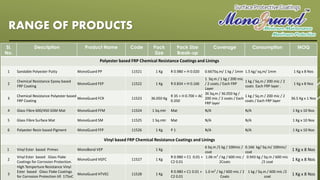

Monarch Industrial Products (I) Pvt Ltd offers surface protective coatings designed to guard concrete structures against corrosion from environmental factors, ensuring the longevity and integrity of modern infrastructure. The coatings provide a robust barrier against water, chemicals, and UV radiation, while being essential for maintenance cost reduction, as repairs are significantly more expensive than preventative measures. Their product range includes various epoxy, polyurethane, and acrylic coatings suitable for diverse industrial applications, aiming to preserve and protect concrete surfaces effectively.