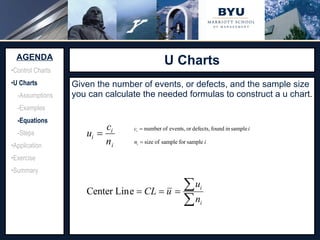

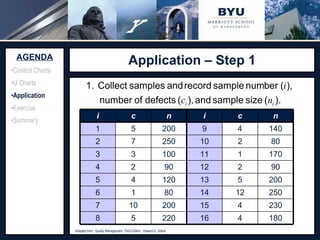

The document discusses U charts, which are a type of control chart used for attribute data where the sample sizes vary. It explains the reasons for using control charts, provides examples of when U charts can be used, and outlines the steps to construct and interpret a U chart, including defining the formulas, control limits, and how to identify special causes of variation. An exercise is included to have the reader construct a U chart for a given dataset.