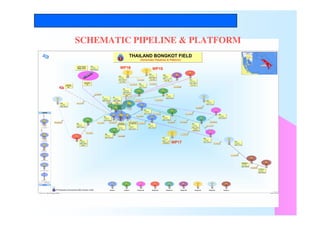

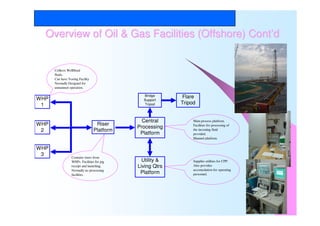

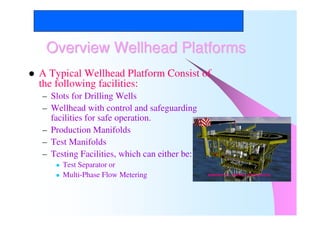

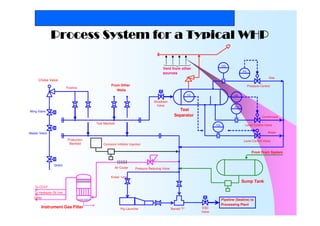

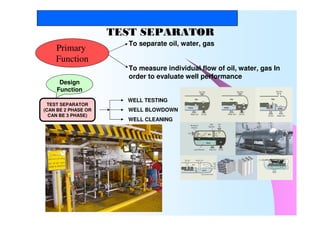

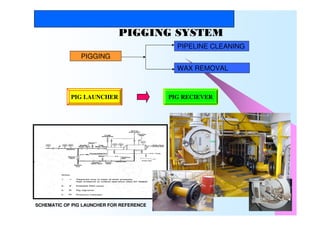

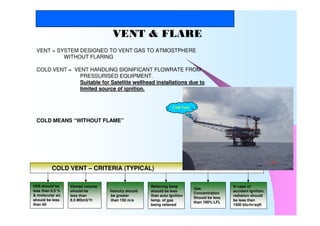

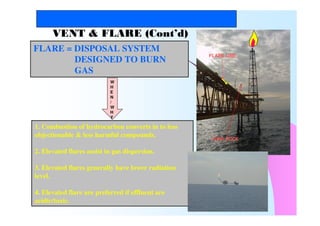

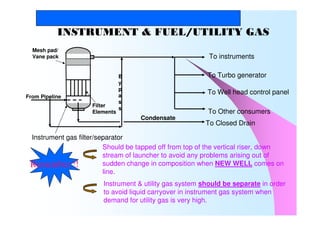

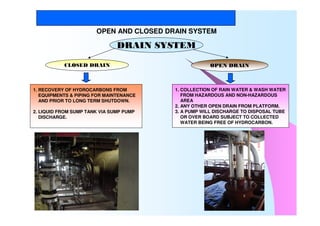

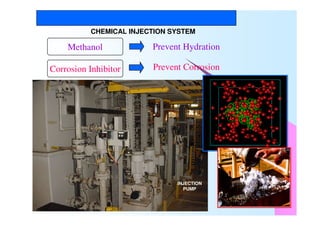

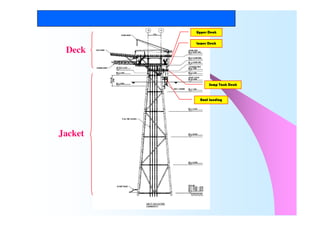

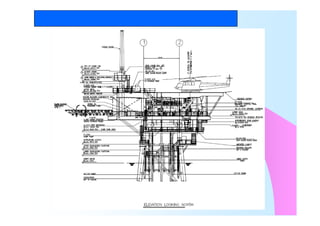

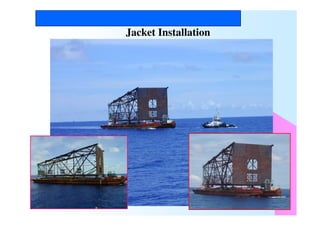

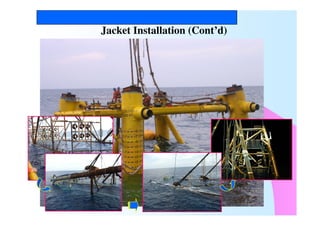

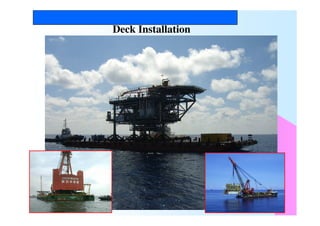

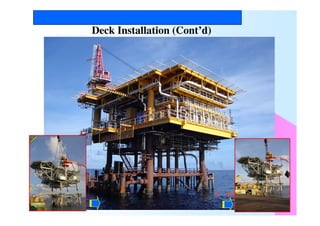

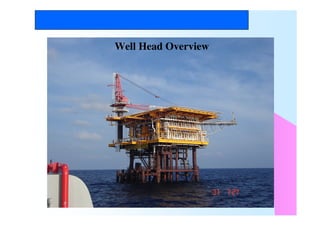

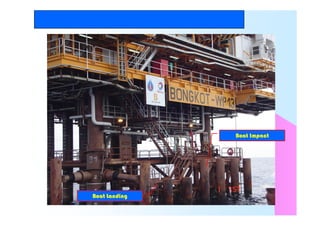

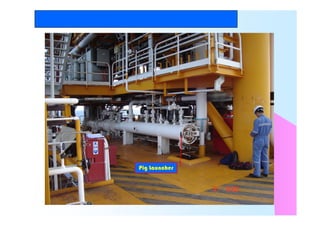

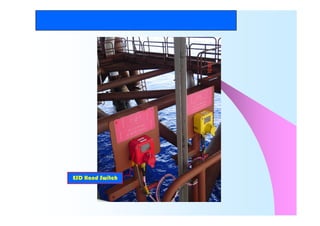

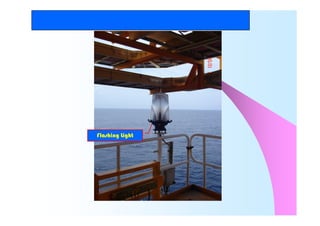

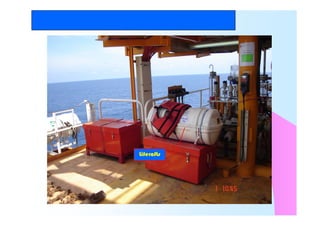

This document provides an overview of offshore oil and gas facilities, including wellhead platforms. It describes the typical components and functions of wellhead platforms, such as slots for drilling wells, wellhead control equipment, production manifolds, test separators, and utilities. The document outlines the process systems of a typical wellhead platform and summarizes the purpose and design of components like pig launchers, vents, flares, utility gas systems, drain systems, and chemical injection. Diagrams illustrate the installation and components of wellhead platforms such as the jacket, decks, cranes, pipelines, and safety equipment.