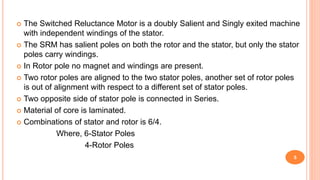

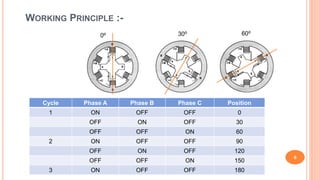

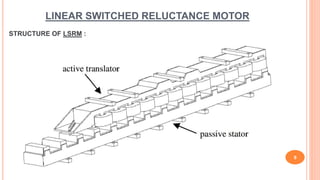

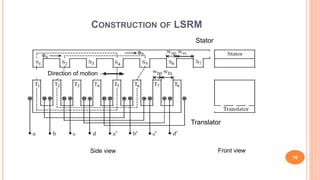

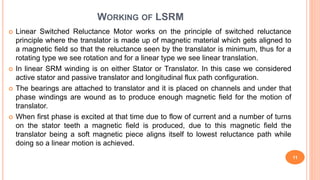

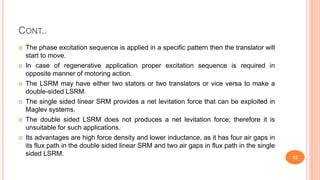

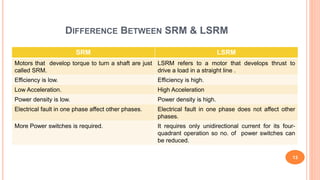

This document analyzes linear switched reluctance motors (LSRM). It begins by describing conventional switched reluctance motors (SRM) and their working principles. It then discusses the construction, working, and advantages of LSRM compared to SRM. Key differences between SRM and LSRM are that LSRM provide linear motion rather than rotational motion and have higher efficiency and power density. The document also covers applications of SRM and concludes by listing topics to be covered in a future review.