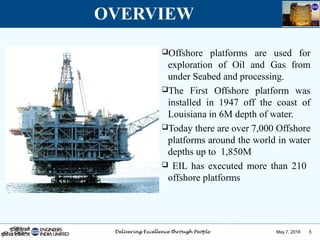

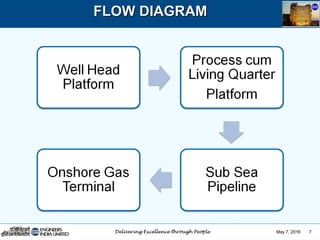

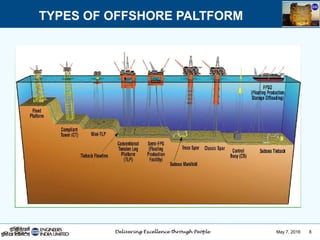

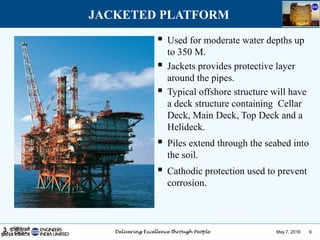

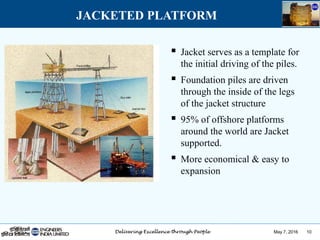

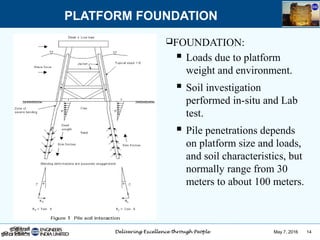

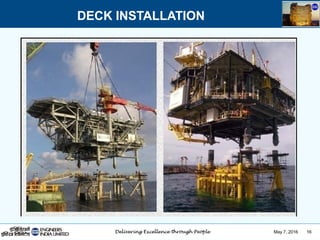

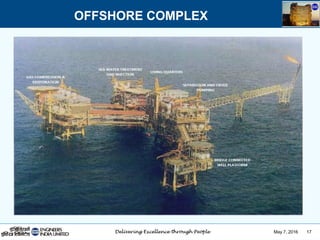

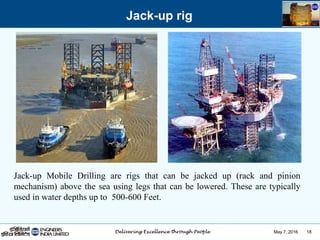

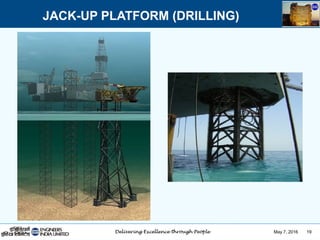

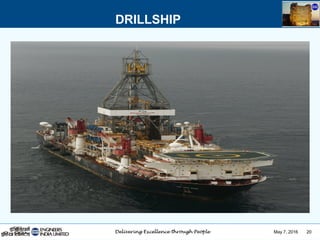

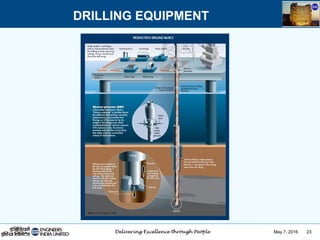

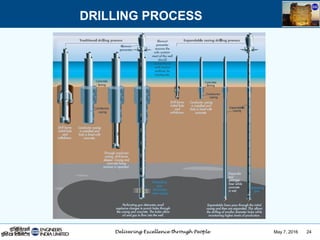

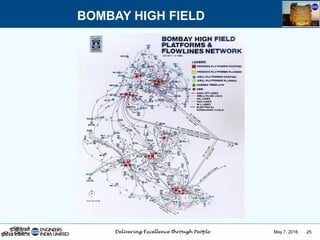

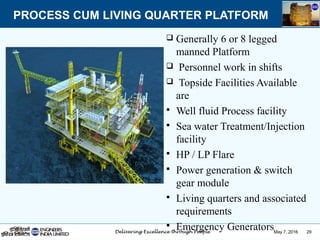

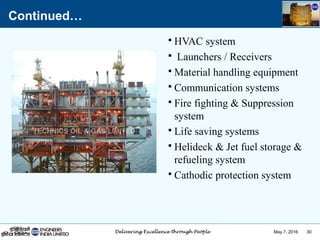

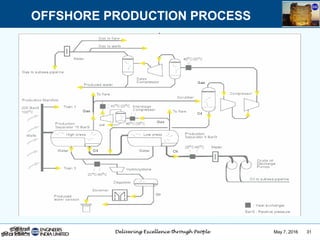

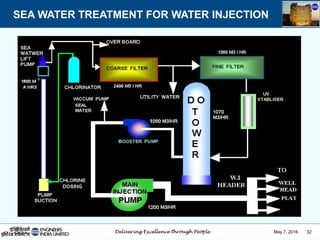

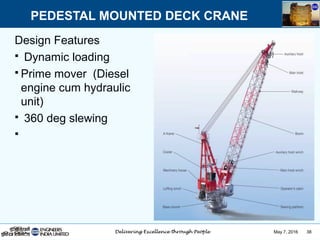

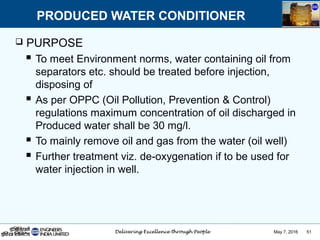

