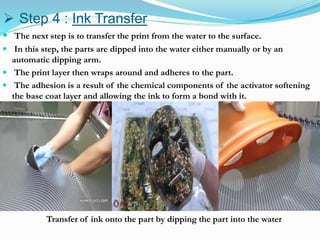

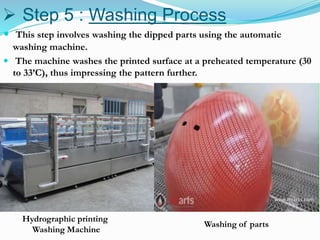

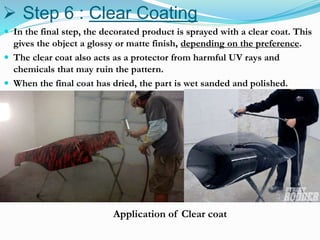

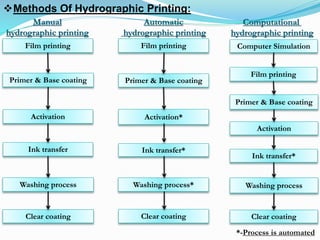

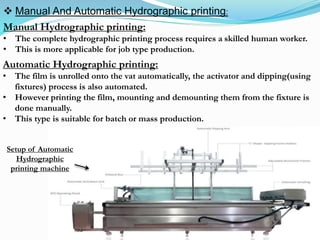

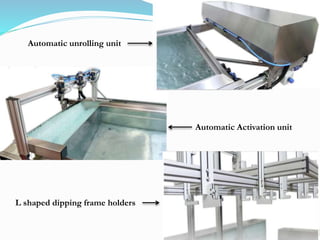

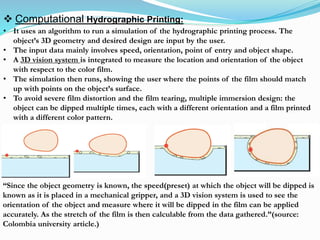

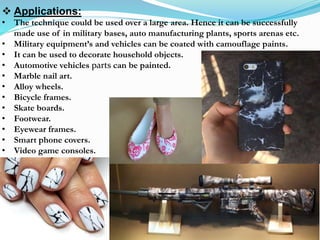

Hydrographic printing is a water-based method that transfers two-dimensional images onto three-dimensional objects, allowing for complex designs like wood grain and camouflage to be applied easily. The process involves six steps: film printing, primer coating, activation, ink transfer, washing, and clear coating, and can be done manually or automatically for different production needs. It has various applications across industries, including automotive and consumer goods, but requires skilled labor and precise alignment for optimal results.