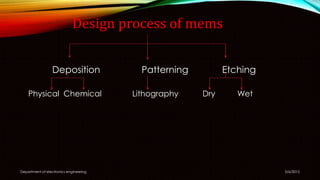

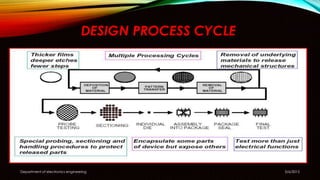

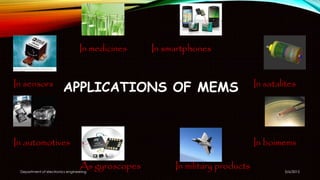

The document summarizes a summer training program at CSIR-CEERI on miniaturizing technologies. CSIR-CEERI is a research institute located in Rajasthan, India that focuses on electronics engineering. The training program covers MEMS (Micro-Electro-Mechanical Systems) which integrate electrical and mechanical components on a small scale using microfabrication. MEMS devices range from 1 to 100 micrometers and are used in applications like smartphones, sensors, automotives and more. The document outlines the MEMS fabrication process including deposition, patterning, etching and discusses some specific MEMS technologies being researched at CSIR-CEERI.