strict process audit in cement industry.pptx

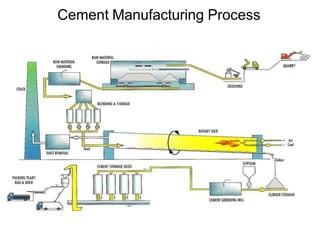

- 2. U N I T - I U N I T - II B L E N D E D L / S B L E N D E D L / S R A W M E A L K I L N F E E D F I N E C O A L F I N E C O A L K I L N F E E D C R U S H I N G A N D S T A C K I N G P R O C E S S C R U S H E D L I M E S T O N E S T O C K P I L E R A W M E A L G R I N D I N G P R O C E S S R A W M E A L M A N U F A C T U R I N G L / S F R O M M I N E S C B S I L O R A W M E A L S T O R A G E & H O M O G . L A T E R I T E C F S I L O R A W M E A L S T O R A G E & H O M O G . C E M E N T P R O C E S S R E C L A I M I N G P R O C E S S R E C L A I M I N G P R O C E S S C L I N K E R S T O C K P I L E P Y R O P R O C E S S H O T C L I N K E R P Y R O P R O C E S S H O T C L I N K E R C L I N K E R C O O L E R C O L D C L I N K E R C L I N K E R C O O L E R C O L D C L I N K E R C R U S H E D C O A L C L I N K E R S T O C K P I L E R A W M E A L G R I N D I N G P R O C E S S C O A L C R U S H I N G S T A C K I N G & R E C L A I M I N G C O A L G R I N D I N G P R O C E S S U N I T-I U N I T-II

- 3. CRUSHER Crushing Input Size: 1-2m Product Size 25 mm for Ball mills 50 - 75 mm for VRM (Based on mill size)

- 4. Pre-Homogenizing of Materials © Confederation of Indian Industry Objective: Homogenizing of Raw Materials Raw Material Storage Raw Material Stacking Raw Material Reclaiming

- 5. Stacker / Reclaimer © Confederation of Indian Industry

- 6. Raw Material Grinding Input Size 50-75 mm VRM Product size 15% on 90 micron

- 7. Raw Mill-Operating Principle 45 – 60 m/s 1500 – 3000 % Nozzle Ring Recirculation 10-25% 100 % 10 – 25% New Feed 100%

- 8. Process Flow Sheet Raw Mill

- 9. Quality Parameters for Raw Mix Design Silica Modulus Increase in Silica ratio – Difficult to burn. Hard to burn Lower sintering temperature Al2 O3 Fe2 O3 SiO6 S / R

- 10. Quality Parameters for Raw Mix Design Alumina Modulus:- F e 2 O 3 Ratio indicates the quantity of initial liquid phase present during burning A /F A l 2 O 3

- 11. Quality Parameters for Raw Mix Design LSF-Lime Statutaration Factor A /F 0 . 6 4 2 . 8 S i O 2 0 . 7 F e 2 O 3 1 . 1 A l 2 O 3 2 . 8 S i O 2 0 . 3 5 F e 2 O 3 1 .6 A l 2 O 3 A /F 0 . 6 4 C a O L S F C a O L S F

- 12. Lime Saturation Factor Lime-Saturation Factor = 1:- The clinker is difficult to burn. High free lime content. Over limed – LSF = 0.97. Excellent indicator. Permissible range of variation of free-lime contents – 0.4 and 1.2%.

- 13. Raw Mix Design Depending Factors Type of Coal(Pet coke or coal) Lime Stone Quality Sulphur alkali ratio in Case of petcoke

- 14. Pyro process Optimization Inputs:- Kiln Feed Primary Air Cooling Air Coal Outputs Clinker PH exit Gases Cooler vent Return dust

- 15. ILC –Double String Kiln System

- 16. ILC –Kiln System

- 17. SLC - Kiln System

- 18. Primary Air Just enough to carry and mix with the fuel thoroughly May vary from 5 to 15 % of total air fed to kiln system but should be as little as possible Burner nozzle velocity : 80-120 m/sec Primary air to fuel ratio : 0.8-1.3

- 19. Effects of Primary Air on Combustion Increase in primary air causes : Decrease in flame temperature Decrease in thermal efficiency of kiln and cooler Increase in fuel consumption Decrease in primary air leads to : Choking in primary air conveying pipe Improper mixing/turbulence

- 20. Secondary Air It is the main part of the combustion air (85 – 95% of total air fed) Preheating of air is done in contact with hot outgoing clinker in the cooler Temperature 700-8500c for wet process 900-10500c for dry process Velocity of the secondary air : 9-11 m/sec Flame direction is usually affected by the buoyancy of secondary air

