and Westbrook, C. K., Proc Comb. Inst.

26:2685–2691 (1996).

2. Ribaucour, M., Minetti, R, and Sochet, L. R., Proc

Comb. Inst. 27:345–351 (1998).

3. Cowart, J. S., Keck, J. C., Heywood, J. B., Westbrook,

C. K., and Pitz, W. J., Proc. Comb. Inst. 23:1055–1062

(1990).

4. Griffiths, J. F., Halford–Maw, P., and Rose, D. J.,

Combust. Flame, 95:291–304 (1993).

5. Minetti, R., Ribaucour, M., Carlier, M., Fittschen, C,

and Sochet, L. R., Combust. Flame,96:201–211 (1994).

6. Griffiths, J. F., and Mohamed, C., Comprehensive

Chemical Kinetics, Vol. 35, (M. J. Pilling, Ed.) Elsevier,

Amsterdam, pp. 545–660 (1997).

7. Desgroux, P., Gasnot, L., and Sochet, L. R., Appl. Phys.

B61:69 (1995).

8. Desgroux, P., Minetti, R., and Sochet, L. R., Combust.

Sci. Tech. 113:93–203 (1996).

9. Zhao, F-Q., and Hiroyasu, H., Prog. Energy Combust.

Sci. 19:447–485 (1993).

10. Zhao, H., and Ladommatos, N., Prog. Energy Combust.

Sci. 24:297–336 (1998).

11. Kim, G. S., Hitchcock, L. M., Siegler, F., Rothe, E. W.,

Tung, C. C., and Reck, G. P., Appl. Phys, B56:139–145

(1993).

12. Espey, C., Dec, J. E., Litzinger, T. A., and Santavicca,

D. A., Combust. Flame109:65–86 (1997).

13. Koch, A., Voges, H., Andresen, P., Schluter, H., Wolff,

D., Hentschel, W., Oppermann, W., and Rothe, E.,

App. Phys. B56:188–184 (1993).

14. Griffiths, J. F., Jiao, Q., Kordylewski, W., Schreiber,

M., Meyer, J., and Knoche, K. F., Combust. Flame

93:309–321 (1993).

15. Beeley, P., Griffiths, J. F., and Gray, P., Combust.

Flame 39:255–268 (1980).

16. Miles, R., and Lempert, W., Appl. Phys. B51:1–7

(1990).

17. Orth, A., Sick, V., Wolfrum, J., Maly, R. R., and Zahn,

M., Proc. Comb. Inst. 25:143–150 (1994).

18. Golz, P., and Andresen, P., Appl. Opt. 35:6054–6061

(1996).

19. Thurber, M. C., Grisch, F., and Hanson, R. K., Opt.

Lett. 22:251–253 (1997).

20. Thurber, M. C., Grisch, F., Kirby, B. J., Votmeier, M.,

and Hanson, R. K., Appl. Opt. 37:4963–4978 (1998).

21. Franck, J., Griffiths, J. F., and Nimmo, W., Proc.

Comb. Inst. 21:447–454 (1986).

22. Griffiths, J. F., Jiao, Q., Schreiber, M., Meyer, J., and

Knoche K. F., Proc. Comb. Inst. 25:1809–1815 (1994).

23. Tabaczinski, R. J., Hoult, D. P., and Keck, J. C., J.

Fluid Mech. 42: 249–256 (1970).

24. Amsden, A. A., Ramshaw, J. D., O’Rourke, P. J., and

Kulowicsz., Los Alamos Lab. Report, LA-102450MS,

1985.

25. Lee, D., and Hochgreb, S., Combust. Flame 114:531–

545 (1998).

26. Pilling, M. J. (Ed), Comprehensive Chemical Kinetics,

Vol. 35, Elsevier, Amsterdam, 1997.

1174 CLARKSON ET AL.](https://image.slidesharecdn.com/temperaturefieldsduringthedevelopmentofcombustioninarapidcompressionmachine-150806102355-lva1-app6891/75/Temperature-fields-during-the-development-of-combustion-in-a-rapid-compression-machine-13-2048.jpg)