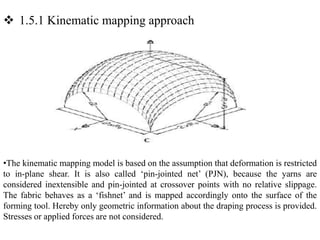

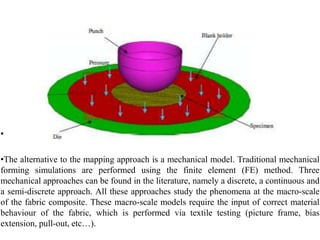

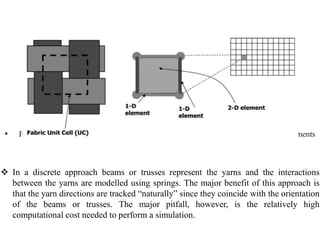

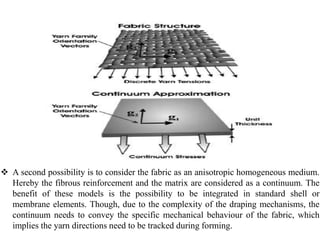

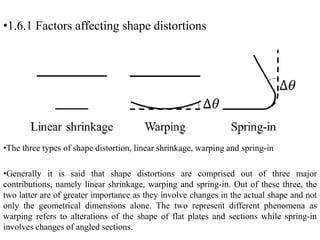

This document discusses numerical and experimental analysis of the thermo-stamping process applied to woven fabric reinforced thermoplastic composites. It provides an overview of polymer matrix materials, fiber reinforcements including woven fabrics, and deformation mechanisms at the micro, meso, and macro scales during forming. It also describes experimental fabric characterization methods like picture frame and bias extension tests. Thermoforming of pre-impregnated thermoplastics and different approaches to textile draping simulation including kinematic mapping, discrete modeling, continuum modeling, and semi-discrete modeling are introduced. Challenges like wrinkling and process-induced shape distortions including warping and spring-in are also covered.

![•Experimental Fabric Characterization Methods

•Testing mechanism of in-plane shear behaviour for fabric materials [Shuai Chen Thesis]

•Standard material testing methods are necessary for researchers to understand the

formability of the material, the effects of process variables on formability, and to

provide input data and validation data for numerical simulations. As shearing is the

major forming mechanism for forming of double curved geometries with woven fabrics

it has been the most intensively studied forming behaviour. Two methods to describe

the intra-ply shearing behaviour are widely used: picture frame and bias extension tests,

both showing benefits and disadvantages.

• .](https://image.slidesharecdn.com/sunum-230302192358-8376b74e/85/sunum-pptx-14-320.jpg)

![•Picture Frame Test

• Geometrical configuration of a PF test: (a) Geometry of the frame; (b) Specimen

mounted in the fixture [Armin Rashidi Mehrabadi Thesis]

For picture frame tests a cross shaped test sample is mounted on a square frame

hinged in the corners. The picture frame is extended subsequently on a tensile

testing machine. Shear force vs. shear angle curves can be calculated from the

force–displacement curves.](https://image.slidesharecdn.com/sunum-230302192358-8376b74e/85/sunum-pptx-15-320.jpg)

![•Geometrical configuration of a BE test

• The bias extension (BE) test is an alternative to the PF test, consisting of a

rectangular sample such that the weft and warp yarns are originally oriented at

45° to the orientation of the applied tension. The initial length of the specimen

must be more than twice the width of the specimen in a BE test . [Armin Rashidi

Mehrabadi Thesis]](https://image.slidesharecdn.com/sunum-230302192358-8376b74e/85/sunum-pptx-16-320.jpg)

![•Papers about Shape Distortion

Beyong Sam Kim et al. [25] investigated the dimensional stability of V shaped

composite parts made from unidirectional polyamide-12/carbon fibre

commingled yarn.

• It was implemented anisotropic thermoviscoelastic material model in a FEA

solver for different cooling cycles.

• In the experimental study, the laminates, with stacking sequences of [08], [908]

and [904/04], were used.](https://image.slidesharecdn.com/sunum-230302192358-8376b74e/85/sunum-pptx-28-320.jpg)

![• To manufacture the laminates, the mould containing the fabric plies was heated from room

temperature to 220 C, held at this temperature for 10 min, and finally cooled back to room

temperature.

• During the consolidation and cooling stages, a pressure of 15 bars was applied to the material.

• Both balanced and slightly unbalanced cooling conditions were applied, with a maximum

cooling rate of 10 C/min.

• Results :

• The angles predicted by the present thermoviscoelastic approach are similar to those

predicted by the thermoelastic approach in the literature. It seems that at these cooling rates in

this semi-crystalline matrix, the effect of viscoelastic relaxation during cooling is relatively

small.

• Low levels of stresses were obtained in the [908] and [08] parts, whereas the significant

stresses was obtained in the [904/04] part.

• The [08] laminate showed the largest deviation from the 900

angle of the mould, whereas the

[904/04] stacking sequence led to the highest curvature of the side planes.

• The differences in angle and curvature between parts cooled under balanced and unbalanced

conditions were found to be small. This is because the difference in temperature between the

upper and lower surfaces of the laminate during cooling was relatively small.](https://image.slidesharecdn.com/sunum-230302192358-8376b74e/85/sunum-pptx-29-320.jpg)