- 21. Effects of Increasing Secondary Air on Combustion Increases thermal efficiency of kiln and cooler Increases flame temperature Increases coal consumption Affects flame direction

- 22. Chemical Reactions Inside kiln & Preheater Temp (Deg C ) Process Chemical Transformation < 100 Drying, removal of H2O (l) H 2O (g) Al 2(OH)8Si 4O10 2(Al2O3. 2SiO2) +4H 2O Al 2O3. 2SiO2 Al 2O3. + +2SiO2 water Decomposition of 100-400 clay with formation of kaolinite Decomposition of 600-900 metakaolinite to a mixture of free reactive oxides

- 23. 600- 1000 CaCO 3 CaO +CO 2 3CaO+ 2SiO 2+2Al 2O3 2( CaO.SiO z) + CaO.Al 2O3 Decomposition of limestone and formation of CS and CA Decomposition of limestone and 800-1300 formation of C2S,C 3Aand C4AF 2CaO +SiO 2CaO.SiO 2 2 CaO.Al 2O3+2CaO 3CaO.Al 2O3 CaO.Al 2O3+3CaO +Fe 2O3 4CaO.Al 2O3.Fe zO3 2CaO 2.SiO 2 CaO 1250- 1450 Further binding of lime by C2S to form C3S 3CaO.SiO 2 Chemical Reactions Inside kiln & Preheater

- 24. Chemical Reactions Inside kiln & Preheater MgCO3 Organic Carbon Sulfur as pyrites : MgCO3 - > MgO +CO2 : C + O2 -> CO2 : 2 FeS2 + 6 1/2 O2 + 2 CaCo3 -> Fe2O3 + 2 SO2+2CaSO4 +2 CO2 Sulfur in fuel : 2S + 3 O2 -> 2SO3 CaO + SO3 -> CaSO4 : CO2 + CaO - > CaCO3 + heat Recarbonation

- 25. Heat And Mass Balance Inputs Primary air Kiln feed Cooling air False air

- 26. Heat and Mass Balance Outputs Clinker Cooler waste / middle air Radiation and Convection PH exhaust gas/dust

- 27. Heat Input INPUT Mass flow Specific heat Temperature Heat Input kg/kg clinker Kcal/Kg0 C 0C Kcal/Kgclinker Sensible heat of kiln feed 1.60 0.213 75 25.60 Sensible heat of kiln feed moisture 0.02 0.446 75 0.803 Sensible heat of Fine Coal 0.09 0.289 70 1.87 Sensible heat of Primary air 0.08 0.238 32 0.58 sensible heat of cooling air 2.57 0.238 32 19.58 Sensible heat of conveying air 0.06 0.238 32 0.49 NCV of fuel heat of fuel 738.34 sensible heat of fine coal moisture 0.002 0.446 68 0.056 4.36 Total Heat Input 48.98

- 28. Heat Output OUTPUT Mass flow Specific heat Temperature Heat Output kg/kg clinker Kcal/Kg0 C 0 C Kcal/Kg clinker Sensible heat preheater exit gases string 2.277 0.26 296 178.02 Sensible heat of raw meal return dust 0.1 0.24 296 6.87 Sensible heat of cooler exit gases 1.67 0.24 281 113.36 Heat of Formation of clinker 400 Cooler & Kiln Hood Radiation 2.99 Kiln Radiation 26.79 T.A.D. radiation 1.3735 Preheater Radiation 41.91 Sensible Heat of clinker 1 0.19 85 16.28 TOTAL HEAT OUTPUT 5.04 787.33 overall radiation loss (kcal/kg clinker) 73.07 %overall heat loss in radiation 9.28

- 29. Optimum Parameters Cooling air for new generation: 2.2 kg air/kg clinker Preheater Gas Volume: 1.5 Nm3/kg Clinker (Pet- coke) & 1.3-1.5 Nm3/kg Clinker(Coal). Cooler Vent air: 1.0 Nm3/Kg Clinker. Overall radiation loss: 7-8% False air: 8% across preheater Preheater Outlet Temp: 250 degree C for 6 Stage. Pressure drop: 450-500 mmwg for 6 stage.

