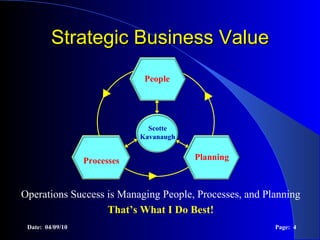

The document summarizes Scotte Kavanaugh's background and experience in business process management, lean/six sigma principles, and turning failing manufacturing operations into profitable ones. It highlights their accomplishments in introducing lean initiatives to improve efficiency, reduce costs and cycle times. It also outlines their strategic value in managing people, processes, and planning to help organizations solve business problems, improve productivity and make the company profitable.

![Delivering sustained profitable growth on the top and bottom line by utilizing my knowledge, skill, and ability in Business Process Management, Lean/Six Sigma Principles and Industry Best Practices. Date: 04/09/10 Page: Scotte Kavanaugh Helping Your Organization Achieve Financial Success Valrico, FL 33596 Home Phone: 813.657.8352 Cellular Phone: 813.240.3536 E-mail: [email_address] LinkedIn: www/linkedin.com/in/scottekavanaugh](https://image.slidesharecdn.com/strategicbusinessvaluetemplatepowerpoint-1270778255704-phpapp02/85/Strategic-Business-Value-Presentation-1-320.jpg)