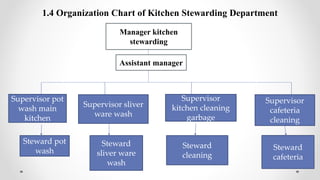

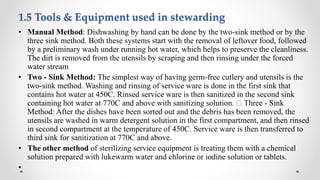

This document provides information about the role and functions of kitchen stewarding. It discusses that kitchen stewarding, also known as maitre d’, is responsible for cleaning all kitchen equipment and utensils. The key roles include washing dishes, pots, pans and service equipment; maintaining cleanliness in the kitchen and cafeteria; garbage disposal; and replenishing service items. It outlines the organization chart and various tools used, such as manual dishwashing, dish machines, and burnishing and plating machines.