- 30. Cooling Air Requirement per kg Clinker 300 275 250 225 200 175 150 125 100 75 50 1.4 1.9 2.4 Specific Cooling Air [Nm3/kg Clinker] Clinker End T [°C above Ambient]

- 31. Cooling Air requirement for different Generation Coolers

- 32. Effect of grate resistance on air distribution Cooler Bed Height Depends on Material characteristics

- 33. Effect of resistance grates TRADITIONAL COOLER KILN UNEVEN AIR FLOW PROFILE FINE SIDE cooling air fan cooling air cooling air cooling air sealing air EVEN AIR FLOW PROFILE COOLAX-CFG COOLER KILN

- 35. Simplified Cooler Balance Conventional TOTAL COOLER LOSS: 160 kcal/kg STD. COOLER LO :SS: 130 kcal/kg

- 36. Simplified Cooler Balance Modern Cooler TOTAL COOLER LOSS: 105 kcal/kg STD. COOLER LOSS: 85 kcal/kg

- 37. Optimized Cooler Loss A . P L A N E T A R Y C O O L E R R a d i a t i o n 9 7 C l i n k e r ( 1 5 0 º C ) 2 5 1 2 2 k c a l / k g B . R O T A R Y C O O L E R R a d i a t i o n 7 5 C l i n k e r ( 2 2 5 º C ) 4 5 1 2 0 k c a l / k g C . C O N V E N T I O N A L G R A T E C O O L E R R a d i a t i o n 6 E x c e s s A i r ( 1 . 8 5 k g / k g @ 2 4 0 º C ) 1 0 8 C l i n k e r ( 9 0 º C ) 1 7 1 3 1 k c a l / k g D. A I R - B E A M G R A T E C O O L E R R a d i a t i o n 6 E x c e s s A i r ( 1 . 2 k g / k g @ 2 4 0 º C ) 7 0 C l i n k e r ( 9 0 º C ) 1 7 9 3 k c a l / k g E . C R O S S - B A R C O O L E R R a d i a t i o n 6 E x c e s s A i r ( 1 . 0 k g / k g @ 2 4 0 C ) 5 8 C l i n k e r ( 9 0 C ) 1 7 8 1 k c a l / k g

- 38. Mill Optimization © Confederation of Indian Industry

- 39. VERTICAL ROLLER MILL Feed chute Separator Housing Roller Grinding table Adjustable nozzle ring Gear box

- 40. Optimization of VRM Optimization of feed size Optimization of Dam Ring height & Nozzle Ring velocity Optimization of air quantities & Temp in Mill circuit Minimization of false air in the circuit Optimization of product residue Operation of Mill with high level control system

- 41. Nozzle Ring Velocity Minimum velocity is required to lift material. Raw mill-35-50 m/sec Coal mill petcoke-45-60 m/sec Coal mill-40-60 m/sec

- 42. Optimum Air Velocity at Nozzle Ring in m/sec With recirculation system : 40 to 45 m/sec Without recirculation system : 60 to 65 m/sec

- 43. Dam Ring Height Generally-2-4% of Table Dia Observations:- Dam ring height too high High mill motor current Low Mill DP © Confederation of Indian Industry

- 44. Dam Ring Height Generally-2-4% of Table Dia Observations:- Dam ring height too LOW Low mill motor current Low Mill DP High rejects level Low mill output High Vibration than Normal © Confederation of Indian Industry

- 45. Mill Grinding Pressure Operating Pressure as per supplier. Observations:- Low grinding pressure Low mill motor current Low capacity for given air flow and DP. High rejects level High DP across nozzle ring and separator.

- 47. Electrical Energy Consumption Per Section

- 48. Latest Inhouse Modifications In Cement plants Suction Box Modifications of Process fans Pressure drop stick inside the cyclones. Installation of Baffle plate in Cooler. Nozzle ring design in Mills.

- 49. Suction Box Modification in Raw MILLS Raw Mill 2fan 1 UOM Before After Flow m3/ hr. 789550 779600 Pressure at fan I/L mmw g -940 -910 Fan speed rpm 965 935-950 Fan Kwh kWh 3200- 3250 3150- 3200 Raw Mill 1fan1 UOM Before After Flow m3/h r. 810000 800000 Pressure at fan I/L mmw g -1100 -1040 Fan speed rpm 965 950 Fan Kwh kWh 3000 2850 1. Raw mill1 Fan inlet suction box increased by extending the width by 330mm. 2. Raw mill 2 fan inlet suction box increased by extending the width by 385mm.

- 50. Modification in Pyrosection TAD Ramp has been made to increase the oxygen percentage at kiln inlet. Around 35% blocked the area. Shifting of cooler water spray nozzles from take off duct to centre of cooler wall.

- 51. Modification in coal mill for pet coke grinding Parameters Before modification After modification Dam Ring height(mm) 145 120 Nozzle ring velocity(m/s) 41 60 Static vanes gap(mm) 35-40mm 30mm Mill outlet dust load(gm/m3) 170 210 Residue(90 micron) in pet coke. 8% 1.2% - 3%

- 52. Installation of Baffle Plate at null point in cooler Before After Input Cooling air(kg air/kg clinker) 2.6 2.36 Specific power of cooler ID fan(kwh/t clinker) 0.714 0.542 Cooler Vent Volume(Nm3/hr) 276834 234164 Specific heat consumption(Kcal/kg clinker) 690 685