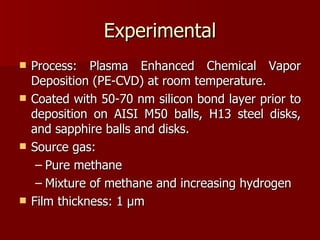

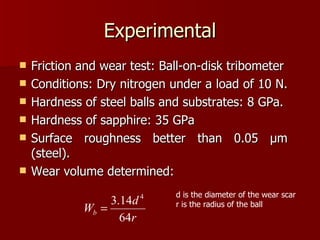

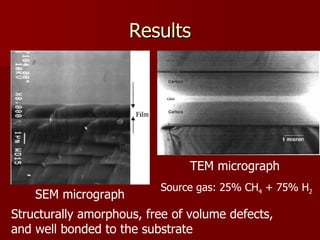

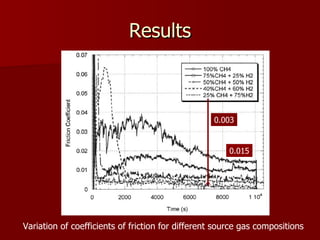

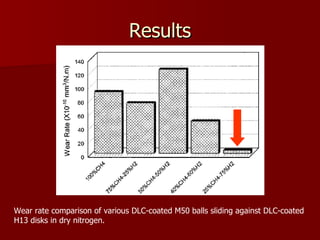

The document details the synthesis and properties of diamond-like carbon (DLC) films, highlighting their unique mechanical, chemical, optical, and electrical characteristics. It discusses deposition processes, the influence of humidity on friction performance, and shows that DLC films grown with methane and hydrogen mixtures exhibit superior friction and wear properties compared to those grown with pure methane. The findings emphasize the role of hydrogen concentration in enhancing the performance of DLC films, achieving friction coefficients as low as 0.001.

![Synthesis of diamond-like carbon films with super-low friction and wear properties A. Erdemir, O.L. Eryilmaz, and G. Fenske J. Vac. Sci. Technol. A 18(4), Jul/Aug 2000 1987-1992 MSE676 All Things Carbon | Fall 2009 Deepak Rajput Center for Laser Applications University of Tennessee Space Institute Tullahoma, Tennessee 37388-9700, USA Email: [email_address] | Web: http://drajput.com](https://image.slidesharecdn.com/erdemirdlcmse676-091217182615-phpapp02/85/Super-low-friction-DLC-films-1-320.jpg)