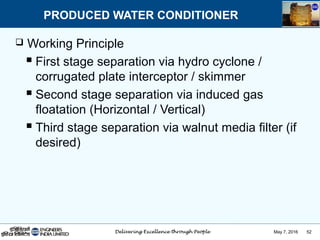

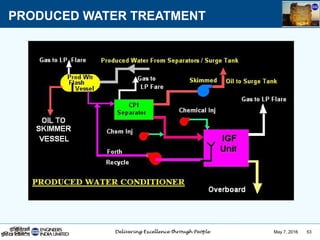

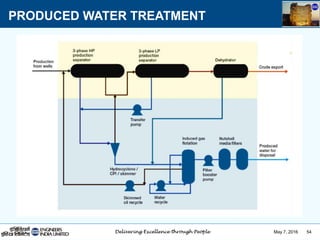

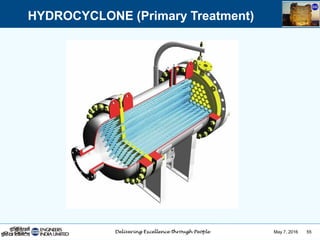

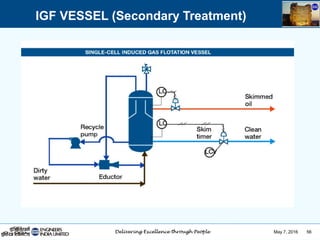

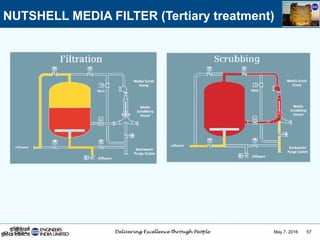

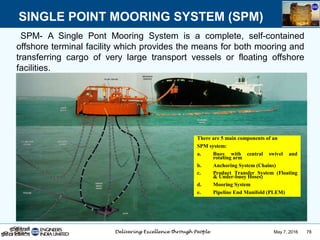

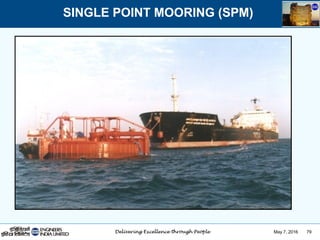

This document provides an overview of offshore platforms used for oil and gas exploration and production. It discusses the different types of offshore platforms including jacketed platforms, jack-up platforms, drillships, wellhead platforms, and process platforms. Jacketed platforms are the most common type used in moderate water depths up to 350 meters. The document also describes the key components and processes involved in offshore platforms, such as sea water treatment, produced water conditioning, and drilling equipment.